Brushstrokes - October 2011 - Surface Coatings Association of New ...

Brushstrokes - October 2011 - Surface Coatings Association of New ...

Brushstrokes - October 2011 - Surface Coatings Association of New ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

www.scanz.org.nz<br />

OCTOBER <strong>2011</strong><br />

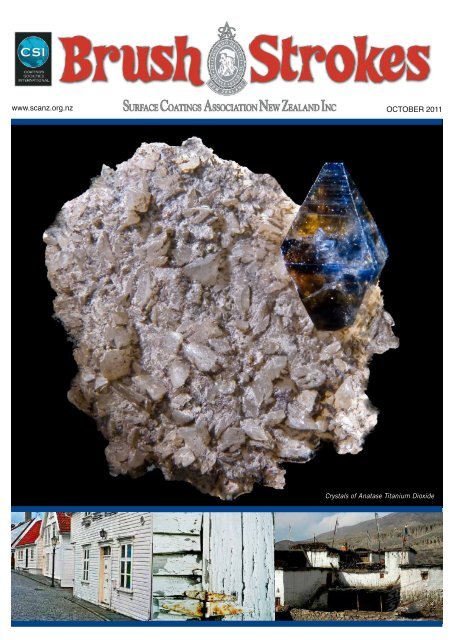

Crystals <strong>of</strong> Anatase Titanium Dioxide

For Your Specialty Chemical Needs<br />

Specialist <strong>of</strong><br />

Industrial Minerals<br />

Auckland 09 444 4650 Brett, Janine, Glenys, Rod<br />

Christchurch 03 338 8995 Mike, Jason<br />

www.chemcolour.co.nz info@chemcolour.co.nz<br />

ISO 9001:2000<br />

Need Innovation?<br />

ISM have the solution!<br />

Representing the leading brands in paint manufacture<br />

Additives<br />

Acrylic Microspheres<br />

AMP95 and VOX 1000<br />

Cellulosics<br />

Bentone Clays<br />

Biocides<br />

“Green” options<br />

Flow, levelling, defoamers<br />

Wetting agents<br />

Rheology Modifiers<br />

Dispersants<br />

Resins<br />

Acrylic polyols<br />

Alkyds<br />

Crosslinkers<br />

Epoxies<br />

Iso Free systems<br />

hydrocarbon resins<br />

Phenolics<br />

Silicones and Siloxanes<br />

Solution polymers<br />

Pigments<br />

AntiCorrosives<br />

Cuprous Oxide<br />

Flame Retardants<br />

Fluorescents<br />

Metallics<br />

Mixed Metallic Oxides<br />

Organic and Inorganics<br />

Pearls<br />

Titanium Dioxide<br />

Ultramarines<br />

ISM NEW ZEALAND LTD, 71C MONTGOMERIE ROAD,<br />

AIRPORT OAKS, MANUKAU CITY 2241, NEW ZEALAND<br />

TELEPhONE: +64 9 275 0745 FACSIMILE: +64 9 275 0746<br />

www.ismnz.com<br />

Liquid Coating Resins & Additives<br />

Bayferrox Iron Oxides<br />

Biocides & Performance Additives<br />

Mineral Fillers & Additives<br />

Surfactants & Enviro-friendly Solvents<br />

Nick Bray 09 306 6091 nick@alchemyagencies.co.nz<br />

Nigel Garland 09 306 6096 nigel@alchemyagencies.co.nz<br />

www.alchemyagencies.co.nz<br />

“Supplier for industrial solutions”<br />

DSM Neoresins; Arch Chemical biocides; BASF Emulsions & solvents; Celanese solvents & monomers;<br />

Extender pigments; Orica chlorinated paraffins; Degussa catalysts; Haltermann Oils & solvents;<br />

Huntsman Tioxide; Kukdo Epoxies; Noveon additives; Lucite monomers; Magruder flushes; Penreco oils;<br />

Rockwood Oxides; Johnson Matthey organic titanates; Wolstenholme metallic pigments and much more…<br />

Free phone 0800 22 22 77<br />

http://www.orica-chemicals.com

This edition was intended to have Titanium<br />

dioxide as its theme but as usual following<br />

the conference, there is some spill over in this<br />

issue and for the next. In this edition we have the full<br />

transcript <strong>of</strong> Adam Berry’s article kindly given to us by<br />

Nuplex Industries Ltd. Adam has joined Rocket Lab<br />

Ltd, a new Zealand based company that is developing<br />

niche technologies in electronics and propulsion<br />

system for rockets. Who would have believed that paint<br />

technology could lead to Rocket Science? Of course<br />

some would say that Rocket Science is no longer<br />

Rocket Science! NASA are planning to hand launch<br />

capability over to the private sector on the grounds<br />

that rocket science has become common science. I<br />

think there may be some pain ahead.<br />

Speaking <strong>of</strong> rocket science, we see from Peter’s<br />

painted memories, that early titanium dioxide started<br />

life as a coprecipitated anatase and barium sulphate<br />

and eventually to uncoated grades in the early 1940’s.<br />

Uncoated titanium dioxide has highly catalytic<br />

effect on any organic binding resins and must have<br />

produced some fierce chalking. The advent <strong>of</strong> surface<br />

treated grades greatly improved the performance as<br />

we see today. Couple that with the improvements in<br />

additives and titanium almost stirs straight into many<br />

paint formulations without the need for prolonged<br />

dispersion. When I started in the paint industry,<br />

everything was done in a ball mill, even laboratory<br />

samples. How many people even remember how to<br />

formulate for a ball mill?<br />

Throughout the time that I have been associated with<br />

the paint industry, the titanium dioxide producers<br />

have been threatening short supply and high prices as<br />

the cost <strong>of</strong> production and the market price squeezed<br />

pr<strong>of</strong>its, or so we were always lead to believe. We even<br />

had some Japanese suppliers use the <strong>New</strong> Zealand<br />

market to get established and then “turn <strong>of</strong>f the tap”<br />

so to speak. Titanium is probably better value in real<br />

dollar terms than it has ever been and with a rebound<br />

recession predicted, the paint industry will no doubt<br />

feel the effects very early in the cycle, resulting in less<br />

pressure on prices. Let’s hope our own paint industry<br />

will be in position to take advantage <strong>of</strong> it.<br />

<strong>Brushstrokes</strong><br />

Editorial<br />

The committee is in the advanced stages <strong>of</strong> planning<br />

for a seminar to be held in mid <strong>October</strong>, similar to the<br />

very successful one held back in 2004. The theme<br />

is basic paint technology, intended fort technicians,<br />

people in sales that think they know it all but <strong>of</strong>ten<br />

don’t, old hand like me that have forgotten it or have<br />

holes in their knowledge they don’t even know about,<br />

or anyone else that is interested to learn, or re learn,<br />

some <strong>of</strong> the fundamentals again. With the changes<br />

that have taken place in the last 10 years or so, there<br />

is always something new to be learnt. Look out for the<br />

notice later in the journal.<br />

In that regard, the <strong>Coatings</strong> and Polymer Science<br />

course is still available at the University <strong>of</strong> Auckland.<br />

It is administered by Neil Edmonds and run at<br />

Tamaki Campus in Glen Innes. The course has<br />

been amalgamated into the polymers and plastics<br />

program and run in conjunction between the School<br />

<strong>of</strong> Chemical Sciences and Engineering and Materials<br />

Science. More details next issue for those that would<br />

like to take their knowledge to a higher level with a<br />

recognised qualification.<br />

CJB.<br />

The theme <strong>of</strong> the next issue is<br />

Ro<strong>of</strong> <strong>Coatings</strong>.<br />

Any technical, historical or market oriented<br />

articles to do with the paint for ro<strong>of</strong>s, painting<br />

ro<strong>of</strong>s or the substrates that ro<strong>of</strong>s are made<br />

from, will be gratefully accepted.<br />

Please send any ideas, articles<br />

or suggestions to the editor.<br />

Email: cbolt@xtra.co.nz<br />

Phone: 021 897 844.<br />

or by mail to PO Box 1282, Pukekohe 2340<br />

Advertising enquires: Marina on<br />

021 781 968 or marina@apconz.co.nz<br />

Visit the SCANZ website<br />

www.scanz.org.nz<br />

SURFACE COATINGS ASSOCIATION OF NEW ZEALAND 1

Painted Memories<br />

A selection <strong>of</strong> Historical Paint References compiled by Peter Walters<br />

Titanium Dioxide, the theme <strong>of</strong> this edition <strong>of</strong> <strong>Brushstrokes</strong>, is,<br />

in spite <strong>of</strong> its now almost universal use as the white opacifying<br />

pigment in most industries, a very recent addition to our<br />

formulating armoury. Titanium Dioxide has only been produced<br />

commercially since 1919, initially by two companies, sharing<br />

technology and development efforts, in Fredrikstad, Norway &<br />

Niagara Falls, USA.<br />

The first Titanium Dioxide products consisted <strong>of</strong> 25% anatase<br />

