Effect of Functionalization of Carbon Black on Rubber Properties

Effect of Functionalization of Carbon Black on Rubber Properties

Effect of Functionalization of Carbon Black on Rubber Properties

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

very low tan δ at high temperature and very high hysteresis at lower temperature, similar<br />

to silica. The same results were also obtained in the strain sweep test (Figure 10). At<br />

70°C, the maximum tan δ is 0.323 for the carb<strong>on</strong> black compound. This value is reduced<br />

by 48% and 50% with CRX4210 and silica, respectively. Based <strong>on</strong> the well-known<br />

correlati<strong>on</strong> between rolling resistance and tan δ at high temperature, it can be expected<br />

that the rolling resistance <str<strong>on</strong>g>of</str<strong>on</strong>g> CRX4210 tire is comparable to that <str<strong>on</strong>g>of</str<strong>on</strong>g> silica tires and much<br />

lower than that <str<strong>on</strong>g>of</str<strong>on</strong>g> carb<strong>on</strong> black tires.<br />

Abrasi<strong>on</strong> resistance:<br />

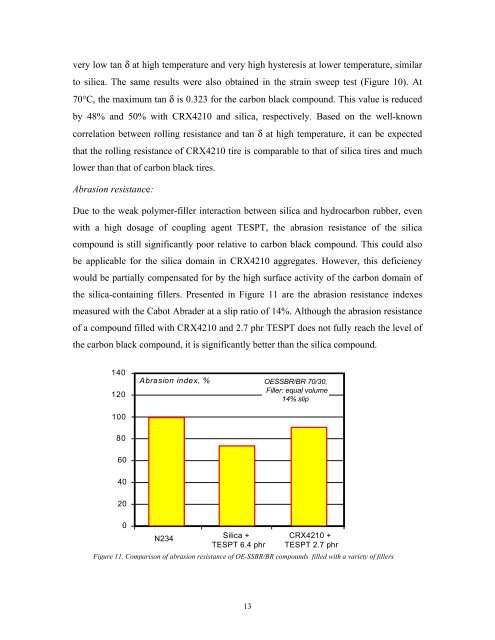

Due to the weak polymer-filler interacti<strong>on</strong> between silica and hydrocarb<strong>on</strong> rubber, even<br />

with a high dosage <str<strong>on</strong>g>of</str<strong>on</strong>g> coupling agent TESPT, the abrasi<strong>on</strong> resistance <str<strong>on</strong>g>of</str<strong>on</strong>g> the silica<br />

compound is still significantly poor relative to carb<strong>on</strong> black compound. This could also<br />

be applicable for the silica domain in CRX4210 aggregates. However, this deficiency<br />

would be partially compensated for by the high surface activity <str<strong>on</strong>g>of</str<strong>on</strong>g> the carb<strong>on</strong> domain <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

the silica-c<strong>on</strong>taining fillers. Presented in Figure 11 are the abrasi<strong>on</strong> resistance indexes<br />

measured with the Cabot Abrader at a slip ratio <str<strong>on</strong>g>of</str<strong>on</strong>g> 14%. Although the abrasi<strong>on</strong> resistance<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> a compound filled with CRX4210 and 2.7 phr TESPT does not fully reach the level <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

the carb<strong>on</strong> black compound, it is significantly better than the silica compound.<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

Abrasi<strong>on</strong> index, %<br />

N234<br />

Silica +<br />

TESPT 6.4 phr<br />

13<br />

OESSBR/BR 70/30,<br />

Filler: equal volume<br />

14% slip<br />

CRX4210 +<br />

TESPT 2.7 phr<br />

Figure 11. Comparis<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> abrasi<strong>on</strong> resistance <str<strong>on</strong>g>of</str<strong>on</strong>g> OE-SSBR/BR compounds filled with a variety <str<strong>on</strong>g>of</str<strong>on</strong>g> fillers