double barrel zap screwlok ® system shear screw and ... - Alcor SA

double barrel zap screwlok ® system shear screw and ... - Alcor SA

double barrel zap screwlok ® system shear screw and ... - Alcor SA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

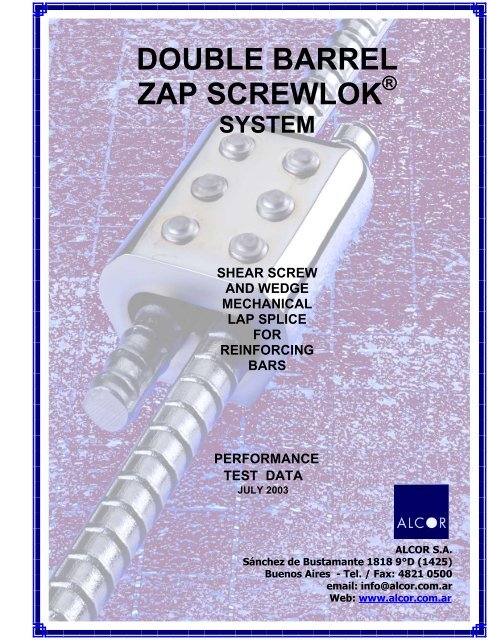

DOUBLE BARREL<br />

ZAP SCREWLOK <strong>®</strong><br />

SYSTEM<br />

SHEAR SCREW<br />

AND WEDGE<br />

MECHANICAL<br />

LAP SPLICE<br />

FOR<br />

REINFORCING<br />

BARS<br />

PERFORMANCE<br />

TEST DATA<br />

JULY 2003

INTRODUCTION<br />

Barsplice Products, Inc. has conducted a series of tests on reinforcing bar mechanical lap splice sizes No. 4<br />

through No. 6. The tests have been conducted on black <strong>and</strong> epoxy coated Double Barrel Zap Screwlok <strong>®</strong><br />

Splices. The purpose of the testing is to ensure that products are manufactured to the quality st<strong>and</strong>ards of<br />

BPI's ISO 9001 Quality System <strong>and</strong> are capable of exceeding strength requirements of various Building<br />

Codes.<br />

TENSILE TEST PROCEDURE<br />

Test specimens were loaded monotonically in tension to failure to determine the capability of the splice<br />

<strong>system</strong>. The tests were conducted in accordance with "St<strong>and</strong>ard Test Methods <strong>and</strong> Definitions for<br />

Mechanical Testing of Steel Products", ASTM A370. The testing was performed to exceed the strength<br />

requirements of ACI (American Concrete Institute) 318, Section 12.14.3.2, namely 125% x specified yield<br />

strength of Grade 60 reinforcing bar.<br />

All monotonic tension tests were carried out in either a 600 kip Forney universal testing machine, located at<br />

the Barsplice Products, Inc. in-house laboratory or a 200 kip Satec universal testing machine, located at the<br />

A-Lab, Inc. independent laboratory. Current calibration certificates for the test machines are on file.<br />

TEST RESULTS<br />

Results of the tension testing are summarized in Table 1.<br />

The reinforcing steel used in these tests conforms to the requirements of ASTM A615, Grade 60.<br />

SUMMARY<br />

Tension test specimens exceeded the Type 1 strength requirements of ACI 318,<br />

Section 12.14.3.2, namely 125% x specified yield strength of Grade 60 rebar.<br />

DOUBLE<br />

BARREL<br />

ZAP SIZE<br />

No. 4<br />

No. 6<br />

TABLE 1 TENSILE TEST RESULTS<br />

PEAK STRENGTH PEAK STRENGTH<br />

TEST ID<br />

NUMBER<br />

BAR<br />

TYPE<br />

STRESS % GRADE<br />

IN REBAR 60 SPEC.<br />

(psi) YIELD<br />

DOUBLE<br />

BARREL<br />

ZAP SIZE<br />

TEST ID<br />

NUMBER<br />

BAR<br />

TYPE<br />

STRESS % GRADE<br />

IN REBAR 60 SPEC.<br />

(psi) YIELD<br />

4T251<br />

4T252<br />

BLACK<br />

BLACK<br />

111,430<br />

111,741<br />

110,149<br />

104,386<br />

186 %<br />

186 %<br />

184 %<br />

174 %<br />

5T438 BLACK<br />

108,435<br />

107,110<br />

105,525<br />

109,005<br />

181 %<br />

179 %<br />

176 %<br />

182 %<br />

98,000 163 % 102,180 170 %<br />

4T255 BLACK 98,000<br />

101,000<br />

163 %<br />

168 %<br />

5T439 BLACK<br />

104,686<br />

105,082<br />

174 %<br />

175 %<br />

4T263<br />

4T278<br />

BLACK<br />

BLACK<br />

107,788<br />

117,315<br />

111,194<br />

105,054<br />

180 %<br />

196 %<br />

185 %<br />

175 % No. 5<br />

5T460 BLACK<br />

101,521<br />

108,630<br />

109,842<br />

102,000<br />

169 %<br />

181 %<br />

183 %<br />

170 %<br />

4T279 EPOXY<br />

102,485<br />

95,409<br />

171 %<br />

159 %<br />

5T464 BLACK 104,000<br />

98,000<br />

173 %<br />

163 %<br />

4T280 EPOXY 98,029 163 % 5T484 BLACK 107,548 179 %<br />

6T419 BLACK<br />

101,156<br />

103,654<br />

169 %<br />

173 % 5T487 BLACK<br />

104,010<br />

101,282<br />

173 %<br />

169 %<br />

6T439 BLACK<br />

111,474<br />

106,731<br />

108,000<br />

186 %<br />

178 %<br />

180 %<br />

5T488 BLACK<br />

104,935<br />

104,778<br />

106,210<br />

175 %<br />

175 %<br />

177 %<br />

6T451 BLACK 108,000<br />

104,000<br />

180 %<br />

173 %<br />

5T489 EPOXY<br />

102,081<br />

93,612<br />

170 %<br />

156 %<br />

6T464 BLACK 107,767<br />

107,497<br />

180 %<br />

179 %<br />

6T492 BLACK<br />

104,829<br />

93,503<br />

175 %<br />

156 %<br />

6T495 EPOXY<br />

98,525<br />

90,618<br />

164 %<br />

151 %