Resources Recruitment - Department of State Development - The ...

Resources Recruitment - Department of State Development - The ...

Resources Recruitment - Department of State Development - The ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

BHP Billiton says that since July 2000, it has<br />

spent more than A$8 million within the shires <strong>of</strong><br />

Ravensthorpe and Esperance on various aspects<br />

<strong>of</strong> its studies.<br />

If the project proceeds to development, it will<br />

generate up to 1000 construction jobs and 300<br />

permanent jobs once the mine and process<br />

plant are up and running in late 2006. About 100<br />

<strong>of</strong> the employees new to the region are expected<br />

to be located at Hopetoun, and another 100 in<br />

Esperance. <strong>The</strong> balance <strong>of</strong> the workforce is<br />

expected to be engaged locally. Additional<br />

employment opportunities are expected in<br />

Ravensthorpe and Esperance through support<br />

industries, such as new services in<br />

Ravensthorpe, additional long-distance haulage<br />

capacity and increased activity at the Port <strong>of</strong><br />

Esperance.<br />

Until the 2003 mid-year completion <strong>of</strong> the A$200<br />

million AMC common-user facility, work such as<br />

that associated with the Semac 1 would have<br />

gone to shipyards in Singapore and other places<br />

in the South East Asia region.<br />

One <strong>of</strong> the most exciting maritime activity clusters<br />

in the Asia–Pacific region, the AMC promises to<br />

deliver significant value-adding opportunities for<br />

Western Australian industry, and also good value<br />

for organisations seeking support services for the<br />

<strong>of</strong>fshore petroleum industry, the onshore<br />

resources industry, plus defence and marine<br />

services sectors.<br />

“<strong>The</strong> beauty <strong>of</strong> this place is that companies don’t<br />

have to make large capital investments to come<br />

here,” said JBFM Babcock’s Richard Clark.<br />

“Our facility <strong>of</strong>fers great flexibility, and has the<br />

advantage <strong>of</strong> being surrounded by a host <strong>of</strong><br />

supporting industries. Visitors can pay a fee and<br />

stay for however long it takes to complete a job.”<br />

Saipem Technical Superintendent, Frank Von<br />

Tilborg, was complimentary about the service<br />

afforded to him and Semac 1’s 200 crew<br />

members during the vessel’s visit.<br />

“Things are a bit different here than Singapore.<br />

However, we were impressed with the facilities at<br />

the AMC — plenty <strong>of</strong> space, good supplies <strong>of</strong><br />

