DGDO-3364 NT - The Dow Chemical Company

DGDO-3364 NT - The Dow Chemical Company

DGDO-3364 NT - The Dow Chemical Company

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Technical Information – Telecommunications<br />

<strong>DGDO</strong>-<strong>3364</strong> <strong>NT</strong><br />

High Density Polyethylene Insulation Compound<br />

<strong>DGDO</strong>-<strong>3364</strong> <strong>NT</strong> is a high molecular weight, high-density polyethylene insulation compound providing<br />

excellent oxidative stability, toughness and abrasion resistance. <strong>DGDO</strong>-<strong>3364</strong> <strong>NT</strong> also provides excellent<br />

processing capability in high speed insulating extrusion processes. <strong>The</strong> <strong>DGDO</strong>-<strong>3364</strong> <strong>NT</strong> insulation<br />

compound has been optimized to yield increased insulation to conductor adhesion. <strong>The</strong> increased<br />

conductor adhesion improves processing latitude and insulation shrinkback performance for heavy wall<br />

insulation and tight pair twisting applications such as data grade LAN.<br />

<strong>DGDO</strong>-<strong>3364</strong> <strong>NT</strong> provides good performance across the full range of twisted pair telecommunication<br />

insulation applications. <strong>DGDO</strong>-<strong>3364</strong> <strong>NT</strong> readily meets Telcordia and ICEA requirements as well as most<br />

international age testing standards and specifications for both solid and foam/skin telephone cable<br />

insulation use. In the demanding grease filled cable application, <strong>DGDO</strong>-<strong>3364</strong> <strong>NT</strong> provides superior long<br />

term aging performance meeting the stringent Telcordia testing requirements. <strong>DGDO</strong>-<strong>3364</strong> <strong>NT</strong> is also<br />

available for a variety of miscellaneous optic cable, coaxial and power cable designs, especially where a<br />

thermoplastic HDPE insulation compound with increased conductor adhesion is desired.<br />

SPECIFICATIONS<br />

<strong>DGDO</strong>-<strong>3364</strong> <strong>NT</strong> meets the following material specifications:<br />

� ASTM D 1248 Type III Category A-4, Grade E8 and E9<br />

� Federal LP-390 C, II-H, Grades 1 and 2, Category 4<br />

Telephone wire insulated with <strong>DGDO</strong>-<strong>3364</strong> <strong>NT</strong>, using sound cable design and fabrication practices, will<br />

meet the following specifications:<br />

� Telcordia GR-421-CORE, Issue 1, December 1998, "Generic Requirements for Metallic<br />

Telecommunications Cables"<br />

� ICEA S-84-608, "Telecommunications Cable; Filled, Polyolefin Insulated, Copper Conductor -<br />

Technical Requirements"<br />

� REA PE 39, "Filled Telephone Cable"<br />

� REA PE 89, "Filled Telephone Cable with Expanded Insulation"<br />

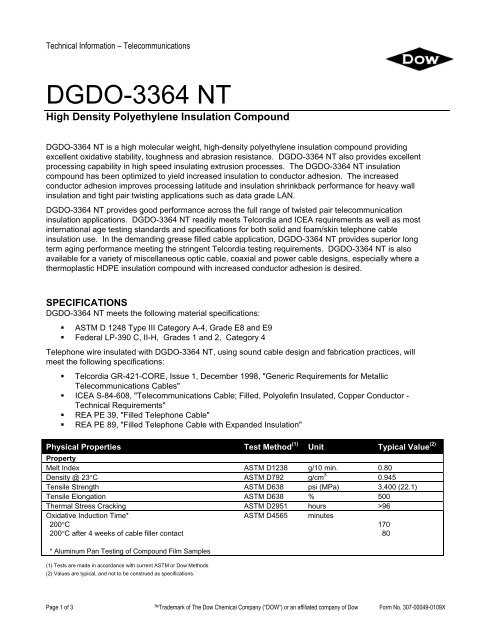

Physical Properties Test Method (1) Unit Typical Value (2)<br />

Property<br />

Melt Index ASTM D1238 g/10 min. 0.80<br />

Density @ 23°C ASTM D792 g/cm 3<br />

0.945<br />

Tensile Strength ASTM D638 psi (MPa) 3,400 (22.1)<br />

Tensile Elongation ASTM D638 % 500<br />

<strong>The</strong>rmal Stress Cracking ASTM D2951 hours >96<br />

Oxidative Induction Time*<br />

ASTM D4565 minutes<br />

200°C<br />

170<br />

200°C after 4 weeks of cable filler contact<br />

80<br />

* Aluminum Pan Testing of Compound Film Samples<br />

(1) Tests are made in accordance with current ASTM or <strong>Dow</strong> Methods<br />

