Technical Specifications - Gammex RMI

Technical Specifications - Gammex RMI

Technical Specifications - Gammex RMI

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

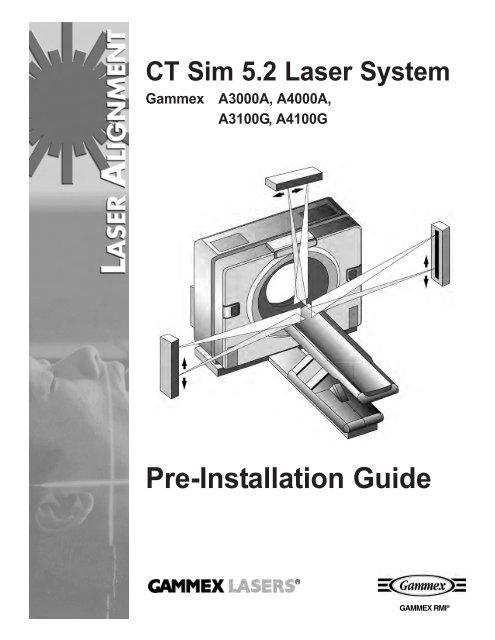

CT Sim 5.2 Laser System<br />

<strong>Gammex</strong> A3000A, A4000A,<br />

A3100G, A4100G<br />

Pre-Installation Guide<br />

GAMMEX <strong>RMI</strong> ®

Table of Contents<br />

1. Introduction...................................................................................... 1<br />

2. Installation Planning Considerations.............................................. 1<br />

3. Room Preparation .......................................................................... 2<br />

4. Considerations for Angled Walls .................................................... 4<br />

5. Electrical and Network Requirements ............................................ 5<br />

6. <strong>Technical</strong> <strong>Specifications</strong> - Red Laser Systems .............................. 7<br />

7. <strong>Technical</strong> <strong>Specifications</strong> - Green Laser Systems ........................... 8<br />

8. <strong>Technical</strong> Assistance and Warranty Information ............................. 9<br />

HARDWARE REQUIREMENTS<br />

The CT Sim 5.2 software has been validated using the computer<br />

and flat screen monitor normally provided with the system. If<br />

<strong>Gammex</strong> supplied computer and monitor are not used, <strong>Gammex</strong><br />

cannot guaantee the functionality and performance of the CT Sim<br />

5.2 Software.<br />

If the computer <strong>Gammex</strong> normally supplied is not used, the<br />

following minimum requirements must be met:<br />

Minimum Requirements, non-<strong>Gammex</strong> supplied Computer<br />

Microsoft Windows 2000 operating system<br />

Intel Pentium-based 1 GHz microprocessor<br />

1 GB free hard drive space<br />

128 MB RAM<br />

Network Interface card 10/100<br />

CD-ROM Drive<br />

256 color 800 x 600 display adapter<br />

2 Serial/Com Ports<br />

It is very important that only the operating system and the<br />

<strong>Gammex</strong> 5.2 Software is installed on the computer. <strong>Gammex</strong><br />

recommends Dell computers. The functionality and performance of<br />

any system not using the computer normally supplied by <strong>Gammex</strong><br />

must be verified by the assembler of the system.

1. Introduction<br />

PRODUCT DESCRIPTION<br />

The <strong>Gammex</strong> CT Sim Laser System consists of one to several<br />

moveable crosshair lasers (the actual number of lasers depends<br />

upon the laser system), a handheld pendant keypad, a power/control<br />

box, and a PC controller, which are operated by the CT Sim 5.2<br />

software. These lasers define the planes in the CT Simulator room.<br />

A calibration phantom is also included.<br />

A3000A System<br />

This red laser system consists of a moveable ceiling laser,<br />

defining the X plane, and two moveable side wall-mounted lasers,<br />

defining the Z plane.<br />

A4000A System<br />

This red laser system consists of a moveable ceiling laser,<br />

defining the X plane, and two side wall-mounted fixed lasers.<br />

A3100G System<br />

This green laser system consists of a moveable ceiling laser,<br />

defining the X plane, and two moveable side wall-mounted lasers,<br />

defining the Z plane.<br />

A4100G System<br />

This green laser system consists of a moveable ceiling laser,<br />

defining the X plane, and two side wall-mounted fixed lasers.<br />

2. Installation Planning Considerations<br />

<strong>Gammex</strong> laser alignment systems provide an accurate, repeatable<br />