TiO2 co-precipitated with 75% barium or calcium sulphate.<br />

These pigments gave between three and four times as much<br />

hiding as the then commonly used white lead. This quantum<br />

leap in performance sounded the death knell <strong>of</strong> white lead as<br />

an effective opacifying pigment. However initial cost <strong>of</strong> these<br />

‘high performance’ pigments relegated their early use to quality<br />

and specialised paints, providing the white lead industry with<br />

breathing space.<br />

The crucial dates in the adoption <strong>of</strong> TiO2 as our preferred<br />

white opacifying pigment are 1920, the first commercial TiO2<br />

composite products became available for purchase, 1928,<br />

‘Pure’ anatase pigments, 1940, ‘Pure’ rutile pigments and 1951<br />

the first surface treated TiO2 products became commercially<br />

available. During the 1950’s TiO2 replaced most previous white<br />

opacifiers as the pigment <strong>of</strong> choice.<br />

This timeline is reflected in the historic texts in my personal<br />

library. The Certain-teed Paints Varnishes handbook <strong>of</strong> 1928<br />

mentions Titanox, a 30% titanium oxide co-precipitated<br />

with 70% barium sulphate, and Titanolith, a very new coprecipitated<br />

three component pigment consisting <strong>of</strong> 15%<br />

titanium oxide, 25% zinc sulphide and 60% barium sulphate.<br />

The handbook contains the comment “Titanium oxide itself<br />

is a very excellent pigment but it is so expensive that it could<br />

not be put to general use.” Even the article on Titanox states<br />

that “Its relatively high cost causes it to be replaced whenever<br />

possible by combinations <strong>of</strong> other pigments which possess<br />

equally good properties.”<br />

By 1935 The Modern Painter and Decorator stated, under an<br />

entry for Titanium Oxide, that it was a “comparatively new<br />

addition to the range <strong>of</strong> white pigments” that had the chief<br />

disadvantage <strong>of</strong> an “expense which has prevented it from being<br />

so widely employed as it deserves to be.”<br />

My extract for our theme is from von Fischer’s comprehensive<br />

textbook “Paint and Varnish Technology” published in 1948 by<br />

the Reinhold Publishing Company. I have chosen to reproduce<br />

the first part <strong>of</strong> Chapter 5 as it comprehensively contrasts and<br />

compares all white opacifying pigments used in the coatings<br />

2 SURFACE COATINGS ASSOCIATION OF NEW ZEALAND<br />

industry at a point in time when Titanium Dioxide was just<br />

coming to dominate this field. A coatings text, therefore, had to<br />

compare TiO2 with the existing technologies that the coatings<br />

technologists at the time would have been familiar with. This<br />

textbook was also published prior to the introduction <strong>of</strong> surface<br />

treated grades <strong>of</strong> TiO2 and at a time when anatase TiO2 was<br />

considered the appropriate choice for exterior white house<br />

paints because <strong>of</strong> the “self-cleaning” properties brought about<br />

by its free-chalking characteristics.<br />

White Hiding Pigments<br />

By W. H. Madson<br />

Pigments Department, E.I. duPont deNemours & Co., Inc.,<br />

Wilmington, Delaware<br />

In this chapter there will be a general consideration <strong>of</strong> the<br />

various white hiding pigments in common use. This subject<br />

is a very large one; therefore it will not be covered completely<br />

but only the more important points will be considered. There<br />

isn’t any good short definition <strong>of</strong> what we mean by a white<br />

hiding pigment. However, it may be defined as a material which<br />

“tends to color something white.”<br />

In order to clarify the topic under consideration it is best to list<br />

the white hiding pigments which will be taken up. The following<br />

are included:<br />

White lead (basic carbonate) Titanium dioxide (Rutile)<br />

White lead (basic sulfate) Titanated Lithopone<br />

Zinc oxide Zinc sulfide-barium<br />

Leaded zinc oxide Zinc sulfide-calcium<br />

Lithopone Zinc sulfide-magnesium<br />

Zinc sulfide Antimony Oxide<br />

Titanium-barium pigment Lead titanate<br />

Titanium-calcium pigment Basic lead silicate<br />

Titanium-magnesium pigment Zirconium oxide<br />

Titanium dioxide (Anatase) Lead tetra-phosphate<br />

Of these 20 white pigments, white lead is the oldest, while<br />

titanium dioxide (pure and extended) is the most important<br />

today. The last three are relatively new in the pigment field.<br />

Probably more will be learned about these in future years.<br />

Figures 2 and 3 summarize the production figures <strong>of</strong><br />

three important pigments. A study <strong>of</strong> these graphs reveals<br />

interesting information on the production <strong>of</strong> these materials.<br />

Attention is called to the effect <strong>of</strong> the depression years and<br />

how the introduction <strong>of</strong> a new pigment tends to affect one<br />

already in production.

Fig. 2 Some white pigment sales.<br />

Fig. 3<br />

As mentioned above White lead is the oldest white pigment<br />

in use today. It was known at least 400 B.C. The first plant<br />

in America was built in 1804 by Samuel Wetherill & Sons<br />

in Philadelphia. There have been recent advances in the<br />

improvement <strong>of</strong> manufacture which is enabling the industry<br />

to make better white lead pigment. It is manufactured by<br />

five different processes. These vary primarily in the type <strong>of</strong><br />

raw material used.<br />

The oldest process is probably the Dutch process, which<br />

uses refined metallic lead in the form <strong>of</strong> perforated discs. It<br />

takes about three months to make the white lead. The Carter<br />

process dates from 1885. It uses powdered lead in revolving<br />

wooden cylinders and takes only 12 days. The Euston process<br />

puts the refined lead in solution and precipitates the white<br />

lead. Feathered lead is used as the raw material, which is<br />

made by running molten lead into water. The Sperry process<br />

is the electric process using a lead anode and iron cathode.<br />

The electrolytes, sodium acetate and sodium carbonate, are<br />

separated by a membrane. The Thompson-Stewart process is<br />

a recent development similar to the Carter process in that lead<br />

oxide is formed. However, all the lead oxide is first formed;<br />

then carbon-dioxide is added and controlled to form a definite<br />

chemical compound: 4PbC03.2Pb(OH)2.PbO.<br />

Basic carbonate white lead has the ability to impart adhesion,<br />

toughness, elasticity, and durability to a paint. It is used in<br />

various types <strong>of</strong> paint, principally in exterior paints. Basic<br />

carbonate white lead is the only white pigment which will<br />

produce a durable exterior paint if used alone without other<br />

pigments. A large proportion <strong>of</strong> the total white-lead production<br />

is used in white-lead pastes, which are thinned to paint form<br />

by the painter or other consumer. The two types <strong>of</strong> commercial<br />

white-lead paste are heavy paste and s<strong>of</strong>t paste. The first is<br />

composed <strong>of</strong> about 91 per cent white lead and 9 per cent<br />

linseed oil, while the latter contains about 89 per cent white<br />

lead, 9 per cent linseed oil, and 2 per cent turpentine. The<br />

linseed oil used is refined oil with an acid number <strong>of</strong> 6 to 12.<br />

About 95 per cent <strong>of</strong> the total production <strong>of</strong> white lead is<br />

consumed by the paint industry, with a small amount used in<br />

putty and by the ceramic and other industries.<br />

Basic lead sulfate is quite widely used as a paint pigment.<br />

It is called white basic lead sulfate, basic sulfate white lead<br />

or “sublimed white lead.” White basic lead sulfate is a quite<br />

recent pigment in comparison to basic carbonate white lead.<br />

It was originated in 1855 by E. O. Bartlett. He was at that<br />

time making zinc oxide directly from zinc ores by the American<br />

process. Applying the same principles to the production <strong>of</strong> a<br />

lead pigment from lead ore, he found that it was possible to<br />

produce a white powder having pigment properties.<br />

The first plant was built in 1876 in Joplin, Missouri, where lead<br />

ore deposits were sufficiently free from other metals for the<br />

production <strong>of</strong> white basic lead sulfate. It is manufactured by two<br />

processes, called the fume process and the chemical process;<br />

these are self-explanatory as far as manufacturing is concerned.<br />

Almost the entire production <strong>of</strong> white basic lead sulfate goes into<br />

