Brushstrokes - October 2011 - Surface Coatings Association of New ...

Brushstrokes - October 2011 - Surface Coatings Association of New ...

Brushstrokes - October 2011 - Surface Coatings Association of New ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Table 1 – interior wall paint formulation<br />

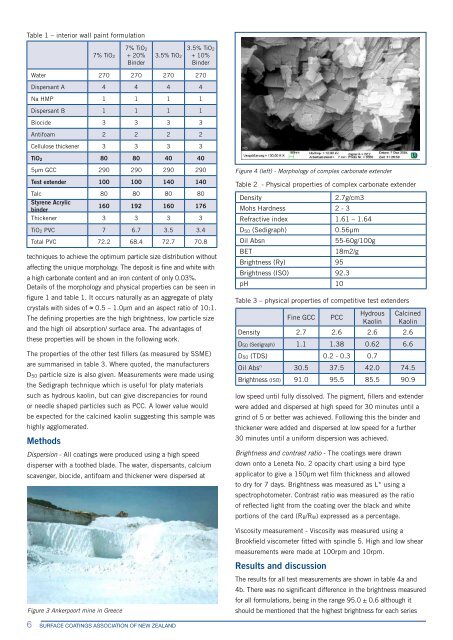

techniques to achieve the optimum particle size distribution without<br />

affecting the unique morphology. The deposit is fine and white with<br />

a high carbonate content and an iron content <strong>of</strong> only 0.03%.<br />

Details <strong>of</strong> the morphology and physical properties can be seen in<br />

figure 1 and table 1. It occurs naturally as an aggregate <strong>of</strong> platy<br />

crystals with sides <strong>of</strong> ≈ 0.5 – 1.0µm and an aspect ratio <strong>of</strong> 10:1.<br />

The defining properties are the high brightness, low particle size<br />

and the high oil absorption/ surface area. The advantages <strong>of</strong><br />

these properties will be shown in the following work.<br />

The properties <strong>of</strong> the other test fillers (as measured by SSME)<br />

are summarised in table 3. Where quoted, the manufacturers<br />

D50 particle size is also given. Measurements were made using<br />

the Sedigraph technique which is useful for platy materials<br />

such as hydrous kaolin, but can give discrepancies for round<br />

or needle shaped particles such as PCC. A lower value would<br />

be expected for the calcined kaolin suggesting this sample was<br />

highly agglomerated.<br />

Methods<br />

7% TiO2<br />

7% TiO2<br />

+ 20%<br />

Binder<br />

3.5% TiO2<br />

Dispersion - All coatings were produced using a high speed<br />

disperser with a toothed blade. The water, dispersants, calcium<br />

scavenger, biocide, antifoam and thickener were dispersed at<br />

6 SURFACE COATINGS ASSOCIATION OF NEW ZEALAND<br />

3.5% TiO2<br />

+ 10%<br />

Binder<br />

Water 270 270 270 270<br />

Dispersant A 4 4 4 4<br />

Na HMP 1 1 1 1<br />

Dispersant B 1 1 1 1<br />

Biocide 3 3 3 3<br />

Antifoam 2 2 2 2<br />

Cellulose thickener 3 3 3 3<br />

TiO2 80 80 40 40<br />

5µm GCC 290 290 290 290<br />

Test extender 100 100 140 140<br />

Talc 80 80 80 80<br />

Styrene Acrylic<br />

binder<br />

160 192 160 176<br />

Thickener 3 3 3 3<br />

TiO2 PVC 7 6.7 3.5 3.4<br />

Total PVC 72.2 68.4 72.7 70.8<br />

Figure 3 Ankerpoort mine in Greece<br />

Figure 4 (left) - Morphology <strong>of</strong> complex carbonate extender<br />

Table 2 - Physical properties <strong>of</strong> complex carbonate extender<br />

Density 2.7g/cm3<br />

Mohs Hardness 2 - 3<br />

Refractive index 1.61 – 1.64<br />

D50 (Sedigraph) 0.56µm<br />

Oil Absn 55-60g/100g<br />

BET 18m2/g<br />

Brightness (Ry) 95<br />

Brightness (ISO) 92.3<br />

pH 10<br />

Table 3 – physical properties <strong>of</strong> competitive test extenders<br />

Fine GCC PCC<br />

low speed until fully dissolved. The pigment, fillers and extender<br />

were added and dispersed at high speed for 30 minutes until a<br />

grind <strong>of</strong> 5 or better was achieved. Following this the binder and<br />

thickener were added and dispersed at low speed for a further<br />

30 minutes until a uniform dispersion was achieved.<br />

Brightness and contrast ratio - The coatings were drawn<br />

down onto a Leneta No. 2 opacity chart using a bird type<br />

applicator to give a 150µm wet film thickness and allowed<br />

to dry for 7 days. Brightness was measured as L* using a<br />

spectrophotometer. Contrast ratio was measured as the ratio<br />

<strong>of</strong> reflected light from the coating over the black and white<br />

portions <strong>of</strong> the card (RB/RW) expressed as a percentage.<br />

Viscosity measurement - Viscosity was measured using a<br />

Brookfield viscometer fitted with spindle 5. High and low shear<br />

measurements were made at 100rpm and 10rpm.<br />

Results and discussion<br />

Hydrous<br />

Kaolin<br />

Calcined<br />

Kaolin<br />

Density 2.7 2.6 2.6 2.6<br />

D50 (Sedigraph) 1.1 1.38 0.62 6.6<br />

D50 (TDS) 0.2 - 0.3 0.7<br />

Oil Absn 30.5 37.5 42.0 74.5<br />

Brightness (ISO) 91.0 95.5 85.5 90.9<br />

The results for all test measurements are shown in table 4a and<br />

4b. There was no significant difference in the brightness measured<br />

for all formulations, being in the range 95.0 ± 0.6 although it<br />

should be mentioned that the highest brightness for each series