DSD/DSDQ Shear Load Connectors - Geo-Hidrol

DSD/DSDQ Shear Load Connectors - Geo-Hidrol

DSD/DSDQ Shear Load Connectors - Geo-Hidrol

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CI/SfB<br />

Jh3<br />

March 2006<br />

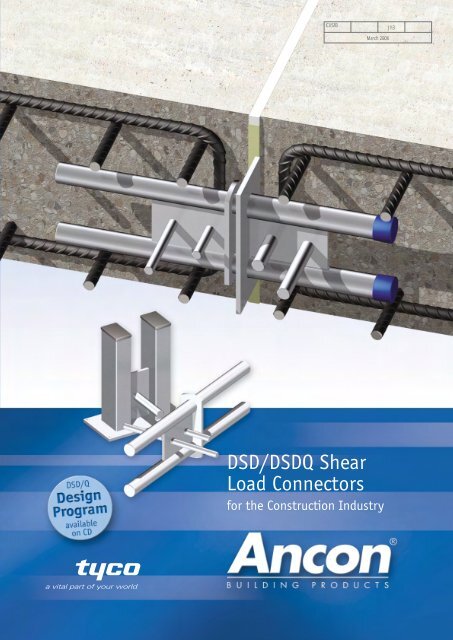

<strong>DSD</strong>/<strong>DSD</strong>Q <strong>Shear</strong><br />

<strong>Load</strong> <strong>Connectors</strong><br />

for the Construction Industry

Ancon designs and manufactures high integrity steel products for<br />

the construction industry. Through continuous programmes of<br />

new product development, inward investment and employee<br />

advancement, the company is committed to maintaining the<br />

highest level of customer service within a dynamic and<br />

challenging industry.<br />

Masonry Support Systems<br />

Windposts and Lintels<br />

Wall Ties and Restraint Fixings<br />

Channel and Bolt Fixings<br />

Tension Systems<br />

Special Fabrications<br />

Flooring & Formed Sections<br />

<strong>Shear</strong> <strong>Load</strong> <strong>Connectors</strong><br />

Reinforcing Bar Couplers<br />

Reinforcement Continuity Systems<br />

Punching <strong>Shear</strong> Reinforcement<br />

Insulated Balcony <strong>Connectors</strong><br />

Refractory Fixings<br />

Reinforced concrete is an important<br />

construction material. It offers strength,<br />

durability and can be formed into a variety of<br />

shapes. Concrete structures are designed with<br />

expansion and contraction joints at appropriate<br />

places to allow movement to take place. The<br />

design of the joint is important for the overall<br />

design to function correctly.<br />

Ancon shear load connectors offer significant<br />

advantages over conventional single dowels.<br />

Ancon Solution to Joints 4<br />

Ancon <strong>DSD</strong>/Q <strong>Shear</strong> <strong>Connectors</strong> 5<br />

