Beat Migration Bloom on Chocolate Products by Optimizing ... - AAK

Beat Migration Bloom on Chocolate Products by Optimizing ... - AAK

Beat Migration Bloom on Chocolate Products by Optimizing ... - AAK

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

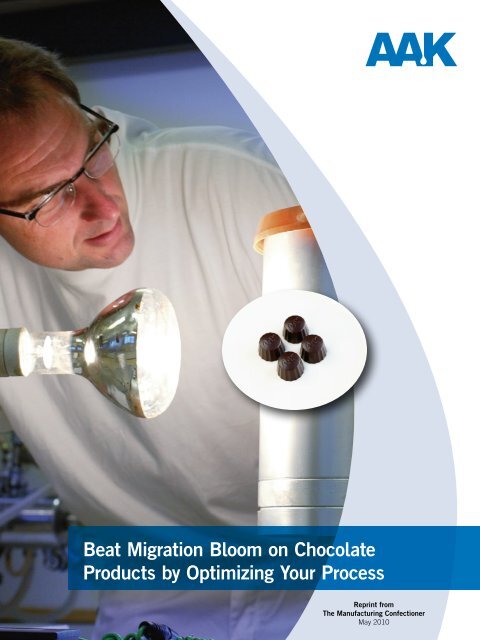

<str<strong>on</strong>g>Beat</str<strong>on</strong>g> <str<strong>on</strong>g>Migrati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>Bloom</str<strong>on</strong>g> <strong>on</strong> <strong>Chocolate</strong><br />

<strong>Products</strong> <strong>by</strong> <strong>Optimizing</strong> Your Process<br />

Reprint from<br />

The Manufacturing C<strong>on</strong>fecti<strong>on</strong>er<br />

May 2010

<str<strong>on</strong>g>Beat</str<strong>on</strong>g> <str<strong>on</strong>g>Migrati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>Bloom</str<strong>on</strong>g> <strong>by</strong><br />

<strong>Optimizing</strong> Your Process<br />

A new look at the tempering process to reduce migrati<strong>on</strong> bloom<br />

in chocolate products.<br />

Bjarne Juul<br />

<strong>AAK</strong><br />

Intensive research has shown a significant<br />

correlati<strong>on</strong> between process parameters and<br />

the speed of migrati<strong>on</strong> bloom development.<br />

It seems that the temperature used for most<br />

temper tests in the world is too low and actually<br />

guides chocolate manufacturers to produce<br />

slightly undertempered chocolate.<br />

The cooling of chocolate and particularly<br />

chocolate shells is too severe, causing too high<br />

cooling rates, which probably affect the ratio of<br />

Form IV and Form V polymorphs in the final<br />

chocolate product.<br />

The subsequent transformati<strong>on</strong>, from Form<br />

IV to Form V, accelerated <strong>by</strong> the migrating oils<br />

from fillings, speeds up the bloom-develop-<br />

ment process.<br />

It is found that if this transformati<strong>on</strong> takes<br />

place at a temperature above room tempera-<br />

ture, a type of heat treatment or “aftertemper-<br />

ing” occurs, and the development of migrati<strong>on</strong><br />

bloom can be delayed significantly.<br />

This heat treatment is applicati<strong>on</strong>- and reci-<br />

pe-dependent and the total treatment is a mul-<br />

tiple of time and temperature.<br />

BACKGROUND<br />

Cocoa butter and cocoa butter equivalents<br />

(cbes) are polymorphic fats (Figure 1). Their<br />

solid stability increases with increasing melt-<br />

ing temperature, but Form V is actually stable<br />

enough in practice for chocolate producti<strong>on</strong><br />

and is easy to make and has a perfect melting<br />

point.<br />

<strong>Chocolate</strong> prefers to crystallize in Forms III<br />

and IV, but <strong>by</strong> using tempering equipment to<br />

make the right combinati<strong>on</strong> of time, shear and<br />

cooling c<strong>on</strong>diti<strong>on</strong>s for a certain fat phase com-<br />

positi<strong>on</strong>, it is possible to make seeds in Form V<br />

in a partly melted chocolate dispersi<strong>on</strong>.<br />

Different types of tempering equipment or<br />

seed techniques have been developed.<br />

Polymorphs of Cocoa Butter<br />

Form Melting point °C<br />

Systematic<br />

Nomenclature<br />

I 17.3 γ<br />

II 23.3 α<br />

III 25.5 β’2<br />

IV 27.5 β’1<br />

V 33.8 β2<br />

VI 36.5 β1<br />

Figure 1<br />

Bjarne Juul is<br />

senior technology<br />

specialist at <strong>AAK</strong>.<br />

He started there in<br />

1991.<br />

Reprint from The Manufacturing C<strong>on</strong>fecti<strong>on</strong>er • May 2010 1

<str<strong>on</strong>g>Beat</str<strong>on</strong>g> <str<strong>on</strong>g>Migrati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>Bloom</str<strong>on</strong>g> <strong>by</strong> <strong>Optimizing</strong> Your Process<br />

