8 6 Helmut Gutenberger and Wojciech Pastuszczyn on ... - Messer

8 6 Helmut Gutenberger and Wojciech Pastuszczyn on ... - Messer

8 6 Helmut Gutenberger and Wojciech Pastuszczyn on ... - Messer

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

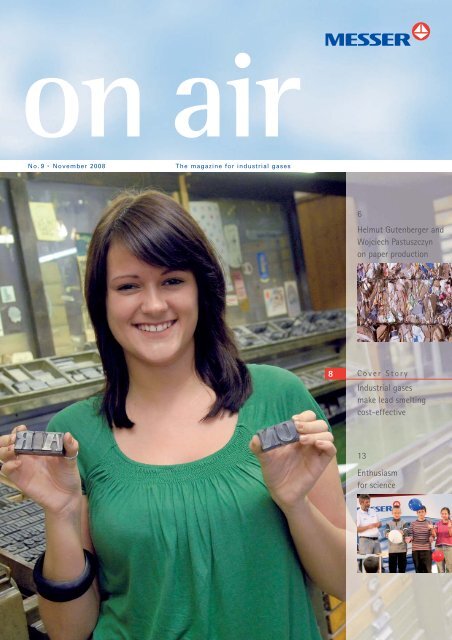

<strong>on</strong> air<br />

No. 9 · November 2008 The magazine for industrial gases<br />

8<br />

6<br />

<str<strong>on</strong>g>Helmut</str<strong>on</strong>g> <str<strong>on</strong>g>Gutenberger</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

<str<strong>on</strong>g>Wojciech</str<strong>on</strong>g> <str<strong>on</strong>g>Pastuszczyn</str<strong>on</strong>g><br />

<strong>on</strong> paper producti<strong>on</strong><br />

Cover Story<br />

Industrial gases<br />

make lead smelting<br />

cost-effective<br />

13<br />

Enthusiasm<br />

for science

2 : C<strong>on</strong>tents<br />

Editorial : 3<br />

News : 4–5<br />

Interview : 6–7<br />

Green paper producti<strong>on</strong><br />

Diana Buss spoke to <str<strong>on</strong>g>Helmut</str<strong>on</strong>g> <str<strong>on</strong>g>Gutenberger</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

<str<strong>on</strong>g>Wojciech</str<strong>on</strong>g> <str<strong>on</strong>g>Pastuszczyn</str<strong>on</strong>g>, experts for paper, about<br />

envir<strong>on</strong>mentally compatible paper producti<strong>on</strong><br />

<strong>Messer</strong> World : 12–13<br />

New air separators under c<strong>on</strong>structi<strong>on</strong><br />

<strong>Messer</strong> is currently building eleven new gas<br />

producti<strong>on</strong> plants in Europe.<br />

100 years of oxygen filling<br />

A century of oxygen under “business licence”<br />

E<br />

Enthusiasm for research<br />

<strong>Messer</strong> in Hungary<br />

supports European Researchers’ Night<br />

People at <strong>Messer</strong> : 14<br />

Meeting of retirees:<br />

being together is what counts<br />

Gasette : 15<br />

Tips, events <str<strong>on</strong>g>and</str<strong>on</strong>g> other useful informati<strong>on</strong><br />

Cover story : 8–11<br />

Lead – from ore or scrap to metal<br />

Industrial gases such as oxygen are used in lead melting <str<strong>on</strong>g>and</str<strong>on</strong>g> lead recycling,<br />

where they make the processes even more ec<strong>on</strong>omical <str<strong>on</strong>g>and</str<strong>on</strong>g> effective.<br />

Angela Bockstegers, business/commercial trainee at <strong>Messer</strong> with<br />

a lead hot type as used in the printing industry in the past.<br />

Today lead is mainly found in lead accumulators such as in car batteries.<br />

<str<strong>on</strong>g>Helmut</str<strong>on</strong>g> <str<strong>on</strong>g>Gutenberger</str<strong>on</strong>g> (2nd from left)<br />

explains paper producti<strong>on</strong> to customers<br />

<strong>Messer</strong> supports the European<br />

Researchers’ Night<br />

Retired <strong>Messer</strong> sales managers have been<br />

meeting regularly for 15 years.<br />

Imprint<br />

Published by:<br />

<strong>Messer</strong> Group GmbH<br />

Corporate Communicati<strong>on</strong>s<br />

Otto-Volger-Straße 3c<br />

D–65843 Sulzbach<br />

Editorial Team:<br />

Diana Buss – Editor-in-Chief<br />

Tel.: +49 6196 7760-361<br />

diana.buss@messergroup.com<br />

Benjamin Auweiler, Thomas<br />

Böckler, Christoph Erdmann,<br />

Tim Evis<strong>on</strong>, Michael Holy,<br />

Anita Kötél, M<strong>on</strong>ika Lammertz,<br />

Angélique Renier, Joachim<br />

Rohovec, Marlen Schäfer<br />

C<strong>on</strong>cept <str<strong>on</strong>g>and</str<strong>on</strong>g> Realisati<strong>on</strong>:<br />

Maenken Kommunikati<strong>on</strong> GmbH<br />

V<strong>on</strong>-der-Wettern-Straße 25<br />

D–51149 Köln<br />

Translati<strong>on</strong>:<br />

C<strong>on</strong>text GmbH<br />

Elisenstraße 4–10<br />

D–50667 Köln<br />

Many thanks to all our<br />

c<strong>on</strong>tributors!<br />

A big thank you to Mareike<br />

Tocha for lots of great photos!<br />

Go to www.messergroup.com<br />

for comprehensive informati<strong>on</strong><br />

about <strong>on</strong> air, as well as the<br />

c<strong>on</strong>tact details of the editorial<br />

team.<br />

<strong>on</strong> air is published four times a<br />

year in German, English <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

Hungarian.<br />

<strong>on</strong> air 09 · 2008

The editorial team<br />

Editor-in-Chief:<br />

Diana<br />

Buss<br />

Corporate Office:<br />

Benjamin<br />

Auweiler<br />

<strong>on</strong> air 09 · 2008<br />

Tim<br />

Evis<strong>on</strong><br />

Applicati<strong>on</strong> Technology:<br />

Thomas<br />

Böckler<br />

M<strong>on</strong>ika<br />

Lammertz<br />

Producti<strong>on</strong> & Engineering:<br />

Dr. Christoph<br />

Erdmann<br />

West Europe Regi<strong>on</strong>:<br />

Angélique<br />

Renier<br />

Central Europe Regi<strong>on</strong>:<br />

Michael<br />

Holy<br />

South-East Europe Regi<strong>on</strong>:<br />

Anita<br />

Kötél<br />

Marlen<br />

Schäfer<br />

Joachim<br />

Rohovec<br />

Dear Readers,<br />

Since 2005, the “European Researchers’<br />

Night” has traditi<strong>on</strong>ally taken place <strong>on</strong> the<br />

fourth Friday in September. Scientists<br />

across Europe open the doors to their<br />

research facilities, inspiring young <str<strong>on</strong>g>and</str<strong>on</strong>g> old<br />

with their research work. In this issue of <strong>on</strong><br />

air, you can find out more about the<br />

Researchers’ Night in Hungary as well as<br />

the innovati<strong>on</strong> fund with which <strong>Messer</strong> is<br />

supporting research projects at various<br />

universities.<br />

E d i t o r i a l : 3<br />

The financial crisis has been dominating<br />

Stefan <strong>Messer</strong><br />

the headlines in Europe <str<strong>on</strong>g>and</str<strong>on</strong>g> around the<br />