Performance Details 6-7<br />

Dimensions and Spacings 8<br />

Reinforcement Details 9-10<br />

Material Properties 10<br />

Applications 11<br />

Other Ancon Products 11<br />

BS EN ISO 9001 : 2000<br />

FM12226<br />

3

4<br />

<strong>Shear</strong> <strong>Load</strong> <strong>Connectors</strong><br />

ANCON SOLUTION TO JOINTS<br />

In most cases conventional dowelled or<br />

corbelled joints can be replaced by joints<br />

incorporating Ancon shear connectors. These<br />

are more effective at transferring load and<br />

allowing movement to take place, easier to fix<br />

on site and a far more cost effective solution.<br />

They can be used for movement joints in floor<br />

slabs, suspended slabs, and for replacing<br />

double columns and beams at structural<br />

movement joints. Applications in civil<br />

engineering include joints in bridge parapets,<br />

bridge abutments and diaphragm wall<br />

construction.<br />

Comparison of Performance with<br />

Conventional Single Dowels<br />

Grade C30<br />

Concrete & Six 32mm<br />

Joint Width One Ancon Dia Dowel<br />

of 20mm <strong>DSD</strong>130 Bars<br />

Dowel<br />

Diameter mm<br />

2 @ 35 32<br />

Area of<br />

2 Dowel mm<br />

1924 4825<br />

Serviceability<br />

<strong>Load</strong> kN<br />

145 138<br />

1 Ancon <strong>DSD</strong> 130 Serviceability<br />

<strong>Load</strong> 145kN<br />

6 Dowel Bars 32mm Diameter<br />

Serviceability <strong>Load</strong> 138kN<br />

Conventional Joints<br />

Slip Joint<br />

Slab Corbel<br />

Structural Movement Joint<br />

Ancon Solutions<br />

Ancon <strong>DSD</strong><br />

Double Columns Ancon <strong>DSD</strong><br />

Floor to Wall Connection<br />

Corbel Support Ancon <strong>DSD</strong>

Tel: +44 (0) 114 275 5224 Web: www.ancon.co.uk<br />

ANCON SHEAR LOAD CONNECTORS<br />

The <strong>DSD</strong> range of connectors offers significant<br />

advantages over conventional single dowels.<br />

Each connector is a two-part assembly<br />

comprising a sleeve and a dowel component.<br />

Installation is a fast and accurate process,<br />

drilling of either formwork or concrete is not<br />

required. The sleeve is simply nailed to the<br />

formwork ensuring subsequent alignment with<br />

the dowel, essential for effective movement.<br />

They are manufactured from stainless steel to<br />

ensure a high degree of corrosion resistance<br />

with no requirement for additional protection.<br />

Free software is available from Ancon that<br />

simplifies the design of movement joints in<br />

reinforced concrete. For a given application,<br />

Ancon’s design program will calculate the size<br />

and quantity of shear load connectors<br />

required, the edge distance and spacings at<br />

which they should be installed, and details of<br />

the local reinforcement.<br />

Ancon <strong>DSD</strong> <strong>Shear</strong> <strong>Connectors</strong><br />

The Ancon <strong>DSD</strong> is the original two-part,<br />

double dowel, shear load connector. The<br />

dowel component can move longitudinally<br />

within the sleeve to accommodate movement.<br />

The connector is available in ten standard<br />

sizes and can transfer loads from around 20kN<br />

to over 450kN. The larger connectors can be<br />

used in joints up to 60mm wide. Larger joints<br />

can be accommodated using special dowels.<br />

Please contact Ancon’s Technical Department<br />

for further information.<br />

Ancon <strong>DSD</strong>Q <strong>Shear</strong> <strong>Connectors</strong><br />

The Ancon <strong>DSD</strong>Q shear load connector<br />

uses the same dowel component as the<br />

Ancon <strong>DSD</strong>, but the cylindrical sleeve is<br />

contained within a rectangular box section to<br />

allow lateral movement in addition to the<br />

longitudinal movement. Nine standard sizes<br />

can be used to transfer loads from around<br />

30kN to over 450kN.<br />

Dowel bar<br />

Web plate<br />

Ancon <strong>DSD</strong>Q <strong>Shear</strong> <strong>Connectors</strong> allowing<br />

rotation<br />

Plan<br />

Lateral movement<br />

or rotation<br />

Guide tube<br />

Longitudinal<br />

movement<br />

Longitudinal<br />

movement<br />

End plate with<br />

nail holes<br />

Cross dowels<br />

End cap<br />

<strong>DSD</strong><br />

Sleeve within<br />

rectangular<br />

box section<br />

<strong>DSD</strong>Q<br />

Ancon <strong>DSD</strong>Q <strong>Shear</strong> <strong>Connectors</strong> allowing<br />

movement in two directions<br />

Ancon <strong>DSD</strong>Q<br />

<strong>Shear</strong> <strong>Connectors</strong><br />

Slab movement will be<br />

in opposite directions in<br />

this area<br />

5

6<br />

<strong>Shear</strong> <strong>Load</strong> <strong>Connectors</strong><br />

Ultimate Failure <strong>Load</strong>s (kN) for Various Design Joint Widths (mm) and Slab Thickness (mm)*<br />