It appears that<br />

the process is the<br />

major part of many<br />

migrati<strong>on</strong> bloom<br />

problems and this<br />

opini<strong>on</strong> is<br />

supported <strong>by</strong><br />

different<br />

investigati<strong>on</strong>s.<br />

A typical well-tempered chocolate c<strong>on</strong>tains ap-<br />

proximately 2 to 4 percent Form V seed crys-<br />

tals when leaving the tempering unit; the Form<br />

V crystals just survive because of their higher<br />

melting point in this specific fat phase.<br />

An excepti<strong>on</strong> is a new technique that seeds<br />

with approximately 0.5 percent Form VI crys-<br />

tals, which ensures Form V crystallizati<strong>on</strong> in the<br />

remaining 99.5 percent cocoa butter and is sta-<br />

ble enough to induce crystallizati<strong>on</strong> at a slightly<br />

higher temperature.<br />

The purpose of all tempering techniques is<br />

basically to start and ensure the Form V crys-<br />

tallizati<strong>on</strong> in a chocolate. If a chocolate is not<br />

seeded correctly with sufficient Form V crystals,<br />

the chocolate will crystallize in a lower form fol-<br />

lowed <strong>by</strong> transformati<strong>on</strong>, resulting in problems<br />

such as poor c<strong>on</strong>tracti<strong>on</strong> and bloom.<br />

Even producing a well-tempered (Form V)<br />

chocolate does not guarantee that the rest of<br />

the chocolate will crystallize in the same poly-<br />

morphic form. The outcome is highly depend-<br />

ent <strong>on</strong> process cooling and heat treatments.<br />

Too fast a cooling will favor Form IV crystalliza-<br />

ti<strong>on</strong> even if the tempering has created perfect<br />

Form V seeds. Too much heat treatment will<br />

melt the seed.<br />

The applicati<strong>on</strong> has a significant influence<br />

up<strong>on</strong> bloom. For applicati<strong>on</strong>s with <strong>on</strong>ly <strong>on</strong>e fat<br />

phase, such as solid bars or solid pralines, it is<br />

not very critical, whereas for applicati<strong>on</strong>s with<br />

more than <strong>on</strong>e fat phase, like filled bars and<br />

pralines, it is much more critical and much<br />

more difficult to understand.<br />

Applicati<strong>on</strong>s c<strong>on</strong>taining more than <strong>on</strong>e fat<br />

phase c<strong>on</strong>stitute perhaps 90 percent of all<br />

bloom problems and for that reas<strong>on</strong> it is the<br />

most important problem to solve.<br />

It appears that the process is the major part<br />

of many migrati<strong>on</strong> bloom problems and this<br />

opini<strong>on</strong> is supported <strong>by</strong> different investigati<strong>on</strong>s.<br />

2 May 2010 • Reprint from The Manufacturing C<strong>on</strong>fecti<strong>on</strong>er<br />

Tri-unsaturated tri-acylglycerols (TAGs) such as<br />

1-oleoyl-2-oleoyl3-oleoyl-glycerol (OOO) accel-<br />

erate the transformati<strong>on</strong> from Form V to Form<br />

VI and it is very likely that the same will happen<br />

with the Form IV to Form V transformati<strong>on</strong>.<br />

The tri-unsaturated TAG, OOO, is the major<br />

TAG in many nuts, e.g., hazelnut, alm<strong>on</strong>d and<br />

peanut, and all are frequently used in many<br />

fillings in large amounts and migrati<strong>on</strong> bloom<br />

is often seen in this kind of applicati<strong>on</strong>. In this<br />

paper, the focus is <strong>on</strong> the tempering test, tem-<br />

pering and the producti<strong>on</strong> cooling, especially<br />

for shell cooling.<br />

TEMPERING<br />

The traditi<strong>on</strong>al way of tempering is a process<br />

where all the chocolate is cooled to a tempera-<br />

ture where the fat phase starts crystallizing in a<br />

mixture of Forms III, IV and V. This process is<br />

based <strong>on</strong> the possibility of remelting all Form<br />

III and Form IV crystals in a following reheating<br />

z<strong>on</strong>e.Then, <strong>by</strong> testing the tempering curve <strong>on</strong><br />

a standard instrument, it should be possible to<br />

determine the tempering c<strong>on</strong>diti<strong>on</strong>s of the final<br />

chocolate.<br />

It is quite easy to evaluate the slope of a tem-<br />

pering curve but not as easy to evaluate the<br />

plateau level or inflecti<strong>on</strong> point of the curve.<br />

It is found that the plateau is correlated to<br />

the crystal stability and bloom stability of the<br />

chocolate.A lower crystallizati<strong>on</strong> plateau pro-<br />

duces less stable crystals and a less bloom-<br />

resistant chocolate. The target for the inflecti<strong>on</strong><br />

plateau must therefore be as high as possible<br />

for a certain chocolate compositi<strong>on</strong>.<br />

It is well known that the fat phase composi-<br />

ti<strong>on</strong> affects the inflecti<strong>on</strong> point level. More milk<br />

fat in a recipe, for example, produces a lower<br />

inflecti<strong>on</strong> point. This fact does not directly influ-<br />

ence the purity of Form V seed crystals because<br />

it is possible to adjust for it. But when tempering

equipment is unable to make the high inflecti<strong>on</strong><br />

level or there is ignorance about how important<br />

it is or how to change it, then it is much worse<br />

and more difficult to change.<br />

COOLING FOR TEMPER TESTERS<br />

AND SHELL COOLING<br />

Nearly all tempermeters use a cooling tempera-<br />

ture somewhere between +7° and +10°C even<br />

though cocoa butter prefers gentle cooling to<br />

ensure Form V crystallizati<strong>on</strong>. Years ago an ice-<br />

and-water bath was used; this was even further<br />

away from “perfect” chocolate cooling.<br />

Tests carried out in our pilot laboratory <strong>on</strong> a<br />

dark chocolate using a standard tempermeter<br />

have shown a clear correlati<strong>on</strong> between the<br />

chosen cooling temperature <strong>on</strong> the temperme-<br />

ter and the inflecti<strong>on</strong> point level and slope for a<br />

certain chocolate (Figure 2).<br />

From Figure 2 it can be seen that as the cool-<br />

ing temperature in the tempermeter increases<br />

so does the slope.<br />

For example, the 17°C cooling temper ature<br />

gives a slope of +0.41, an indicati<strong>on</strong> of under-<br />

temper, that there is an insufficient quantity of<br />

Form V seed. To correct this, slightly lower cool-<br />

ing temperatures in the crystallizati<strong>on</strong> z<strong>on</strong>es<br />

