w w w .vlb

w w w .vlb

w w w .vlb

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

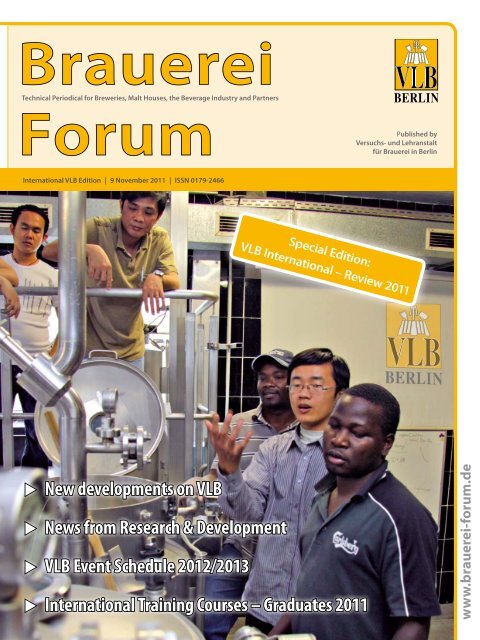

Brauerei<br />

Technical Periodical for Breweries, Malt Houses, the Beverage Industry and Partners<br />

Forum<br />

International VLB Edition | 9 November 2011 | ISSN 0179-2466<br />

� New developments on VLB<br />

� News from Research & Development<br />

� VLB Event Schedule 2012/2013<br />

Published by<br />

Versuchs- und Lehranstalt<br />

für Brauerei in Berlin<br />

Special Edition:<br />

VLB International – Review 2011<br />

� International Training Courses – Graduates 2011<br />

www.brauerei-forum.de

AND COFELY BECOMES A TWO-TIME NO. 1<br />

Building ServiceS energy ServiceS facility ServiceS refrigeration<br />

OPTIMAL USE OF ENERGIES.<br />

Proenergy is<br />

noW CoFeLy<br />

In June 2011, we became part of<br />

Cofely Deutschland. Under the new<br />

name, we will of course continue<br />

to offer the same exceptional<br />

standard of expertise as one of<br />

Germany’s leading contracting<br />

specialists, and your contact<br />

person will remain the same.<br />

Contracting is our business.<br />

proenergy.de<br />

By joining forces with Proenergy, Cofely, Europe’s no. 1 for energy and environmental<br />

efficiency, will also become the no. 1 in contracting, operating more than 4,000 energy<br />

systems, which is more than any other company in Germany. Get to know the new<br />

major player in energy and technical services.<br />

www.cofely.de

� VLB Berlin Inside<br />

4 The new VLB training centre – Status update<br />

5 New international VLB members<br />

6 VLB Berlin and SENAI Rio, Brazil, announcing cooperation /<br />

Deniz Bilge joins VLB´s team of experts<br />

8 Stay tuned to VLB: New website and social network /<br />

VLB Alumni Meeting at the Craft Brewers Conference 2011<br />

9 Wolfgang Kunze 85<br />

� Research & Development<br />

10 Fermentation tests with improved EBC fermentation modules<br />

12 New analytical method for determination of high molecular arabinoxylan<br />

content in wort<br />

14 VLB laboratories achieved ISO/IEC17025 reaccreditation /<br />

Dr. Diedrich Harms, DLG´s Managing Beer Test Officer<br />

15 “AHA collaborative trials“ of the hop analytics work group<br />

16 Stable isotope dilution assay: An outstanding tool in beer analysis<br />

� Training & Events<br />

18 VLB Berlin bids farewell to its Certified Brewmasters 2011<br />

22 VLB International Seminars in Berlin: Training in Germany<br />

23 “Technology Brewing and Malting“ / “The Yeast in the Brewery – Management,<br />

Pure yeast cultures, Propagation”<br />

24 VLB Russian Brewers Course 2011 finished successfully<br />

27 Meet VLB´s experts at trade fairs and conferences!<br />

28 International VLB conventions 2011<br />

30 VLB institutes and departments – contacts<br />

32 VLB International Events 2011/2012<br />

Dear friends and alumni of VLB Berlin!<br />

Every year we publish an English edition of VLB’s monthly trade journal Brauerei<br />