mixed-pigment exterior paints, either directly or as the basic lead<br />

sulfate portion <strong>of</strong> blended leaded zinc oxides.<br />

White basic lead sulfate, like basic carbonate white lead, has<br />

the ability to impart to paints adhesion, toughness, elasticity,<br />

and durability, but is not as effective in this respect as is the<br />

basic carbonate. In exterior mixed-pigment paints, it is used<br />

principally as a substitute for basic carbonate white lead.<br />

White basic lead sulfate may be used for the “white lead”<br />

content <strong>of</strong> many specification paints, such as Federal<br />

Specification paints TT-P-40 and TT-P-81. White basic lead<br />

sulfate is a less expensive pigment than basic carbonate<br />

white lead, and this has been an influencing factor in its<br />

use. White basic lead sulfate is not generally used for singlepigment<br />

paints or pastes but is used in conjunction with<br />

other pigments in ready-mixed exterior paints. Ninety-seven<br />

per cent <strong>of</strong> the total production <strong>of</strong> this material is used in<br />

the paint industry, the remaining 3 per cent being used in<br />

the rubber and other industries.<br />

Zinc oxide pigments are made primarily by either the American<br />

or French process. In both these processes the characteristics<br />

<strong>of</strong> the pigment are determined by:<br />

1. The temperature <strong>of</strong> the oxidation <strong>of</strong> the fume;<br />

2. The time the zinc oxide is held at a high temperature;<br />

3. The composition <strong>of</strong> the gases;<br />

4. The rate <strong>of</strong> cooling.<br />

SURFACE COATINGS ASSOCIATION OF NEW ZEALAND 3

The French process uses purified metal which is melted and<br />

vaporized at 1650 to 1850°F under controlled conditions. The<br />

main difference in the American process is that this process<br />

uses ore instead <strong>of</strong> refined metal.<br />

However, the effects for which it is used in paints can be<br />

summarized, together with the known or suggested explanations<br />

for the results:<br />

“Use <strong>of</strong> Zinc Oxide in Paints (Nelson-Mattiello)<br />

To aid mixing and grinding - Consistency control - Penetration<br />

control and sealing - Drying - Hardening or solidifying the film<br />

Gloss and gloss retention - To minimize discoloration and<br />

yellowing - Reduced chalking - Color and tint retention<br />

Dirt shedding (self-cleansing), washability, and ease <strong>of</strong><br />

polishing - Mildew control - Resistance to moisture and to<br />

blistering under moist conditions - Neutralizing and inhibiting”<br />

Leaded zinc oxide was first introduced into the paint industry<br />

about 1896 as a result <strong>of</strong> developments on smelting Colorado<br />

complex zinc and lead ores. With improvements in the<br />

manufacturing process the product was standardized. Several<br />

grades were developed containing 5, 20 and 35 per cent lead<br />

sulfate and basic lead sulfate, the remainder being zinc oxide.<br />

The more recent developments have been the introduction <strong>of</strong><br />

a 50 per cent grade <strong>of</strong> leaded zinc and the manufacture <strong>of</strong><br />

leaded zinc oxides by blending white basic lead sulfate and<br />

lead-free zinc oxide. A considerable portion <strong>of</strong> the leaded zinc<br />

oxide on the market today is entirely or in part a mechanical<br />

mixture. Practically the entire production <strong>of</strong> leaded zinc oxide<br />

is used by the paint industry. It is used in conjunction with<br />

other white pigments in exterior house paints. When leaded<br />

zinc oxide is used in a paint it usually furnishes the entire<br />

amount <strong>of</strong> zinc oxide required in the particular paint.<br />

Co-fumed leaded zinc is made in the same general manner as<br />

American process lead-free zinc oxide. Dry-mixing zinc oxide<br />

and basic lead sulfate in the proper proportions yields blended<br />

leaded zinc oxide.<br />

Lithopone was not very important for some time after its<br />

introduction. This is <strong>of</strong>ten characteristic, and some attribute this<br />

condition to the fact that people do not like to make changes.<br />

However, the fact that lithopone was not light-stable prior to<br />

about 1920 no doubt had a definite effect on its acceptance. The<br />

improvement in lithopone at this time was very marked and made<br />

it possible for the material to be used much more widely than<br />

previously. Lithopone is primarily used in paints, rubber, textiles,<br />

paper and printing inks. It is receiving very stiff competition from<br />

titanium dioxide and extended titanium dioxide.<br />

High strength lithopones are made by blending lithopone with<br />

zinc sulfide or titanium dioxide. The former are made in several<br />

“strengths,” the 50 to 55 per cent zinc sulfide grade being<br />

the most popular. This is also known as zinc sulfide-barium<br />

pigment. Blends with titanium dioxide are called “titanated<br />

lithopones,” and usually contain about 15 per cent <strong>of</strong> titanium<br />

dioxide. Also in this same class are the zinc sulfide-calcium<br />

and zinc sulfide-magnesium pigments; these are blends <strong>of</strong> zinc<br />

sulfide with calcium sulfate or magnesium silicate.<br />

4 SURFACE COATINGS ASSOCIATION OF NEW ZEALAND<br />

Zinc sulfide is a relatively high-strength pigment, but it has not<br />

been used as widely as the blends with lithopone or extenders.<br />

Extended titanium pigments were introduced shortly after World<br />

War I. First to be produced was titanium-barium pigment,<br />

consisting <strong>of</strong> 25 per cent titanium dioxide and 75 per cent<br />

barium sulfate. Later came titanium-calcium pigment, with 30<br />

per cent titanium dioxide, and a 30 per cent titanium-barium<br />

pigment. Relatively recently, titanium-magnesium pigment (30<br />

per cent titanium dioxide and 70 per cent magnesium silicate)<br />

was made for use in house paints.<br />

These pigments, particularly straight titanium dioxide, met<br />

great resistance because <strong>of</strong> their relatively high price per<br />

pound, and a long educational program was required to<br />

convince the pigment users that these prices were really low<br />

when considered on the basis <strong>of</strong> cost per unit <strong>of</strong> hiding power<br />

developed in the finished product.<br />

Fig. 4 Titanium dioxide pigment<br />

Titanium dioxide has the highest hiding power <strong>of</strong> any <strong>of</strong> the<br />

white pigments, but its manufacture is more complicated and<br />

more expensive than any <strong>of</strong> the other pigments which have been<br />

considered. Figure 4 shows the manufacture <strong>of</strong> titanium dioxide<br />

pigment. Examination <strong>of</strong> this flow sheet shows how complicated<br />

the manufacture <strong>of</strong> this pigment really is. In order to<br />

manufacture pigment <strong>of</strong> a high quality today, extreme care must<br />

be taken in all steps, and impurities controlled very accurately.<br />

Previously the subject <strong>of</strong> hiding power was mentioned. It is<br />

this quality <strong>of</strong> titanium dioxide that makes it very important in<br />

the paint field. The comparison <strong>of</strong> the hiding power <strong>of</strong> various<br />

pigments is given in Figure 5. There may be some disagreement<br />

in the actual values <strong>of</strong> hiding power. This disagreement is<br />

due primarily to the fact that different conditions are used in<br />

measuring it. However, in general, the order given in Figure 5<br />

will be found under usual conditions.<br />

Fig. 5 Comparison <strong>of</strong> hiding power <strong>of</strong> various pigments.

A Naturally Occurring Sub-Micron Titanium<br />

Dioxide Extender for Decorative Paints<br />

Introduction<br />

By Simon Bussell*, Technical Sales Manager, Sibelco Speciality Minerals Europe * Corresponding author<br />

Mart Verheijen, Application Development Manager, Sibelco Speciality Minerals Europe<br />

In the first quarter <strong>of</strong> 2009 the price <strong>of</strong> titanium dioxide (TiO2)<br />

stood at $2,400/tonne for the US and Asia. Since that time<br />

regular increases have seen the price increase dramatically<br />

to $2,750-2,950/tonne by the end <strong>of</strong> 2010. Prices are even<br />

higher in Europe at up to €2,780/tonne.‚ At the same time<br />

supply has been severely limited with manufacturers rationing<br />

deliveries to customers. There are several causes for this,<br />

shortages <strong>of</strong> titanium ores such as ilmenite and rutile as well<br />

as other raw materials such as sulphuric acid, increased energy<br />

costs, increased demand from Asia and capacity reduction by<br />

suppliers. This situation has forced formulators to look again<br />

at the level <strong>of</strong> TiO2 in their coatings and consider options for<br />

reducing the quantities used. One such option is a complex<br />

carbonate extender produced by the Sibelco Group company<br />

Ankerpoort based a mixture <strong>of</strong> calcium and magnesium<br />

carbonates and hydrated carbonates. The material is marketed<br />

by Sibelco Speciality Minerals Europe (SSME) a new<br />

commercial group focused on the supply <strong>of</strong> functional fillers for<br />

coatings, polymers and adhesives. This work will show that the<br />

mixture, which occurs naturally as sub-micron, platy crystals,<br />

is an ideal TiO2 extender, maintaining and improving brightness<br />

and hiding power in comparison to other ultrafine extenders.<br />

Experimental<br />

Titanium Dioxide is responsible for two principle features <strong>of</strong><br />

paints and coatings, whiteness and opacity. TiO2 is the best<br />

pigment for these properties because <strong>of</strong> its high refractive<br />

index (2.75). This gives the highest level <strong>of</strong> scattering when<br />

light crosses the boundary between binder and TiO2 particle or<br />

air and TiO2 particle. Reduction <strong>of</strong> TiO2 content is a balancing<br />

act between the need to reduce cost and the need to maintain<br />

quality. To be effective a TiO2 extender must allow TiO2 levels to<br />

be reduced while maintaining whiteness and opacity levels.<br />

In the 1970’s a wall paint could contain more than 18% TiO2 by<br />

volume. 3 This has been steadily reduced since that time, typically<br />

by improving the dispersion and separation <strong>of</strong> TiO2 particles in the<br />

film. Figure 1 shows diagrammatically how this can be done by<br />

reducing the average particle size <strong>of</strong> the filler material.<br />