and slightly less heat in the heating z<strong>on</strong>es of<br />

the temperering unit are needed.<br />

Figure 3 shows the correlati<strong>on</strong> between the<br />

inflecti<strong>on</strong> point for the same chocolate as used<br />

in Figure 2 and the cooling temperature, but<br />

now the tempering unit has been optimized<br />

(see above) for each of the four cooling tem-<br />

peratures <strong>on</strong> the tempermeter.<br />

It seems that increasing the cooling tempera-<br />

ture increases the inflecti<strong>on</strong> point of the choco-<br />

late.That indicates that more stable crystals are<br />

produced at higher cooling temperatures.<br />

In Figure 4 the well-tempered chocolate<br />

from the above tempering-test measurements is<br />

<str<strong>on</strong>g>Beat</str<strong>on</strong>g> <str<strong>on</strong>g>Migrati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>Bloom</str<strong>on</strong>g> <strong>by</strong> <strong>Optimizing</strong> Your Process<br />

evaluated. After the tempering test is finished,<br />

the different chocolates are kept for 10 minutes<br />

at 15°C and refined <strong>on</strong> a grater and weighed<br />

into dsc (differential scanning calorimeter)<br />

cups and melted using the following program<br />

<strong>on</strong> a Mettler Toledo DSC 823:<br />

The temperature regime is 2 min. at 15°C<br />

and then 15°C to 60°C at +5°C/min.<br />

Figure 4 shows the correlati<strong>on</strong> between the dsc<br />

peak values for the melting curves and the cool-<br />

ing temperature <strong>on</strong> the Exotherm equipment.<br />

It seems that the higher the cooling tempera-<br />

ture, the higher the peak value, which indicates<br />

a purer Form V crystallizati<strong>on</strong>.<br />

Cooling and Temper Curve Slopes<br />

Temperature curve slope<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

Figure 2<br />

Correlati<strong>on</strong> of Inflecti<strong>on</strong> Point <strong>on</strong><br />

Optimized Temper Unit<br />

Inflecti<strong>on</strong> point °C<br />

Figure 3<br />

0<br />

7 9 11 13 15 17 19<br />

Cooling temperature °C<br />

26.5<br />

The influence of cooling temperature<br />

<strong>on</strong> the slope of temper curves<br />

26<br />

25.5<br />

25<br />

24.5<br />

24<br />

23.5<br />

7 9 11 13 15 17 19<br />

Cooling temperature °C<br />

Increasing<br />

the cooling<br />

temperature<br />

increases the<br />

inflecti<strong>on</strong> point<br />

of the chocolate.<br />

That indicates<br />

that more stable<br />

crystals are<br />

produced at<br />

higher cooling<br />

temperatures.<br />

Reprint from The Manufacturing C<strong>on</strong>fecti<strong>on</strong>er • May 2010 3

<str<strong>on</strong>g>Beat</str<strong>on</strong>g> <str<strong>on</strong>g>Migrati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>Bloom</str<strong>on</strong>g> <strong>by</strong> <strong>Optimizing</strong> Your Process<br />

Why do these<br />

special heat or<br />

cooling treatments<br />

sometimes improve<br />

bloom stability in<br />

filled products?<br />

In general, it is a<br />

questi<strong>on</strong> of compensating<br />

for some<br />

defects in the<br />

basic producti<strong>on</strong>.<br />

DSC Peak Values<br />

Peak values<br />

Figure 4<br />

33.5<br />

33.4<br />

33.3<br />

33.2<br />

33.1<br />

33.0<br />

32.9<br />

32.8<br />

32.7<br />

32.6<br />

32.5<br />

Figure 2 shows that when making a temper<br />

test at a low cooling temperature the same<br />

chocolate would be undertempered if it had<br />

been measured at a higher cooling tempera-<br />

ture, which actually is more similar to the tem-<br />

perature used in producti<strong>on</strong> lines.<br />

The lower the cooling temperature, the lower<br />

the inflecti<strong>on</strong> point, see Figure 3.The <strong>on</strong>ly ex-<br />

planati<strong>on</strong> for this kind of lower inflecti<strong>on</strong> point<br />

for the same chocolate and lower values for<br />

dsc peak (Figure 4) must be the different ratio<br />

between Forms IV and V in the final chocolate<br />

samples. The more the cooling, the more Form<br />

IV crystals are generated in the final chocolate.<br />

Pure Form IV crystals are very unstable and<br />

for that reas<strong>on</strong> they will quickly transform into<br />

Form V depending <strong>on</strong> fat compositi<strong>on</strong> and tem-<br />

