Engine Room - Hastings Deering

Engine Room - Hastings Deering

Engine Room - Hastings Deering

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ENGINE ROOM June-July<br />

CATERPIllAR<br />

REPORTS<br />

fOR DuTy<br />

When Steber International received the contract from Defence<br />

Maritime Services (DMS), for and on behalf of the Royal Australian<br />

Navy (RAN), to build five vessels, Cat ® C7 engines and 2.2 gen sets<br />

were specified.<br />

“We offered the RAN two brands to choose from,” explained Alan<br />

Steber. “However, as is the case with many other vessels in its fleet,<br />

the DMS insisted on Cat.”<br />

Already, two of these general support vessels are hard at work in<br />

Sydney. In fact, Steber International delivered the first of these boats<br />

a couple of months before schedule.<br />

Energy Power Systems Australia (EPSA), assisted by Cat dealer<br />

WesTrac, carried out the commissioning and rigorous sea trials<br />

in front of 200 visitors including personnel from the Defence<br />

Department, industry suppliers from around the country and<br />

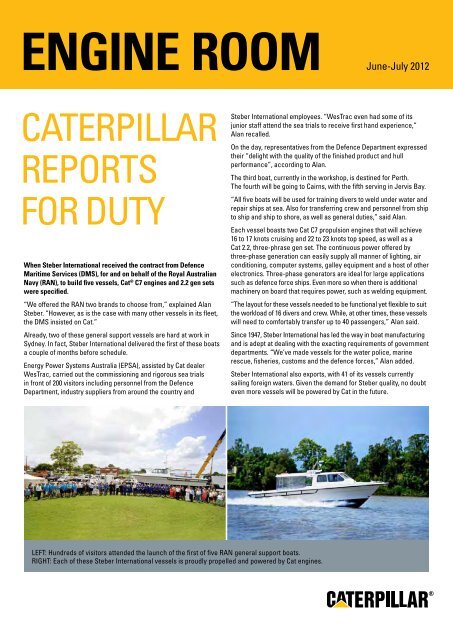

lEfT: Hundreds of visitors attended the launch of the first of five RAN general support boats.<br />

RIGHT: Each of these Steber International vessels is proudly propelled and powered by Cat engines.<br />

2012<br />

Steber International employees. “WesTrac even had some of its<br />

junior staff attend the sea trials to receive first hand experience,”<br />

Alan recalled.<br />

On the day, representatives from the Defence Department expressed<br />

their “delight with the quality of the finished product and hull<br />

performance”, according to Alan.<br />

The third boat, currently in the workshop, is destined for Perth.<br />

The fourth will be going to Cairns, with the fifth serving in Jervis Bay.<br />

“All five boats will be used for training divers to weld under water and<br />

repair ships at sea. Also for transferring crew and personnel from ship<br />

to ship and ship to shore, as well as general duties,” said Alan.<br />

Each vessel boasts two Cat C7 propulsion engines that will achieve<br />

16 to 17 knots cruising and 22 to 23 knots top speed, as well as a<br />

Cat 2.2, three-phrase gen set. The continuous power offered by<br />

three-phase generation can easily supply all manner of lighting, air<br />

conditioning, computer systems, galley equipment and a host of other<br />

electronics. Three-phase generators are ideal for large applications<br />

such as defence force ships. Even more so when there is additional<br />

machinery on board that requires power, such as welding equipment.<br />

“The layout for these vessels needed to be functional yet flexible to suit<br />

the workload of 16 divers and crew. While, at other times, these vessels<br />

will need to comfortably transfer up to 40 passengers,” Alan said.<br />

Since 1947, Steber International has led the way in boat manufacturing<br />

and is adept at dealing with the exacting requirements of government<br />

departments. “We’ve made vessels for the water police, marine<br />

rescue, fisheries, customs and the defence forces,” Alan added.<br />

Steber International also exports, with 41 of its vessels currently<br />

sailing foreign waters. Given the demand for Steber quality, no doubt<br />

even more vessels will be powered by Cat in the future.