There is a limit to how effective this method can be. Beyond<br />

a certain particle size suitable finely ground fillers may not be<br />

available, and if they are binder demand, dispersant levels and<br />

dispersion time would all be increased. An alternative method<br />

is to use ultrafine particles to space the TiO2 particles in the<br />

interstitial voids between large filler particles (figure 2). Typically<br />

Figure 1 – improved TiO2 distribution by reduction <strong>of</strong> filler particle size<br />

(not to scale).<br />

particles <strong>of</strong> around twice the diameter <strong>of</strong> TiO2 particles (0.5-<br />

0.6µm) are found to be most effective.<br />

The purpose <strong>of</strong> this work was<br />

to determine how effective this<br />

complex carbonate mineral<br />

is as a TiO2 extender. To do<br />

this it was compared with four<br />

other materials commonly<br />

used for TiO2 extension, finely<br />

ground calcite, precipitated<br />

calcium carbonate, fine<br />

hydrous kaolin and calcined<br />

kaolin at two different TiO2<br />

volume concentrations.<br />

Figure 2 - TiO2 spacing by ultrafine extender (not to scale)<br />

Materials<br />

This work was undertaken at the SSME paint lab in Maastricht<br />

using a formulation (table 1) based on a styrene-acrylic<br />

emulsion. Initially two coatings were prepared using 7% TiO2 by<br />

volume and 3.5% TiO2 by volume. Selected coatings from these<br />

trials were repeated using a higher binder level. With the PVC<br />

above critical and a low level <strong>of</strong> TiO2 these coatings were felt to<br />

represent a general use interior wall paint.<br />

Fillers<br />

The complex carbonate extender is a mixed alkaline earth<br />

carbonate with the general formula Mg3Ca(CO3)4. It is formed<br />

by the weathering <strong>of</strong> magnesite or dolomite and subsequent<br />

deposition. Ankerpoort mine and partially process the material<br />

in Greece (figure 3) where the raw material is screened and<br />

beneficiated to provide a reasonably pure feedstock for further<br />

processing. The material is then shipped to The Netherlands<br />

where Ankerpoort have developed proprietary processing<br />

SURFACE COATINGS ASSOCIATION OF NEW ZEALAND 5

Table 1 – interior wall paint formulation<br />

techniques to achieve the optimum particle size distribution without<br />

affecting the unique morphology. The deposit is fine and white with<br />

a high carbonate content and an iron content <strong>of</strong> only 0.03%.<br />

Details <strong>of</strong> the morphology and physical properties can be seen in<br />

figure 1 and table 1. It occurs naturally as an aggregate <strong>of</strong> platy<br />

crystals with sides <strong>of</strong> ≈ 0.5 – 1.0µm and an aspect ratio <strong>of</strong> 10:1.<br />

The defining properties are the high brightness, low particle size<br />

and the high oil absorption/ surface area. The advantages <strong>of</strong><br />

these properties will be shown in the following work.<br />

The properties <strong>of</strong> the other test fillers (as measured by SSME)<br />

are summarised in table 3. Where quoted, the manufacturers<br />

D50 particle size is also given. Measurements were made using<br />

the Sedigraph technique which is useful for platy materials<br />

such as hydrous kaolin, but can give discrepancies for round<br />

or needle shaped particles such as PCC. A lower value would<br />

be expected for the calcined kaolin suggesting this sample was<br />

highly agglomerated.<br />

Methods<br />

7% TiO2<br />

7% TiO2<br />

+ 20%<br />

Binder<br />

3.5% TiO2<br />

Dispersion - All coatings were produced using a high speed<br />

disperser with a toothed blade. The water, dispersants, calcium<br />

scavenger, biocide, antifoam and thickener were dispersed at<br />

6 SURFACE COATINGS ASSOCIATION OF NEW ZEALAND<br />

3.5% TiO2<br />

+ 10%<br />

Binder<br />

Water 270 270 270 270<br />

Dispersant A 4 4 4 4<br />

Na HMP 1 1 1 1<br />

Dispersant B 1 1 1 1<br />

Biocide 3 3 3 3<br />

Antifoam 2 2 2 2<br />

Cellulose thickener 3 3 3 3<br />

TiO2 80 80 40 40<br />

5µm GCC 290 290 290 290<br />

Test extender 100 100 140 140<br />

Talc 80 80 80 80<br />

Styrene Acrylic<br />

binder<br />

160 192 160 176<br />

Thickener 3 3 3 3<br />

TiO2 PVC 7 6.7 3.5 3.4<br />

Total PVC 72.2 68.4 72.7 70.8<br />

Figure 3 Ankerpoort mine in Greece<br />

Figure 4 (left) - Morphology <strong>of</strong> complex carbonate extender<br />

Table 2 - Physical properties <strong>of</strong> complex carbonate extender<br />

Density 2.7g/cm3<br />

Mohs Hardness 2 - 3<br />

Refractive index 1.61 – 1.64<br />

D50 (Sedigraph) 0.56µm<br />

Oil Absn 55-60g/100g<br />

BET 18m2/g<br />

Brightness (Ry) 95<br />

Brightness (ISO) 92.3<br />

pH 10<br />

Table 3 – physical properties <strong>of</strong> competitive test extenders<br />

Fine GCC PCC<br />

low speed until fully dissolved. The pigment, fillers and extender<br />

were added and dispersed at high speed for 30 minutes until a<br />

grind <strong>of</strong> 5 or better was achieved. Following this the binder and<br />

thickener were added and dispersed at low speed for a further<br />

30 minutes until a uniform dispersion was achieved.<br />

Brightness and contrast ratio - The coatings were drawn<br />

down onto a Leneta No. 2 opacity chart using a bird type<br />

applicator to give a 150µm wet film thickness and allowed<br />

to dry for 7 days. Brightness was measured as L* using a<br />

spectrophotometer. Contrast ratio was measured as the ratio<br />

<strong>of</strong> reflected light from the coating over the black and white<br />

portions <strong>of</strong> the card (RB/RW) expressed as a percentage.<br />

Viscosity measurement - Viscosity was measured using a<br />

Brookfield viscometer fitted with spindle 5. High and low shear<br />

measurements were made at 100rpm and 10rpm.<br />

Results and discussion<br />

Hydrous<br />

Kaolin<br />

Calcined<br />

Kaolin<br />

Density 2.7 2.6 2.6 2.6<br />

D50 (Sedigraph) 1.1 1.38 0.62 6.6<br />

D50 (TDS) 0.2 - 0.3 0.7<br />

Oil Absn 30.5 37.5 42.0 74.5<br />

Brightness (ISO) 91.0 95.5 85.5 90.9<br />

The results for all test measurements are shown in table 4a and<br />

4b. There was no significant difference in the brightness measured<br />

for all formulations, being in the range 95.0 ± 0.6 although it<br />

should be mentioned that the highest brightness for each series

Table 4a – test results for 7% TiO2 formulation<br />

7% Titan<br />

7% Titan<br />

+ 20%<br />

Binder<br />

was given by the complex carbonate extender. As may be expected<br />

the brightness <strong>of</strong> the coatings containing 7% TiO2 was higher than<br />

those containing 3.5% TiO2, although in reality the difference was<br />

on average only half a point. Gloss measurements were also very<br />

similar for all samples ranging from 2.4 to 3.8. All coating would<br />

be suitable for low sheen applications.<br />

The variation in contrast ratio was far greater, ranging from<br />

a low <strong>of</strong> 90.1 to a high <strong>of</strong> 96.2. Once again the complex<br />

carbonate formulations had the highest value in all test series,<br />

in some cases by a significant margin, being at least two points<br />

above the average value for each series <strong>of</strong> tests. The results<br />

for the fine GCC and the PCC were very similar and it would be<br />

difficult to place one above the other in terms <strong>of</strong> contrast ratio.<br />