Slab <strong>DSD</strong>/<strong>DSD</strong>Q Ref 0 10 20 30 40 50 60<br />

160 61.2 52.0 46.0 39.9 31.0 - -<br />

180 66.5 56.5 50.0 39.9 31.0 - -<br />

200<br />

220<br />

25**<br />

72.2<br />

78.5<br />

61.4<br />

66.7<br />

54.3<br />

55.0<br />

39.9<br />

39.9<br />

31.0<br />

31.0<br />

-<br />

-<br />

-<br />

-<br />

240 81.6 69.3 55.0 39.9 31.0 - -<br />

260 81.6 69.3 55.0 39.9 31.0 - -<br />

180 94.0 87.0 78.8 58.3 45.6 - -<br />

200 101.2 93.6 78.8 58.3 45.6 - -<br />

220<br />

240<br />

30<br />

108.9<br />

117.3<br />

100.8<br />

108.6<br />

78.8<br />

78.8<br />

58.3<br />

58.3<br />

45.6<br />

45.6<br />

-<br />

-<br />

-<br />

-<br />

260 125.3 111.2 78.8 58.3 45.6 - -<br />

280 125.3 111.2 78.8 58.3 45.6 - -<br />

180 112.3 104.2 97.3 81.0 64.0 52.5 -<br />

200 120.8 112.2 104.7 81.0 64.0 52.5 -<br />

220<br />

240<br />

50<br />

130.1<br />

140.1<br />

120.8<br />

130.1<br />

107.5<br />

107.5<br />

81.0<br />

81.0<br />

64.0<br />

64.0<br />

52.5<br />

52.5<br />

-<br />

-<br />

260 149.6 139.0 107.5 81.0 64.0 52.5 -<br />

280 149.6 139.0 107.5 81.0 64.0 52.5 -<br />

200 147.5 138.4 130.3 108.4 86.4 71.2 -<br />

220 157.6 147.9 139.2 108.4 86.4 71.2 -<br />

240<br />

260<br />

65<br />

168.5<br />

180.1<br />

158.0<br />

168.9<br />

141.2<br />

141.2<br />

108.4<br />

108.4<br />

86.4<br />

86.4<br />

71.2<br />

71.2<br />

-<br />

-<br />

280 192.4 180.5 141.2 108.4 86.4 71.2 -<br />

300 196.6 184.4 141.2 108.4 86.4 71.2 -<br />

240 179.7 169.6 160.5 140.5 113.0 93.7 -<br />

260 190.0 179.2 169.6 140.5 113.0 93.7 -<br />

280<br />

300<br />

75<br />

200.8<br />

212.3<br />

189.4<br />

200.2<br />

179.3<br />

179.7<br />

140.5<br />

140.5<br />

113.0<br />

113.0<br />

93.7<br />

93.7<br />

-<br />

-<br />

320 224.4 211.6 179.7 140.5 113.0 93.7 -<br />

340 237.1 223.7 179.7 140.5 113.0 93.7 -<br />

320 303.8 289.9 277.2 235.7 199.4 170.7 148.2<br />

340 316.6 302.1 278.4 235.7 199.4 170.7 148.2<br />

360<br />

380<br />

100<br />

330.1<br />

336.7<br />

314.9<br />

318.8<br />

278.4<br />

278.4<br />

235.7<br />

235.7<br />

199.4<br />

199.4<br />

170.7<br />

170.7<br />

148.2<br />

148.2<br />

400 336.7 318.8 278.4 235.7 199.4 170.7 148.2<br />

420 336.7 318.8 278.4 235.7 199.4 170.7 148.2<br />

360 380.9 364.4 349.2 335.3 298.3 259.3 227.5<br />

380 395.2 378.0 362.3 345.0 298.3 259.3 227.5<br />

400<br />

420<br />

130<br />

410.0<br />

425.5<br />

392.2<br />

407.0<br />

375.9<br />

390.1<br />

345.0<br />

345.0<br />

298.3<br />

298.3<br />

259.3<br />

259.3<br />

227.5<br />

227.5<br />

440 441.5 422.4 395.9 345.0 298.3 259.3 227.5<br />

460 458.2 438.3 395.9 345.0 298.3 259.3 227.5<br />

450 505.7 488.0 469.8 452.8 430.3 381.3 339.4<br />

500 544.2 525.2 505.6 484.8 430.3 381.3 339.4<br />

550<br />

600<br />

150<br />

586.0<br />

599.7<br />

565.5<br />

583.0<br />

539.6<br />

539.6<br />

484.8<br />

484.8<br />

430.3<br />

430.3<br />

381.3<br />

381.3<br />

339.4<br />

339.4<br />

650 599.7 583.0 539.6 484.8 430.3 381.3 339.4<br />

700 599.7 583.0 539.6 484.8 430.3 381.3 339.4<br />

600 643.7 631.7 599.2 554.8 506.4 459.5 416.7<br />

650 643.7 631.7 599.2 554.8 506.4 459.5 416.7<br />

700<br />

750<br />

400<br />

643.7<br />

643.7<br />

631.7<br />

631.7<br />

599.2<br />

599.2<br />

554.8<br />

554.8<br />

506.4<br />

506.4<br />

459.5<br />

459.5<br />

416.7<br />

416.7<br />

800 643.7 631.7 599.2 554.8 506.4 459.5 416.7<br />

850 643.7 631.7 599.2 554.8 506.4 459.5 416.7<br />

650 1005.8 993.6 959.6 910.0 851.8 791.2 732.2<br />

700 1005.8 993.6 959.6 910.0 851.8 791.2 732.2<br />

750 1005.8 993.6 959.6 910.0 851.8 791.2 732.2<br />

800<br />

850<br />

450<br />

1005.8<br />

1005.8<br />

993.6<br />

993.6<br />

959.6<br />

959.6<br />

910.0<br />

910.0<br />

851.8<br />

851.8<br />

791.2<br />

791.2<br />

732.2<br />

732.2<br />

900 1005.8 993.6 959.6 910.0 851.8 791.2 732.2<br />

950 1005.8 993.6 959.6 910.0 851.8 791.2 732.2<br />

* In C25/30 concrete as defined in EN206-1 : 2000<br />

** <strong>DSD</strong> only<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

Installation<br />

Direction<br />

of load

Tel: +44 (0) 114 275 5224 Web: www.ancon.co.uk<br />

Serviceability <strong>Load</strong>s (kN) for Various Design Joint Widths (mm) and Slab Thickness (mm)*<br />