ENGINE ROOM<br />

GEARED uP TO GO<br />

An emergency stopover in Cairns was significantly reduced, thanks<br />

to the Caterpillar network using its contacts to quickly source the<br />

right gear for a repower.<br />

It all started when Dave frewin of Australian Offshore Solutions was<br />

bringing a newly purchased vessel from Airlie Beach in Queensland<br />

to Dampier in WA. The boat was being delivered as a crew change<br />

vessel to and from Barrow Island.<br />

However, trouble struck on the voyage with the vessel’s existing<br />

propulsion engines, reducing the “Reef Jet” to the speed of a row<br />

boat. As a result, it was decided to dock in Cairns and replace them<br />

both with Cat ® engines. So Energy Power System Australia (EPSA)<br />

was called in to assist.<br />

“In Brisbane, we had two new Cat C18 engines offering 1000hp @<br />

2300rpm. However, the ratio best suited a Zf gearbox and, at the time,<br />

there were none of these in stock, not anywhere in the world. In fact,<br />

manufacture of this gearbox, then delivery by air from Italy, would<br />

take up to 14 weeks or more,” explained Tony East at EPSA.<br />

using his extensive networks, Tony located a pair of Zf gearboxes.<br />

“But they were Zf 550 straight ratio 2.5:1, which was not what we<br />

wanted for the jet application. So we suggested sending the gears to<br />

June-July 2012<br />

Thanks to the resourcefulness and quick thinking of the Caterpillar team, “live Wire” was back on the water better than ever.<br />

the Zf Sydney factory where, in just three to four weeks, they could<br />

be stripped and completely rebuilt to the required ratio<br />

of 1.743:1, then shipped on to EPSA’s Queensland facility,” Tony<br />

elaborated.<br />

In the EPSA Queensland workshop, Steve Balman and his crew fitted<br />

the gearbox and mounts, while custom-making a wiring harness and<br />

Cofe Me exhaust to size. As this was being done, new Hamilton Jets<br />

were being shipped from New Zealand.<br />

With everything now ready to go, it was on to Cairns for installation.<br />

A team from EPSA, headed by Glen Cook, flew to Cairns for the<br />

commissioning and sea trials. In fact, the vessel performed so well<br />

its name was changed to “live Wire”.<br />

The Maritime Department of Queensland issued the certificates a<br />

week later and the vessel left Cairns for Darwin. There, Cat dealer<br />

<strong>Hastings</strong> <strong>Deering</strong> checked out a minor issue with the rpm, before<br />

the boat refuelled and sailed the last leg of its journey. upon arrival<br />

in Dampier, the Cat dealer for that region, WesTrac, conducted the<br />

100 hours service.<br />

Not only did the Caterpillar team manage to get all this done in less<br />

than eight weeks, this vessel continues to perform as good as new.<br />

2 – June-July 2012

ENGINE ROOM June-July<br />

A WIN-WIN fOR GODWIN<br />

Since buying diesel-powered Godwin Pumps, Xylem Water<br />

Solutions has discovered that you can’t go past Cat. ®<br />

Not if you want a ready supply of top notch engines, convenient<br />

local service and the most extensive nation-wide support.<br />

Global company Xylem Water Solutions (formerly ITT Water & Waste<br />

Water) has been supplying Australia for over 40 years with fluid<br />

transport, waste water treatment and dewatering pumps. When<br />

it came to adding to its extensive sales and rental equipment, the<br />

company acquired the well known Godwin pump brand.<br />

“At Xylem we were looking for a complete dewatering solution.<br />

We already had electric flygt Submersible Pumps but we needed<br />

a diesel-powered alternative to complement the fleet,” explained<br />

Business Development Manager, Doug Darville.<br />

Xylem has 16 branches in Australia and two in New Zealand serving<br />

water authorities, industry and also the thriving mining sector. To<br />

meet this increasing demand, Xylem has wasted no time in bringing<br />

Godwin Dewatering Pumps over from the uK, where they are<br />

manufactured, then ordering Cat diesel engines to power them.<br />

Choosing Cat made sense. “Energy Power Systems Australia (EPSA)<br />

already had all the engines we needed in stock so they delivered<br />

them progressively from last December,” Doug explained. “Add<br />

to that nationwide after sales parts and service from Cat dealers<br />

WesTrac, <strong>Hastings</strong> <strong>Deering</strong>, William Adams and Cavpower.<br />

