Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

iom<strong>as</strong>s design best practice<br />

26<br />

What happens if that water supply is from<br />

a cold-water boost set? Water in a break<br />

tank can run out. The emergency cooling<br />

water supply must be testable for flow, and<br />

monitored for supply pressure by the BMS.<br />

Effective control of biom<strong>as</strong>s boilers<br />

Biom<strong>as</strong>s boilers are far more complex<br />

to control effectively. Biom<strong>as</strong>s systems<br />

must be designed to take account of the<br />

complete system operation, recognising<br />

that biom<strong>as</strong>s boilers produce heat for<br />

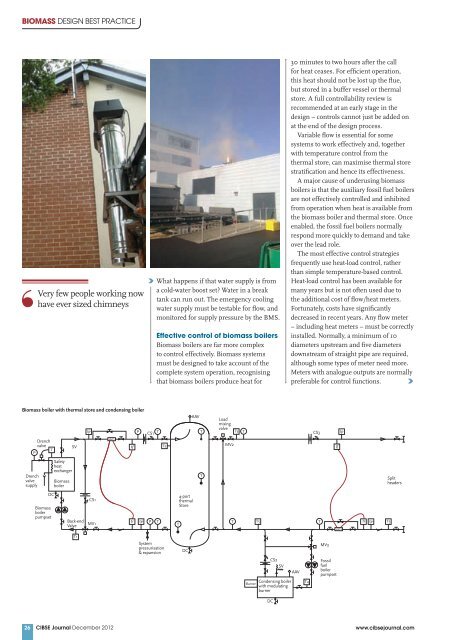

Biom<strong>as</strong>s boiler with thermal store and condensing boiler<br />

AAV<br />

Load<br />

mixing<br />

tp P<br />

CS1<br />

T<br />

T<br />

valve<br />

T3 T<br />

CS3 tp<br />

Drench<br />

valve<br />

T<br />

P<br />

SV<br />

HM 1<br />

tf<br />

T2<br />

MV2<br />

tf<br />

Drench<br />

valve<br />

supply<br />

Very few people working now<br />

have ever sized chimneys<br />

DC<br />

Biom<strong>as</strong>s<br />

boiler<br />

pumpset<br />

Safety<br />

heat<br />

exchanger<br />

Biom<strong>as</strong>s<br />

boiler<br />

Back-end<br />

Valve<br />

T1<br />

CS1<br />

MV1<br />

tr<br />

4-port<br />

thermal<br />

Store<br />

tp P T T<br />

T5<br />

T<br />

System<br />

pressurisation<br />

& expansion<br />

DC<br />

T<br />

Condensing boiler<br />

with modulating<br />

burner<br />

30 minutes to two hours after the call<br />

for heat ce<strong>as</strong>es. For efficient operation,<br />

this heat should not be lost up the flue,<br />

but stored in a buffer vessel or thermal<br />

store. A full controllability review is<br />

recommended at an early stage in the<br />

design – controls cannot just be added on<br />

at the end of the design process.<br />

Variable flow is essential for some<br />

systems to work effectively and, together<br />

with temperature control from the<br />

thermal store, can maximise thermal store<br />

stratification and hence its effectiveness.<br />

A major cause of underusing biom<strong>as</strong>s<br />

boilers is that the auxiliary fossil fuel boilers<br />

are not effectively controlled and inhibited<br />

from operation when heat is available from<br />

the biom<strong>as</strong>s boiler and thermal store. Once<br />

enabled, the fossil fuel boilers normally<br />

respond more quickly to demand and take<br />

over the lead role.<br />

The most effective control strategies<br />

frequently use heat-load control, rather<br />

than simple temperature-b<strong>as</strong>ed control.<br />

Heat-load control h<strong>as</strong> been available for<br />

many years but is not often used due to<br />

the additional cost of flow/heat meters.<br />

Fortunately, costs have significantly<br />

decre<strong>as</strong>ed in recent years. Any flow meter<br />

– including heat meters – must be correctly<br />

installed. Normally, a minimum of 10<br />

diameters upstream and five diameters<br />

downstream of straight pipe are required,<br />

although some types of meter need more.<br />

Meters with analogue outputs are normally<br />

preferable for control functions.<br />

<strong>CIBSE</strong> <strong>Journal</strong> December 2012 www.cibsejournal.com<br />

Burner<br />

DC<br />

CS2<br />

SV<br />

AAV<br />

T4<br />

T<br />

MV3<br />

Fossil<br />

fuel<br />

boiler<br />

pumpset<br />

HM 2<br />

Tr tp T5<br />

Split<br />

headers