Slab <strong>DSD</strong>/<strong>DSD</strong>Q Ref 0 10 20 30 40 50 60<br />

160 25.5 21.7 19.2 17.5 16.8 - -<br />

180 27.7 23.5 20.8 19.0 16.8 - -<br />

200<br />

220<br />

25**<br />

30.1<br />

32.7<br />

25.6<br />

27.8<br />

22.6<br />

24.6<br />

20.7<br />

21.7<br />

16.8<br />

16.8<br />

-<br />

-<br />

-<br />

-<br />

240 34.0 28.9 25.5 21.7 16.8 - -<br />

260 34.0 28.9 25.5 21.7 16.8 - -<br />

180 39.2 36.3 33.7 31.6 24.8 - -<br />

200 42.2 39.0 36.3 31.7 24.8 - -<br />

220<br />

240<br />

30<br />

45.4<br />

48.9<br />

42.0<br />

45.2<br />

39.1<br />

42.1<br />

31.7<br />

31.7<br />

24.8<br />

24.8<br />

-<br />

-<br />

-<br />

-<br />

260 52.2 48.3 42.8 31.7 24.8 - -<br />

280 52.2 48.3 42.8 31.7 24.8 - -<br />

180 46.8 43.4 40.5 38.0 34.8 28.5 -<br />

200 50.3 46.7 43.6 40.9 34.8 28.5 -<br />

220<br />

240<br />

50<br />

54.2<br />

58.4<br />

50.3<br />

54.2<br />

47.0<br />

50.6<br />

44.0<br />

44.0<br />

34.8<br />

34.8<br />

28.5<br />

28.5<br />

-<br />

-<br />

260 62.4 57.9 54.0 44.0 34.8 28.5 -<br />

280 62.4 57.9 54.0 44.0 34.8 28.5 -<br />

200 61.4 57.6 54.3 51.3 46.9 38.7 -<br />

220 65.7 61.6 58.0 54.8 46.9 38.7 -<br />

240<br />

260<br />

65<br />

70.2<br />

75.0<br />

65.9<br />

70.4<br />

62.0<br />

66.3<br />

58.6<br />

58.9<br />

46.9<br />

46.9<br />

38.7<br />

38.7<br />

-<br />

-<br />

280 80.2 75.2 70.8 58.9 46.9 38.7 -<br />

300 81.9 76.8 72.4 58.9 46.9 38.7 -<br />

240 74.9 70.6 66.9 63.5 60.4 50.9 -<br />

260 79.1 74.7 70.7 67.1 61.4 50.9 -<br />

280<br />

300<br />

75<br />

83.7<br />

88.4<br />

78.9<br />

83.4<br />

74.7<br />

79.0<br />

70.9<br />

74.9<br />

61.4<br />

61.4<br />

50.9<br />

50.9<br />

-<br />

-<br />

320 93.5 88.2 83.5 76.3 61.4 50.9 -<br />

340 98.8 93.2 88.2 76.3 61.4 50.9 -<br />

320 126.6 120.8 115.5 110.6 106.2 92.8 80.5<br />

340 131.9 125.9 120.4 115.3 108.4 92.8 80.5<br />

360<br />

380<br />

100<br />

137.5<br />

143.4<br />

131.2<br />

136.8<br />

125.5<br />

130.8<br />

120.2<br />

125.3<br />

108.4<br />

108.4<br />

92.8<br />

92.8<br />

80.5<br />

80.5<br />

400 149.5 142.6 136.4 128.1 108.4 92.8 80.5<br />

420 155.8 148.7 142.2 128.1 108.4 92.8 80.5<br />

360 158.7 151.8 145.5 139.7 134.3 129.4 123.6<br />

380 164.7 157.5 151.0 144.9 139.4 134.2 123.6<br />

400<br />

420<br />

130<br />

170.8<br />

177.3<br />

163.4<br />

169.6<br />

156.6<br />

162.5<br />

150.4<br />

156.0<br />

144.6<br />

150.1<br />

139.3<br />

140.9<br />

123.6<br />

123.6<br />

440 184.0 176.0 168.7 161.9 155.7 140.9 123.6<br />

460 190.9 182.6 175.0 168.0 161.6 140.9 123.6<br />

450 210.7 203.3 195.7 188.7 182.1 176.0 170.3<br />

500 226.8 218.8 210.7 203.1 196.0 189.4 183.2<br />

550<br />

600<br />

150<br />

244.2<br />

262.9<br />

235.6<br />

253.7<br />

226.8<br />

244.3<br />

218.6<br />

235.4<br />

211.0<br />

227.3<br />

203.9<br />

207.2<br />

184.5<br />

184.5<br />

650 280.9 271.0 260.9 251.5 233.8 207.2 184.5<br />