2012<br />

“In fact some of our customers’ mines already have WesTrac<br />

service personnel, “ Doug added.<br />

“Godwin Pumps is a market leader, around for over a century. Even<br />

better, Godwin revolutionised the portable pumping industry with the<br />

introduction of the original automatic Dri-Prime pumping principle,”<br />

Doug elaborated. “This enables the Godwin pump to start dry and<br />

create a suction lift up to 8.5 metres.”<br />

The engines purchased to power these pumps have an equally<br />

impressive reputation. These range from Cat C2.2 diesel engines for<br />

pumps with 3-4 inch outlets, up to Cat C27s for units with 12 inch outlets.<br />

“As this was the first time we’d had diesel-powered pumps,<br />

the learning curve was steep,” Doug recalled. “We had a lot<br />

of assistance from John Goodall and Robert Eamer at EPSA in<br />

understanding the local condition requirements. These included air<br />

intake filters, fuel coolers and the like, as well as meeting the service<br />

regime demanded in the Australian market.”<br />

The units were assembled at Xylem’s WA facility. “We also sourced<br />

local fabricators to build and test the skids on which the pumps and<br />

engines would be mounted. This ensured these units complied with<br />

the stringent Australian and New Zealand standards.”<br />

Since then, these Cat-powered Godwin pumps have been<br />

commissioned in Western Australia, the Northern Territory,<br />

Queensland, New South Wales and Victoria. As such, this<br />

business relationship is already off to a great start!<br />

With many new Cat engines in Xylem’s sales and rental fleet, this business relationship is off to a great start.<br />

3 – June-July 2012

ENGINE ROOM<br />

June-July 2012<br />

EPSA CElEBRATES<br />

20 yEARS!<br />

In July 1992, the largest Australian Olympic team ever was headed<br />

for Barcelona, where they would claim their best medal haul on<br />

foreign soil. Here in Australia, performance was also top of mind.<br />

Cat ® Dealers CavPower, <strong>Hastings</strong> <strong>Deering</strong>, WesTrac and William<br />

Adams were in the process of amalgamating all Cat engine sales<br />

into the one dedicated engine specific sales and rental Cat dealer,<br />

namely Energy Power Systems Australia (EPSA).<br />

from this point on, Cat engines would be exclusively sold by EPSA<br />

throughout Australia, PNG and Solomon Islands, with servicing and<br />

parts then provided by the local Cat dealers. for customers, the<br />

result has been a seamless end-to-end offering, not unlike a relay<br />

race, where the entire Caterpillar team comes together to deliver an<br />

impressive end result.<br />

OuR fIRST<br />

MEMORIES<br />

Of EPSA<br />

Ian Allison (IA): Back in ‘92 there was<br />

only a handful of staff. I have seen<br />

the company grow from where you<br />

knew everyone by name to the many<br />

divisions we have today, with several<br />

hundred staff involved in the everexpanding<br />

business.<br />

These days, EPSA supplies new Cat engines, engineered custom<br />

solutions, power generation, temperature control and compressed air<br />

solutions, along with an extensive fleet of rental and used equipment.<br />

Over the past two decades EPSA and the Cat dealers have seen many<br />

lasting customer relationships develop. EPSA is also equally proud of its<br />

long-serving staff members. Congratulations to Ian Allison,<br />

Bruce Horwood, David Moore, Sharyn Sullivan and Peter Wootton<br />

for 20 years of dedicated hard work with EPSA, extending even further<br />

back into <strong>Hastings</strong> <strong>Deering</strong> and William Adams.<br />