The lowest contrast ratio was given by the hydrous and calcined<br />

kaolins which were also very similar. In terms <strong>of</strong> particle size<br />

and shape the hydrous kaolin was closest in morphology to<br />

the complex carbonate, however the results show it is not as<br />

effective as the complex carbonate as a TiO2 extender.<br />

There was some variation between the contrast ratio <strong>of</strong> the<br />

higher and lower TiO2 contents. Increasing the level <strong>of</strong> extender<br />

and reducing the level <strong>of</strong> TiO2 gave a higher contrast ratio for<br />

the complex carbonate, fine GCC and hydrous kaolin while a<br />

lower value for PCC and calcined kaolin.<br />

The area which showed the greatest difference between the<br />

complex carbonate and the other extenders was viscosity.<br />

The GCC, PCC and hydrous kaolin give reasonably similar<br />

viscosities, however the complex carbonate gives a noticeably<br />

higher viscosity and the calcined kaolin a noticeably lower<br />

viscosity. The highly thixotropic nature <strong>of</strong> dispersions<br />

containing the complex carbonate can be an advantage in that<br />

settling is less pronounced and thickener levels can reduced. If<br />

lower viscosities are required then subsequent work has shown<br />

that alternative combinations <strong>of</strong> dispersant and thickener are<br />

Portafill H5 Fine GCC PCC Hydrous Kaolin Calcined Kaolin<br />

Brightness L* 95.8 95.0 95.4 94.9 95.4<br />

CR/% 96.4 92.4 92.5 92.4 90.1<br />

Gloss 85° 2.8 2.4 3.2 2.5 2.6<br />

Viscosity100rpm/cP 2640 1880 2040 1680 1240<br />

Viscosity10rpm/cP 14000 7200 7600 7200 4400<br />

Brightness L* 95.8 95.3<br />

CR/% 95.9 94.9<br />

Gloss 85° 2.6 2.7<br />

Table 4b – test results for 3.5% TiO2 formulation<br />

3.5% Titan<br />

3.5% Titan<br />

+ 10%<br />

Binder<br />

Portafill H5 Fine GCC PCC Hydrous Kaolin Calcined Kaolin<br />

Brightness L* 95.6 94.5 95.1 94.4 94.8<br />

CR/% 95.2 94.3 91.1 92.2 92.0<br />

Gloss 85° 3.6 3.4 3.8 2.9 2.9<br />

Viscosity100rpm/cP 3600 1880 1680 1920 1160<br />

Viscosity10rpm/cP 21200 7600 5600 9200 2000<br />

Brightness L* 93.2 94.4 94.4 94.1<br />

CR/% 94.5 92.0 90.3 91.5<br />

Gloss 85° 3.2 3.1 2.8 3.1<br />

effective in controlling the rheological behaviour.<br />

The relatively low viscosity <strong>of</strong> the mixes containing the calcined<br />

kaolin, despite the highest oil absorption, may be further<br />

evidence <strong>of</strong> the difficulty in deagglomerating the material and<br />

achieving a fine dispersion. This in turn would account for the<br />

poor performance in terms <strong>of</strong> contrast ratio.<br />

Conclusions<br />

SSME’s complex carbonate extender is an ultrafine, platy<br />

extender and has been compared in this series <strong>of</strong> tests against<br />

ultrafine carbonate extenders and ultrafine platy extenders.<br />

Overall the results show that it works well as a TiO2 extender,<br />

brightness in the test formulations was slightly better than<br />

the competitive materials however the most important result<br />

was contrast ratio. In formulations above critical PVC it is<br />

relatively easy to achieve a good brightness using white fillers<br />

but dry hiding power can be difficult to maintain as TiO2<br />

levels are reduced. This work shows that increasing the level<br />

<strong>of</strong> the complex carbonate extender in a formulation allows<br />

the TiO2 level to be reduced while actually increasing the<br />

dry hiding power to a level not achieved by other fillers. This<br />

has advantages both in terms <strong>of</strong> cost reduction and quality<br />

improvement. In addition the rheological behaviour makes this<br />

extender highly suitable for viscous materials such as sealants,<br />

underbody coatings and putties.<br />

References<br />

1. Titanium dioxide price pressure, Industrial Minerals, March 2009<br />

2. Titanium dioxide market most “buoyant” for a decade, Industrial<br />

Minerals, Jan <strong>2011</strong><br />

3. The Effect <strong>of</strong> Fine Particle Size Extenders and Entrapped Air on TiO2<br />

in Emulsion Paints, Paul F. Dietz, PCI Magazine, September 2003.<br />

Contact details<br />

Simon Bussell, Sibelco Europe, Brookside Hall, Sandbach,<br />

Cheshire, UK. Contact: Simon.bussell@sibelco.com,<br />

Ph: +44 1270 752914, +44 7889 057206<br />

SURFACE COATINGS ASSOCIATION OF NEW ZEALAND 7

Formulating for the Future<br />

<strong>New</strong> open-time binder for the Australasian Market<br />

Summary<br />

By S.B. Browning and A. Berry - Nuplex Resins, Australasia<br />

In Australasia, the open time <strong>of</strong> current water borne enamels<br />

is limited by the binder system, which in gloss systems is<br />

about three minutes. Incremental gains in open time may be<br />

made from changing the rheological pr<strong>of</strong>ile and/or with certain<br />

additives, but the open time will still be significantly shorter<br />

than solvent borne systems. In addition these additives have<br />

the potential to compromise the chemical and mechanical<br />

properties <strong>of</strong> the coating and significantly reduce the coverage.<br />

Nuplex Industries acknowledges this fact and has developed an<br />

experimental binder using proprietary binder technology that<br />

gives coatings two and a half times the open time <strong>of</strong> commercial<br />

water borne trim enamels with improved early water resistance.<br />

Introduction<br />

Over the past 15 years, the trim enamel market has undergone<br />

a dramatic shift from solvent borne alkyds to waterborne<br />

acrylic systems. A number <strong>of</strong> reasons have been given for<br />

this including the perceived environmentally friendliness to<br />

hazard mitigation. This transformation has lead to a number <strong>of</strong><br />

advantages, such as water wash up and fast curing times.<br />

However, this transition has exposed the weaknesses<br />

<strong>of</strong> waterborne acrylic trim enamels. Due to their drying<br />

behaviour, the open time and gloss are poorer than the older<br />

solvent borne technologies, whilst their lower solids deliver<br />

poor telegraphing resistance.<br />

To resolve these deficiencies Nuplex Resins embarked on<br />

a project to understand the rheological parameters that<br />

determine open time with the intention <strong>of</strong> developing a series<br />

<strong>of</strong> binders with better application properties without increasing<br />

the concentrations <strong>of</strong> surfactants or solvents. This is important<br />

as the desired improvement in open time should not be at the<br />

expense <strong>of</strong> dry film properties.<br />

What is open time?<br />

Open time is many things to many people. However a good<br />

definition <strong>of</strong> this property was put forward by Reuvers in 1999:<br />

“the period <strong>of</strong> time during curing when small corrections can<br />

be made without leaving clearly visible brush strokes”<br />

This definition covers the time in which a painter can repair<br />

any deformations in the film (the repair time) and the time<br />

when painter can re-brush (the wet edge or lapping time.)<br />

One must bear in mind that this is not only the time when<br />

surface imperfections can flow out <strong>of</strong> the coating but also<br />

when sagging, slumping and runs can occur (Akkerman et al,<br />

8 SURFACE COATINGS ASSOCIATION OF NEW ZEALAND<br />

2009.) All <strong>of</strong> these properties are to do with flow and hence<br />

are related.<br />

Whilst it is generally acknowledged that the high shear viscosity<br />

will determine how much paint is applied and hence wet film<br />

thickness, Bosma et al. found by manipulation <strong>of</strong> the Orchard<br />

equation that a paint will cease flow, levelling and hence<br />

open time once it has reached a certain low shear viscosity<br />

and from this concluded that paints with a high degree <strong>of</strong><br />

pseudoplasticity will always have poor open times.<br />

The differences between solvent borne and<br />

water borne coatings.<br />

There are number <strong>of</strong> reasons why the open times <strong>of</strong> solvent<br />

borne coatings are superior to those <strong>of</strong> their water borne<br />

cousins, but the main reason is the relationship between<br />

fluidity (inverse viscosity) and solids content. Dispersions and<br />

waterborne dispersions in particular decrease their fluidity with<br />

increasing solids at a much faster rate than solutions regardless<br />

<strong>of</strong> solvent content. As a result water borne binders have<br />

virtually no flow above 50%, whilst solvent borne alkyds still<br />

have a degree <strong>of</strong> fluidity at 75% solids. This allows the painter<br />

significantly longer period to work with the coating, hence<br />

better open times, and thus better dry film appearance.<br />

This fluidity effect is exacerbated by the different levelling<br />

mechanisms between water borne and solvent borne coatings.<br />

In the initial phase <strong>of</strong> curing, the evaporate rate is constant<br />

regardless <strong>of</strong> local layer thickness. In solvent based paints<br />

this leads to an increase in surface tension in areas <strong>of</strong> low<br />

film build - as white spirits has a surface tension <strong>of</strong> 24 dynes/<br />

cm whilst the final coatings typically have a surface tension <strong>of</strong><br />