700 280.9 271.0 260.9 251.5 233.8 207.2 184.5<br />

600 319.0 308.8 299.2 290.1 275.2 249.7 226.5<br />

650 337.0 326.2 316.1 301.5 275.2 249.7 226.5<br />

700<br />

750<br />

400<br />

349.8<br />

349.8<br />

343.3<br />

343.3<br />

325.7<br />

325.7<br />

301.5<br />

301.5<br />

275.2<br />

275.2<br />

249.7<br />

249.7<br />

226.5<br />

226.5<br />

800 349.8 343.3 325.7 301.5 275.2 249.7 226.5<br />

850 349.8 343.3 325.7 301.5 275.2 249.7 226.5<br />

650 453.4 440.2 427.9 416.2 405.1 394.6 384.6<br />

700 477.0 463.2 450.2 437.9 426.2 415.2 397.9<br />

750 502.0 487.5 473.8 460.9 448.6 430.0 397.9<br />

800<br />

850<br />

450<br />

528.4<br />

546.6<br />

513.1<br />

540.0<br />

498.7<br />

521.5<br />

485.1<br />

494.5<br />

462.9<br />

462.9<br />

430.0<br />

430.0<br />

397.9<br />

397.9<br />

900 546.6 540.0 521.5 494.5 462.9 430.0 397.9<br />

950 546.6 540.0 521.5 494.5 462.9 430.0 397.9<br />

* In C25/30 concrete as defined in EN206-1 : 2000<br />

** <strong>DSD</strong> only<br />

7

8<br />

<strong>Shear</strong> <strong>Load</strong> <strong>Connectors</strong><br />

DIMENSIONS<br />

Dowel Component <strong>DSD</strong> Sleeve <strong>DSD</strong>Q Sleeve<br />

Dowel bar<br />

diameter<br />

Dowel length<br />

Anchor bar<br />

lengths<br />

Anchor bar<br />

position<br />

Projection<br />

Ref<br />

Dowel Component <strong>DSD</strong> Sleeve <strong>DSD</strong>Q Sleeve<br />

<strong>DSD</strong> Overall Dowel Dowel Dowel Anchor Bar Anchor Bar Overall Anchor Bar Anchor Bar Overall Anchor Bar Anchor Bar Lateral<br />

<strong>DSD</strong>Q Length Dia Centres Projection Position Lengths Length Position Lengths Length Position Length Mov’nt<br />

25* 250 14 40 120 31 80/140 120 28 80/140 - - - -<br />

30 260 16 48 120 31 80/140 120 28 80/140 140 33 100 26<br />

50 280 18 50 130 31 80/160 135 28 80/160 160 33 100 25<br />

65 300 20 65 150 31 80/160 155 29 80/160 175 33 150 21<br />

75 340 22 75 150 33 100/180 155 31 100/180 175 33 150 20<br />

100 400 30 100 210 34 100/200 210 36 100/200 235 54 200 41<br />

130 470 35 105 260 34 100/200 265 36 100/200 275 59 200 36<br />

150 550 42 120 270 54 100/240 275 41 100/240 305 54 210 21<br />

400 660 52 160 330 70 150/300 335 70 150/300 350 64 350 27<br />

450 690 65 180 360 80 180/350 370 80 180/350 400 89 350 54<br />

SPACINGS, SLAB & BEAM THICKNESSES<br />

Ancon <strong>DSD</strong> and <strong>DSD</strong>Q connectors should be<br />

positioned in slabs and beams within the<br />

minimum dimensions shown in the table below<br />

to ensure full load transfer. For information on<br />

reduced spacings or edge distances please<br />

contact Ancon.<br />

For slabs or beams with a thickness greater<br />

than the standard, the values for standard<br />

thickness apply. For slabs and beams with a<br />

thickness between the minimum and standard,<br />

use the formula shown.<br />

Ancon <strong>DSD</strong> and <strong>DSD</strong>Q Spacings and Minimum Concrete Thicknesses<br />