Bruce Horwood (BH): I was asked<br />

if I wanted a computer but the only<br />

ones who had PCs were the Regional<br />

Manager and the receptionist/<br />

secretary/administrator. I didn’t<br />

take the computer that first year as<br />

everything was via the fax or snail mail.<br />

The www thing was still a couple of<br />

years away.<br />

4 – June-July 2012

ENGINE ROOM June-July<br />

OUR FIRST MEMORIES OF EPSA continued<br />

David Moore (DM): We had to start<br />

the company from scratch while still<br />

managing the day-to-day business. We<br />

took over some items from the dealer<br />

network but we had to secure an<br />

office, furniture, telephones, cars and<br />

stationery. In fact everything we now<br />

take for granted.<br />

Challenges/successes along the way<br />

Sharyn Sullivan (SS): Moving<br />

from <strong>Hastings</strong> <strong>Deering</strong> to be Office<br />

Administrator for EPSA was exciting<br />

for me. Ian Allison and myself are the<br />

only two left in Queensland from the<br />

initial group. I have fond memories of<br />

Noel Anderson and Dave Smith who<br />

have since passed but they were<br />

integral to the success of EPSA’s<br />

Queensland branch.<br />

IA: They have been many and varied. Initially at EPSA I was employed<br />

as a Business Manager. Since then, however, my responsibilities<br />

have included training, Sales <strong>Engine</strong>ering, Project Management,<br />

Applications <strong>Engine</strong>ering, Business Development and now, being<br />