Peak value Linear (Peak value)<br />

y = 0.0622x = 32.17<br />

R² = 0.92<br />

7 9 11 13 15 17 19<br />

Cooling temperature °C<br />

Cooling Rates vs. Melting Peak Values<br />

Cooling Peak value °C<br />

Rates melting curve<br />

28°C –> 15°C 32.3<br />

Rate 0.3°C/min<br />

10 min at 15°C<br />

15°C –> 60°C with 5°C/min<br />

28°C –> 15°C 32.0<br />

Rate 0.5°C/min<br />

10 min at 15°C<br />

15°C –> 60°C with 5°C/min<br />

28°C –> 15°C 31.6<br />

Rate 1.5°C/min<br />

10 min at 15°C<br />

15°C –> 60°C with 5°C/min<br />

Figure 5<br />

4 May 2010 • Reprint from The Manufacturing C<strong>on</strong>fecti<strong>on</strong>er<br />

perature. Smaller amounts of Form IV crystals<br />

in mixtures with a lot of Form V will probably<br />

make the chocolate unstable, too, but how<br />

much probably depends <strong>on</strong> the ratio between<br />

the two polymorphs and the above-menti<strong>on</strong>ed<br />

factors. Nobody knows how much Form IV<br />

“c<strong>on</strong>taminati<strong>on</strong>” you can have in a chocolate<br />

without influencing c<strong>on</strong>tracti<strong>on</strong>, gloss, etc.<br />

Figure 5 shows a well-tempered dark choco-<br />

late cooled <strong>on</strong> a dsc with three different cooling<br />

rates.<br />

The chocolate is tempered <strong>on</strong> a 50 kg three-<br />

z<strong>on</strong>e tempering unit and a small sample is<br />

weighed into preheated dsc cups and placed in<br />

the dsc equipment. The samples are stored for<br />

2 minutes at 28°C and then cooled with three<br />

different rates to 15°C, kept at 15°C for 10 min-<br />

utes and then remelted at 5°C/min from 15°C<br />

to 60°C. The different values for the melting<br />

peaks are shown in Figure 5.<br />

These results show the same tendency as<br />

seen from the results menti<strong>on</strong>ed in Figures 3<br />

and 4.<br />

The faster the cooling, the lower the peak value<br />

and the wider the melting curves.<br />

SPECIAL HEAT OR COOLING<br />

TREATMENT<br />

Individual companies sometimes use different<br />

types of special treatment to optimize bloom<br />

stability. Some store in cool c<strong>on</strong>diti<strong>on</strong>s for a<br />

week or more, others store in hot c<strong>on</strong>diti<strong>on</strong>s for<br />

a few days up to <strong>on</strong>e week.<br />

Why do these special heat treatments or<br />

special cooling treatments sometimes improve<br />

bloom stability in filled products? And why is<br />

this effect different from applicati<strong>on</strong> to applica-<br />

ti<strong>on</strong> and time to time?<br />

In general, it is a questi<strong>on</strong> of compensating<br />

for some defects in the basic producti<strong>on</strong>. It<br />

seems that a heat treatment compensates for

a tempering with some amount of Form III/IV<br />

formati<strong>on</strong> and/or too fast a cooling of the choco-<br />

late where some Form III/IV formati<strong>on</strong> happens<br />

afterwards. While alternatively a special “after”<br />

cooling compensates for too high a producti<strong>on</strong><br />

speed and for that reas<strong>on</strong> an insufficient remov-<br />

al of crystallizati<strong>on</strong> heat from the product before<br />

packing and an insufficient structure building<br />

in the filling. Often product is stored in rooms<br />

held at 12°C to 16°C. During this special cool-<br />

ing the TAG compositi<strong>on</strong> in fillings and shells<br />

has found its optimum network structure.<br />

<str<strong>on</strong>g>Migrati<strong>on</strong></str<strong>on</strong>g> speed will be minimized and<br />

therefore the migrati<strong>on</strong>-induced bloom will be<br />

reduced. Again it is a compensati<strong>on</strong> for insuf-<br />

ficient cooling time in the producti<strong>on</strong> line and it<br />

actually takes much l<strong>on</strong>ger to remove all crys-<br />

tallizati<strong>on</strong> heat from a filling if it is in the center<br />

of a pallet and the risk of migrati<strong>on</strong>-induced<br />

bloom is higher than if the product had been<br />

cooled correctly at the start.<br />

<str<strong>on</strong>g>Bloom</str<strong>on</strong>g> Evaluati<strong>on</strong> Results<br />

Weeks before visible<br />

migrati<strong>on</strong> bloom<br />

Special storage around nuts<br />

1 week at 20°C, reference 29<br />

1 week at 23°C 45<br />

1 week at 25°C > 52<br />

1 week at 28°C > 52<br />

Figure 6<br />

<strong>Chocolate</strong> without Heat Treatment<br />

Figure 7<br />

<str<strong>on</strong>g>Beat</str<strong>on</strong>g> <str<strong>on</strong>g>Migrati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>Bloom</str<strong>on</strong>g> <strong>by</strong> <strong>Optimizing</strong> Your Process<br />