optical aid for patient positioning. Proper room preparation ensures<br />

precision, maximizes the alignment accuracy and expedites the<br />

installation.<br />

This pre-installation guide presents the preferred methods for stable<br />

mounting of <strong>Gammex</strong> laser alignment systems. These techniques<br />

should be used for all new construction and can be used with existing<br />

rooms. With new construction, it is essential that these requirements<br />

are incorporated into the room plans as early as possible. For<br />

existing rooms where optimal methods cannot be used, alternate<br />

methods are described. All of the procedures focus on providing<br />

stability for the laser system, since even a slight motion or shift can<br />

degrade performance.<br />

Additional technical support is available from <strong>Gammex</strong> <strong>RMI</strong> Service<br />

Representatives, who are available to work with facility planners,<br />

architects and hospital personnel throughout the planning and<br />

installation process. <strong>Gammex</strong> <strong>RMI</strong> can be contacted at 1-800-232-<br />

9699 or 1-608-828-7000.<br />

NOTE: These lasers allow for direct mounting on angled<br />

walls without the use of unsightly and potentially unstable<br />

wall brackets. In cases where the walls are not accessible we<br />

offer stable laser stanchion systems to meet every need.<br />

Installation Planning Considerations<br />

Pre-Installation Guide<br />

1

CT Sim Laser Alignment Systems<br />

3. Room Preparation<br />

The primary concern for laser accuracy is stability. If stability is<br />

compromised, it will result in inferior performance. In all cases, it is<br />

important that the mounting surfaces are flat. Concrete subwalls<br />

provide the optimum mounting surface. However, this is not available<br />

in most CT rooms. Adding an aluminum/steel plate is needed in most<br />

cases.<br />

If architectural drawings are available use them to determine the<br />

isocenter and plate location.<br />

For drop ceilings, please do not install the ceiling tiles until installation<br />