Regional Sales Manager, based in Brisbane.<br />

BH: Starting in Sydney Office as Project Manager for the generator<br />

systems required at the Optus telco facilities around Australia. This<br />

was followed by commercial developments in the Sydney CBD, a<br />

power station upgrade at Norfolk Island, as well as waste water<br />

treatment plants in Wellington, NZ. Also, moving to Brisbane to help<br />

launch Cat Rental Power there and build the fleet.<br />

DM: Winning deals like supplying 94 G3516s for the Appin project,<br />

the sale of the first G3520s in the region for the Cannington Mine, as<br />

well as 47 gen sets for the West Kimberley project. In later years,<br />

the much wider product offering has certainly grown the sales<br />

opportunity. Our customers are also much more knowledgeable and<br />

always expecting a better deal.<br />

SS: I have met and dealt with a variety of customers, many of whom<br />

we are still dealing with today.<br />

PW: The more significant moments are the important sales we<br />

have made over the years. They include the Crown Casino co gen<br />

sets. Also ADI (Australian Defence Industries, now Thales) and the<br />

involvement with the Bushmaster program.<br />

A career high point<br />

2012<br />

Peter Wootton (PW): Each contract<br />

carries its own unique demands and<br />

outcomes, then depending on these<br />

introduces you to different people.<br />

In the beginning this made working<br />

for EPSA very interesting and it still<br />

remains that way today.<br />

IA: In 2008 when I was involved in 6 Sigma Black Belt training.<br />

During this training I was fortunate to meet many interesting people<br />

from other Cat dealers in the Pacific area. To this day I still remain in<br />

contact with some of the other Black Belts.<br />

BH: Where I am now, working on the Bechtel APlNG Project at<br />

Curtis Island. This has involved supplying seven C175, two 3516<br />

and one C32 generator set. Projects like these test all the skills you<br />

have learned over the years - in liaising with the client developing<br />

solutions, complying with the many procedures, then completing the<br />

documentation.<br />

DM: Working closely from “day one” with a customer like lMS<br />

Energy who rely almost entirely upon the Caterpillar product for<br />

their success.<br />

SS: One of the highlights was being selected to be part of the<br />

implementation team for the lawson M3 project - something I had<br />

never done before.<br />

PW: We were absolutely flat out with getting gen sets installed and<br />

commissioned in the last half of 1999, in preparation for the y2K bug.<br />

On the big day nothing happened. The greatest non-event! But we<br />

sold plenty of sets.<br />

5 – June-July 2012

ENGINE ROOM<br />

June-July 2012<br />

WESTRAC’S COST SAVING SERVICE<br />

When WesTrac was servicing a Cat ® 3512 engine, the technicians<br />

noticed a problem and investigated further. Good thing they did.<br />

Their diligent workmanship has saved Halliburton oil service<br />

company the cost of a new engine.<br />

As WesTrac’s field service coordinator, Adrian Rumble, recalled:<br />

“WesTrac was on-site, servicing a Cat petroleum engine that is used<br />

to drive a high pressure pump mounted on a frac trailer. When we<br />

went to start the engine, it misfired, so we went looking.”<br />

Delving further, the WesTrac service technicians uncovered an issue<br />

with the intake system.<br />

“Rather than decide on the spot if the engine would need a rebuild,<br />

we opted to bring it back from Dongara gas field to our service centre<br />

in Geraldton for a more thorough inspection,” explained Adrian’s<br />

colleague Brad Ekert.<br />

In Geraldton, the WesTrac team disassembled the cylinder heads<br />

and found water from an unknown source had affected all the<br />

cylinders and caused extensive corrosion to the crankshaft and the<br />

cylinder liners.<br />

In the best interests of the customer, it was decided to send the<br />

engine to WesTrac’s Service Centre in Perth that specialises in large<br />

3500 engines.<br />

At this engine rebuilding facility, WesTrac work with the most<br />

advanced systems and processes available. Here they ensure that<br />

the very latest components are used always for the longest possible<br />

engine life. As such, this engine couldn’t have been in better hands.<br />

“We were also fortunate to be dealing with Halliburton’s Service<br />

Operations Manager, Daniel Gillies. A job like this certainly has its<br />

A STAR-<br />

STuDDED<br />

PERfORMANCE<br />

challenges so when you’re working with a professional like Daniel,<br />

it makes a big difference,” Adrian added and Brad agreed.<br />