The following example shows the effect of<br />

heat treatment <strong>on</strong> milk chocolate with whole<br />

nuts.<br />

A milk chocolate is well tempered and mixed<br />

with 10 percent whole hazelnuts.<br />

The mixture is deposited into 100 g moulds<br />

and cooled in a three-z<strong>on</strong>e cooling tunnel (at<br />

12°C, 10°C, 14°C) for 30 minutes, 10 minutes<br />

in each z<strong>on</strong>e.<br />

After cooling, all the tablets are stored for <strong>on</strong>e<br />

day at 20°C and then divided into four batches:<br />

• <strong>on</strong>e batch is kept at 20°C for <strong>on</strong>e week<br />

• <strong>on</strong>e batch is kept at 23°C for <strong>on</strong>e week<br />

• <strong>on</strong>e batch is kept at 25°C for <strong>on</strong>e week<br />

• <strong>on</strong>e batch is kept at 28°C for <strong>on</strong>e week<br />

After <strong>on</strong>e week all tablets are placed in a 20°C<br />

isothermal cabinet for bloom evaluati<strong>on</strong>. Re-<br />

sults from the bloom evaluati<strong>on</strong> are found in<br />

Figure 6.<br />

Figures 7 and 8 show the difference between<br />

heat treatment and no heat treatment. The <strong>on</strong>ly<br />

producti<strong>on</strong> difference between the two tablets<br />

is the <strong>on</strong>e-week heat treatment. An analysis of<br />

the TAG compositi<strong>on</strong> of the chocolate at a dis-<br />

tance of 0.5 mm from the nuts does not show<br />

a significant difference in the TAG compositi<strong>on</strong>.<br />

For both cases, migrati<strong>on</strong> of triunsaturated TAG<br />

(OOO) has taken place, but with two different<br />

bloom results.<br />

<strong>Chocolate</strong> with Heat Treatment<br />

One week at 20°C followed <strong>by</strong> 29 weeks at 20°C One week at 28°C followed <strong>by</strong> 52 weeks at 20°C<br />

Figure 8<br />

It takes much<br />

l<strong>on</strong>ger to remove<br />

all crystallizati<strong>on</strong><br />

heat from a filling<br />

if it is in the<br />

center of a pallet<br />

and the risk of<br />

migrati<strong>on</strong>induced<br />

bloom is higher<br />

than if the product<br />

had been cooled<br />

correctly at<br />

the start.<br />

Reprint from The Manufacturing C<strong>on</strong>fecti<strong>on</strong>er • May 2010 5

<str<strong>on</strong>g>Beat</str<strong>on</strong>g> <str<strong>on</strong>g>Migrati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>Bloom</str<strong>on</strong>g> <strong>by</strong> <strong>Optimizing</strong> Your Process<br />

Heat treatment at<br />

28°C for <strong>on</strong>e week<br />

purifies the<br />

polymorphism and<br />

at the same time<br />

inhibits visual<br />

bloom development<br />

for 12 m<strong>on</strong>ths<br />

despite the<br />

oil migrati<strong>on</strong>.<br />

Dsc performed <strong>on</strong> the chocolate at a distance<br />

of 0.5mm from the nuts shows a 0.6°C higher<br />

melting peak value in the chocolate which is<br />

heat treated at 28°C compared with the 20°C<br />

“heat-treated” chocolate, and exactly the same<br />

difference is found 10mm from a nut surface<br />

for both.<br />

It seems that heat treatment at 28°C for <strong>on</strong>e<br />

week purifies the polymorphism and at the<br />

same time inhibits visual bloom development<br />

for 12 m<strong>on</strong>ths despite the oil migrati<strong>on</strong>. This<br />

suggests that either the tempering or the cool-<br />

ing or both favored Form IV crystallizati<strong>on</strong> that<br />

was expressed as bloom in the n<strong>on</strong>-heat-treat-<br />

ed samples.<br />

It shows how important it is to c<strong>on</strong>trol crystal<br />

development and ensure crystal stability to re-<br />

tard bloom development.<br />

A theory could be that if this transformati<strong>on</strong><br />

happens fully above the solidificati<strong>on</strong> point of<br />

Form IV for this chocolate’s particular TAG com-<br />

positi<strong>on</strong>, no visual bloom is developed and all<br />

Form IV crystals are moved to Form V without<br />

bloom development. However, if this transfor-<br />

mati<strong>on</strong> happens at a lower temperature, below<br />

the Form IV solidificati<strong>on</strong> temperature, larger<br />

bloom crystals will appear.<br />

One week at 28°C has speeded up the mi-<br />

grati<strong>on</strong> to an equilibrium state and no essential<br />

Form IV-to-V transformati<strong>on</strong>s happen after the<br />

<strong>on</strong>e week and therefore no bloom develops.<br />

Of course, bloom will reappear when the<br />

Form V-to-VI transformati<strong>on</strong> starts, but that<br />

takes much l<strong>on</strong>ger and is therefore not the big-<br />

gest problem for producers of filled products.<br />

The above theory explains the results from<br />

Results from Heat-treated Filled Praline Bars<br />

6 May 2010 • Reprint from The Manufacturing C<strong>on</strong>fecti<strong>on</strong>er<br />

a real producti<strong>on</strong> line (Figure 9), which is <strong>on</strong>e<br />