Ref<br />

Minimum Thickness Standard Thickness<br />

<strong>DSD</strong> Minimum Slab/ Minimum Minimum End Standard Slab/ Minimum Minimum End<br />

<strong>DSD</strong>Q Beam Thickness Centres Distance Beam Thickness Centres Distance<br />

25* 160 240 120 240 160 80<br />

30 180 270 135 270 180 90<br />

50 180 270 135 270 180 90<br />

65 200 300 150 300 200 100<br />

75 240 360 180 360 240 120<br />

100 320 480 240 480 320 160<br />

130 360 540 270 540 360 180<br />

150 450 675 337 675 450 225<br />

400 600 900 450 900 600 300<br />

450 650 975 487 975 650 325<br />

Minimum Centres =<br />

(2.5 x Min. Slab/Beam Thickness) – Actual Thickness<br />

End Distance = 0.5 x Minimum Centres<br />

Centres<br />

Notes:* <strong>DSD</strong> only. All dimensions are in millimetres (mm).<br />

Notes:* <strong>DSD</strong> only. All dimensions are in millimetres (mm).<br />

End<br />

distance Centres<br />

Anchor bar<br />

position<br />

Sleeve length<br />

Anchor bar<br />

lengths<br />

Example: Ancon <strong>DSD</strong>100 used in 350mm thick slab<br />

Minimum Centres = (2.5 x 320) - 350 = 450mm<br />

End Distance = 0.5 x 450 = 225mm<br />

=<br />

=<br />

Slab<br />

thickness<br />

Anchor bar<br />

position<br />

Sleeve length<br />

Anchor bar<br />

length<br />

Maximum<br />

lateral<br />

movement<br />

Beam thickness<br />

= =<br />

End<br />

distance<br />

Centres

Tel: +44 (0) 114 275 5224 Web: www.ancon.co.uk<br />

REINFORCEMENT<br />

Local Reinforcement<br />

Local reinforcement is required around each<br />

<strong>DSD</strong> dowel and sleeve component to bridge<br />

any fine cracks that develop in the concrete as<br />

the dowels transfer load. Correct detailing in<br />

accordance with BS 8110 and the<br />

recommendations provided here, will ensure<br />

the Ancon <strong>DSD</strong> and <strong>DSD</strong>Q shear connectors<br />

attain their full capacity.<br />

Slab Reinforcement<br />

Joint<br />

width<br />

Serviceability load<br />

Cover<br />

Bar diameter<br />

Vertical Reinforcement<br />

Cross Sectional Area (CSA) is calculated as<br />

CSA =<br />

2.4 x Serviceability <strong>Load</strong> x (Joint Width + Slab Thickness) x 103 follows:-<br />