(2) Values are typical, and not to be construed as specifications.<br />

Page 1 of 3 Trademark of <strong>The</strong> <strong>Dow</strong> <strong>Chemical</strong> <strong>Company</strong> (“DOW”) or an affiliated company of <strong>Dow</strong> Form No. 307-00049-0109X

Electrical Properties Test Method (1) Unit Typical Value (2)<br />

Property<br />

Dielectric Constant<br />

Original<br />

After 14 day water immersion at 23°C<br />

Dissipation Factor<br />

Original<br />

After 14 day water immersion at 23°C<br />

ASTM D1531 1 MHz<br />

ASTM D1531 1 MHz, radians<br />

Page 2 of 3 Trademark of <strong>The</strong> <strong>Dow</strong> <strong>Chemical</strong> <strong>Company</strong> (“DOW”) or an affiliated company of <strong>Dow</strong> Form No. 307-00049-0109X<br />

2.32<br />

2.32<br />

0.00006<br />

0.00006<br />

Volume Resistivity ASTM D257 ohm-cm >1x10 15<br />

(1) Tests are made in accordance with current ASTM or <strong>Dow</strong> Methods<br />

(2) Values are typical, and not to be construed as specifications.<br />

PROCESSING<br />

<strong>DGDO</strong>-<strong>3364</strong> <strong>NT</strong> provides very good processing capabilities in high speed thin wall insulation extrusion<br />

processes as both solid insulation and the skin material for skin/foam coextrusion.<br />

Properly designed polyethylene metering or double flighted barrier screws are used with good success for<br />

cellular extrusion. Typical extruder barrel temperatures are:<br />

Feed zone: 150 °C<br />

Transition zone: 190 °C<br />

Metering zone: 230 °C<br />

Crosshead and Die 230 °C<br />

Short land, double taper polyethylene dies are typically used for high speed extrusion processes. For solid<br />

insulation applications, an extrusion die size equaling or slightly oversize (+0.02mm/+0.001 inch) versus the<br />

finish diameter is recommended. For the skin/foam extrusion, a slightly undersize die size (-0.02mm/-0.001<br />

inch) versus the finish diameter is recommended<br />

A conductor preheat temperature of approximately 140 ºC is recommended for HDPE insulation<br />

applications. Very low insulation tensile elongation values will be achieved if the conductor preheat<br />

temperature is too low. Marginally low conductor preheat may provide insulation with good initial but poor<br />

aged insulation elongation performance.<br />

It is recommended that a menu of optimized extrusion conditions be developed and maintained for each<br />

insulation product on each production line.

Product<br />

Stewardship<br />

Customer<br />

Notice<br />

Medical<br />

Applications Policy<br />

Disclaimer<br />

Additional<br />

Information<br />

<strong>The</strong> <strong>Dow</strong> <strong>Chemical</strong> <strong>Company</strong> and its subsidiaries (“<strong>Dow</strong>”) has a fundamental concern for all who make, distribute,<br />

and use its products, and for the environment in which we live. This concern is the basis for our Product Stewardship<br />

philosophy by which we assess the safety, health, and environmental information on our products and then take<br />

appropriate steps to protect employee and public health and our environment. <strong>The</strong> success of our Product Stewardship<br />

program rests with each and every individual involved with <strong>Dow</strong> products ─ from the initial concept and research, to<br />

manufacture, use, sale, disposal, and recycle of each product.<br />

<strong>Dow</strong> strongly encourages its customers to review both their manufacturing processes and their applications of <strong>Dow</strong><br />

products from the standpoint of human health and environmental quality to ensure that <strong>Dow</strong> products are not used in<br />

ways for which they are not intended or tested. <strong>Dow</strong> personnel are available to answer your questions and to provide<br />

reasonable technical support. <strong>Dow</strong> product literature, including safety data sheets, should be consulted prior to use of<br />