example am<strong>on</strong>g many.<br />

The applicati<strong>on</strong> is a standard praline bar<br />

with a soft “bloom-critical” filling inside and a<br />

dark chocolate shell.All the praline bars were<br />

produced <strong>on</strong>e week before the test was start-<br />

ed and all pralines were glossy and free from<br />

any bloom. The pralines were divided into two<br />

batches and unwrapped.<br />

• Reference batch is kept for 24 h at 20°C be-<br />

fore it is stored in 15°C and 23°C isothermal<br />

bloom test cabinets<br />

• Test batch is kept for 24 h at 25°C before it<br />

is stored in 15°C and 23°C isothermal bloom<br />

test cabinets<br />

Other examples are tests made where some<br />

FrozenC<strong>on</strong>e (FCT) shells are heat treated be-<br />

fore the filling is deposited.<br />

Some dark praline shells are made <strong>on</strong> FCT<br />

pilot equipment. Cooling is 3 sec<strong>on</strong>ds at 15°C<br />

and the shell thickness is 1.5mm.Afterwards all<br />

shells are cooled for 20 minutes at 12°C and<br />

then divided into two batches.<br />

Batch 1, reference<br />

• Shells are filled with a nougat filling with high<br />

amounts of hazelnut paste<br />

• Cooled for 15 min at 12°C<br />

• Backed off and then cooled at 12°C for 30<br />

min.<br />

Batch 2, test samples<br />

• Shells are stored for 30 min at 30°C<br />

• Filled with nougat filling with high amounts of<br />

hazelnut paste<br />

• Cooled for 15 min at 12°C<br />

• Backed off and then cooled at 12°C for 30<br />

Batch 1, Reference Batch 2, Test Samples<br />

20°C for 24 hrs 25°C for 24 hrs<br />

15°C isothermal cabinet 7 weeks, str<strong>on</strong>g bloom > 25 weeks, no bloom<br />

23°C isothermal cabinet 9 weeks, str<strong>on</strong>g bloom > 25 weeks, no bloom<br />

Figure 9<br />

min

The above two examples show how two dif-<br />

ferent heat treatments at different producti<strong>on</strong><br />

stages are able to compensate for some pro-<br />

ducti<strong>on</strong> “fault.”<br />

The first examples (Figure 9) show that even<br />

a <strong>on</strong>e-week-old product is still able to be “re-<br />

paired” <strong>by</strong> heat treatment, probably <strong>by</strong> a Form<br />

V purificati<strong>on</strong>. It is the same phenomen<strong>on</strong> as<br />

seen in the earlier example (Figure 6) with ha-<br />

zelnuts in milk chocolate where migrati<strong>on</strong> hap-<br />

pens but there is no visible bloom.<br />

The example in Figure 10 is slightly more<br />

complicated with two variants in the trial—the<br />

heat treatment and the storage time of the shell<br />

before filling.<br />

Dsc analyses show that the dsc melting peak<br />

and end set of the shell increase around 0.3°C<br />

when the shell is heat treated as menti<strong>on</strong>ed for<br />

batch 2, but <strong>on</strong>ly between a third to a half of<br />

this increase in peak/end set value is caused<br />

<strong>by</strong> the extra 30 minutes’ storage time. The re-<br />

mainder is due to the higher temperature (heat<br />

treatment) applied.<br />

The c<strong>on</strong>clusi<strong>on</strong> is that this 30-minute pe-<br />

riod at 30°C makes a significant difference to<br />

the shelf life, caused <strong>by</strong> some changes in the<br />

shell, maybe purificati<strong>on</strong> of Form V crystals in<br />

the chocolate shells (which is supported <strong>by</strong><br />

the slightly higher dsc peak values) and/or a<br />

type of aftertempering with l<strong>on</strong>ger residence<br />

times.<br />

Tests have been d<strong>on</strong>e using microwaves as<br />

a fast <strong>on</strong>line heat treatment method instead of<br />

using l<strong>on</strong>ger times in heat cabinets. It is pos-<br />

sible to find the correct combinati<strong>on</strong> of energy<br />

and time to delay bloom development <strong>by</strong> using<br />

<str<strong>on</strong>g>Beat</str<strong>on</strong>g> <str<strong>on</strong>g>Migrati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>Bloom</str<strong>on</strong>g> <strong>by</strong> <strong>Optimizing</strong> Your Process<br />

microwaves early in the producti<strong>on</strong> process but<br />

very difficult to c<strong>on</strong>trol.<br />

The optimal energy level and time is a ques-<br />

ti<strong>on</strong> of recipes, applicati<strong>on</strong>s and fat composi-<br />

ti<strong>on</strong>s.<br />

SUMMARY<br />

No two cases are the same with respect to mi-<br />

grati<strong>on</strong> bloom development.The applicati<strong>on</strong> is<br />

too complex, therefore, it is important to look<br />

at all factors influencing migrati<strong>on</strong> bloom de-<br />

velopment before changing recipe, applicati<strong>on</strong><br />

and process parameters, for example.<br />

The above examples show that the process is<br />

a major factor as regards fast migrati<strong>on</strong> bloom<br />

in chocolate products.<br />

Results from Heat-treated FCT Shells—Filled Praline Shells<br />

A n<strong>on</strong>optimal tempering process combined<br />

with a too high cooling rate favor a final crystal-<br />

lizati<strong>on</strong> mix of Form IV and Form V and that<br />

is probably the most comm<strong>on</strong> reas<strong>on</strong> for fast<br />

migrati<strong>on</strong> bloom.The transformati<strong>on</strong> of some fat<br />

from Form IV to Form V together with oil migra-<br />

ti<strong>on</strong> seems to have a larger influence <strong>on</strong> the de-<br />

velopment of migrati<strong>on</strong> bloom than expected.<br />

Even though a chocolate shows a well-temper-<br />

ed curve, it does not guarantee the producti<strong>on</strong><br />

of Form V seeds.The effect of heat treatments<br />

shows that the chocolate is not perfectly tem-<br />

pered and it is possible to purify the crystal pol-<br />

ymorphism even in a well-tempered chocolate<br />

shell, adding more bloom stability as a result.<br />

It’s also important to realize that changing the<br />

fat compositi<strong>on</strong> of a filling recipe will not solve<br />

this process problem but <strong>on</strong>ly help to delay it.<br />

The objective is always to start with perfect<br />

tempering at the highest inflecti<strong>on</strong> point level<br />

Batch 1, Reference Batch 2, Test Samples<br />

20°C isothermal cabinet 9 weeks, str<strong>on</strong>g bloom > 25 weeks, no bloom<br />