world. However, as far as our thoughts <str<strong>on</strong>g>and</str<strong>on</strong>g> acti<strong>on</strong>s are c<strong>on</strong>cerned, it has not superseded<br />

the most important subject of all: that of protecting our planet. On the c<strong>on</strong>trary,<br />

when the ec<strong>on</strong>omy is weaker it is all the more important to make targeted<br />

investments in efficient technologies that make a lasting c<strong>on</strong>tributi<strong>on</strong> to stopping<br />

climate change <str<strong>on</strong>g>and</str<strong>on</strong>g> improving water, air <str<strong>on</strong>g>and</str<strong>on</strong>g> soil quality. The aim of “green paper<br />

producti<strong>on</strong>”, a c<strong>on</strong>cept that <strong>Messer</strong> has been putting a lot of work into, is to produce<br />

paper with c<strong>on</strong>siderably reduced water <str<strong>on</strong>g>and</str<strong>on</strong>g> energy c<strong>on</strong>sumpti<strong>on</strong>, thereby reducing<br />

the carb<strong>on</strong> footprint (CO2 emissi<strong>on</strong>s) during the entire process chain. In an interview<br />

with <strong>on</strong> air, the experts from <strong>Messer</strong> reveal why this has to be the primary<br />

objective in paper producti<strong>on</strong>.<br />

Still <strong>on</strong> the subject of envir<strong>on</strong>mental protecti<strong>on</strong>, but in a different industry: leadfree<br />

is not always possible – today this metal is primarily used for energy storage<br />

in car batteries <str<strong>on</strong>g>and</str<strong>on</strong>g> other lead acid accumulators. Since lead is a toxic heavy metal,<br />

particular attenti<strong>on</strong> has to be given to envir<strong>on</strong>mentally friendly <str<strong>on</strong>g>and</str<strong>on</strong>g> resourcec<strong>on</strong>serving<br />

producti<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> processing. In smelting, as in many other combusti<strong>on</strong><br />

processes, the air is therefore enriched with pure oxygen. Increasing the oxygen<br />

c<strong>on</strong>tent raises the burning temperature <str<strong>on</strong>g>and</str<strong>on</strong>g> thereby accelerates the combusti<strong>on</strong> process.<br />

This saves energy <str<strong>on</strong>g>and</str<strong>on</strong>g> produces fewer harmful substances such as nitrous oxides<br />

due to the reduced nitrogen c<strong>on</strong>tent. The cover story in this issue of <strong>on</strong> air also<br />

looks at the process of lead recycling which is made more cost-effective by the<br />

use of industrial gases.<br />

I hope you enjoy reading this issue of <strong>on</strong> air!<br />

Best regards<br />

Stefan <strong>Messer</strong>

4 : N e w s<br />

<strong>Messer</strong> has installed a further nitrogen generator for Bosch in<br />

Hungary. The Bosch Group is a leading internati<strong>on</strong>al technology<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> service company that uses nitrogen for wave soldering of<br />

electr<strong>on</strong>ic assemblies. <strong>Messer</strong> secured the c<strong>on</strong>structi<strong>on</strong> of<br />

the producti<strong>on</strong> unit with a ten-year c<strong>on</strong>tract. Bosch put its<br />

first nitrogen generator from <strong>Messer</strong> into operati<strong>on</strong> back in<br />

April 2006. The company’s rapidly advancing technological<br />

<strong>Messer</strong>’s European C<strong>on</strong>trol<br />

development led to an increased dem<str<strong>on</strong>g>and</str<strong>on</strong>g> for gas, making the c<strong>on</strong>structi<strong>on</strong><br />

Center for On-Site Plants<br />

in Budapest also m<strong>on</strong>itors of another unit necessary.<br />

the operati<strong>on</strong> of the new Anita Kötél, <strong>Messer</strong> Hungarogáz<br />

nitrogen generator.<br />

Castolin Eutectic wins<br />

Frost & Sullivan Award<br />

The renowned business c<strong>on</strong>sulting firm Frost &<br />

Sullivan has h<strong>on</strong>oured Castolin Eutectic, a member<br />

of the <strong>Messer</strong> family, as the European market<br />

leader for customer service. As part of a study,<br />

Frost & Sullivan looked at the most important<br />

companies in the welding industry, including related<br />

repair <str<strong>on</strong>g>and</str<strong>on</strong>g> maintenance processes, <str<strong>on</strong>g>and</str<strong>on</strong>g> assessed<br />

their quality of customer service.<br />

The comparis<strong>on</strong> shows that, with its filler<br />

materials, Castolin Eutectic offers the most comprehensive<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> innovative service across Europe.<br />

The jury was particularly impressed by Castolin’s<br />

flexible <str<strong>on</strong>g>and</str<strong>on</strong>g> direct customer support. The central<br />

elements of which comprise deficiency analysis,<br />

applicati<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> wear analysis - both generally<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> in key industries as well as comprehensive<br />

customer management via special telemarketing<br />

activities.<br />

Dr. Gary Heath, Castolin Eutectic<br />

More nitrogen for Bosch in Hungary<br />

Castolin Eutectic’s<br />

award for outst<str<strong>on</strong>g>and</str<strong>on</strong>g>ing<br />

customer<br />

service<br />

Very successful market entry<br />

<strong>Messer</strong> <strong>on</strong>ly resumed selling its products in the German market at the<br />

beginning of May, since which time it has clinched more than 75 c<strong>on</strong>tracts<br />

for the supply of liquid gases such as oxygen, nitrogen, carb<strong>on</strong><br />

dioxide <str<strong>on</strong>g>and</str<strong>on</strong>g> arg<strong>on</strong>. To date, the young German <strong>Messer</strong> subsidiary<br />

has installed 25 gas storage facilities <strong>on</strong> customer sites; a further 25<br />

will follow by the end of the year, with the same again in the first<br />

half of next year. Since May 2008, <strong>Messer</strong> has managed to sign c<strong>on</strong>tracts<br />

with more than 150 new customers in Germany for cylinder<br />

gases with a total annual value of around two milli<strong>on</strong> euros. A comprehensive<br />

network of 16 sales partners in the states of Hesse,<br />

Rhinel<str<strong>on</strong>g>and</str<strong>on</strong>g>-Palatinate, Baden-Württemberg <str<strong>on</strong>g>and</str<strong>on</strong>g> North Rhine-<br />

Westphalia ensures reliability of supply to our customers.<br />

Diana Buss, <strong>Messer</strong> Group<br />

Old acquaintance:<br />

Schages is <strong>on</strong>ce<br />

again being supplied<br />

by <strong>Messer</strong><br />

<strong>Messer</strong> recommenced<br />

supplying gases in<br />

Germany in May.<br />

<strong>on</strong> air 09 · 2008

New “old” customer<br />

The Krefeld-based firm Schages, <strong>on</strong>e of the industry’s largest <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

most flexible c<strong>on</strong>tract-cutting companies, is <strong>on</strong>ce again a <strong>Messer</strong> customer,<br />

having also been supplied back in the <strong>Messer</strong> Griesheim days.<br />