0.87 x fy x (Slab Thickness - (2 x Cover) - Bar Diameter)<br />

Example <strong>DSD</strong>100 used in 400mm thick slab<br />

Actual serviceability load = 100kN Joint width = 20mm<br />

Bar diameter = 16mm fy = 500N/mm 2 Cover = 40mm<br />

CSA = = 762mm2 2.4 x 100 x (20 + 400) x 103<br />

0.87 x 500 x (400 - 80 - 16)<br />

Use 4 - H16 U-Bars (actual area - 804mm 2 )<br />

Top and Bottom Reinforcement<br />

CSA =<br />

Area of Vertical Reinforcement<br />

π<br />

From the example above<br />

CSA =<br />

762<br />

π<br />

= 243mm 2<br />

Use 6 - H8 (actual area - 301mm 2 )<br />

=<br />

=<br />

Slab<br />

Thickness<br />

100 100 100<br />

Typical Layout<br />

100<br />

(130 for<br />

<strong>DSD</strong> 400<br />

and above)<br />

Typical Layout<br />

Other U-bars<br />

top and bottom<br />

reinforcement<br />

not shown.<br />

Reinforcement Arrangement 1<br />

Ancon <strong>DSD</strong>25 - <strong>DSD</strong>150<br />

100<br />

100<br />

Reinforcement Arrangement 2<br />

Ancon <strong>DSD</strong>130 - <strong>DSD</strong>450<br />

9

10<br />

<strong>Shear</strong> <strong>Load</strong> <strong>Connectors</strong><br />

Beam Reinforcement<br />

The main consideration for beams is usually<br />

the design reinforcement to carry the shear<br />

load. This is provided in accordance with well<br />

established procedures set out in international<br />

codes, and will require shear links local to the<br />

Ancon <strong>DSD</strong> units.<br />

In addition to this reinforcement, particularly in<br />

thin beams, reinforcement must be added to<br />

prevent vertical splitting of the concrete. The<br />

reinforcement should be located as shown in<br />

the diagrams below.<br />

Cross Sectional<br />

Area of Local =<br />

Reinforcement<br />

Cross Sectional<br />

Area of Local =<br />

Reinforcement<br />

2.4 x Serviceability <strong>Load</strong> x 10 3<br />

π x 0.87 x fy<br />

Example: Ancon <strong>DSD</strong>100 in 350mm wide beam<br />

Actual serviceability load = 100kN<br />

fy of reinforcement = 500N/mm 2<br />

2.4 x 100 x 10 3<br />

π x 0.87 x 500<br />

Use 2 - H12 U-Bars (actual area - 226mm 2 )<br />

A<br />

A<br />

Width<br />

= =<br />

Section A-A<br />

= 176mm 2<br />

For further details of beam reinforcement, or<br />

for specific applications, please contact Ancon<br />

Building Products.<br />

75mm max<br />

Typical shape<br />

38 bar<br />

Typical shape<br />

60 bar<br />

Normal<br />

reinforcement<br />

Direction<br />

of load<br />

Typical<br />

shape<br />

38 bar<br />

Typical<br />

shape<br />

60 bar<br />

Normal<br />

reinforcement<br />

Wall Reinforcement<br />

Reinforcement in walls is designed in the<br />

conventional way as though the slab was<br />

integral with the wall. The additional local<br />

reinforcement is in the form of a square mesh<br />

or loose bar equivalent to the details as shown<br />

below.<br />

Minimum Width<br />

and Depth<br />

Ref Bar Maximum Minimum<br />

<strong>DSD</strong> Diameter Centres Width/Depth<br />

<strong>DSD</strong>Q (mm) (mm) (mm)<br />

25* 8 100 300<br />

30 8 100 300<br />

50 8 100 300<br />

65 10 100 400<br />

75 12 150 450<br />

100 12 150 450<br />

130 12 150 600<br />

150 12 175 700<br />

* <strong>DSD</strong> only<br />

Reinforcement for <strong>DSD</strong> 75s in a Wall<br />

H12 at 150mm<br />

max.centres<br />

450mm min.<br />

Wall Reinforcement<br />

Local Reinforcement<br />

to Connector<br />

<strong>DSD</strong>75<br />

Sleeve<br />

component<br />

450<br />

mm<br />

min.<br />

Cover<br />

Minimum cover to local reinforcement is to the<br />

recommendations of BS 8110 Part 1 : 1997.<br />

Maximum cover is as shown below:-<br />

Ref<br />

<strong>DSD</strong> Max Cover<br />

<strong>DSD</strong>Q to Face (mm)<br />

25* 30<br />

30 30<br />

50 30<br />

65 40<br />

75 50<br />

100 50<br />

130 50<br />

150 50<br />

400 60<br />

450 60<br />

* <strong>DSD</strong> only<br />

Cover<br />

Where a sleeve component<br />

is cast into a wall the<br />

thickness of the wall should<br />

be at least 50mm more than<br />

the length of the sleeve.<br />

50mm min.<br />

MATERIAL PROPERTIES<br />

Material Specification of Ancon <strong>DSD</strong><br />

<strong>Shear</strong> <strong>Connectors</strong><br />

Component Specification<br />

Dowel bar 1.4462<br />

Plate 1.4301<br />

Cross dowels 1.4301<br />

Material Strengths of Ancon <strong>DSD</strong>/Q<br />

Dowel Bars<br />

Ref 0.2% Tensile Elongation<br />

<strong>DSD</strong> Proof Stress Strength at Rupture<br />

<strong>DSD</strong>Q N/mm2 (Rp) N/mm2 (Rm) % (A10) 25* 780 850 15<br />

30 780 850 15<br />

50 780 850 15<br />

65 780 850 15<br />

75 780 850 15<br />

100 550 700 20<br />

130 550 700 20<br />

150 500 650 20<br />

400 350 650 25<br />

450 350 650 25<br />

* <strong>DSD</strong> only

Tel: +44 (0) 114 275 5224 Web: www.ancon.co.uk<br />

