Brushstrokes - October 2011 - Surface Coatings Association of New ...

Brushstrokes - October 2011 - Surface Coatings Association of New ...

Brushstrokes - October 2011 - Surface Coatings Association of New ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Table 2. WB2K formulations.<br />

Component Raw material Weight<br />

Clear varnish White paint<br />

Polyol<br />

emulsion<br />

51.41 36.37<br />

Wetting<br />

additives<br />

0.52 0.36<br />

Base<br />

High shear<br />

thickener<br />

2.70 1.91<br />

Defoamer variable variable<br />

Hardener<br />

Diluents<br />

Properties<br />

Demineralized<br />

water<br />

13.73 11.86<br />

Mill base<br />

HDI/IPDI<br />

- 27.11<br />

based<br />

hydrophilic<br />

isocyanate<br />

HDI based<br />

9.85 6.97<br />

hydrophilic<br />

isocyanate<br />

8.66 6.12<br />

Co-solvents* 5.82 4.12<br />

Demineralized<br />

water<br />

7.31 5.18<br />

Density (kg/l) 1.04 1.22<br />

Volume solids<br />

(%)<br />

38.9 38.9<br />

Weight solids<br />

(%)<br />

42.3 50.5<br />

VOC ready to<br />

use (g/l)<br />

87 73<br />

NCO/OH ratio 1.25 1.25<br />

* co-solvent mixture consisting <strong>of</strong> butyl acetate:dipropylene glycol<br />

dimethyl ether:butyldiglycol acetate in a ratio <strong>of</strong> 13/74/13.<br />

In the base for the clear varnish formulation given in table 2,<br />

a number <strong>of</strong> different defoamer types were added at different<br />

concentration levels.<br />

All varnish samples were subjected to a foam test that is<br />

carried out as follows: the coating is applied with a pipette to<br />

the white part <strong>of</strong> a black-white paper contrast chart. After that,<br />

Table 3. Results for the foam test in a clear varnish.<br />

14 SURFACE COATINGS ASSOCIATION OF NEW ZEALAND<br />

coating is applied to half <strong>of</strong> the black part <strong>of</strong> the chart using a<br />

brush. The varnish on the white chart is stipulated intensively<br />

with the brush to incorporate a lot <strong>of</strong> air. This varnish is then<br />

brushed over the second half <strong>of</strong> the black part <strong>of</strong> the chart. The<br />

amount <strong>of</strong> foam in the two black parts <strong>of</strong> the chart is judged<br />

after drying overnight according to a scale <strong>of</strong> one (bad) to five<br />

(good). Also the clarity <strong>of</strong> the varnish applied onto glass was<br />

judged after drying. The results are given in table 3.<br />

In the foaming test the defoamers based on a mixture <strong>of</strong><br />

hydrophobic solids and polysiloxanes and the polyether siloxane<br />

defoamer perform well both at high and low addition levels.<br />

However the first type does introduce a strong orange peel<br />

effect in the dried film, even at low concentrations. Also this<br />

defoamer has a negative influence on the clarity <strong>of</strong> the film.<br />

The polyether siloxane defoamer also introduces a slight orange<br />

peel effect, but at low concentrations this is judged to be<br />

acceptable. The defoamer based on the mixture <strong>of</strong> polymers<br />

and hydrophobic solids is somewhat less effective but has<br />

no effect on gloss and haze. At the lower addition level, no<br />

negative effect on the leveling properties was observed.<br />

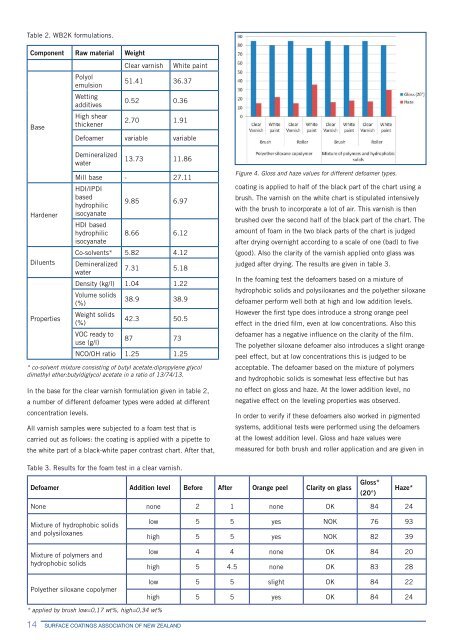

In order to verify if these defoamers also worked in pigmented<br />

systems, additional tests were performed using the defoamers<br />

at the lowest addition level. Gloss and haze values were<br />

measured for both brush and roller application and are given in<br />

Defoamer Addition level Before After Orange peel Clarity on glass Gloss*<br />

(20°)<br />

None none 2 1 none OK 84 24<br />

Mixture <strong>of</strong> hydrophobic solids<br />

and polysiloxanes<br />

Mixture <strong>of</strong> polymers and<br />

hydrophobic solids<br />

Polyether siloxane copolymer<br />

* applied by brush low=0,17 wt%, high=0,34 wt%<br />

Figure 4. Gloss and haze values for different defoamer types.<br />

Haze*<br />

low 5 5 yes NOK 76 93<br />

high 5 5 yes NOK 82 39<br />

low 4 4 none OK 84 20<br />

high 5 4.5 none OK 83 28<br />

low 5 5 slight OK 84 22<br />

high 5 5 yes OK 84 24