Since July 2008, <strong>Messer</strong> has been supplying nitrogen 5.0 for high<br />

pressure laser cutting of aluminium <str<strong>on</strong>g>and</str<strong>on</strong>g> high alloy steels as well as<br />

oxygen 3.5 for optimum laser flame cutting.<br />

<strong>Messer</strong> has signed a l<strong>on</strong>g-term supply c<strong>on</strong>tract with Schages with<br />

a two-year extensi<strong>on</strong> opti<strong>on</strong>. The c<strong>on</strong>tractually specified yearly requirement<br />

comes to more than 700,000 cubic metres of liquid nitrogen 5.0<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> more than 25,000 cubic metres of liquid oxygen.<br />

Karl-Heinz Breilmann, <strong>Messer</strong> Industriegase<br />

High-protein<br />

treats<br />

Functi<strong>on</strong>al food refers to<br />

value-added products that<br />

not <strong>on</strong>ly taste <str<strong>on</strong>g>and</str<strong>on</strong>g> look good,<br />

but are also supposed to have a positive<br />

effect <strong>on</strong> our health. Protein Foods<br />

Vejprnice (Czech Republic) produces highly c<strong>on</strong>centrated<br />

protein food, c<strong>on</strong>sisting of 100 per cent pure chicken egg protein. It is fat-, sugar<str<strong>on</strong>g>and</str<strong>on</strong>g><br />

cholesterol-free <str<strong>on</strong>g>and</str<strong>on</strong>g> c<strong>on</strong>tains <strong>on</strong>ly 220 kilojoules per 100 grams. After successful<br />

tests by <strong>Messer</strong> in the Czech Republic, protein products frozen with liquid nitrogen<br />

are now <strong>on</strong> sale in the shops. Freezing this protein food improves the quality.<br />

M<strong>on</strong>ika Lammertz, <strong>Messer</strong> Group<br />

Reference project with SPAR<br />

In August of this year, SPAR opened its sec<strong>on</strong>d<br />

logistics centre – <strong>on</strong>e of the most modern logistics<br />

depots in Hungary – in Üllő near Budapest.<br />

SPAR has opted to use the Siber technology,<br />

developed jointly by <strong>Messer</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> the French company<br />

Olivo, as an innovative cryogenic system<br />

for cooling <str<strong>on</strong>g>and</str<strong>on</strong>g> freezing food in transport c<strong>on</strong>tainers.<br />

The 2,400 Siber c<strong>on</strong>tainers used at SPAR<br />

are suitable for transporting <str<strong>on</strong>g>and</str<strong>on</strong>g> storing both<br />

<strong>on</strong> air 09 · 2008<br />

Freezing with nitrogen<br />

improves the quality of<br />

protein food.<br />

refrigerated <str<strong>on</strong>g>and</str<strong>on</strong>g> frozen food, with flexible cold<br />

chain maintenance of up to 48 hours. The compartments<br />

in the Siber c<strong>on</strong>tainers are filled with<br />

dry ice in the SPAR logistics centre, thereby providing<br />

direct refrigerati<strong>on</strong> without any power<br />

c<strong>on</strong>sumpti<strong>on</strong>. This collaborati<strong>on</strong> between <strong>Messer</strong><br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> SPAR is a reference project for the whole<br />

South-East Europe regi<strong>on</strong>.<br />

László Kapás, <strong>Messer</strong> Hungarogáz<br />

<strong>Messer</strong> supplies<br />

nitrogen <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

hydrogen to its<br />

partner TS Tubes<br />

Systems.<br />

Aktuelles : 5<br />

<strong>Messer</strong> supplies Slovakian<br />

automotive suppliers<br />

The Swiss-Slovakian company TS Tubes Systems,<br />

which was established in Surany (Slovakia) at the<br />

beginning of this year, is a supplier to the European<br />

automotive industry. Its Swiss parent company,<br />

Zobex AG based in Sarnen, decided to relocate<br />

its brazing hose producti<strong>on</strong> to a former textile producti<strong>on</strong><br />

hall at this locati<strong>on</strong> in the south-west of<br />

the country. <strong>Messer</strong> has been a partner of TS Tubes<br />

Systems since the start of operati<strong>on</strong>s. The two partners<br />

have signed a supply c<strong>on</strong>tract for 100,000 cubic<br />

metres of liquid nitrogen <str<strong>on</strong>g>and</str<strong>on</strong>g> 3,500 cubic metres of<br />

hydrogen. Producti<strong>on</strong> started in September 2008.<br />

Michael Holy, <strong>Messer</strong> Tatragas<br />

Filling a Siber c<strong>on</strong>tainer:<br />

flexible refrigerati<strong>on</strong> for up to 48 hours

Photo: www.Pixelio.de | Stephanie Hofschlaeger<br />

6 : Interview<br />

YOUR CONTACTS:<br />

<str<strong>on</strong>g>Helmut</str<strong>on</strong>g> <str<strong>on</strong>g>Gutenberger</str<strong>on</strong>g><br />

Applicati<strong>on</strong> Technology<br />

<strong>Messer</strong> Austria<br />

Tel.: +43 (0) 50603-366<br />

helmut.gutenberger@messergroup.com<br />

Languages:<br />

<str<strong>on</strong>g>Wojciech</str<strong>on</strong>g> <str<strong>on</strong>g>Pastuszczyn</str<strong>on</strong>g><br />

Producti<strong>on</strong><br />

<strong>Messer</strong> Polska Sp. z o.o.<br />

Tel.: +48 327726-121<br />

wojciech.pastuszczyn@messer.pl<br />

Languages:<br />

Green paper producti<strong>on</strong><br />

<str<strong>on</strong>g>Helmut</str<strong>on</strong>g> <str<strong>on</strong>g>Gutenberger</str<strong>on</strong>g> (Manager Pulp <str<strong>on</strong>g>and</str<strong>on</strong>g> Paper) <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>Wojciech</str<strong>on</strong>g> <str<strong>on</strong>g>Pastuszczyn</str<strong>on</strong>g><br />

(Specialist Pulp <str<strong>on</strong>g>and</str<strong>on</strong>g> Paper), both paper experts at <strong>Messer</strong>, want to make<br />

paper producti<strong>on</strong> in Europe much more envir<strong>on</strong>mentally friendly through the<br />

use of industrial gases. In an interview with <strong>on</strong> air, they reveal some inter-<br />

esting facts about this mass-produced yet extremely varied product.<br />

<strong>on</strong> air: How would you characterise the paper industry?<br />

To what extent can the different manufacturers<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> their processes be compared?<br />

<str<strong>on</strong>g>Wojciech</str<strong>on</strong>g> <str<strong>on</strong>g>Pastuszczyn</str<strong>on</strong>g>: Only the basic principle of<br />

paper producti<strong>on</strong> is the same for all producers: it<br />

requires a raw material – wood or recycled paper or<br />

both, lots of water <str<strong>on</strong>g>and</str<strong>on</strong>g> a huge amount of energy, as<br />

well as chemicals, various process materials <str<strong>on</strong>g>and</str<strong>on</strong>g>, of<br />

course, a paper machine. But there are just as many<br />

papermaking processes as there are types of paper.<br />

You can’t have a paper mill without an appropriate<br />

producti<strong>on</strong> process. The paper for <strong>on</strong>e issue of<br />

