on air - Messer

on air - Messer

on air - Messer

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

10 : Cover story<br />

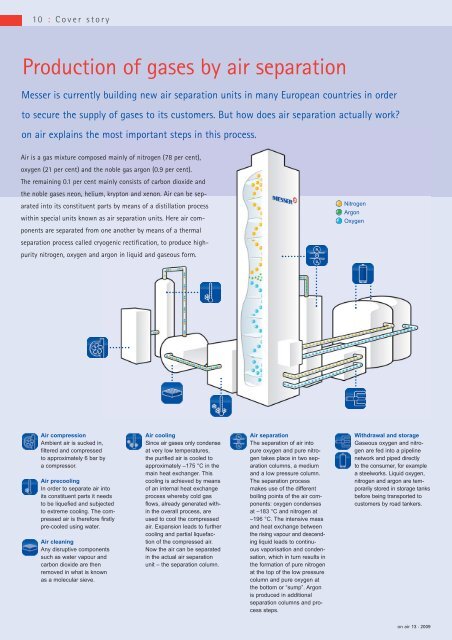

Producti<strong>on</strong> of gases by <strong>air</strong> separati<strong>on</strong><br />

<strong>Messer</strong> is currently building new <strong>air</strong> separati<strong>on</strong> units in many European countries in order<br />

to secure the supply of gases to its customers. But how does <strong>air</strong> separati<strong>on</strong> actually work?<br />

<strong>on</strong> <strong>air</strong> explains the most important steps in this process.<br />

Air is a gas mixture composed mainly of nitrogen (78 per cent),<br />

oxygen (21 per cent) and the noble gas arg<strong>on</strong> (0.9 per cent).<br />

The remaining 0.1 per cent mainly c<strong>on</strong>sists of carb<strong>on</strong> dioxide and<br />

the noble gases ne<strong>on</strong>, helium, krypt<strong>on</strong> and xen<strong>on</strong>. Air can be sep -<br />

arated into its c<strong>on</strong>stituent parts by means of a distillati<strong>on</strong> process<br />

within special units known as <strong>air</strong> separati<strong>on</strong> units. Here <strong>air</strong> com -<br />

p<strong>on</strong>ents are separated from <strong>on</strong>e another by means of a thermal<br />

sep arati<strong>on</strong> process called cryogenic rectificati<strong>on</strong>, to produce highpurity<br />

nitrogen, oxygen and arg<strong>on</strong> in liquid and gaseous form.<br />

Air compressi<strong>on</strong><br />

Ambient <strong>air</strong> is sucked in,<br />

filtered and compressed<br />

to approximately 6 bar by<br />

a compressor.<br />

Air precooling<br />

In order to separate <strong>air</strong> into<br />

its c<strong>on</strong>stituent parts it needs<br />

to be liquefied and subjected<br />

to extreme cooling. The compressed<br />

<strong>air</strong> is therefore firstly<br />

pre-cooled using water.<br />

Air cleaning<br />

Any disruptive comp<strong>on</strong>ents<br />

such as water vapour and<br />

carb<strong>on</strong> dioxide are then<br />

removed in what is known<br />

as a molecular sieve.<br />

Air cooling<br />

Since <strong>air</strong> gases <strong>on</strong>ly c<strong>on</strong>dense<br />

at very low temperatures,<br />

the purified <strong>air</strong> is cooled to<br />

approximately –175 °C in the<br />

main heat exchanger. This<br />

cooling is achieved by means<br />

of an internal heat exchange<br />

process whereby cold gas<br />

flows, already generated with -<br />

in the overall process, are<br />

used to cool the compressed<br />

<strong>air</strong>. Expansi<strong>on</strong> leads to further<br />

cooling and partial liquefac -<br />

ti<strong>on</strong> of the compressed <strong>air</strong>.<br />

Now the <strong>air</strong> can be separated<br />

in the actual <strong>air</strong> separati<strong>on</strong><br />

unit – the separati<strong>on</strong> column.<br />

Air separati<strong>on</strong><br />

The separati<strong>on</strong> of <strong>air</strong> into<br />

pure oxygen and pure nitrogen<br />

takes place in two sep -<br />

arati<strong>on</strong> columns, a medium<br />

and a low pressure column.<br />

The separati<strong>on</strong> process<br />

makes use of the different<br />

boiling points of the <strong>air</strong> comp<strong>on</strong>ents:<br />

oxygen c<strong>on</strong>denses<br />

at –183 °C and nitrogen at<br />

–196 °C. The intensive mass<br />

and heat exchange between<br />

the rising vapour and de scend -<br />

ing liquid leads to c<strong>on</strong>tinuous<br />

vaporisati<strong>on</strong> and c<strong>on</strong>densati<strong>on</strong>,<br />

which in turn results in<br />

the formati<strong>on</strong> of pure nitrogen<br />

at the top of the low pressure<br />

column and pure oxygen at<br />

the bottom or “sump”. Arg<strong>on</strong><br />

is produced in additi<strong>on</strong>al<br />

separati<strong>on</strong> columns and process<br />

steps.<br />

Nitrogen<br />

Arg<strong>on</strong><br />

Oxygen<br />

Withdrawal and storage<br />

Gaseous oxygen and nitrogen<br />

are fed into a pipeline<br />

network and piped directly<br />

to the c<strong>on</strong>sumer, for example<br />

a steelworks. Liquid oxygen,<br />

nitrogen and arg<strong>on</strong> are tem -<br />

po rarily stored in storage tanks<br />

before being transported to<br />

customers by road tankers.<br />

<strong>on</strong> <strong>air</strong> 13 · 2009