In Perth, the 3512 engine was given a complete overhaul, with dyno<br />

tune. Then returned to be reinstalled on the frac trailer and sent back<br />

to work.<br />

As Brad summarised: “Because of WesTrac’s diligence when<br />

servicing, we were able to discover the problem, overhaul the engine<br />

and salvage components, successfully avoiding a complete – and<br />

expensive – engine failure.<br />

The WesTrac team saved Haliburton the cost of a new engine.<br />

In Caterpillar’s recent assessment of its rental operations, EPSA’s<br />

Cat ® Rental Power scored an impressive 81 per cent, equating to<br />

4-Stars from a possible 5. As David Southwell, national manager<br />

of branches - rental division, announced: “This is a great result<br />

and a credit to every member on the rental team.”<br />

As part of its Rental Operations Review, senior Caterpillar<br />

representatives conducted a thorough investigation of every<br />

aspect of the business, then presented all findings in a<br />

comprehensive report.<br />

for both performance control and enquiry handling, Cat Rental<br />

Power achieved perfect 5-Star scores. In the areas of facility and<br />

fleet management, the Cat Rental Power Group was awarded<br />

another 4-Stars apiece - the same for fleet maintenance and<br />

repairs. And when it came to delivering on commitments to<br />

customers, Cat Rental Power received a very strong 4-Star mark.<br />

6 – June-July 2012

ENGINE ROOM June-July<br />

A STAR-STUddEd PERFORMAncE continued<br />

All up, from a possible total of 30 stars, the team achieved 26 of<br />

these glittering symbols of excellence. Even so, “our goal is to be<br />

the first ever 5-Star Cat Rental Power operation on the planet”,<br />

according to David.<br />

The review also brought to light some Caterpillar initiatives to<br />

further secure the future of Cat Rental Power. These include<br />

even more product development in the areas of air compression<br />

TAKING THE<br />

HEAT Off<br />

When a power cable, supplying two states, needed to remain cool<br />

throughout the long, hot summer, Energy Power Systems Australia’s<br />

(EPSA’s) Cat ® Rental Power devised a temperature control solution.<br />

Covering some 290 kilometres in Bass Strait, this is the second<br />

longest submarine cable in the world. However, with so many people<br />

in Tasmania and the mainland relying on this electricity supply, the<br />

60.8 kilometres of overhead line in Victoria needed to be protected<br />

from searing temperatures.<br />

As temperature control was only required temporarily over summer,<br />

Chris Morrison at OP Industries, a HVACR and Mechanical Services<br />

Contractor, approached Cat Rental Power about cooling the cable.<br />

“Our 100kW DX unit could have been considered over-sized but<br />

they needed a solution that would handle 50 Celsius ambient<br />

temperatures,” explained Cat Rental Power’s Simon Buckley. “I<br />

discussed the challenge with colleagues Wade Bailey and Simon<br />

Rickerby. As we already had one of those units coping with that<br />

kind of heat at the Stawell Gold Mine, we were able to confidently<br />

recommend using the larger unit.”<br />

With no time to lose, Cat Rental Power received the order in early<br />

November and three weeks later, with the help of OP Industries,<br />

installation took place.<br />

The high-voltage electricity cable in question is used to supply some of<br />

the peak load capacity to Victoria. Also to take any excess base load<br />

capacity to supply Tasmania. This sharing of power has economic and<br />

environmental benefits. Even so, reliability is paramount.<br />

As such, the original controller that came with the unit was replaced<br />

with an Innotech Maxim 11. The new controller allowed for additional<br />

analogue input and output. “Simply put, we could install not one but<br />

two temperature sensors in the air conditioned space and have these<br />

2012<br />

and gas-fuelled engines, with Cat Rental Power committed<br />

to ever increasing fuel efficiency, while looking to reduce<br />

environmental impact. Caterpillar also plans to expand the Cat<br />

Rental Power business in places like India and South America<br />

and is busy pitching to win the rental equipment business for the<br />

2014 fIfA World Cup in Brazil.<br />

As David surmised: “It really is great to be part of this team that<br />

I am sure will continue to deliver very impressive results.”<br />

both wired back to the new Maxim Controller,” Simon elaborated.<br />

A new damper actuator was also supplied. In the event that the<br />

space dropped too far in temperature, this actuator would dump the<br />

supply of air,” Simon emphasised. further to these, software and 3G<br />