23°C isothermal cabinet 7 weeks, str<strong>on</strong>g bloom 25 weeks, str<strong>on</strong>g bloom<br />

Figure 10<br />

A n<strong>on</strong>optimal<br />

tempering process<br />

combined with a<br />

too high cooling<br />

rate favor a final<br />

crystallizati<strong>on</strong> mix<br />

of Form IV and<br />

Form V, probably<br />

the most comm<strong>on</strong><br />

reas<strong>on</strong> for fast<br />

migrati<strong>on</strong> bloom.<br />

Reprint from The Manufacturing C<strong>on</strong>fecti<strong>on</strong>er • May 2010 7

<str<strong>on</strong>g>Beat</str<strong>on</strong>g> <str<strong>on</strong>g>Migrati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>Bloom</str<strong>on</strong>g> <strong>by</strong> <strong>Optimizing</strong> Your Process<br />

A n<strong>on</strong>optimal<br />

tempering process<br />

combined with a<br />

too high cooling<br />

rate favor a final<br />

crystallizati<strong>on</strong> mix<br />

of Form IV and<br />

Form V, probably<br />

the most comm<strong>on</strong><br />

reas<strong>on</strong> for fast<br />

migrati<strong>on</strong> bloom.<br />

followed <strong>by</strong> a gentle shell cooling, which seems<br />

to be a chocolate cooling rate of around -0.3°C/<br />

min, as shown in Figures 3 and 5.<br />

This very low cooling rate is of course expect-<br />

ed to be more important at the start of cool-<br />

ing rather than later <strong>on</strong> and it will depend very<br />

much <strong>on</strong> air velocity, crystallizati<strong>on</strong> heat from<br />

center, shell thickness, size of applicati<strong>on</strong>, etc.<br />

After that it is more a questi<strong>on</strong> of applicati<strong>on</strong>,<br />

the fat compositi<strong>on</strong> of the filling and optimal<br />

storage.The less”optimized” a chocolate is in<br />

its crystallizati<strong>on</strong> progress, the more sensitive it<br />

is to incorrect process parameters.<br />

This paper indicates that a cooling rate in a<br />

well-tempered chocolate shell should be at a<br />

maximum of -0.5°C/min to ensure a sufficiently<br />

pure Form V crystallizati<strong>on</strong> with a high degree<br />

of bloom stability.<br />

At the same time, it is important to make sure<br />

that the tempering process is producing very<br />

pure Form V seeds to ensure a very high inflec-<br />

ti<strong>on</strong> point measured at a producti<strong>on</strong>-realistic<br />

cooling temperature.<br />

A perfect cooling tunnel for the future could<br />

be a tunnel which starts with a traditi<strong>on</strong>al gentle<br />

shell-cooling z<strong>on</strong>e, followed <strong>by</strong> a short heating<br />

z<strong>on</strong>e (perhaps micro waves), which purifies the<br />

8 May 2010 • Reprint from The Manufacturing C<strong>on</strong>fecti<strong>on</strong>er<br />

polymorphism, followed <strong>by</strong> an extremely cold<br />

filling-cooling z<strong>on</strong>e, perhaps freezing z<strong>on</strong>e, to<br />

ensure a high degree of network structure and<br />

small crystals, and finally a short reheating<br />

z<strong>on</strong>e to remove any possible c<strong>on</strong>densate <strong>on</strong> the<br />

product.<br />

Before doing that we have to carry out more<br />

studies to test a lot of different applicati<strong>on</strong>s, fat<br />

compositi<strong>on</strong>s and other variables to find the<br />

correct cooling c<strong>on</strong>diti<strong>on</strong> for a certain applica-<br />

ti<strong>on</strong>.<br />

REFERENCES<br />

- <strong>AAK</strong> pilot laboratory, Aarhus, Denmark<br />

- Beckett, Steve. Industrial <strong>Chocolate</strong> Manu-<br />

facture and Use, Sec<strong>on</strong>d Editi<strong>on</strong>, pp 186,<br />

191.<br />

- Minifie, Bernard W. <strong>Chocolate</strong>, Cocoa and<br />

C<strong>on</strong>fecti<strong>on</strong>ery: Science and Technology.<br />

Third Editi<strong>on</strong>. Page 212.<br />

- Smith, Kevin, Geoff Talbot. Food Chemistry.<br />

- Timms, Ralph E., PhD. The Manufacturing<br />

C<strong>on</strong>fecti<strong>on</strong>er, June 2002.<br />

- Ziegleder, G, Dr. Dr.–Ing habil. Frauenhofer<br />

Institut, ZDS Fat <str<strong>on</strong>g>Bloom</str<strong>on</strong>g> Symposium, May<br />

16 –17, 2000.