Germany’s biggest daily newspaper, the Bild Zeitung,<br />

is produced in just two hours because a large number<br />

of processes take place simultaneously. We therefore<br />

have to be very customer-oriented, since the customer<br />

knows the producti<strong>on</strong> cycle best. A precise system<br />

analysis will pinpoint the problems we have to solve<br />

together. Our focus is <strong>on</strong> the European market, where<br />

there are many paper mills, especially in Germany,<br />

France <str<strong>on</strong>g>and</str<strong>on</strong>g> Italy.<br />

<str<strong>on</strong>g>Helmut</str<strong>on</strong>g> <str<strong>on</strong>g>Gutenberger</str<strong>on</strong>g>: In Slovenia, we are working<br />

very intensively with the Koliçevo paper mill <str<strong>on</strong>g>and</str<strong>on</strong>g> the<br />

University of Maribor in order to achieve the best<br />

results in terms of optimising the process technology.<br />

In Italy, we are collaborating with the University of<br />

Fabriano. This is something people in the industry are<br />

aware of: the paper mill operators know <str<strong>on</strong>g>and</str<strong>on</strong>g> support<br />

each other because, as manufacturers of different<br />

types of paper, they are not in direct competiti<strong>on</strong> with<br />

each other.<br />

Carb<strong>on</strong> dioxide is<br />

used during waste<br />

paper recycling.<br />

<strong>on</strong> air: What are the potential problems in paper<br />

producti<strong>on</strong>?<br />

<str<strong>on</strong>g>Helmut</str<strong>on</strong>g> <str<strong>on</strong>g>Gutenberger</str<strong>on</strong>g>: I can give you an example here:<br />

mixtures of recycled paper <str<strong>on</strong>g>and</str<strong>on</strong>g> water are stored in<br />

large storage tanks or vats. Recycled paper is a resource<br />

that has passed through many h<str<strong>on</strong>g>and</str<strong>on</strong>g>s, resulting in a<br />

high level of microbiological activity in the storage<br />

tank. The bacteria, or acidifiers as they are called, lead<br />

to a lowering of the mixture’s pH to around 6.5. Solid<br />

calcium carb<strong>on</strong>ate – which is used as a filler in the<br />

papermaking process – dissolves when the pH is less<br />

than 8, resulting in the formati<strong>on</strong> of free calcium. Free<br />

calcium is very reactive <str<strong>on</strong>g>and</str<strong>on</strong>g> forms calcium sulphate<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> calcium soaps am<strong>on</strong>g other things, <str<strong>on</strong>g>and</str<strong>on</strong>g> agglomerates<br />

microstickies to form macrostickies. This not

<strong>on</strong>ly leads to unwanted deposits; the solid calcium<br />

carb<strong>on</strong>ate, due to its high degree of whiteness, also<br />

has a very big influence <strong>on</strong> the whiteness of the paper.<br />

We raise the pH value by adding carb<strong>on</strong> dioxide from<br />

<strong>Messer</strong>, which reduces the dissoluti<strong>on</strong> of calcium carb<strong>on</strong>ate.<br />

Though carb<strong>on</strong> dioxide also forms a mild acid<br />

– carb<strong>on</strong>ic acid – when dissolved in water, it has a<br />

bacteriostatic effect <str<strong>on</strong>g>and</str<strong>on</strong>g> therefore inhibits the growth<br />

of microbes in a natural way.<br />

<strong>on</strong> air: Is the use of carb<strong>on</strong> dioxide really a good<br />

choice in terms of envir<strong>on</strong>mental compatibility?<br />

<str<strong>on</strong>g>Helmut</str<strong>on</strong>g> <str<strong>on</strong>g>Gutenberger</str<strong>on</strong>g>: We obtain most of the carb<strong>on</strong><br />

dioxide from industrial waste gas, thereby preventing<br />

the CO2 from getting into the atmosphere in the first<br />

place. Instead it is used in processes in which its role<br />

is to prevent envir<strong>on</strong>mental polluti<strong>on</strong>. In the aforementi<strong>on</strong>ed<br />

example, the carb<strong>on</strong> dioxide is completely<br />

dissolved in the water. A paper mill’s extremely high<br />

energy dem<str<strong>on</strong>g>and</str<strong>on</strong>g> means that its “carb<strong>on</strong> footprint” – the<br />

CO2 emissi<strong>on</strong>s during the entire process chain – is<br />

inherently very large. We are currently working <strong>on</strong> the<br />

c<strong>on</strong>cept of a “green paper mill” which produces absolutely<br />

no CO2 emissi<strong>on</strong>s <str<strong>on</strong>g>and</str<strong>on</strong>g> in which fresh water c<strong>on</strong>sumpti<strong>on</strong><br />

is reduced significantly by recycling the<br />

water. The paper industry must aim to reduce CO2, water <str<strong>on</strong>g>and</str<strong>on</strong>g> energy c<strong>on</strong>sumpti<strong>on</strong> – as must we all!<br />

Sustainability is vital. We entered the market with the<br />

aim of being the partner of choice for the paper industry.<br />

We want to c<strong>on</strong>serve resources together.<br />

<str<strong>on</strong>g>Wojciech</str<strong>on</strong>g> <str<strong>on</strong>g>Pastuszczyn</str<strong>on</strong>g>: By using CO2 we can reduce the<br />

use of biocides. Biocides get into the wastewater<br />

<strong>on</strong> air 09 · 2008<br />

where they inhibit microbiological activity, without<br />

which wastewater treatment plants d<strong>on</strong>’t work. Most<br />

paper mills have their own wastewater treatment<br />

plants; here, too, carb<strong>on</strong> dioxide can be used as an<br />

envir<strong>on</strong>mentally friendly substitute for sulphuric acid<br />

in order to achieve wastewater neutralisati<strong>on</strong>.<br />

<strong>on</strong> air: How do you achieve know-how transfer?<br />

<str<strong>on</strong>g>Wojciech</str<strong>on</strong>g> <str<strong>on</strong>g>Pastuszczyn</str<strong>on</strong>g>: I know what I d<strong>on</strong>’t know – the<br />

paper industry is developing at a rapid pace, so in my<br />

view the best way to learn is to study the processes<br />

intensively. At the beginning, I carried out system analyses<br />

at twelve Polish mills before c<strong>on</strong>cluding the first<br />

c<strong>on</strong>tract for pulp washing with carb<strong>on</strong> dioxide. After<br />

initial c<strong>on</strong>tact has been made, it can take anything<br />

from six m<strong>on</strong>ths to three or four years for a c<strong>on</strong>tract<br />

to be c<strong>on</strong>cluded.<br />

<str<strong>on</strong>g>Helmut</str<strong>on</strong>g> <str<strong>on</strong>g>Gutenberger</str<strong>on</strong>g>: Both my father <str<strong>on</strong>g>and</str<strong>on</strong>g> gr<str<strong>on</strong>g>and</str<strong>on</strong>g>father<br />

were papermakers <str<strong>on</strong>g>and</str<strong>on</strong>g> I myself have worked in the<br />

paper industry for over 20 years. I am hugely fascinated<br />

by this industry – which is why I am happy to pass<br />

<strong>on</strong> my knowledge, although the diversity factor does<br />

make transferring know-how difficult. After four years,<br />

we can say that we are very successful in the pulp <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

paper sector thanks to the good working relati<strong>on</strong>ship<br />

we have with our customers, with institutes <str<strong>on</strong>g>and</str<strong>on</strong>g> with<br />

our colleagues in <strong>Messer</strong>’s European subsidiaries. To<br />

quote figures: we have sold 14 milli<strong>on</strong> cubic metres of<br />

our gases to paper manufacturers.<br />

Diana Buss, <strong>Messer</strong> Group<br />

Paper webs during the producti<strong>on</strong><br />

process. “There are just as many<br />

papermaking processes as there<br />

are types of paper”, says <str<strong>on</strong>g>Wojciech</str<strong>on</strong>g><br />

