OH - The Dow Chemical Company

OH - The Dow Chemical Company

OH - The Dow Chemical Company

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

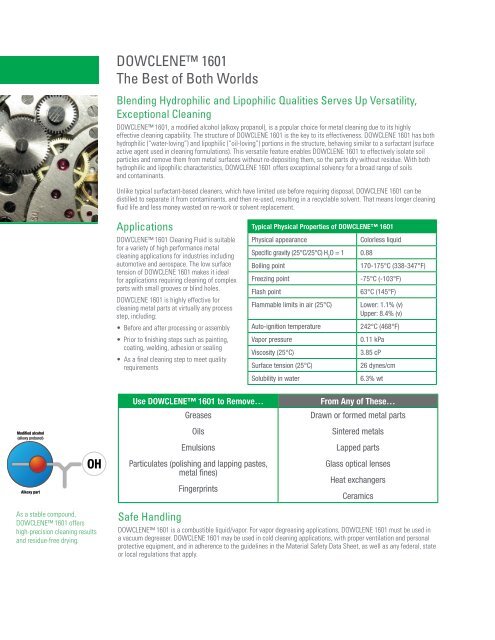

Modified alcohol<br />

(alkoxy probanol)<br />

Alkoxy part<br />

<strong>OH</strong><br />

As a stable compound,<br />

DOWCLENE 1601 offers<br />

high-precision cleaning results<br />

and residue-free drying.<br />

DOWCLENE 1601<br />

<strong>The</strong> Best of Both Worlds<br />

Blending Hydrophilic and Lipophilic Qualities Serves Up Versatility,<br />

Exceptional Cleaning<br />

DOWCLENE 1601, a modified alcohol (alkoxy propanol), is a popular choice for metal cleaning due to its highly<br />

effective cleaning capability. <strong>The</strong> structure of DOWCLENE 1601 is the key to its effectiveness. DOWCLENE 1601 has both<br />

hydrophilic (“water-loving”) and lipophilic (“oil-loving”) portions in the structure, behaving similar to a surfactant (surface<br />

active agent used in cleaning formulations). This versatile feature enables DOWCLENE 1601 to effectively isolate soil<br />

particles and remove them from metal surfaces without re-depositing them, so the parts dry without residue. With both<br />

hydrophilic and lipophilic characteristics, DOWCLENE 1601 offers exceptional solvency for a broad range of soils<br />

and contaminants.<br />

Unlike typical surfactant-based cleaners, which have limited use before requiring disposal, DOWCLENE 1601 can be<br />

distilled to separate it from contaminants, and then re-used, resulting in a recyclable solvent. That means longer cleaning<br />

fluid life and less money wasted on re-work or solvent replacement.<br />

Applications<br />

DOWCLENE 1601 Cleaning Fluid is suitable<br />

for a variety of high performance metal<br />

cleaning applications for industries including<br />

automotive and aerospace. <strong>The</strong> low surface<br />

tension of DOWCLENE 1601 makes it ideal<br />

for applications requiring cleaning of complex<br />

parts with small grooves or blind holes.<br />

DOWCLENE 1601 is highly effective for<br />

cleaning metal parts at virtually any process<br />

step, including:<br />

• Before and after processing or assembly<br />

• Prior to finishing steps such as painting,<br />

coating, welding, adhesion or sealing<br />

• As a final cleaning step to meet quality<br />

requirements<br />

Typical Physical Properties of DOWCLENE 1601<br />

Physical appearance Colorless liquid<br />

Specific gravity (25°C/25°C) H O = 1 2 0.88<br />

Boiling point 170-175°C (338-347°F)<br />

Freezing point -75°C (-103°F)<br />

Flash point 63°C (145°F)<br />

Flammable limits in air (25°C) Lower: 1.1% (v)<br />

Upper: 8.4% (v)<br />

Auto-ignition temperature 242°C (468°F)<br />

Vapor pressure 0.11 kPa<br />

Viscosity (25°C) 3.85 cP<br />

Surface tension (25°C) 26 dynes/cm<br />

Solubility in water 6.3% wt<br />

Use DOWCLENE 1601 to Remove… From Any of <strong>The</strong>se…<br />

Greases<br />

Drawn or formed metal parts<br />

Oils<br />

Emulsions<br />

Particulates (polishing and lapping pastes,<br />

metal fines)<br />

Safe Handling<br />

Fingerprints<br />

Sintered metals<br />

Lapped parts<br />

Glass optical lenses<br />

Heat exchangers<br />

Ceramics<br />

DOWCLENE 1601 is a combustible liquid/vapor. For vapor degreasing applications, DOWCLENE 1601 must be used in<br />

a vacuum degreaser. DOWCLENE 1601 may be used in cold cleaning applications, with proper ventilation and personal<br />

protective equipment, and in adherence to the guidelines in the Material Safety Data Sheet, as well as any federal, state<br />

or local regulations that apply.