is complete. Ceiling tile support runners should not cross over or<br />

obstruct the laser. A minimum of four inches clearance is needed for<br />

cover removal.<br />

MOUNTING TO CONCRETE<br />

No aluminum or steel plate is needed. The minimum space required<br />

is 54 x 15 in. (137 x 38 cm) (H, W) of bare concrete. The center of<br />

the concrete space should be placed at CT isocenter height, 600 mm in<br />

front of the CT scan plane. See figures 1 and 2. Use the mounting<br />

hardware provided.<br />

MOUNTING TO UNISTRUT<br />

A steel, or preferably aluminum mounting plate, is required with<br />

minimum dimensions of 54 x 20 x 3/8 in. (137 x 50.8 x 0.95 cm)<br />

(H,W,D). The plate thickness should not exceed 5/8 inch (1.6 cm).<br />

The center of the mounting plate should be placed at CT isocenter<br />

height, 600 mm in front of the CT scan plane. See figures 1 and 2.<br />

MOUNTING TO EXISTING WALLS<br />

An aluminum mounting plate of sufficient width to span three studs is<br />

required (minimum 20 in.) A steel plate may be substituted with wood<br />

stud construction, but should not be used with metal studs. The plate<br />

should have minimum dimensions of 54" high by 3/8" thick (137 x<br />

0.95). Thickness should not exceed 1/2 in. (1.27 cm). The center of<br />

the plate should be placed at CT isocenter height, 600 mm in front of<br />

the CT scan plane (See figures 1 and 2). Use 3 3/4 in. Number 12<br />

hardened steel deck screws to mount the aluminum plate to the wall<br />

studs (see the deck screw mounting configuration at right).<br />

NOTE: A solid mounting to the studs is required. Mounting<br />

plates must not be attached directly to drywall. Do NOT cover<br />

the plates with drywall after installation.<br />

The wall mounting location must be level to provide a planar surface<br />

for the laser and to allow the laser beams to project perpendicularly to<br />

the isocenter height but located 600 mm out of the scan plane. In<br />

some cases a stand off bracket may be required for the ceiling laser.<br />

This plate can be mounted 3.5 in. (8.9 cm) above the finished ceiling<br />

for flush mount lasers. If room is not available above the ceiling, the<br />

plate can be mounted flush with the ceiling or just below.<br />

NOTE: Walls at an angle to the CT scan plane require special<br />

consideration. Please see Figure 2 and Page 4.<br />

2<br />

Room Preparation<br />

Metal Plate<br />

Wall Studs<br />

Deck Screw Mounting<br />

Configuration<br />

54"

