You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

the technology industry to help drive innovation and promote industry standards that will yield innovative<br />

and improved products for customers.<br />

<strong>Molex</strong> incurred total research and development costs of $134 million in fiscal <strong>2005</strong>, $119 million in<br />

fiscal 2004 and $117 million in fiscal 2003. The Company believes this investment, typically at 5% or more<br />

of net revenue, is among the highest level relative to the largest participants in the industry and helps it<br />

achieve a competitive advantage.<br />

<strong>Molex</strong> strives to provide customers with the most advanced interconnection products through<br />

intellectual property development and participation in industry standards committees. <strong>Molex</strong> engineers are<br />

active in approximately 45 such committees, helping give the Company a voice in shaping the technologies of<br />

the future. In fiscal <strong>2005</strong>, <strong>Molex</strong> commercialized approximately 384 new products and received 775 product<br />

patents.<br />

<strong>Molex</strong> performs a majority of its design and development of connector products in the U.S. and<br />

Japan, but has additional product development capabilities in various locations, including China, Germany,<br />

India, Ireland, Korea, Malaysia and Singapore.<br />

Manufacturing<br />

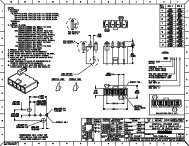

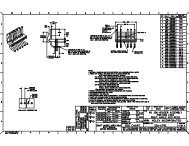

<strong>Molex</strong>’s core manufacturing expertise includes molding, stamping, plating and assembly operations.<br />

The Company utilizes state of the art plastic injection molding machines and metal stamping and forming<br />

presses. <strong>Molex</strong> has created new processes to meet the ongoing challenge of manufacturing smaller and<br />

smaller connectors. The Company has also developed proprietary plated plastic technology, which provides<br />

excellent shielding performance while eliminating secondary manufacturing processes in applications such as<br />

mobile phone antennas.<br />

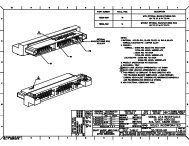

The Company also has expertise in printed circuit card and harness assembly for its integrated<br />

products operations, which build devices that leverage <strong>Molex</strong> connector content. Because integrated products<br />

require labor-intensive assembly, each <strong>Molex</strong> region operates at least one low-cost manufacturing center,<br />

whether in China, India, Malaysia, Mexico, Poland, Slovakia or Thailand.<br />

<strong>Molex</strong> continually looks for ways to reduce its manufacturing costs as it increases capacity, resulting<br />

in a trend of fewer but larger factories. The Company achieved economies of scale and higher capacity<br />

utilization while continuing to assure on time delivery. <strong>Molex</strong> has consolidated certain plants and expanded<br />

others, with the result that the average <strong>Molex</strong> factory is 25% larger and generally manufactures a wider range<br />

of products than five years ago.<br />

Raw Materials<br />

The principal raw materials that <strong>Molex</strong> purchases for the manufacture of its products include plastic<br />

resins for molding, metal alloys (primarily copper based) for stamping and gold and palladium salts for use in<br />

the plating process. The Company also purchases molded and stamped components and connector<br />

assemblies. Most materials and components used in the Company’s products are available from several<br />

sources. To achieve economies of scale, <strong>Molex</strong> concentrates purchases from a limited number of suppliers,<br />

and therefore in the short term may be dependent upon certain suppliers to meet performance and quality<br />

specifications and delivery schedules. <strong>Molex</strong> anticipates that its raw material expenditures as a percentage of<br />

sales may increase due to growth in <strong>Molex</strong>’s integrated products business and increases in certain commodity<br />

costs.<br />

Backlog and Seasonality<br />

The backlog of unfilled orders at June 30, <strong>2005</strong> was approximately $259.5 million, a 22% decline<br />

compared with backlog of $332.6 million at June 30, 2004. The decrease in backlog was partially attributable<br />

to an increase in distribution orders in June 2004 of approximately $36 million in advance of a price increase.<br />

In addition, during fiscal <strong>2005</strong> the Company provided additional vendor-managed inventory progress to<br />

customers. Under this method, the new order and shipment occur simultaneously and without impacting<br />

8