cards were provided to remotely monitor and control the system.<br />

By achieving an 11.00 Celsius difference between the outside and<br />

the air conditioned space, this temperature control system has<br />

effectively beat the heat.<br />

A cooling solution from Cat Rental Power has taken some<br />

heat off overhead power cables.<br />

7 – June-July 2012

ENGINE ROOM June-July<br />

For sales, rental, engineering support and technical advice<br />

throughout the lifetime of your plant, call Energy Power Systems:<br />

VICTORIA AND TASMANIA<br />

(Head Office)<br />

47-51 Westpool Drive<br />

Hallam 3803<br />

Tel: (613) 9703 4000<br />

fax: (613) 9703 4004<br />

NEW SOuTH WAlES<br />

Cat Rental Power<br />

22 Abel Street<br />

Jamisontown 2750<br />

Tel: (612) 8796 9204<br />

fax: (612) 4732 5294<br />

QuEENSlAND (Roma)<br />

lot 5<br />

215 Raglan Street<br />

Roma 4455<br />

Tel: (617) 4622 1020<br />

fax: (617) 4622 1020<br />

SOuTH AuSTRAlIA<br />

19 Taminga Street<br />

Regency Park 5010<br />

Tel: (618) 8244 0088<br />

fax: (618) 8244 0545<br />

For service and parts, call:<br />

VICTORIA<br />

William Adams Pty ltd<br />

Clayton<br />

Tel: (613) 9566 0666<br />

fax: (613) 9561 6273<br />

SOuTH AuSTRAlIA<br />

Cavill Power<br />

Products Pty ltd<br />

Adelaide<br />

Tel: (618) 8343 1600<br />

fax: (618) 8344 9949<br />

VICTORIA (Melbourne)<br />

Cat Rental Power<br />

47 Industrial Drive<br />

Sunshine 3020<br />

Tel: (613) 9703 4083<br />

fax: (613) 9311 0360<br />

QuEENSlAND<br />

50 Arc Place<br />

larapinta 4110<br />

Tel: (617) 3722 1400<br />

fax: (617) 3722 1495<br />

WESTERN AuSTRAlIA<br />

(Karratha)<br />

Cat Rental Power<br />

lot 2497, Pemberton Way<br />

Karratha 6714<br />

Tel: (618) 9183 8425<br />

fax: (618) 9183 9499<br />

SOuTH AuSTRAlIA<br />

Cat Rental Power<br />

106-110 Bedford Street<br />

Gillman 5013<br />

Tel: (618) 8249 3100<br />

fax: (618) 8249 3199<br />

TASMANIA<br />

William Adams Pty ltd<br />

Somerset<br />

Tel: (613) 6433 8888<br />

fax: (613) 6435 2375<br />

NORTHERN TERRITORy<br />

<strong>Hastings</strong> <strong>Deering</strong><br />

(Australia) ltd<br />

Berrimah<br />

Tel: 131 228<br />

fax: (618) 8984 1250<br />

Energy Power Systems Australia Pty ltd<br />

47-51 Westpool Drive, Hallam, Victoria 3803. Tel: 1800 800 441<br />

www.energypower.com.au<br />

VICTORIA (Warrnambool)<br />

Cat Rental Power<br />

38 Braithwaite Street<br />

Warrnambool 3280<br />

Tel: (613) 5560 5020<br />

fax: (613) 5560 5059<br />

QuEENSlAND (Townsville)<br />

Cat Rental Power<br />

12 Reward Court<br />

Bohle 4818<br />

Tel: (617) 4774 6244<br />

fax: (617) 4774 6954<br />

WESTERN AuSTRAlIA<br />

(Kalgoorlie)<br />

Cat Rental Power<br />

11 Epis Street<br />

Kalgoorlie 6430<br />

Tel: (618) 9025 2690<br />

fax: (618) 9022 4233<br />

NORTHERN TERRITORy<br />

2 Olive Place<br />

Holtze 0829<br />

Tel: (618) 8931 0022<br />

fax: (618) 8932 8295<br />

NEW SOuTH WAlES<br />

WesTrac Pty ltd<br />

Holroyd<br />

Tel: (612) 9840 4600<br />

fax: (612) 9840 4689<br />

PAPuA NEW GuINEA<br />

<strong>Hastings</strong> <strong>Deering</strong><br />

(PNG) ltd<br />

Port Moresby<br />

Tel: (675) 300 8300<br />

fax: (675) 325 0141<br />

© 2012 Caterpillar. All rights reserved. CAT, CATERPILLAR, their respective logos and “Caterpillar Yellow”, and the POWER EDGE trade dress,<br />

as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.<br />

NEW SOuTH WAlES<br />

8-10 Bosci Road<br />

Ingleburn 2565<br />

Tel: (612) 8796 9200<br />

fax: (612) 8796 9299<br />

QuEENSlAND (Rockhampton)<br />

Cat Rental Power<br />

level 1, Suite 15, 214 Quay St<br />

Rockhampton 4700<br />

Tel: (617) 4927 8432<br />

fax: (617) 4927 8476<br />

WESTERN AuSTRAlIA<br />

118 Daddow Road<br />

Kewdale 6105<br />

Tel: (618) 9442 8500<br />

fax: (618) 9442 8555<br />

PAPuA NEW GuINEA<br />

Spring Garden Road<br />

Hohola NCD, Port Moresby<br />

Tel: (675) 325 4399<br />

fax: (675) 323 5324<br />

QuEENSlAND<br />

<strong>Hastings</strong> <strong>Deering</strong> (Australia) ltd<br />

Brisbane<br />

Tel: 131 228<br />

fax: (617) 3274 0043<br />

Energy Power<br />

Systems<br />

2012<br />

NEW SOuTH WAlES<br />

(Newcastle)<br />

Cat Rental Power<br />

PO Box 3335<br />

Thornton 2322<br />

Tel: (612) 4028 6515<br />

QuEENSlAND (Cairns)<br />

Cat Rental Power<br />

Cnr fearnley & Kenny Streets<br />

Cairns 4870<br />

Tel: (617) 4035 0335<br />

fax: (617) 4035 0348<br />

WESTERN AuSTRAlIA<br />

Cat Rental & GMEC<br />

118 Daddow Road<br />

Kewdale 6105<br />

Tel: (618) 9442 8566<br />

fax: (618) 9442 8523<br />

WESTERN AuSTRAlIA<br />

WesTrac Pty ltd<br />

South Guildford<br />

Tel: (618) 9377 9444<br />

fax: (618) 9377 1791