Control Room<br />

Control Room<br />

Mounting Plate<br />

Ceiling Plate<br />

String or<br />

Laser line<br />

Mounting Plate<br />

600 mm<br />

Figure 1: Side Wall Installation<br />

Mounting Plate<br />

Plate Shift Direction<br />

Ceiling Plate<br />

Plate Shift Direction<br />

Mounting Plate<br />

String or<br />

Laser line<br />

Figure 2: Angled Wall Installation<br />

Room Preparation<br />

Pre-Installation Guide<br />

Isocenter<br />

Isocenter<br />

600 mm<br />

3

CT Sim Laser Alignment Systems<br />

4. Considerations for Angled Walls<br />

The chart below is to help determine the plate shift needed so that<br />

the mounting plate will be centered properly. Plate shifts should<br />

always be towards the smaller angle. See figure 2 on page 3 and<br />

figure 3 on this page.<br />

Walls angled 80-90° will not need a plate shift<br />

Walls angled 75° will need a 1 /2" plate shift<br />

Walls angled 70° will need a 1" plate shift<br />

Walls angled 65° will need a 11 /4" plate shift<br />

Walls angled 60° will need a 111 /16" plate shift<br />

Walls angled 55° will need a 2" plate shift<br />

Walls angled 50° will need a 21 /2" plate shift<br />

Walls angled 45° will need a 3" plate shift<br />

Figure 3: This<br />

illustration shows how<br />

to determine the offset<br />

needed for mounting<br />

templates on angled<br />

walls. Place a protractor<br />

or similar device where<br />

the string or laser line<br />

contacts the wall to<br />

measure the wall’s angle<br />

to the scan plane.<br />

4<br />

Couch<br />

Mounting Plate<br />

String or<br />

Laser Line<br />

Considerations for Angled Walls<br />

600 mm<br />

Direction of Offset<br />

CT<br />

Scan<br />

Plane<br />

Isocenter<br />

Mounting Plate

Electrical and Network Requirements<br />

Pre-Installation Guide<br />

5. Electrical and Network Requirements<br />

Note: There should not be ground potential differences<br />

between the PC ground and the controller box ground.<br />

If so, equipotential grounding or additional protective<br />

grounding must be provided.<br />

A separate, 1 inch minimum metal conduit, raceway or equivalent<br />

should be placed between the three lasers and the control room<br />

where the computer will be located. Three separate 110/220 volt<br />

outlets will be needed to power the computer, monitor and controller<br />

box in the control room. See Figure 4<br />

An IP address/default gateway and sub net mask should be<br />

available to <strong>Gammex</strong> at the time of Installation.<br />

A live network connection along with network cable should be<br />

provided.<br />

The system can be wired as a branch or series circuit.<br />

See Figure 5 on page 6<br />

Figure 4: Conduit Wiring Diagram<br />

Junction Boxes for Z1 and Z2<br />

should be at the bottom or bottom<br />

left of the laser. For the X laser,<br />

mount the junction box on the left<br />

when viewed from the foot of the<br />

treatment couch.<br />

5

CT CT Sim Sim Laser Laser Alignment Alignment Systems Systems<br />

6<br />

Figure 5: CT Sim Wiring Diagrams<br />

Electrical and Network Requirements

<strong>Technical</strong> <strong>Specifications</strong> - Red<br />

Installation Guide<br />

6. <strong>Technical</strong> <strong>Specifications</strong><br />

A3000A and A4000A Red Laser Systems<br />

POWER REQUIREMENTS<br />

Laser Unit (Moving Laser, Power Module Input)<br />

Voltage: .............. 100-240 V~(auto-select)<br />

Current:............... 4.5A Max<br />

Frequency:.......... 60/50 Hz<br />

Laser Unit (Probe+ - A4000A only)<br />

Voltage: .............. 12 VDC<br />

Current:............... 300 mA<br />

Power: ................ 3.6 W<br />

LASER SPECIFICATIONS<br />

Less than 1.0 mW (each beam) Laser Class II<br />

Wavelength:........ 6350 Å (635nm) visible red<br />

ENVIRONMENTAL (SHIPPING AND STORAGE CONDITIONS)<br />

Temperature:<br />

Systems should be stored and shipped<br />

between -20°C to 70°C (-4°F and 150° F).<br />

Humidity:<br />

The operating and non-operating relative humidity<br />

(non-condensing) range is 10% and 95%.<br />

PHYSICAL DIMENSIONS<br />

Laser Unit (Moving Lasers): ..................... 117 x 21 x 9 cm (HWD)<br />

Laser Unit (Probe+; A4000A only): .......... 17.3 x 14 x 8 cm (HWD)<br />

Power Module: ......................................... 42 x 21 x 9 cm (HWD)<br />

WEIGHT<br />

Laser Unit (Moving Lasers): ..................... 11.6 kg<br />

Laser Unit (Probe+; A4000A only): .......... 1.8 kg<br />

Power Module: ......................................... 3.3 kg<br />

Communications: ...................................... Two RS-232 port<br />

DISPOSAL<br />

These units should be disposed of according to national<br />

laws and regulations. Recycle components as required.<br />

EMC INFLUENCES<br />

These units were tested under the IEC 601-1-2 standard and<br />

they should not be adversely affected by other outside influences.<br />

LEAKAGE REQUIREMENTS<br />

The personal computer (PC) must be plugged into a different and<br />

properly grounded branch circuit other than the power supply module<br />

for the lasers. This prevents the possibility of leakage currents in the<br />

event of a fault in the protective earth connection.<br />

7

CT Sim Laser Alignment Systems<br />

7. <strong>Technical</strong> <strong>Specifications</strong><br />

A3100G and A4100G Green Laser Systems<br />

POWER REQUIREMENTS<br />

Laser Unit (Moving Laser, Power Module Input)<br />

Voltage: .............. 100-240 V~(auto-select)<br />

Current:............... 3.0A Max<br />

Frequency:.......... 60/50 Hz<br />

Laser Unit (ProbeG - A4100G only)<br />

Voltage: .............. 100-240 VAC<br />

Current:............... 0.4 A<br />

Frequency:.......... 60/50 Hz<br />

LASER SPECIFICATIONS<br />

Less than 1.0 mW (each beam) Laser Class II<br />

Wavelength:........ 5320 Å (532nm) visible green<br />

ENVIRONMENTAL (SHIPPING AND STORAGE CONDITIONS)<br />

Temperature:<br />

Systems should be stored and shipped<br />

between -20°C to 70°C (-4°F and 150° F).<br />

Humidity:<br />

The operating and non-operating relative humidity<br />

(non-condensing) range is 10% and 95%.<br />

PHYSICAL DIMENSIONS<br />

Laser Unit (Moving Lasers): ..................... 117 x 21 x 9 cm (HWD)<br />

Laser Unit (ProbeG; A4100G only): ......... 27 x 14 x 8 cm (HWD)<br />

Power Module: ......................................... 42 x 21 x 9 cm (HWD)<br />