<str<strong>on</strong>g>Pastuszczyn</str<strong>on</strong>g>.<br />

Interview : 7

8 : Cover story<br />

Lead by the bar:<br />

recycling the heavy<br />

metal also involves<br />

the use of industrial<br />

gases.<br />

Lead – from ore or<br />

scrap to metal<br />

Lead is a heavy metal that was used as l<strong>on</strong>g ago as the early Br<strong>on</strong>ze<br />

Age thanks to its low melting point. Today it is mainly used in lead acid<br />

accumulators such as car batteries. The process of lead smelting is made<br />

particularly efficient by the use of industrial gases.<br />

<strong>on</strong> air 09 · 2008

Today we need lead as much as we ever did,<br />

though the number of applicati<strong>on</strong>s has decreased<br />

sharply. “The popularity that this metal enjoyed just<br />

a few decades ago has declined markedly. This is due<br />

partly to the health hazards <str<strong>on</strong>g>and</str<strong>on</strong>g> envir<strong>on</strong>mental polluti<strong>on</strong><br />

associated with lead compounds, which were<br />

caused by outdated producti<strong>on</strong> methods, <str<strong>on</strong>g>and</str<strong>on</strong>g> partly<br />

to the issue of ec<strong>on</strong>omic efficiency”, explains<br />

Burkhardt Holleis from Applicati<strong>on</strong> Technology<br />

Metallurgy at <strong>Messer</strong> Austria.<br />

Nevertheless, the heavy metal is still of great<br />

value, particularly for special applicati<strong>on</strong>s such as<br />

radiati<strong>on</strong> shields or in accumulators such as car batteries.<br />

Lead (latin Plumbum, chemical symbol Pb) is a very<br />

soft <str<strong>on</strong>g>and</str<strong>on</strong>g> malleable heavy metal with a low melting<br />

point. It very rarely occurs in its pure form in nature,<br />

with lead sulphide (PbS, blue lead, galenite) being<br />

the most important lead mineral. The most frequent<br />

natural deposits are found in seams where the galenite<br />

is mainly found in combinati<strong>on</strong> with zinc blende<br />

(ZnS, sphalerite) <str<strong>on</strong>g>and</str<strong>on</strong>g> pyrite (FeS2, ir<strong>on</strong> pyrite).<br />

Primary lead<br />

“Lead metal can either be produced from lead ores<br />

(primary lead) or recycled products (sec<strong>on</strong>dary lead)”,<br />

says Holleis. In primary lead producti<strong>on</strong>, the lead ore<br />

is first c<strong>on</strong>verted, by means of physical processes,<br />

into a fine-grained c<strong>on</strong>centrate with maximum<br />

metal c<strong>on</strong>tent - this process is called ore dressing.<br />

The ore is crushed <str<strong>on</strong>g>and</str<strong>on</strong>g> graded in several stages.<br />

<strong>on</strong> air 09 · 2008<br />

During the subsequent flotati<strong>on</strong> in an emulsi<strong>on</strong>, the<br />

fine-grained solids are separated from <strong>on</strong>e another.<br />

In order to c<strong>on</strong>vert the enriched lead sulphide into<br />

metals in classic smelting, it is roasted in the sinter<br />

plant with the additi<strong>on</strong> of hot air. The liquid lead<br />

oxide that is separated in this process is reduced to<br />

metallic lead bulli<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> slag in a shaft furnace with<br />

the aid of coke, lime <str<strong>on</strong>g>and</str<strong>on</strong>g> ir<strong>on</strong>. “By adding oxygen,<br />

this process becomes even more effective”, explains<br />

Burkhardt Holleis.<br />

Modern technological methods involve direct<br />

reducti<strong>on</strong> processes. The advantage here relates to<br />

the greater efficiency of the plants, in which the<br />

roasting <str<strong>on</strong>g>and</str<strong>on</strong>g> reducti<strong>on</strong> processes take place in <strong>on</strong>e step.<br />

“Accordingly, envir<strong>on</strong>mental polluti<strong>on</strong> is reduced <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

ec<strong>on</strong>omic efficiency increased”, says the expert.<br />

Roasting is not fully completed <str<strong>on</strong>g>and</str<strong>on</strong>g> lead oxide<br />

can react with lead sulphide to form metallic lead.<br />

This produces lead bulli<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> slag with a higher<br />

lead c<strong>on</strong>centrati<strong>on</strong> than with the previously menti<strong>on</strong>ed<br />

process. The reducti<strong>on</strong> of the slag means<br />

that the remaining lead in it can also be recovered<br />

as a resource. “Here, too, oxygen is used in order to<br />

keep down the producti<strong>on</strong> costs”, says Holleis,<br />

highlighting another advantage of the use of oxygen<br />

in smelting. The raw lead now has to be refined<br />

before further processing.<br />

Sec<strong>on</strong>dary lead<br />

Liquid lead being tapped from<br />

a short rotary furnace<br />

It is not just the lead in lead-acid batteries that is<br />

recycled, but also the plastic housing <str<strong>on</strong>g>and</str<strong>on</strong>g> the sulphuric<br />

Cover story : 9<br />

YOUR CONTACTS:<br />

Burkhardt Holleis<br />

Applicati<strong>on</strong> Technology Metallurgy<br />

<strong>Messer</strong> Austria GmbH<br />

Tel.: +43 (0) 50603-281<br />

burkhardt.holleis@messergroup.com<br />

Languages:<br />

Dr. Martin Demuth<br />

Applicati<strong>on</strong> Technology Metallurgy<br />

<strong>Messer</strong> Austria GmbH<br />

Tel.: +43 (0) 50603-205<br />

martin.demuth@messergroup.com<br />

Languages:<br />

c<strong>on</strong>tinued <strong>on</strong> page 10

10 : Cover story<br />

Oxygen burner – the key<br />

to more efficiency<br />

Nowadays lead is used in<br />

storage batteries such as<br />

car batteries, from which it<br />

is also recycled.<br />

acid. The process begins in remelting plants with the<br />

breaking down <str<strong>on</strong>g>and</str<strong>on</strong>g> grading of the storage batteries.<br />

This is followed by the lead smelting process, i.e. the<br />

melting <str<strong>on</strong>g>and</str<strong>on</strong>g> refining.<br />

In shaft furnaces or direct reducti<strong>on</strong> plants, the<br />

roughly broken down batteries have their sulphuric<br />

acid removed <str<strong>on</strong>g>and</str<strong>on</strong>g> are then processed in a mixture with<br />

additives such as coke, limest<strong>on</strong>e <str<strong>on</strong>g>and</str<strong>on</strong>g> ir<strong>on</strong>. The air that<br />

is required for combusti<strong>on</strong> is enriched with oxygen.<br />

Again, this process produces slag <str<strong>on</strong>g>and</str<strong>on</strong>g> raw lead.<br />