<strong>AAK</strong> – Wherever you are<br />

Head office<br />

AarhusKarlshamn AB<br />

Jungmansgatan 12<br />

SE-211 19 Malmö<br />

Sweden<br />

Teleph<strong>on</strong>e: +46 406 278 300<br />

Fax: +46 406 278 311<br />

E-mail: info@aak.com<br />

www.aak.com<br />

Sales and Producti<strong>on</strong><br />

AarhusKarlshamn Denmark A/S<br />

M.P. Bruuns Gade 27<br />

DK-8000 Aarhus C<br />

Denmark<br />

Teleph<strong>on</strong>e: +45 8730 6000<br />

Fax: +45 8730 6012<br />

AarhusKarlshamn Sweden AB<br />

SE-374 82 Karlshamn<br />

Sweden<br />

Visit address: Västra Kajen<br />

Teleph<strong>on</strong>e: +46 454 820 00<br />

Fax: +46 454 828 88<br />

AarhusKarlshamn Netherlands BV<br />

P.O. Box 17<br />

Visit address: Kreeftstraat 1<br />

NL-1540 AA Zaandijk<br />

The Netherlands<br />

Teleph<strong>on</strong>e: +31 75 627 84 00<br />

Fax: +31 75 627 84 78<br />

AarhusKarlshamn UK Ltd.<br />

King George Dock<br />

Hull HU9 5PX<br />

United Kingdom<br />

Teleph<strong>on</strong>e: +44 1482 701271<br />

Fax: +44 1482 709447<br />

AarhusKarlshamn USA Inc.<br />

131 Marsh Street<br />

Port Newark<br />

NJ 07114<br />

USA<br />

Teleph<strong>on</strong>e: +1 973 344 1300<br />

Fax: +1 973 344 9049<br />

Sales offices<br />

Producti<strong>on</strong><br />

AarhusKarlshamn México S.A. de C.V.<br />

Av. Héroes de Nocupétaro 1022<br />

Col. Industrial, C.P. 58130<br />

Morelia, Michoacán<br />

Mexico<br />

Teleph<strong>on</strong>e: +52 443 312 0175<br />

Fax: +52 443 312 5822<br />

AarhusKarlshamn Latin America<br />

Camino al Paso de la Arena 2460<br />

12600 M<strong>on</strong>tevideo<br />

Uruguay<br />

Teleph<strong>on</strong>e: +5 982 313 5135<br />

Fax: +5 982 313 5075<br />

Sales offices<br />

AarhusKarlshamn Asia-Pacific Sdn. Bhd.<br />

26th Floor, Menara KH<br />

Jalan Sultan Ismail<br />

50250 Kuala Lumpur<br />

Malaysia<br />

Teleph<strong>on</strong>e: +60 327 108 493<br />

Fax: +60 327 108 496<br />

AarhusKarlshamn Australia Pty Ltd<br />

4 Endeavour Close<br />

Castle Hill<br />

NSW 2154<br />

Australia<br />

Teleph<strong>on</strong>e: +61 288 503 522<br />

Fax: +61 288 503 422<br />

AarhusKarlshamn Canada Ltd<br />

2800 Skymark Avenue, Suite 203.<br />

Mississauga, Ontario<br />

Canada<br />

Teleph<strong>on</strong>e: +14 166 214 845<br />

Fax: +14 166 224 130<br />

AarhusKarlshamn Czech<br />

Czech Republic Spol. sro.<br />

P.O. Box 263<br />

Visiting address: Vaclávské nám. 64<br />

CS-111 21 Prague 1<br />

Czech Republic<br />

Teleph<strong>on</strong>e: +420 222 210 406<br />

Fax: +420 222 212 087<br />

AarhusKarlshamn do Brasil<br />

Desenvolvimento de Negócios Ltda<br />

Av. das Nações Unidas, 12.551<br />

17º andar - Sala 1710<br />

Brooklin Novo - São Paulo<br />

CEP 04578-903<br />

SP - Brazil<br />

Teleph<strong>on</strong>e: + 55 11 4195 4648<br />

Fax: + 55 11 4195 2075<br />

AarhusKarlshamn H<strong>on</strong>g K<strong>on</strong>g,<br />

representative office<br />

1/F, House No. 166<br />

Tin Sam Village<br />

Tai Wai, Shatin<br />

New Territories<br />

H<strong>on</strong>g K<strong>on</strong>g<br />

Teleph<strong>on</strong>e: +852 9029 3338<br />

Fax: +852 2604 4469<br />

AarhusKarlshamn Norway AS<br />

PO Box 2570 – Solli<br />

0202 Oslo<br />

Norway<br />

Teleph<strong>on</strong>e: +47 22 73 19 00<br />

Fax: +47 22 73 19 01<br />

AarhusKarlshamn Poland Sp. z o.o<br />

Ul. Walecznych 44/3<br />

PL-03-916 Warszawa<br />

Poland<br />

Teleph<strong>on</strong>e: +48 226 164 182<br />

Fax: +48 226 160 255<br />

AarhusKarlshamn Russia OOO<br />

Zemlyanoy Val 54, Office 2<br />

109004 Moscow<br />

Russia<br />

Teleph<strong>on</strong>e: +7 495 7486000<br />

Fax: +7 495 7486001<br />

AarhusKarlshamn Sweden AB,<br />

Ukraine representative office<br />

Reytarskaya str., 17 of. 5<br />

Kiev 01034<br />

Ukraine<br />

Teleph<strong>on</strong>e: +380 44 581 16 46<br />

Fax: +380 44 581 16 45<br />

For further informati<strong>on</strong> visit www.aak.com<br />

or e-mail chocolate@aak.com