WEIGHT<br />

Laser Unit (Moving Lasers): ..................... 9.5 kg<br />

Laser Unit (ProbeG; A4100G only): ......... 3.2 kg<br />

Power Module: ......................................... 3.3 kg<br />

Communications: ...................................... Two RS-232 port<br />

DISPOSAL<br />

These units should be disposed of according to national<br />

laws and regulations. Recycle components as required.<br />

EMC INFLUENCES<br />

These units were tested under the IEC 601-1-2 standard and<br />

they should not be adversely affected by other outside influences.<br />

LEAKAGE REQUIREMENTS<br />

The personal computer (PC) must be plugged into a different and<br />

properly grounded branch circuit other than the power supply module<br />

for the lasers. This prevents the possibility of leakage currents in the<br />

event of a fault in the protective earth connection.<br />

8<br />

<strong>Technical</strong> <strong>Specifications</strong> - Green

8. <strong>Technical</strong> Support<br />

<strong>Technical</strong> support is available from <strong>Gammex</strong> <strong>RMI</strong> Service<br />

Representatives who are available to work with facility planners,<br />

architects and hospital personnel throughout the planning and<br />

installation process. Contact the <strong>Gammex</strong> <strong>RMI</strong> Service<br />

department at 1-800-232-9699.<br />

Product Warranty<br />

<strong>Gammex</strong> Inc. warrants its patient positioning equipment to be free<br />

from defects in materials and workmanship under normal use and<br />

service for 1 year from the date of shipment. The sole obligation of<br />

<strong>Gammex</strong> Inc. under this warranty is to repair or replace without<br />

charge or to refund the purchase price, at the option of <strong>Gammex</strong> Inc.,<br />

of any parts which its examination shall have disclosed to be<br />

defective, provided that Buyer shall have given to <strong>Gammex</strong> Inc., a<br />

written notice of the claimed defect no later than 7 days after the end<br />

of the warranty period (one (1) year of the date of shipment of such<br />

equipment to Buyer). At the request of <strong>Gammex</strong> Inc., Buyer, at its<br />

expense, shall return the claimed defective part to <strong>Gammex</strong> Inc.<br />

THIS CLASS II LASER PRODUCT COMPLIES<br />

WITH DHHS REQUIREMENTS PURSUANT TO<br />

21 CFR, SUB-CHAPTER J.<br />

DISCLAIMER OF OTHER WARRANTIES<br />

Pre-Installation Installation Guide Guide<br />

The aforesaid warranty rights are buyer's exclusive remedies and are in lieu of any<br />

other remedies, obligations, or rights, including, without limitation, any other warranties,<br />

expressed or implied (e.g., implied warranties of merchantability or fitness for a<br />

particular purpose). Under no circumstances shall <strong>Gammex</strong> Inc. be liable for any<br />

incidental, indirect, special or consequential damages or for any other loss, damage,<br />

penalty or expense of any kind, including, without limitation, loss of profits or overhead,<br />

reimbursement, personal injury or property damage. The aforesaid warranty obligation<br />

of <strong>Gammex</strong> Inc. constitutes its sole liability, and under no circumstances, shall the<br />

maximum liability of <strong>Gammex</strong> Inc., under any legal theory(e.g., contract, warranty,<br />

negligence, promisory estoppel, strict liability, misrepresentation, tort) and for any<br />

reason whatsoever(e.g., defect, delay or otherwise) exceed the purchase price of the<br />

defective part regardless whether the claim is asserted by buyer or any other person or<br />

entity. The liabilities of <strong>Gammex</strong> Inc. as above set forth, shall not be extended because<br />

of advice given by it in connection with the design, installation or use of the equipment<br />

or parts therefore.<br />

<strong>Technical</strong> Support and Warranty Information<br />

9

CT Sim Laser Alignment Systems<br />

10<br />

Notes<br />

Notes

Notes<br />

Pre-Installation Guide<br />

Notes<br />

11

CT Sim Laser Alignment Systems<br />

About GAMMEX <strong>RMI</strong>…<br />

<strong>Gammex</strong> <strong>RMI</strong> has been a leader in the manufacture and distribution<br />

of Quality Control devices for medical imaging and radiation therapy,<br />

including laser alignment systems, for over 35 years. <strong>Gammex</strong> was<br />

incorporated in 1969 as a manufacturer of laser alignment devices<br />

for use in medical imaging and oncology treatment. The acquisition<br />

of <strong>RMI</strong> in 1987 gave the company the ability to expand into the<br />

manufacture of quality control equipment for ultrasound, diagnostic<br />

radiology and mammography.<br />

<strong>Gammex</strong> <strong>RMI</strong> research and development team has patented a<br />

number of devices over the years. These include numerous patents<br />

on laser technology, optical chains, kV detecting devices and<br />

diagnostic phantoms. There are over 25 patents issued to <strong>Gammex</strong><br />