Recycling with rotary furnaces involves separating<br />

the metallic lead fracti<strong>on</strong> (lattice) <str<strong>on</strong>g>and</str<strong>on</strong>g> the lead oxide<br />

fracti<strong>on</strong> (paste) from plastic <str<strong>on</strong>g>and</str<strong>on</strong>g> sulphuric acid. By<br />

adding coke, ir<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> soda, these lead fracti<strong>on</strong>s are<br />

then processed into raw lead, with slag again being<br />

produced in the process. Depending <strong>on</strong> its quality, the<br />

slag is disposed of or used in road c<strong>on</strong>structi<strong>on</strong>. The<br />

energy required for the melting process in rotary furnaces<br />

is delivered by means of fuel/oxygen burners.<br />

Refining<br />

Refining involves purifying the raw lead of the<br />

traces of other elements that are still c<strong>on</strong>tained in it<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> producing the lead alloy requested by the customer.<br />

After removing the copper with sulphur, the residual<br />

elements antim<strong>on</strong>y, arsenic <str<strong>on</strong>g>and</str<strong>on</strong>g> tin are removed<br />

through selective oxidati<strong>on</strong> with oxygen. The leadc<strong>on</strong>taining<br />

dross that is produced in this process is<br />

recycled <str<strong>on</strong>g>and</str<strong>on</strong>g> remelted.<br />

Use of oxygen<br />

Combusti<strong>on</strong> processes are optimised by, <strong>on</strong> the <strong>on</strong>e<br />

h<str<strong>on</strong>g>and</str<strong>on</strong>g>, preheating the fuel <str<strong>on</strong>g>and</str<strong>on</strong>g> combusti<strong>on</strong> air <str<strong>on</strong>g>and</str<strong>on</strong>g>, <strong>on</strong><br />

the other, adding oxygen. The best combusti<strong>on</strong> effi-<br />

+<br />

<strong>on</strong> air 09 · 2008

C<strong>on</strong>trolled system for a natural<br />

gas/oxygen burner<br />

ciency is achieved with pure oxygen since the waste<br />

gas heat losses are minimised by the removal of the<br />

79% of n<strong>on</strong>-reactive nitrogen ballast that exists in air.<br />

Furthermore, the less nitrogen, the less envir<strong>on</strong>mental<br />

polluti<strong>on</strong> through nitrous oxides (NOx).<br />

A large number of lead works in Europe are already<br />

benefiting from <strong>Messer</strong>’s know-how <str<strong>on</strong>g>and</str<strong>on</strong>g> industrial<br />

gases for lead refining in order to maximise the efficiency<br />

of the melting process with Oxijet® lance<br />

systems or the tailor-made burners of the Oxipyr®<br />

family (see table).<br />

Dr. Martin Demuth, <strong>Messer</strong> Austria<br />

THE MAIN ADVANTAGES OF<br />

USING OXYGEN ARE:<br />

+ Greater flexibility due to higher melting efficiency<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> shorter load times<br />

+ Reducti<strong>on</strong> in specific energy c<strong>on</strong>sumpti<strong>on</strong><br />

+ Decrease in amount of waste gas<br />

+ Less envir<strong>on</strong>mental polluti<strong>on</strong> from emissi<strong>on</strong>s<br />

+ Less dust discharge due to lower flow rates<br />

+ Lower investment costs due to smaller<br />

filtrati<strong>on</strong> systems<br />

+ No air preheating necessary<br />

+ Integrated afterburning possible<br />

<strong>on</strong> air 09 · 2008<br />

Lead bulli<strong>on</strong> before further processing: Today the heavy metal is<br />

mainly used for lead accumulators<br />

Cover story : 11<br />

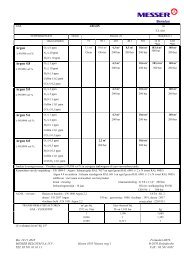

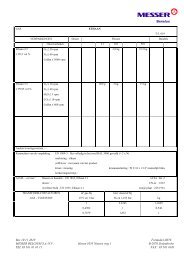

Possible applicati<strong>on</strong>s of oxygen in lead producti<strong>on</strong><br />

Oxygen Pure <strong>Messer</strong><br />

enrichment oxygen process<br />

Primary producti<strong>on</strong><br />

Sinter plant (agglomerati<strong>on</strong>) x Oxijet®<br />

Pb shaft furnace x Oxijet®, Pulsox<br />

Pb-Zn shaft furnace (I.M. furnace) x Oxijet®, Pulsox<br />

Rotary furnace x x Oxipyr®<br />

TBRC/Kaldo x x Oxipyr®<br />

QSL x<br />

Kivcet x<br />

Isasmelt x x Oxijet®<br />

Ausmelt x x Oxijet®<br />

Flash smelter x Oxijet®<br />

Recycling/Sec<strong>on</strong>dary producti<strong>on</strong><br />

Scrap cutting x<br />

Rotary furnace x x Oxipyr®<br />

TBRC/Kaldo x Oxipyr®<br />

Isasmelt x Oxijet®<br />

Ausmelt<br />

Refining<br />

x Oxijet®<br />

Removal of Sb, Sn <str<strong>on</strong>g>and</str<strong>on</strong>g> As<br />

Selective oxidati<strong>on</strong><br />

x x Oxijet®<br />

of Sb, Sn <str<strong>on</strong>g>and</str<strong>on</strong>g> As<br />

Envir<strong>on</strong>ment<br />

x x Oxipot<br />

Sulphur recovery x<br />

Afterburning x x Oxipyr®, Oxijet®

12 : <strong>Messer</strong> World<br />

E<br />

This is what Gumpoldskirchen<br />

looked like<br />

100 years ago, when the<br />

Austro-Hungarian oxygen<br />

works were granted<br />

permissi<strong>on</strong> for oxygen<br />

cylinder filling.<br />

New air separators under c<strong>on</strong>structi<strong>on</strong><br />

<strong>Messer</strong> is currently building eleven new producti<strong>on</strong> units across Europe. These will produce<br />

nitrogen, oxygen <str<strong>on</strong>g>and</str<strong>on</strong>g> arg<strong>on</strong> by separating air into its c<strong>on</strong>stituent comp<strong>on</strong>ents. Three<br />

of these projects are presented below:<br />

Tarrag<strong>on</strong>a (Spain):<br />

The plant, which was started up in September of this year, now provides a steady supply<br />

of up to 16,000 st<str<strong>on</strong>g>and</str<strong>on</strong>g>ard cubic metres of oxygen <str<strong>on</strong>g>and</str<strong>on</strong>g> 16,000 st<str<strong>on</strong>g>and</str<strong>on</strong>g>ard cubic metres of<br />

nitrogen per hour to major customers in the Tarrag<strong>on</strong>a industrial estate via gas pipelines.<br />

Zenica (Bosnia):<br />

The distinctive aspect of this project is that the new air separator will c<strong>on</strong>tinue to<br />

be supplied with compressed air by the two existing compressors of the ArcelorMittal<br />

steelworks until the new, more efficient air compressor arrives next year. We are<br />

currently completing the trial run at a maximum capacity of 16,000 st<str<strong>on</strong>g>and</str<strong>on</strong>g>ard cubic<br />

metres of oxygen per hour.<br />

L<strong>on</strong>za (Switzerl<str<strong>on</strong>g>and</str<strong>on</strong>g>):<br />

The installati<strong>on</strong> of the producti<strong>on</strong> unit at the foot of the Matterhorn has begun thanks<br />

to the timely delivery of the equipment from China. <strong>Messer</strong> will produce liquid oxygen for<br />

medical purposes at the L<strong>on</strong>za site, so the validati<strong>on</strong> of the entire plant according to<br />