<strong>Dow</strong> products. Current safety data sheets are available from <strong>Dow</strong>.<br />

NOTICE REGARDING MEDICAL APPLICATION RESTRICTIONS: <strong>Dow</strong> will not knowingly sell or sample any product or service<br />

(“Product”) into any commercial or developmental application that is intended for:<br />

a. long-term or permanent contact with internal bodily fluids or tissues. “Long-term” is contact which exceeds 72 continuous<br />

hours;<br />

b. use in cardiac prosthetic devices regardless of the length of time involved (“cardiac prosthetic devices” include, but are not<br />

limited to, pacemaker leads and devices, artificial hearts, heart valves, intra-aortic balloons and control systems, and<br />

ventricular bypass-assisted devices);<br />

c. use as a critical component in medical devices that support or sustain human life; or<br />

d. use specifically by pregnant women or in applications designed specifically to promote or interfere with human reproduction.<br />

<strong>Dow</strong> requests that customers considering use of <strong>Dow</strong> products in medical applications notify <strong>Dow</strong> so that appropriate<br />

assessments may be conducted.<br />

<strong>Dow</strong> does not endorse or claim suitability of its products for specific medical applications. It is the responsibility of the medical<br />

device or pharmaceutical manufacturer to determine that the <strong>Dow</strong> product is safe, lawful, and technically suitable for the<br />

intended use. DOW MAKES NO WARRA<strong>NT</strong>IES, EXPRESS OR IMPLIED, CONCERNING THE<br />

SUITABILITY OF ANY DOW PRODUCT FOR USE IN MEDICAL APPLICATIONS.<br />

NOTICE: No freedom from infringement of any patent owned by <strong>Dow</strong> or others is to be inferred. Because use<br />

conditions and applicable laws may differ from one location to another and may change with time, the Customer is<br />

responsible for determining whether products and the information in this document are appropriate for the Customer’s<br />

use and for ensuring that the Customer’s workplace and disposal practices are in compliance with applicable laws<br />

and other governmental enactments. <strong>Dow</strong> assumes no obligation or liability for the information in this document.<br />

NO WARRA<strong>NT</strong>IES ARE GIVEN; ALL IMPLIED WARRA<strong>NT</strong>IES OF MERCHA<strong>NT</strong>ABILITY OR FITNESS FOR A<br />

PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.<br />

NOTICE: If products are described as “experimental” or “developmental”: (1) product specifications may not be fully<br />

determined; (2) analysis of hazards and caution in handling and use are required; (3) there is greater potential for <strong>Dow</strong><br />

to change specifications and/or discontinue production; and (4) although <strong>Dow</strong> may from time to time provide samples<br />

of such products, <strong>Dow</strong> is not obligated to supply or otherwise commercialize such products for any use or application<br />

whatsoever.<br />

North America Europe/Middle East +800-3694-6367<br />

U.S. & Canada: 1-800-441-4369 +32-3-450-2240<br />

1-989-832-1426 Italy: +800-783-825<br />

Mexico: +1-800-441-4369<br />

Latin America South Africa +800-99-5078<br />

Argentina: +54-11-4319-0100<br />

Brazil: +55-11-5188-9000<br />

Colombia: +57-1-219-6000 Asia Pacific +800-7776-7776<br />

Mexico: +52-55-5201-4700 +603-7965-5392<br />

www.dowplastics.com This document is intended for use within North America, Europe, Pacific<br />

Published January, 2009.<br />

© 2009 <strong>The</strong> <strong>Dow</strong> <strong>Chemical</strong> <strong>Company</strong><br />

Page 3 of 3 Trademark of <strong>The</strong> <strong>Dow</strong> <strong>Chemical</strong> <strong>Company</strong> (“DOW”) or an affiliated company of <strong>Dow</strong> Form No. 307-00049-0109X