APPLICATIONS<br />

Channel Tunnel Terminal, UK<br />

Forum Shopping Centre, Algarve<br />

Melbourne Cricket Ground, Australia<br />

Scottish Widows, Edinburgh, UK<br />

Olympic Stadium, Sydney, Australia<br />

OTHER ANCON PRODUCTS<br />

Reinforcement Continuity Systems<br />

Reinforcement Continuity Systems are an<br />

increasingly popular means of maintaining<br />

continuity of reinforcement at construction<br />

joints in concrete. The system eliminates the<br />

need to drill shuttering and can simplify<br />

formwork design, thereby accelerating the<br />

construction process. The Ancon Eazistrip is<br />

available in both standard units and special<br />

configurations.<br />

Reinforcing Bar Couplers<br />

The use of reinforcing bar couplers can<br />

provide significant advantages over lapped<br />

joints. Design and construction of the concrete<br />

can be simplified and the amount of<br />

reinforcement required can be reduced.<br />

Because the strength of a mechanical splice is<br />

independent of the concrete in which it is<br />

located, the joint can also remain unaffected<br />

by any loss of cover. The range includes<br />

threaded and mechanically bolted couplers.<br />

Punching <strong>Shear</strong> Reinforcement<br />

Used within a slab to provide additional<br />

reinforcement around columns, Ancon <strong>Shear</strong>fix<br />

is the ideal solution to the design and<br />

construction problems associated with<br />

punching shear. The system consists of<br />

double-headed studs welded to flat rails,<br />

positioned in a symmetrical pattern around the<br />

column head. The shear load from the slab is<br />

transferred through the studs into the column.<br />

Insulated Balcony <strong>Connectors</strong><br />

Ancon Isolan connectors join external concrete<br />

balconies to internal floor slabs. Used to<br />

minimise cold bridging, they provide continuity<br />

to the thermal insulation. Standard systems,<br />

comprising rigid CFC-free polystyrene insulation<br />

and duplex stainless steel shear reinforcement,<br />

suit most depths of free cantilever and propped<br />

cantilever balconies. Conventional reinforcing<br />

bars are used to provide the tension and<br />

compression reinforcement.<br />

Channels and Bolts for Fixings to Concrete<br />

Cast-in channels are used for fixing masonry<br />

support systems to the edges of concrete<br />

floors and beams. Channels are available in<br />

different sizes ranging from simple self<br />

anchoring channels for restraints, to large<br />

capacity channels with integral anchors.<br />

A selection of channels can also be supplied<br />

plain-backed for surface fixing. Expansion<br />

bolts, resin anchors and set screws in stainless<br />

steel complete the range of fixings.<br />

11

Ancon Building Products<br />

President Way, President Park<br />

Sheffield S4 7UR<br />

United Kingdom<br />

Tel: +44 (0) 114 275 5224<br />

Fax: +44 (0) 114 276 8543<br />

Email: info@ancon.co.uk<br />

Visit: www.ancon.co.uk<br />

Ancon (Middle East) FZE<br />

PO Box 17225<br />

Jebel Ali<br />

Dubai<br />

United Arab Emirates<br />

Tel: +971 (0) 4 883 4346<br />

Fax: +971 (0) 4 883 4347<br />

Email: anconccl@emirates.net.ae<br />

Ancon Building Products<br />

114 Kurrajong Avenue<br />

Mount Druitt<br />

Sydney<br />

NSW 2770<br />

Australia<br />

Tel: +61 (0) 2 9675 1000<br />

Fax: +61 (0) 2 9675 3390<br />

Email: pac.ancon@anconbp.com.au<br />

Visit: www.anconbp.com.au<br />

These products are available from:<br />

© Ancon Building Products 2006<br />

Ancon (Schweiz) AG<br />

Gewerbezone Widalmi 10<br />

3216 Ried bei Kerzers<br />

Switzerland<br />

Tel: +41 (0) 31 750 3030<br />

Fax: +41 (0) 31 750 3033<br />

Email: info@ancon.ch<br />

Visit: www.ancon.ch<br />

Ancon Building Products GesmbH<br />

Gerspergasse 9/3 Top 1<br />

A-1210 Vienna<br />

Austria<br />

Tel: +43 (0) 1 259 58 62-0<br />

Fax: +43 (0) 1 259 58 62-40<br />

Email: info@ancon.at<br />

Visit: www.ancon.at<br />

Ancon GmbH<br />

Bartholomäusstrasse 26<br />

90489 Nuremberg<br />

Germany<br />

Tel: +49 (0) 911 955 1234 0<br />

Fax: +49 (0) 911 955 1234 9<br />

Email: info@anconbp.de<br />

Visit: www.anconbp.de<br />

The construction applications and details provided in this literature<br />

are indicative only. In every case, project working details should be<br />

entrusted to appropriately qualified and experienced persons.<br />

Whilst every care has been exercised in the preparation of this<br />

document to ensure that any advice, recommendations or<br />

information is accurate, no liability or responsibility of any kind is<br />

accepted in respect of Ancon Building Products.<br />

With a policy of continuous product development Ancon Building<br />

Products reserves the right to modify product design and<br />

specification without due notice.<br />

BS EN ISO 9001 : 2000<br />

FM12226