45 dynes/cm. As the surface tension tries to equilibrate, that<br />

is the surface area reduces, material is forced to flow from<br />

locations <strong>of</strong> low surface tension to areas where the surface<br />

tension is higher. This results in a surface tension gradient that<br />

promotes levelling, but this phenomena is opposite for water<br />

based coatings as water has a surface tension <strong>of</strong> 72 dynes/cm.<br />

This factor can be minimized by the addition <strong>of</strong> surfactants<br />

and solvents, but this has a negative effect on hardness<br />

development, water resistance and in the case <strong>of</strong> solvents, an<br />

increase in VOC.<br />

Another reason why waterborne coatings are observed to be<br />

inferior to solvent borne coatings is telegraphing resistance,<br />

the transmission <strong>of</strong> substrate defects from the substrate to the<br />

surface. In the absence <strong>of</strong> surface tension gradients (as occurs<br />

at initial application <strong>of</strong> the coating) the telegraphed amplitude<br />

only depends on the initial solids content (also known as

the shrinkage factor) and is thus irrespective <strong>of</strong> rheological<br />

properties, thickness, applied surface pr<strong>of</strong>ile or surface tension.<br />

The shrinkage factor can thus be modelled as:<br />

where ρ solids is density <strong>of</strong> solids and SC-0 is initial solids<br />

content. Using this formula we can ascertain that by either<br />

increasing the solids content or by decreasing the density <strong>of</strong><br />

the solid, the degree <strong>of</strong> shrinkage can be reduced (See graph<br />

below) In solvent borne coatings, both the solids content is<br />

higher, and due to the higher resin component, the density <strong>of</strong><br />

the solids is lower, hence much better telegraphing resistance.<br />

The Development <strong>of</strong> an Experimental Open<br />

Time Binder<br />

As we have seen, the application and appearance <strong>of</strong> self<br />

cross linking acrylics are inferior to their solvent borne alkyd<br />

predecessors. To try and minimize the shortfall in open-time,<br />

paint chemists commonly add humectants such as glycols or<br />

surfactants; with conventional logic being that these will hold<br />

back water and therefore extend open time.<br />

However propylene glycol does not form an azeotrope 1 with<br />

water, and it is the belief <strong>of</strong> the authors that propylene glycol<br />

only improves the wet edge <strong>of</strong> the paint and not the ability for<br />

a paint to flow out after brush/roller corrections. Significantly<br />

greater gains in open time have been found by slightly reducing<br />

the volume solids content rather than by increasing the<br />

surfactant and solvent concentrations, with only a minimal<br />

reduction in telegraphing resistance.<br />

1 An Azeotropic mixture is defined as a liquid mixture <strong>of</strong> two or more<br />

substances, that when mixed behave as a single species as the<br />

vapour produced from partial evaporation <strong>of</strong> the liquid has the same<br />

composition as the liquid (Turner, 1950.) Whilst propylene glycol is<br />

infinitely dissolvable in water, the resulting liquid exhibits two distinct<br />

boiling points.<br />

Even when the volume solids <strong>of</strong> a coating with a <strong>New</strong>tonian<br />

rheology pr<strong>of</strong>ile is around 35%, the open time using the Nuplex<br />

Cross Open Time (COT) method will be at best between three<br />

and four minutes. This is because the curing mechanism <strong>of</strong> the<br />

resin is the overriding factor in determining the open time in<br />

waterborne acrylic enamel systems.<br />

The self cross-linking acrylic polymers commonly used in the<br />

manufacture <strong>of</strong> trim enamels are classified as dispersions.<br />

In the wet state these resins exist as semi solid particles<br />

suspended in water, and film for through deformation or<br />

coalescence <strong>of</strong> these polymer particles. The dry film retains<br />

some <strong>of</strong> the structure <strong>of</strong> the polymer particles which reduces<br />

the gloss, particularly at 20°. In general the acrylic polymer<br />

particles are high molecular weight and cannot easily move<br />

past one another, so the viscosity increases rapidly on drying,<br />

hence the short open times. These polymers get the majority <strong>of</strong><br />

their performance properties from their high molecular weight<br />

and not from cross-linking, which is why they appear to cure<br />

at a much faster rate than alkyd systems. It is also why acrylic<br />

systems need to have higher glass transition temperatures than<br />

alkyd systems to get the same blocking resistance.<br />

There are two other waterborne technologies that are currently<br />

available for use in the waterborne trim enamel market; alkyd<br />

emulsions and solutions.<br />

Alkyd emulsions are supplied as alkyd droplets in water (an oil<br />

in water or o/w emulsion.) As water evaporates, the viscosity<br />

increases until the resin inverts from an oil in water emulsion to<br />

a water in oil (w/o) emulsion, and the viscosity decreases. The<br />

dry time <strong>of</strong> alkyd emulsions is similar to solvent borne alkyds,<br />

as they both require oxidative cross-linking for chemical and<br />

mechanical properties.<br />

Unlike acrylic dispersions, the resin droplets in alkyd emulsions<br />

are liquid, which gives these binders a higher degree <strong>of</strong> fluidity<br />

at the same solids content, and as alkyd emulsions do not<br />

coalesce, they do not require a coalescing solvent and they<br />

contain renewable (but yellowing) oils. This yellowing and the<br />

slow dry times are two reasons why this technology has fallen<br />

from favour in the Australasian trim market.<br />

Currently the only other technologies that can be utilised are<br />

water soluble polymers. Traditionally the trim market was<br />

dominated by (alkyd solvent borne) solutions, which have<br />

issues with odour, dry time VOCs and yellowing, but have good<br />

open time and telegraphing resistance (due to being able to<br />

flow above 70% volume solids.) Water soluble polymers also<br />

have excellent gloss and open time but perform very poorly<br />

when exposed to water, <strong>of</strong>ten re-dissolving within two minutes.<br />

They mostly have poor mechanical properties.<br />

The Experimental Binder EM8683<br />

These deficiencies in current resin technology have led Nuplex<br />

to develop EM8683, an experimental polymer designed to<br />

have much better open time than current technologies on the<br />

market. As we have already seen, the open time <strong>of</strong> the current<br />

waterborne self cross-linking acrylics is limited by the binder<br />

system. Nuplex have addressed this by developing a fast curing<br />

acrylic copolymer emulsion. Unlike traditional self cross-linking<br />

acrylics, this system is oil modified and oxidatively cross-links,<br />

hence the MFFT is significantly reduced without compromising<br />

mechanical properties.<br />

To ensure that the performance <strong>of</strong> this experimental polymer is<br />

SURFACE COATINGS ASSOCIATION OF NEW ZEALAND 9

similar to current market standards, paints made on EM8683<br />

have been evaluated and compared to six commercially<br />

available paints; three high gloss solvent borne alkyd trim<br />

enamels, two high gloss waterborne trim enamels and a water<br />

based trim enamel based on an alkyd emulsion.<br />

The open time was tested using a standardised method very<br />

similar to ASTM D7488-10, and evaluated a number <strong>of</strong><br />

properties including how long the open time is in the wet (open<br />

time a’) and dry (open time b) films. It was found that the open<br />

time <strong>of</strong> EM8683 was nearly as long as the waterborne alkyd<br />

and 250% longer than a commercial waterborne acrylic market<br />

standards. Significantly, and unlike paints based on self crosslinking<br />

acrylics, the open time in the wet film was identical to<br />

that in the dry film.<br />

As previously mentioned, EM8683 utilises oxidative crosslinking<br />

technology. There have been a number <strong>of</strong> advantages<br />

in doing this, such as reducing the coalescent demand and<br />

improving the resistances to water and hydrophilic stains.<br />

To ensure that the coating did not suffer from loss <strong>of</strong> dry,<br />

it was placed in the oven at 60°C for seven and 42 days<br />

(1000 hours.) In this test it was found that EM8683 had dry<br />

times longer than acrylics but still shorter than solvent borne<br />

enamels. It was also found that the dry time <strong>of</strong> the heat aged<br />

samples was similar to the un-aged sample, unlike three<br />

commercial solvent borne standards.<br />

To observe the mechanical properties <strong>of</strong> the coatings; block<br />

resistance and pendulum (Koenig) hardness tests were<br />

undertaken. Block resistance was carried out using a method<br />

based upon ASTM D4946-89 (2003.) In this test EM8683<br />

had a block resistance within the solvent borne and waterborne<br />

market standards, even though the MFFT <strong>of</strong> EM8683 is much<br />

lower than the self cross-linking acrylics, and a pendulum<br />

hardness akin to the solvent borne alkyds.<br />

Finally the 20° gloss <strong>of</strong> the coating based in EM8683 was<br />

67%. This is a step improvement from the current technology<br />

as it places it roughly half way between the solvent borne<br />

<strong>Coatings</strong> that Michelman has successfully tested for repulpability<br />

and their applications include:<br />

VaporCoat® 330C – a wax replacement solution typically used on roll wrap, produce boxes, poultry boxes and<br />

anywhere packaged goods require protection from water and/or moisture vapor.<br />