potable water, good ship-to-shore communication<br />

systems, goods support services and good<br />

security.”<br />

Centrepiece <strong>of</strong> the AMC’s common-user facility is<br />

Australia’s largest mobile assembly hall, a 4800<br />

square metre shed that is designed to travel up to<br />

80 metres on an east–west traverse. Highly<br />

adaptable for multi-purpose fabrication, assembly<br />

and loadout work, and suitable for overlapping<br />

projects, the hall design incorporates extensive<br />

portal and gantry crane systems with 30 metre,<br />

under-hook capacity <strong>of</strong> 200 tonnes.<br />

Other important features include two wharfs, one<br />

350 metre-long marine services wharf (which<br />

Semac 1 used), and a smaller 3000 tonne<br />

loadout wharf that is 200<br />

metres long.<br />

Assured water supplies<br />

for the Burrup<br />

“Water, water<br />

everywhere … nor<br />

any drop to drink” are<br />

the famous words that British poet<br />

Samuel Taylor Coleridge (1772–1834)<br />

wove into his classic <strong>The</strong> Rime <strong>of</strong> the<br />

Ancient Mariner.<br />

A couple <strong>of</strong> centuries later, the<br />

same words must have rung in the<br />

ears <strong>of</strong> planners aiming to establish a<br />

world-class gas processing precinct<br />

on the strategically important Burrup<br />

Peninsula in northwest Western<br />

Australia.<br />

However, the Western Australian<br />

Government has addressed this by<br />

injecting A$80 million worth <strong>of</strong><br />

infrastructure into a program to<br />

ensure an efficient long-term water<br />

supply for industry in the area.<br />

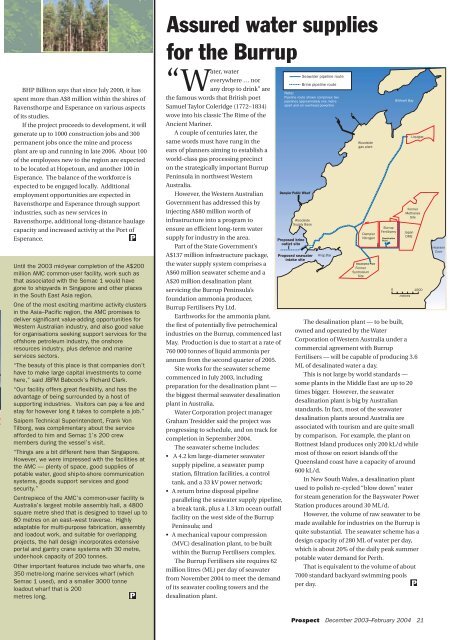

Part <strong>of</strong> the <strong>State</strong> Government’s<br />

A$137 million infrastructure package,<br />

the water supply system comprises a<br />

A$60 million seawater scheme and a<br />

A$20 million desalination plant<br />

servicing the Burrup Peninsula’s<br />

foundation ammonia producer,<br />

Burrup Fertilisers Pty Ltd.<br />

Earthworks for the ammonia plant,<br />

the first <strong>of</strong> potentially five petrochemical<br />

industries on the Burrup, commenced last<br />

May. Production is due to start at a rate <strong>of</strong><br />

760 000 tonnes <strong>of</strong> liquid ammonia per<br />

annum from the second quarter <strong>of</strong> 2005.<br />

Site works for the seawater scheme<br />

commenced in July 2003, including<br />

preparation for the desalination plant —<br />

the biggest thermal seawater desalination<br />

plant in Australia.<br />

Water Corporation project manager<br />

Graham Tresidder said the project was<br />

progressing to schedule, and on track for<br />

completion in September 2004.<br />

<strong>The</strong> seawater scheme includes:<br />

• A 4.2 km large-diameter seawater<br />

supply pipeline, a seawater pump<br />

station, filtration facilities, a control<br />

tank, and a 33 kV power network;<br />

• A return brine disposal pipeline<br />

paralleling the seawater supply pipeline,<br />

a break tank, plus a 1.3 km ocean outfall<br />

facility on the west side <strong>of</strong> the Burrup<br />

Peninsula; and<br />

• A mechanical vapour compression<br />

(MVC) desalination plant, to be built<br />

within the Burrup Fertilisers complex.<br />

<strong>The</strong> Burrup Fertilisers site requires 62<br />

million litres (ML) per day <strong>of</strong> seawater<br />

from November 2004 to meet the demand<br />

<strong>of</strong> its seawater cooling towers and the<br />

desalination plant.<br />

Seawater pipeline route<br />

Brine pipeline route<br />

Note:<br />

Pipeline route shown comprises two<br />

pipelines approximately one metre<br />

apart and an overhead powerline<br />

Dampier Public Wharf<br />

Woodside<br />

Supply Base<br />

Proposed brine<br />

outlet site<br />

Proposed seawater<br />

intake site<br />

King Bay<br />

Woodside<br />

gas plant<br />

Dampier<br />

Nitrogen<br />

Desalination Plant<br />

Former<br />

Syntroleum<br />

Site<br />

Burrup<br />

Fertilisers<br />

Desalination<br />

Desalination<br />

Plant<br />

Withnell Bay<br />

Liquigaz<br />

Former<br />

Methanex<br />

Site<br />

Japan<br />

DME<br />

NORTH<br />

0 1000<br />

metres<br />

<strong>The</strong> desalination plant — to be built,<br />

owned and operated by the Water<br />

Corporation <strong>of</strong> Western Australia under a<br />

commercial agreement with Burrup<br />

Fertilisers — will be capable <strong>of</strong> producing 3.6<br />

ML <strong>of</strong> desalinated water a day.<br />

This is not large by world standards —<br />

some plants in the Middle East are up to 20<br />

times bigger. However, the seawater<br />

desalination plant is big by Australian<br />

standards. In fact, most <strong>of</strong> the seawater<br />

desalination plants around Australia are<br />

associated with tourism and are quite small<br />

by comparison. For example, the plant on<br />

Rottnest Island produces only 200 kL/d while<br />

most <strong>of</strong> those on resort islands <strong>of</strong>f the<br />

Queensland coast have a capacity <strong>of</strong> around<br />

600 kL/d.<br />

In New South Wales, a desalination plant<br />

used to polish re-cycled “blow down” water<br />

for steam generation for the Bayswater Power<br />

Station produces around 30 ML/d.<br />

However, the volume <strong>of</strong> raw seawater to be<br />

made available for industries on the Burrup is<br />

quite substantial. <strong>The</strong> seawater scheme has a<br />

design capacity <strong>of</strong> 280 ML <strong>of</strong> water per day,<br />

which is about 20% <strong>of</strong> the daily peak summer<br />

potable water demand for Perth.<br />

That is equivalent to the volume <strong>of</strong> about<br />

7000 standard backyard swimming pools<br />

per day.<br />

Prospect December 2003–February 2004 21<br />

Hearson<br />

Cove