The air separator<br />

medical st<str<strong>on</strong>g>and</str<strong>on</strong>g>ards represents a particular challenge.<br />

in L<strong>on</strong>za will also<br />

Dr. Christoph Erdmann, <strong>Messer</strong> Group<br />

produce medical<br />

oxygen.<br />

A trip <strong>on</strong> the<br />

Danube for a<br />

family business:<br />

the centenary<br />

celebrati<strong>on</strong>s in<br />

Austria<br />

100 years of oxygen filling<br />

Austria: The setting could not have been more<br />

appropriate, <strong>on</strong> 11 July this year, <strong>Messer</strong> celebrated<br />

100 years of oxygen cylinder filling in Austria with<br />

240 business partners, customers <str<strong>on</strong>g>and</str<strong>on</strong>g> friends <strong>on</strong> board<br />

the Danube steamer MS Austria. The magistrate of the<br />

imperial capital Vienna granted a commercial license<br />

to the Austro-Hungarian oxygen works <strong>on</strong><br />

11 July 1908. In his speech, Helge Kreiker, Managing<br />

Director of <strong>Messer</strong> Austria GmbH, referred to the<br />

locati<strong>on</strong>’s eventful history as well as to <strong>Messer</strong>’s<br />

years of success in Austria. “<strong>Messer</strong>’s goal is<br />

to be the preferred supplier <str<strong>on</strong>g>and</str<strong>on</strong>g> partner to our customers<br />

in the core areas of food, industry, envir<strong>on</strong>ment,<br />

chemistry <str<strong>on</strong>g>and</str<strong>on</strong>g> medicine”, said Kreiker.<br />

“We are <str<strong>on</strong>g>and</str<strong>on</strong>g> will c<strong>on</strong>tinue to be a family-run business<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> offer our customers a product portfolio which<br />

is acknowledged as <strong>on</strong>e of the most extensive in the<br />

market”, said Hans-Gerd Wien<str<strong>on</strong>g>and</str<strong>on</strong>g>s, Chief Financial<br />

Officer of the <strong>Messer</strong> Group, <str<strong>on</strong>g>and</str<strong>on</strong>g> promised “to work<br />

hard to bring this visi<strong>on</strong> to life”.<br />

Herbert Herzog, <strong>Messer</strong> Austria<br />

<strong>on</strong> air 09 · 2008

Children marvel at <strong>Messer</strong> experiments<br />

Science inspires young people<br />

Hungary: The aim of the European Commissi<strong>on</strong>’s “European Researchers’<br />

Night” initiative is to get young people interested in science. In 2008,<br />

Hungarian researchers <strong>on</strong>ce again took part in this event. <strong>Messer</strong> was <strong>on</strong>e of<br />

the main sp<strong>on</strong>sors in Hungary.<br />

Ast<strong>on</strong>ished children, surprised young people <str<strong>on</strong>g>and</str<strong>on</strong>g> interested<br />

grown-ups – both young <str<strong>on</strong>g>and</str<strong>on</strong>g> old watched in<br />

amazement as the <strong>Messer</strong> scientists <str<strong>on</strong>g>and</str<strong>on</strong>g> employees <strong>on</strong><br />

the stage performed their spectacular experiments.<br />

Under the motto “miracles out of thin air”, the<br />

researchers showed where <str<strong>on</strong>g>and</str<strong>on</strong>g> how gases that are<br />

found in air are encountered in our everyday lives <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

how interesting the world of oxygen <str<strong>on</strong>g>and</str<strong>on</strong>g> co can be in<br />

their different states.<br />

Open research establishments<br />

This was the third time that Hungary took part in<br />

the “Researchers’ Night”, which was held simultaneously<br />

in more than 200 towns across 27 European<br />

countries <strong>on</strong> 26 September. The European<br />

Commissi<strong>on</strong> had <strong>on</strong>ce again called <strong>on</strong> laboratories,<br />

museums, universities <str<strong>on</strong>g>and</str<strong>on</strong>g> research centres to open<br />

their doors to the public in order to get young<br />

people, in particular, interested in the world of science.<br />

<strong>Messer</strong> was <strong>on</strong>e of the main sp<strong>on</strong>sors of the<br />

<strong>on</strong> air 09 · 2008<br />

event in Hungary, supplying the gases needed for a<br />

wide range of experiments.<br />

Supporting science <str<strong>on</strong>g>and</str<strong>on</strong>g> innovati<strong>on</strong> is an important<br />

part of the <strong>Messer</strong> Group’s policy. Within the framework<br />

of an innovati<strong>on</strong> fund, <strong>Messer</strong> has been supporting<br />

research projects at several Hungarian universities<br />

with gas supplies. One such project is based at<br />

the University of Pann<strong>on</strong>, which is c<strong>on</strong>ducting research<br />

into the possibilities of industrial gas applicati<strong>on</strong>s in<br />

the producti<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> treatment of biofuel. The<br />

University of Miskolc is home to another project supported<br />

by <strong>Messer</strong>. The researchers there have studied<br />

ways of using industrial gases to reduce envir<strong>on</strong>mental<br />

polluti<strong>on</strong>. Meanwhile, the Technical University of<br />

Budapest is researching innovative technologies aimed<br />

at improving the quality of welding applicati<strong>on</strong>s in the<br />

automotive industry. For the past two years, <strong>Messer</strong> in<br />

Hungary has been supporting competiti<strong>on</strong>s for vehicles<br />

powered by alternative fuels<br />

Anita Kötél, <strong>Messer</strong> Hungarogáz<br />

<strong>Messer</strong> World : 13<br />

On the stage, young<br />

people had the opportunity<br />

to watch scientific experiments<br />

up close.

14 : People at <strong>Messer</strong><br />

<strong>Messer</strong> retirees...<br />

…met in the Swiss town<br />

of Interlaken.<br />

Being together is what counts<br />

They have been meeting <strong>on</strong>ce a year for the past 15 years – last summer they<br />

gathered in the picturesque town of Interlaken near the Swiss capital, Berne.<br />

Gerd Haase from Berlin is <strong>on</strong>e of the former <strong>Messer</strong> sales managers who stay in<br />

touch with each other <str<strong>on</strong>g>and</str<strong>on</strong>g> get together to reminisce about the old days <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

share their latest experiences.<br />

In 1954, the student Gerd Haase got a temporary job<br />

at the <strong>Messer</strong> head office in Frankfurt. His “Berliner<br />

Schnauze” (manner in which people from Berlin speak)<br />

was noticed <str<strong>on</strong>g>and</str<strong>on</strong>g> two years later he became assistant to<br />

the commercial representative for Berlin, East Germany,<br />

Pol<str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> Czechoslovakia. For various reas<strong>on</strong>s, it has<br />

become a rarity for some<strong>on</strong>e to spend his entire career<br />

with <strong>on</strong>e company. “Changing companies was unusual<br />

in those days, with firms outdoing each other when it<br />

came to years of service”, says Gerd Haase. “After fifty<br />

years of service, you got a<br />

gold ring <str<strong>on</strong>g>and</str<strong>on</strong>g> a h<str<strong>on</strong>g>and</str<strong>on</strong>g>shake<br />

from the boss.” In Interlaken,<br />

the eight former sales<br />

managers still vividly<br />

remember the merger of<br />

<strong>Messer</strong> GmbH <str<strong>on</strong>g>and</str<strong>on</strong>g> the<br />

