Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Kisssoft software, the vital link<br />

ZuIDbERG FRONTLINE SYSTEMS bV <strong>23</strong><br />

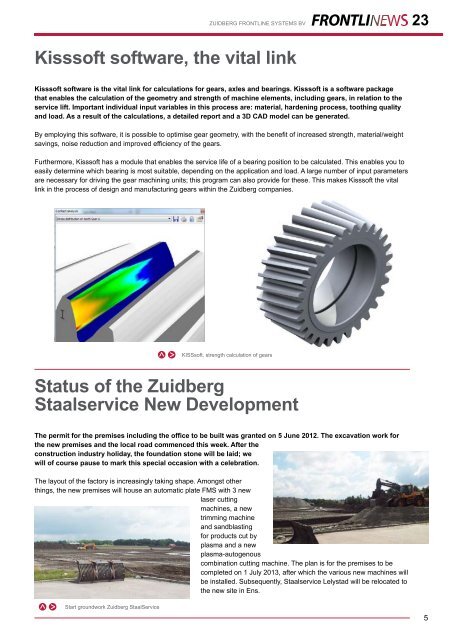

Kisssoft software is the vital link for calculations for gears, axles and bearings. Kisssoft is a software package<br />

that enables the calculation of the geometry and strength of machine elements, including gears, in relation to the<br />

service lift. Important individual input variables in this process are: material, hardening process, toothing quality<br />

and load. as a result of the calculations, a detailed report and a 3D caD model can be generated.<br />

by employing this software, it is possible to optimise gear geometry, with the benefit of increased strength, material/weight<br />

savings, noise reduction and improved efficiency of the gears.<br />

Furthermore, Kisssoft has a module that enables the service life of a bearing position to be calculated. This enables you to<br />

easily determine which bearing is most suitable, depending on the application and load. A large number of input parameters<br />

are necessary for driving the gear machining units; this program can also provide for these. This makes Kisssoft the vital<br />

link in the process of design and manufacturing gears within the <strong>Zuidberg</strong> companies.<br />

KISSsoft, strength calculation of gears<br />

Status of the <strong>Zuidberg</strong><br />

Staalservice New Development<br />

The permit for the premises including the office to be built was granted on 5 June 2012. The excavation work for<br />

the new premises and the local road commenced this week. after the<br />

construction industry holiday, the foundation stone will be laid; we<br />

will of course pause to mark this special occasion with a celebration.<br />

The layout of the factory is increasingly taking shape. Amongst other<br />

things, the new premises will house an automatic plate FMS with 3 new<br />

laser cutting<br />

machines, a new<br />

trimming machine<br />

and sandblasting<br />

for products cut by<br />

plasma and a new<br />

plasma-autogenous<br />

combination cutting machine. The plan is for the premises to be<br />

completed on 1 July 2013, after which the various new machines will<br />

be installed. Subsequently, Staalservice Lelystad will be relocated to<br />

the new site in Ens.<br />

Start groundwork <strong>Zuidberg</strong> StaalService<br />

5