Michem® Coat 40EAF - another wax replacement coating that is water resistant and also demonstrates some<br />

grease resistance. Typically used on fruit, vegetable and protein/meat boxes.<br />

Nomar 70AF - a water based, abrasion resistant coating, generally used to provide abrasion protection for gas<br />

flushed food packaging or small appliances.<br />

Coating X300AF - another waterborne coating that provides a high level <strong>of</strong> water resistance and good moisture<br />

resistance on kraft paper. It is used to protect food products from excessive moisture, freezer burn and sticking.<br />

MaxWhite 17 - a decorative white coating that provides excellent brightness before and after wax applications.<br />

10 SURFACE COATINGS ASSOCIATION OF NEW ZEALAND<br />

alkyds and the water borne self cross-linking acrylics.<br />

Conclusion<br />

With commercial pressures from the marketplace and our<br />

share holders, environmental pressures from legislators,<br />

specifiers and consumers and performance pressures from all<br />

<strong>of</strong> the above, we are all continually trying to formulate for the<br />

future. One <strong>of</strong> the last bastions <strong>of</strong> solvent borne technology<br />

in architectural coatings is gloss trim paints. To overcome the<br />

limitations <strong>of</strong> acrylic water borne enamels in both open time<br />

and telegraphing, Nuplex has developed a new binder resin.<br />

Whilst the ultimate parameters <strong>of</strong> this resin are currently being<br />

finalised, the results, thus far, look very promising.<br />

It is anticipated that this binder will be utilised in one <strong>of</strong> two<br />

ways, either in coatings with the same volume solids but much<br />

better open time; or in coatings with higher volume solids to<br />

minimise telegraphing. This second route may be a way <strong>of</strong><br />

reducing TiO2 demand as coverage will be better with the higher<br />

film build. Either way, the coalescent demand will be lower<br />

which may lead to lower formulation costs, reduced VOC’s and<br />

due to the low MFFT and hydrophobic nature <strong>of</strong> this resin, it is<br />

believed that it will be a good candidate for DTS applications as<br />

it is expected have good tannin bleed resistance.<br />

While this polymer is being commercialised we will still be<br />

formulating for the future – working on the next generation<br />

<strong>of</strong> polymers which will give even longer open times and emit<br />

even less VOC’s and having physical and chemical properties in<br />

advance <strong>of</strong> those already achieved.<br />

Acknowledgements:<br />

Nuplex Technical team in Australia and <strong>New</strong> Zealand<br />

Nuplex Technical Team in Holland and Adam Berry<br />

References:<br />

1. Akkerman, J. Bosma, M. Berry, A. Fallani, F. Adolphs, R. Mestach,<br />

D. “<strong>New</strong> developments op open time resins for waterborne<br />

decorative coatings” European <strong>Coatings</strong> Congress, 2009<br />

2. Turner (ed) “The Condensed Chemical Dictionary” Forth Edition,<br />

Reinhold Publishing Corporation, 1950

Bridging the gap in performance deficiency <strong>of</strong><br />

eco-friendly waterborne coatings by making use<br />

<strong>of</strong> a nanoparticle containing additive<br />

Eco-friendly waterborne paints and coatings already gained<br />

considerable interest and market shares compared to traditional<br />

solvent borne systems driven by stricter legislation as well as<br />

the general environmental awareness. Nevertheless waterbornes<br />

have well known limitation in overall performance compared to<br />

classical solvent borne systems.<br />

A innovative concept based on metal oxide nanoparticle<br />

technology potentially improving waterborne coatings will be<br />

introduced. With a chemo-mechanical milling process particles<br />

with tailored surface properties were generated. A overall good<br />

compatibility <strong>of</strong> the particles with a broad variety <strong>of</strong> binders<br />

was observed. Especially acrylic binders and copolymers with<br />

acrylic compartments are very well suited for the use with<br />

Oxylink. This also includes acrylic modified alkyds and PUDs.<br />

MEK double<br />

rubs<br />

[#]<br />

120<br />

80<br />

40<br />

0<br />

? = 85<br />

0.00 1.00 2.00<br />

wt.-% Oxylink 3101 (solids on solids)<br />

Figure 1: Concentration <strong>of</strong> Oxylink 3101 in transparent wood stain<br />

formulation based on Primal AC 337ER versus the<br />

MEK rub resistance<br />

The particles in the additive improve the overall coating<br />

performance due to direct particle-to-resin interaction. This<br />

effect closely depends on the high degree <strong>of</strong> dispersion as<br />

well as on the high surface area <strong>of</strong> the nanoparticles. We<br />

recommend a usage level <strong>of</strong> 1.0 % additive for first formulation<br />

experiments (see. Fig. 1).<br />

In particular the MEK rub stability, drying time, blocking<br />

resistance and stability against humidity will be improved.<br />

Detailed test results for a wood stain and a direct-to-metal<br />

By Marc Herold and Frank Tabellion<br />

Figure 2: Performance charts <strong>of</strong> a transparent Coating for wood based<br />

on Primal AC-337 ER (top) and a white DTM formulation based on<br />

Neocryl XK 86 (bottom).<br />

coating are depicted in Figure 2. The main performance benefit<br />

for the wood coating by the additive is a reduced drying time<br />

and a higher blocking resistance. The humidity resistance and<br />

the MEK-double rub resistance are the main effects for the<br />

direct-to-metal coating.<br />

The above shown results demonstrate that a nanoparticle<br />

based additive like Oxylink can significantly improve the overall<br />

properties <strong>of</strong> waterborne coatings. With steadily improving the<br />

properties <strong>of</strong> waterborne coatings, the gap between waterbornes<br />

and solvent borne coatings becomes narrower and the hurdles<br />

for using waterbornes become lower. As a consequence,<br />

nanotechnology can play an important role in bringing greener<br />

coatings forward.<br />

Bühler PARTEC GmbH<br />

Science Park 2<br />

66123 Saarbrücken<br />

Phone: +49 681 394 6550<br />

oxylink@buhlergroup.com<br />

SURFACE COATINGS ASSOCIATION OF NEW ZEALAND 11

Introduction<br />

To brush or not to brush.<br />

Formulating hand applied waterborne high performance<br />

two pack polyurethane coatings<br />

By Adriaan Sanderse, Jan Goossen, Jaap Akkerman, Dirk Mestach - Nuplex Industries.<br />

Progress made over the last years in the design <strong>of</strong> waterborne<br />

acrylic polyols and polyisocyanates for two pack polyurethane<br />

coatings has enabled the coatings formulator to overcome<br />

the drawbacks that were associated with the first generation<br />

<strong>of</strong> water-borne polyurethanes. Consequently waterborne two<br />

pack (WB2K) technology has gained a strong foothold in the<br />

industrial coatings market, meeting all <strong>of</strong> the requirements to<br />

<strong>of</strong>fer a true alternative for solventborne coatings.<br />

In addition to <strong>of</strong>fering reduced emissions <strong>of</strong> volatile organic<br />

compounds (VOC) during application <strong>of</strong> the coating resulting<br />

in reduced exposure <strong>of</strong> the painter to organic vapours, these<br />

coatings reduce risk <strong>of</strong> fire and are easier to clean up (creating<br />

less hazardous waste to dispose <strong>of</strong>).<br />

Most WB2K coatings have been optimized for application by<br />

means <strong>of</strong> spraying, either airless or air assisted or electrostatic.<br />