Hoechst subsidiary Knapsack-Griesheim in 1964.<br />

“Suddenly we had to answer the ph<strong>on</strong>e with ‘<strong>Messer</strong><br />

Griesheim’”, recalls Reinhold Hartlieb, former head of<br />

the Stuttgart subsidiary in southern Germany <str<strong>on</strong>g>and</str<strong>on</strong>g>, subsequently,<br />

managing director of <strong>Messer</strong> in Switzerl<str<strong>on</strong>g>and</str<strong>on</strong>g>.<br />

The merger brought a difficult integrati<strong>on</strong> phase that<br />

lasted several years. After all, it was a merger of two<br />

independent companies that had previously been fierce<br />

competitors in the market place for many years. The c<strong>on</strong>versati<strong>on</strong>s<br />

get heated when they talk about the mistakes<br />

that could have been avoided if “those at the top had<br />

talked more frequently with <strong>on</strong>e another” <str<strong>on</strong>g>and</str<strong>on</strong>g> had listened<br />

to their employees’ suggesti<strong>on</strong>s for improvement.<br />

The company first<br />

Judging by the reacti<strong>on</strong> of the wives, this isn’t the first<br />

time that they have seen their husb<str<strong>on</strong>g>and</str<strong>on</strong>g>s get worked up<br />

about this subject. One of the wives also used to work<br />

at <strong>Messer</strong>, while the others looked after their families.<br />

“We were a men-<strong>on</strong>ly club”, says Gerd Haase with a<br />

smile, “just like our customers. Sales c<strong>on</strong>versati<strong>on</strong>s<br />

would start with a cigarette <str<strong>on</strong>g>and</str<strong>on</strong>g> a cup of coffee. We<br />

knew what our customers liked, even their favourite<br />

whisky.” “The family had to make sacrifices”, adds<br />

Traute Haase, <str<strong>on</strong>g>and</str<strong>on</strong>g> the other ladies agree that the company<br />

came first <strong>on</strong> too many occasi<strong>on</strong>s. Now that they<br />

are retired, they have plenty of other things to talk<br />

about <str<strong>on</strong>g>and</str<strong>on</strong>g> time to exchange photos from the last gettogether,<br />

share a laugh <str<strong>on</strong>g>and</str<strong>on</strong>g> explore the surrounding<br />

area. This year’s event was organised by Reinhold<br />

Hartlieb, who stayed <strong>on</strong> in Switzerl<str<strong>on</strong>g>and</str<strong>on</strong>g> after retiring.<br />

“We try to do things we find enjoyable”, he explains,<br />

although the group excursi<strong>on</strong> to his beloved Jungfrau,<br />

Eiger <str<strong>on</strong>g>and</str<strong>on</strong>g> Mönch mountain peaks was thwarted by descending<br />

fog. But that doesn’t matter, because being<br />

together is what counts.<br />

Diana Buss, <strong>Messer</strong> Group<br />

<strong>on</strong> air 09 · 2008

><br />

COMPETITION<br />

Win...<br />

<strong>on</strong>e of three books about German family-owned businesses<br />

The book “Deutsche St<str<strong>on</strong>g>and</str<strong>on</strong>g>ards – aus bester Familie”<br />

was edited by Florian Langenscheidt <str<strong>on</strong>g>and</str<strong>on</strong>g> published by<br />

Gabler, price 79.90 euros. To win, tell us <strong>on</strong> which<br />

page of the magazine this photo appears? Keep your<br />

eyes peeled <str<strong>on</strong>g>and</str<strong>on</strong>g> send your* answer in an e-mail to<br />

diana.buss@messergroup.com<br />

MEDICINE<br />

Resp<strong>on</strong>sible advice over the Internet<br />

www.laborex-sanesco.at<br />

A medical practiti<strong>on</strong>er expects a supplier of<br />

medical products to be able to provide detailed<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> comprehensive informati<strong>on</strong> about these<br />

products – patients often wish to receive a pers<strong>on</strong>al<br />

c<strong>on</strong>sultati<strong>on</strong>. As a medical service provider,<br />

Laborex-Sanesco GmbH, a <strong>Messer</strong> Group<br />

company, supports hospitals, health care facilities,<br />

doctors <str<strong>on</strong>g>and</str<strong>on</strong>g> the patients themselves. The<br />

TRADE SHOW CALENDAR<br />

In the coming weeks we will be at ...<br />

IPA Sal<strong>on</strong><br />

Food trade show<br />

Paris, France<br />

17 to 21 November<br />

arenier@messer.fr<br />

foodatech<br />

Food <str<strong>on</strong>g>and</str<strong>on</strong>g> packaging<br />

Budapest, Hungary<br />

18 to 20 November<br />

anita.kotel@messer.hu<br />

Energetika<br />

Energy trade show<br />

Belgrade, Serbia<br />

26 to 28 November<br />

marija.vukovic@messer.co.yu<br />

* This competiti<strong>on</strong> is not<br />

open to employees of<br />

<strong>Messer</strong> or their relatives.<br />

ECOFair<br />

Envir<strong>on</strong>mental trade show<br />

Belgrade, Serbia<br />

26 to 28 November<br />

marija.vukoviç@messer.co.yu<br />

Annual Meeting<br />

Belgian Society for Pneumology<br />

Brussels, Belgium<br />

28 to 29 November<br />

marina.deridder@messerbenelux.com<br />

VINITECH<br />

Vine fair<br />

Bordeaux, France<br />

2 to 4 December<br />

arenier@messer.fr<br />

Pollutec<br />

Envir<strong>on</strong>mental trade show<br />

Ly<strong>on</strong>, France<br />

2 to 5 December<br />

arenier@messer.fr<br />

Closing date<br />

for entries:<br />

16.12.08<br />

C<strong>on</strong>gratulati<strong>on</strong>s to Rüdiger Strauß, Johns<strong>on</strong> & Johns<strong>on</strong> Medical GmbH, Norderstedt who submitted the right answer (“page 12”)<br />

to the competiti<strong>on</strong> questi<strong>on</strong> in Issue No. 8 of <strong>on</strong> air. He can look forward to receiving a <strong>Messer</strong> mug in the style of a gas cylinder.<br />

Gasette : 15<br />

new website therefore features informati<strong>on</strong><br />

<strong>on</strong> products <str<strong>on</strong>g>and</str<strong>on</strong>g> applicati<strong>on</strong>s as well as more<br />

detailed descripti<strong>on</strong>s of the individual departments<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> c<strong>on</strong>tacts: the Laborex-Sanesco<br />

experts are always happy to answer any pers<strong>on</strong>al<br />

questi<strong>on</strong>s patients <str<strong>on</strong>g>and</str<strong>on</strong>g> relatives may have<br />

in a direct <str<strong>on</strong>g>and</str<strong>on</strong>g> competent manner.

Coming up in the next issue:<br />

Carb<strong>on</strong> footprint: <strong>Messer</strong> is committed to the efficient use of resources. In the next<br />

issue of <strong>on</strong> air you can read about what we are doing to reduce our carb<strong>on</strong> footprint <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

that of our customers.<br />

By signing up to the EU Road Safety Charter, the signatories are helping to cut the<br />

number of road deaths in Europe.