Minimized Risk,<br />

Maximized Results<br />

SAFECHEM offers solutions<br />

that provide more than a<br />

precision-cleaned part – they<br />

provide a comprehensive<br />

approach for safety,<br />

sustainability and costeffectiveness,<br />

enabling:<br />

• Responsible solventhandling<br />

practices that<br />

protect both workers and<br />

the environment<br />

• Reuse of high-grade<br />

solvents that reduce<br />

solvent consumption – and<br />

operating costs*<br />

• Collection of waste<br />

materials for professional<br />

recycling, contributing to<br />

sustainability initiative<br />

*When equipment is properly calibrated<br />

SAFECARE System with<br />

fresh solvent<br />

Maintenance<br />

SAFECHEM’s MAXICHECK DCL-1 Test Kit can be used to easily monitor the quality of DOWCLENE 1601 Cleaning Fluid<br />

on-site. If needed, MAXIBOOST ST-1 Additive is available to help maintain the alkalinity of the solvent for long-term<br />

use.<br />

<strong>The</strong> SAFECHEM Advantage<br />

<strong>Dow</strong> is a proven leader in the production of solvents like DOWCLENE 1601 Cleaning Fluid, all of which are available<br />

through the SAFECHEM SAFECARE System. When used in conjunction with this innovative, closed-loop system and<br />

compatible closed cleaning equipment, these solvents provide exceptionally safe, efficient and cost-effective precision<br />

metal cleaning.<br />

<strong>Dow</strong> is committed to the principles of the Responsible Care ® program of the American Chemistry Council.<br />

SAFECARE System Available Solvents<br />

• DOWPER SVG Double Stabilized (perchloroethylene)<br />

• NEU-TRI (trichloroethylene)<br />

• DOWCLENE 1601 (modified alcohol)<br />

Cleaning and<br />

degreasing equipment<br />

Continuous<br />

internal recycling<br />

SAFECHEM North America LLC<br />

2040 <strong>Dow</strong> Center<br />

Midland, MI 48674 USA<br />

Tel: 877.376.8343<br />

service@dowsafechem.com<br />

www.dowsafechem.com<br />

Return of vapor<br />

Used solvent<br />

SAFECARE System<br />

with waste materials<br />

(oil, dirt, used solvent)<br />

How the SAFECARE System Works<br />

1. Fresh solvent is delivered in sealed SAFECARE<br />

containers designed to meet road, rail and sea transport<br />

regulations.<br />

2. Solvent is transferred to cleaning equipment with virtually<br />

no risk of emissions or spills.<br />

3. Used solvent is transferred from cleaning equipment to<br />

SAFECARE recycling containers, again with minimal risk of<br />

spills or emissions.<br />

4. Reputable waste management firms allied with<br />

SAFECHEM collect used solvent.<br />

5. SAFECHEM documents waste and conducts a<br />

comprehensive waste analysis to identify improvement<br />

opportunities.<br />

NOTICE: No freedom from infringement of any patent owned by <strong>Dow</strong> or others is to be inferred. Because use conditions and applicable laws may differ from one location to another<br />

and may change with time, Customer is responsible for determining whether products and the information in this document are appropriate for Customer’s use and for ensuring that<br />

Customer’s workplace and disposal practices are in compliance with applicable laws and other government enactments. <strong>The</strong> product shown in this literature may not be available for<br />

sale and/or available in all geographies where <strong>Dow</strong> is represented. <strong>The</strong> claims made may not have been approved for use in all countries. <strong>Dow</strong> assumes no obligation or liability for the<br />

information in this document. References to “<strong>Dow</strong>” or the “<strong>Company</strong>” mean the <strong>Dow</strong> legal entity selling the products to Customer unless otherwise expressly noted. NO WARRANTIES<br />

ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.<br />

®Trademark of <strong>The</strong> <strong>Dow</strong> <strong>Chemical</strong> <strong>Company</strong> (“<strong>Dow</strong>”) or an affiliated company of <strong>Dow</strong><br />

SAFECHEM North America LLC is a subsidiary of <strong>The</strong> <strong>Dow</strong> <strong>Chemical</strong> <strong>Company</strong> 898-02001-08/12 BB