Until now, not much work was done to develop formulation<br />

guideline for WB2K systems that can be hand applied, by<br />

roller or brush. However if it would be possible to hand apply<br />

WB2K systems with final aesthetical and film-properties that<br />

are equivalent to spray applied WB2K would open up a number<br />

<strong>of</strong> new end-use applications where properties such as high<br />

durability and excellent resistance properties are <strong>of</strong> prime<br />

importance. Typical examples <strong>of</strong> such end-use applications<br />

are highly durable clear and pigmented exterior woodcoatings,<br />

yacht coatings, site-applied flooring coatings and coatings to<br />

repair or refinish interior wood.<br />

Water-borne two component<br />

polyurethane technology<br />

As for all paint formulation work, the right selection <strong>of</strong> the base<br />

resin components is crucial to obtain a satisfactory end result.<br />

In a WB2K coating system for hand application, component<br />

A is a polyol binder, consisting <strong>of</strong> small colloidal polyol<br />

particles that are suspended in water. Because <strong>of</strong> the fact that<br />

most waterborne acrylic polyols can not sufficiently emulsify<br />

hydrophobic isocyanates to achieve proper homogeneous film<br />

formation 2,1 , component B is preferably a water dispersible<br />

polyisocyanate hardener. Water dispersible hydrophylic<br />

polyisocyanates can be prepared by reacting isocyanate<br />

trimers with mono-functional polyethers 2 . Most suitable<br />

polyisocyanate hardners for this application are based on<br />

hexamethylene diisocyanate (HDI) trimers, however in order to<br />

optimize properties such as hardness development, also water<br />

12 SURFACE COATINGS ASSOCIATION OF NEW ZEALAND<br />

dispersible polyisocyanates based on isophoronediisocyanate<br />

(IPDI) trimers can be used in combination with HDI-types.<br />

Just before application the polyol component is mixed with<br />

the polyisocyanate hardener. After application onto the<br />

substrate, the coating cures through the hydroxyl-isocyanate<br />

reaction resulting in the formation <strong>of</strong> urethane crosslinks. In<br />

waterborne systems a important side-reaction occurs when<br />

isocyanate reacts with water. Some <strong>of</strong> the polyisocyanate<br />

groups are sacrificed because <strong>of</strong> this reaction forming the<br />

unstable carbamic acid which immediately decomposes and<br />

releases CO2 gas and a primary amine. The amine can then<br />

react with the isocyanate forming polyurea. Because <strong>of</strong> the<br />

water side-reaction, the NCO:OH ratio will have a significant<br />

impact on the coating properties: dry times, sanding, pot<br />

life, hardness development and chemical resistance. The<br />

competition between urethane versus urea reaction is<br />

governed by a number <strong>of</strong> parameters such as the surface area/<br />

particle size <strong>of</strong> the polyisocyanate emulsion, the emulsion<br />

stabilization mechanism3 , neutralizing agents and the time<br />

between mixing components A and B and the application <strong>of</strong><br />

the coating. Publications by Urban et al. 4,5 discuss in great<br />

detail the mechanisms and the influence <strong>of</strong> the ratio between<br />

hydrophobic / hydrophilic isocyanates and the curing conditions<br />

such as relative humidity on film-properties.<br />

Binder selection<br />

Most waterborne polyol emulsions are stabilized by either<br />

anionic or non-ionic stabilizing groups or a combination there<strong>of</strong>.<br />

Anionic groups are required for fine particle size emulsions.<br />

Generally there is a relation between the acid value <strong>of</strong> the<br />

polyol and the particle size <strong>of</strong> the emulsion. Most commonly<br />

the anionic groups are introduced by the copolymerization<br />

with carboxylic acid functional (meth)acrylic monomers such<br />

as acrylic or methacrylic acid. The carboxylic acid groups are<br />

converted in the salts using a volatile amine before or during<br />

emulsification in water. The problem associated with the<br />

presence <strong>of</strong> amines in the coating system is the catalytic action<br />

towards the isocyanate-water reaction. In order to decouple the<br />

emulsion particle size with the negative catalytic influence <strong>of</strong><br />

the neutralizing amine, the resin chemists at Nuplex Resins<br />

developed a proprietary technology to replace part <strong>of</strong> the<br />

carboxyl acid groups in the polyol by sulfonate-functional<br />

groups. The advantage <strong>of</strong> the sulfonate functionality is the<br />

fact that these acid groups are neutralized with an inorganic<br />

base that has no unfavourable catalytic action. As a result the<br />

curing <strong>of</strong> the WB2K coating become more controllable and

the flow and levelling properties are positively influenced. Also<br />

the risk <strong>of</strong> CO2 bubbles getting trapped in the drying coating<br />

is reduced. In Table 1 the main properties <strong>of</strong> the waterborne<br />

acrylic polyol used in this study are given.<br />

Table 1. Resin properties.<br />

Hydroxyl value 4.2 % OH<br />

Solids content 47 %<br />

pH 8<br />

Acid value (on solids) 16 mg KOH g mixed<br />

carboxylic and sulfonic<br />

Particle size ± 100 nm<br />

Co-solvent Butyl glycol (approx. 2 %)<br />

Rheology <strong>of</strong> hand applied WB2K coatings<br />

The paint rheology is one <strong>of</strong> the most important parameters<br />

for brush or roller application. When comparing the flow-curve<br />

<strong>of</strong> a conventional solvent-borne 2K paint formulated for hand<br />

application (VOC <strong>of</strong> ± 500 g/l) with that <strong>of</strong> a WB2K system, the<br />

initial flow curves immediately after mixing are quite different<br />

(figure 1).<br />

Figure 1. Flow curve <strong>of</strong> SB 2K and WB 2K paints.<br />

The flow curves also change in a different way as a function <strong>of</strong><br />

the time after mixing (graph 2).<br />

Figure 2. Changes in rheology during the pot-life <strong>of</strong> WB and SB 2K<br />

formulations.<br />

At high shear the viscosity <strong>of</strong> WB2K paint is much lower,<br />

resulting in an initial brush resistance that is far too low.<br />

Furthermore the viscosity decreases during the pot-life, so<br />

application properties become worse after mixing <strong>of</strong> the paint.<br />

Under low shear on the other side, the viscosity is much higher,<br />

with relatively poor flow as a consequence. Because <strong>of</strong> this<br />

rheological behaviour defoaming <strong>of</strong> the paint after application<br />

also becomes difficult.<br />

In order to adjust the rheological behaviour <strong>of</strong> the WB2K paint<br />

a high shear a polyurethane thickener is used to increase<br />

the ICI viscosity to a level <strong>of</strong> 1.6 Poise, similar to that <strong>of</strong><br />

the solventborne paint. By adding the thickener the solids<br />

content <strong>of</strong> the paint could be lowered in order to reduce the<br />

low shear viscosity. This results in adequate brush resistance<br />

in combination with acceptable levelling, flow and defoaming<br />

properties. Most waterborne two pack systems still require the<br />

use <strong>of</strong> some co-solvent and the influence on the rheological<br />

pr<strong>of</strong>ile needs to be taken into account. With this specific polyol<br />

it was found that a mixture <strong>of</strong> butyl acetate, dipropylene glycol<br />

dimethyl ether and butyldiglycol acetate <strong>of</strong>fered the best<br />

results regarding the balance between gloss and levelling. The<br />

flow-curves as function <strong>of</strong> time after mixing for the adjusted<br />

formulation are given in figure 3.<br />

Figure 3. Time dependant flow-curves <strong>of</strong> adjusted formulations.<br />

Formulation parameters for clear and<br />

pigmented coatings<br />

A basic formulation for a hand applied WB2K formulation (both<br />

pigmented and clear) is given in Table 2. The white mill base<br />

used in the pigmented formulation was prepared by dispersing<br />

in a pearl mill 20.12 parts <strong>of</strong> titanium dioxide with 1.03 grams<br />

<strong>of</strong> a dispersant, 0.16 grams <strong>of</strong> thickener and 5.8 grams <strong>of</strong><br />

demineralized water until a Hegmann fineness <strong>of</strong> less than 10<br />

microns was obtained.<br />

During this work it was found that proper selection <strong>of</strong> the high<br />

shear thickener and defoamer is essential to formulate a paint<br />

with a good balance <strong>of</strong> aesthetical and performance properties.<br />

How to achieve proper defoaming<br />

When formulating without a defoamer, the paint, after brush<br />

or roller application will contain at lot <strong>of</strong> foam. After drying<br />

<strong>of</strong> the paint this will result in surface defects such as pinholes<br />

and foam. The selection <strong>of</strong> a defoamer however is<br />

not straight forward as it should ensure proper defoaming<br />

during application without affecting gloss, flow and levelling.<br />

Preferably the defoamer should be easily introduced into the<br />

base without excessive shear.<br />

SURFACE COATINGS ASSOCIATION OF NEW ZEALAND 13

Table 2. WB2K formulations.<br />

Component Raw material Weight<br />

Clear varnish White paint<br />

Polyol<br />

emulsion<br />