New Dynapac SD pavers for Dezhou ring road

New Dynapac SD pavers for Dezhou ring road

New Dynapac SD pavers for Dezhou ring road

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>New</strong> <strong>Dynapac</strong> <strong>SD</strong> <strong>pavers</strong> <strong>for</strong> <strong>Dezhou</strong> <strong>ring</strong> <strong>road</strong><br />

<strong>Dezhou</strong> City gets new <strong>ring</strong> <strong>road</strong><br />

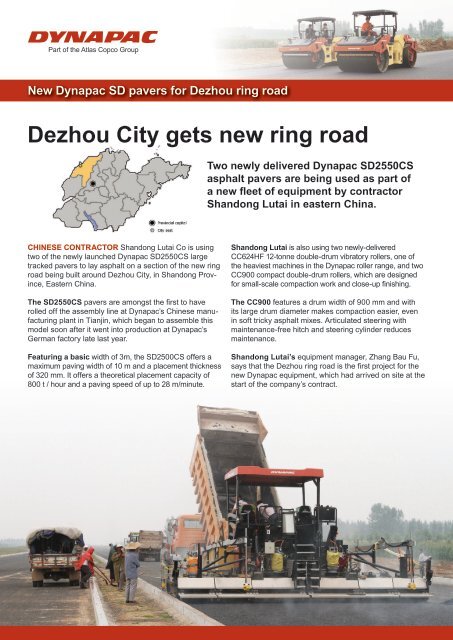

CHINESE CONTRACTOR Shandong Lutai Co is using<br />

two of the newly launched <strong>Dynapac</strong> <strong>SD</strong>2550CS large<br />

tracked <strong>pavers</strong> to lay asphalt on a section of the new <strong>ring</strong><br />

<strong>road</strong> being built around <strong>Dezhou</strong> City, in Shandong Province,<br />

Eastern China.<br />

The <strong>SD</strong>2550CS <strong>pavers</strong> are amongst the first to have<br />

rolled off the assembly line at <strong>Dynapac</strong>’s Chinese manufactu<strong>ring</strong><br />

plant in Tianjin, which began to assemble this<br />

model soon after it went into production at <strong>Dynapac</strong>’s<br />

German factory late last year.<br />

Featu<strong>ring</strong> a basic width of 3m, the <strong>SD</strong>2500CS offers a<br />

maximum paving width of 10 m and a placement thickness<br />

of 320 mm. It offers a theoretical placement capacity of<br />

800 t / hour and a paving speed of up to 28 m/minute.<br />

Two newly delivered <strong>Dynapac</strong> <strong>SD</strong>2550CS<br />

asphalt <strong>pavers</strong> are being used as part of<br />

a new fleet of equipment by contractor<br />

Shandong Lutai in eastern China.<br />

Shandong Lutai is also using two newly-delivered<br />

CC624HF 12-tonne double-drum vibratory rollers, one of<br />

the heaviest machines in the <strong>Dynapac</strong> roller range, and two<br />

CC900 compact double-drum rollers, which are designed<br />

<strong>for</strong> small-scale compaction work and close-up finishing.<br />

The CC900 features a drum width of 900 mm and with<br />

its large drum diameter makes compaction easier, even<br />

in soft tricky asphalt mixes. Articulated stee<strong>ring</strong> with<br />

maintenance-free hitch and stee<strong>ring</strong> cylinder reduces<br />

maintenance.<br />

Shandong Lutai’s equipment manager, Zhang Bau Fu,<br />

says that the <strong>Dezhou</strong> <strong>ring</strong> <strong>road</strong> is the first project <strong>for</strong> the<br />

new <strong>Dynapac</strong> equipment, which had arrived on site at the<br />

start of the company’s contract.

<strong>New</strong> <strong>Dynapac</strong> <strong>SD</strong> <strong>pavers</strong> <strong>for</strong> <strong>Dezhou</strong> <strong>ring</strong> <strong>road</strong><br />

Zhang Bau Fu, Equipment<br />

Manager, Shandong Lutai.<br />

“We have used <strong>Dynapac</strong><br />

equipment be<strong>for</strong>e,<br />

but it was always on<br />

a rental basis,” he<br />

says. “There is a large<br />

amount of infrastructural<br />

work underway and<br />

planned in Shandong,<br />

and so we decided to<br />

invest in the equipment<br />

as a strategic expansion<br />

of our own fleet.”<br />

<strong>Dezhou</strong> is a fast-growing city that bases much of its<br />

economy on the development and manufacture of cleanenergy<br />

technology and products. One of its main activities<br />

is the development of solar energy equipment, and<br />

<strong>Dezhou</strong> raised its international profile in this sector when<br />

it hosted the International Solar City Congress in 2010.<br />

Mr Zhang says that the <strong>ring</strong> <strong>road</strong> has been split into<br />

several different packages, and that Shandong Lutai is<br />

responsible <strong>for</strong> the asphalt laying on a 10 km stretch, with<br />

two carriageways, each of 14.75 m width.<br />

The asphalt layer consists of two courses, a base<br />

course that is 8 cm thick, and a wea<strong>ring</strong> course of 6 cm.<br />

“Working the <strong>pavers</strong> side by side, and<br />

following up directly with the compactors<br />

allows us to maintain a tight site and<br />

proceed at a uni<strong>for</strong>m pace.”<br />

Both <strong>SD</strong>2550CS <strong>pavers</strong> are being used side-by-side on<br />

the carriageway, each working at a width of about 7 m - so<br />

that between them with one sweep they cover the entire<br />

width up to the concrete barriers on either side of the <strong>road</strong>.<br />

“We have a tight deadline of just two months to complete<br />

this project,” says Mr Zhang. “Working the <strong>pavers</strong> side by<br />

side, and following up directly with the compactors allows<br />

us to maintain a tight site and proceed at a uni<strong>for</strong>m pace.<br />

“There is also the fact that this time of year sees a great<br />

deal of rain, and if we work to a pattern like this, where a<br />

section of the <strong>road</strong> is totally completed at one shift, then<br />

we are helping our logistics and planning even if our work<br />

cycle is broken because of a downpour.”<br />

Mr Zhang says that with the machines having only just<br />

begun on site, it is not yet possible to provide an accurate<br />

figure on progress but that 1000 m per machine per day<br />

would be a realistic average <strong>for</strong> this time of the year.<br />

He says that the base course requires two passes of the<br />

CC624HF compactors, followed by a further two passes<br />

on the wea<strong>ring</strong> course, with the same number of passes<br />

by two small CC900 compactors, with one working on<br />

either side of the carriageway and compacting hard up<br />

against the concrete kerb.