<strong>RMI</strong>.<br />

<strong>Gammex</strong> <strong>RMI</strong> corporate headquarters are located in Middleton, WI<br />

with production facilities in that location as well is in Milwaukee, WI<br />

and Benicia, CA. European and other overseas markets are<br />

serviced by <strong>Gammex</strong> <strong>RMI</strong>, Ltd. in Nottingham, UK and <strong>Gammex</strong><br />

<strong>RMI</strong> GmbH in Bad Münstereifel, Germany.<br />

With extensive domestic and international experience, ISO-9001 and<br />

EN 4600 certified <strong>Gammex</strong> <strong>RMI</strong> continues to explore new realms of<br />

technology while keeping its focus on you and your patients.<br />

When there is little room for error, choose the wide range of<br />

<strong>Gammex</strong> <strong>RMI</strong> quality assurance products!<br />

12

Product Ordering Information<br />

and Customer Service<br />

<strong>Gammex</strong> is committed to satisfying our customers’ needs. If you have any<br />

questions, comments or suggestions regarding our products and service, please<br />

call or fax us. Please contact a GAMMEX dealer or representative for a<br />

quotation or for a detailed description of our ordering policies, warranties,<br />

delivery policy, conditions of sale, damaged goods policy, and returned goods<br />

policy.<br />

In the United States, Sales Department hours are:<br />

7:00 a.m. through 6:00 p.m. (Central Time).<br />

SALES/CUSTOMER SERVICE: 608-828-7000<br />

TOLL FREE (U.S. and Canada only): 800-426-6391<br />

FAX: 608-828-7500<br />

Sales e-mail: sales@gammex.com<br />

In the United States, Service Department hours are:<br />

7:00 a.m. through 5:00 p.m. (Central Time).<br />

SERVICE DEPARTMENT: 608-828-7000<br />

TOLL FREE (U.S. and Canada only): 800-232-9699<br />

FAX: 608-831-0964<br />

Service e-mail: support@gammex.com<br />

GAMMEX, Inc.<br />

2500 W. Beltline Hwy<br />

P.O. Box 620327<br />

Middleton, WI 53562-0327 USA<br />

On the internet at: www.gammex.com<br />

VISA, MasterCard and American Express accepted.<br />

All products and specifications are subject to change without notice.<br />

© 2003 GAMMEX-<strong>RMI</strong>. All rights reserved.<br />

Printed in U.S.A. P/N 007084-00-01

GAMMEX <strong>RMI</strong><br />

P.O. Box 620327<br />

Middleton, WI 53562-0327 USA<br />

1-800-GAMMEX 1 (426-6391)<br />

1-608-828-7000<br />

Fax: 1-608-828-7500<br />

www.gammex.com<br />

e-mail: sales@gammex.com<br />

GAMMEX-<strong>RMI</strong> LTD<br />

Karlsruhe House<br />

18 Queens Bridge Road<br />

Nottingham NG2 1NB, England<br />

(+44) (0) 115 985-0808<br />

Fax: (+44) (0) 115-985-0344<br />

e-mail: sales@gammex-rmi.co.uk<br />

GAMMEX-<strong>RMI</strong> GMBH<br />

Odesheimer Weg 17<br />

53902 Bad Münstereifel<br />

Germany<br />

(+49) (0) 2257-823<br />

Fax: (+49) (0) 2257-1692<br />

e-mail: <strong>Gammex</strong>-<strong>RMI</strong>GmbH@t-online.de<br />

GAMMEX <strong>RMI</strong> ®