Forum. The idea is to reach the steadily increasing group of international customers,<br />

members and alumni of VLB Berlin who do not speak German.<br />

Our international edition is focused on the activities of VLB Berlin during the year 2011<br />

with special relevance to its international clientele. You will find news about VLB as<br />

well as reports about selected topics from research and deve lopment. This volume<br />

also covers our international conventions and seminars. Additionally we report on<br />

the VLB Certi fied Brewmaster Course 2011 and our Russian Brewers Course. A list of<br />

contact persons as well as an event schedule for 2012 complete this issue.<br />

This year we would also like to<br />

invite you to join us on LinkedIn.<br />

Follow VLB’s company page or our<br />

group “VLB Berlin”.<br />

Looking forward to meeting<br />

you – personally or virtually!<br />

With best regards,<br />

Your team from<br />

the Brauerei Forum<br />

Olaf Hendel (Editor-in-Chief)<br />

Wiebke Künnemann (Editor)<br />

Dieter Prokein (Editor)<br />

� redaktion@brauerei-forum.de<br />

Content<br />

Small-scale tests of yeast properties<br />

can give valuable insight to optimise or<br />

modify the fermentation process or to<br />

develop new products. In this context the<br />

BBSA of VLB Berlin has improved an EBC<br />

testing method<br />

An analytical method for the determination<br />

of high molecular arabinoxylan<br />

was established at the Research Institute<br />

for Raw Materials (VLB Berlin) in order to<br />

monitor their content in wort and beer<br />

The VLB Research Institute for Special<br />

Analysis (FIS) offers long lasting competence<br />

in mass spectrometry (MS) and<br />

stable isotope dilution assay (SIDA). MS<br />

and SIDA are outstanding tools for trace<br />

analysis from complex matrices such as<br />

mash, wort and beer<br />

After 6 months of intensive training, 36<br />

successful graduates of VLB‘s Certified<br />

Brew master Course 2011 were bid farewell<br />

on Friday, 24 June. This year’s VLB Certifed<br />

Brewmaster Course was attended by<br />

students from 18 nations<br />

Brauerei Forum – VLB International 2011 33<br />

10<br />

12<br />

16<br />

18

VLB inside<br />

The new VLB training centre – Status update<br />

The planning of a new training facility at VLB Berlin is progressing. The new building will accommodate about<br />

6,000 m² floor space of facilities such as major parts of the VLB pilot plants, laboratories and seminar rooms.<br />

In summer 2010 the preliminary planning was submitted to the financing local authorities for approval.<br />

Start of construction is currently scheduled for summer 2012.<br />

� redaktion@brauerei-forum.de<br />

© Gerber Architekten<br />

(oh) In 2009 VLB Berlin received a funding<br />

commitment of € 26.6 million for<br />

a new facility for training and education<br />

(see also the coverage in our International<br />

Editions 2009 and 2010). The<br />

project is financed jointly from local,<br />

federal and European funds. The new<br />

building will be located at the rear of<br />

the property at Seestrasse 13 and<br />

merge with the existing institutes and<br />

departments. In addition to its core<br />

activities in the brewing and malting<br />

sector the new facility will be a precondition<br />

to extend the VLB services<br />

into the fields of beverage technology<br />

and biotechnology.<br />

Preliminary planning is finished<br />

After spending a lot of time with the<br />

numerous public tenders, negotiations<br />

and other administrational tasks the<br />

actual planning was started in early<br />

2011. The new training centre consists<br />

of 6 levels. The basement will host the<br />

VLB pilot brewery and the pilot malting<br />

plant including the technical utilities.<br />

4 Brauerei Forum – VLB International 2011<br />

On the ground floor conference and seminar<br />

rooms and training laboratories<br />

are located. On the 4 upper floors further<br />

laboratories, seminar rooms and<br />

offices are planned. The basic design<br />

follows the idea of an open minded<br />

concept: The inner building will be dominated<br />

by a large and light atrium. A<br />

big glass wall makes the brewing facility<br />

in the basement transparent to the<br />

visitors. Several galleries invite face-toface<br />

communication. The architectural<br />

concept and design was realised by<br />

Gerber Architekten (Dortmund), planning<br />

of building services and laboratories<br />

is carried out by Planungsgruppe<br />

M+M AG (Hamburg) and the structural<br />

design by Ingenieurbüro Wetzel & von<br />

Seht (Berlin). The construction will be<br />

supervised by Peter Widell und KSV<br />

Krüger, Schuberth, Vandreike (Berlin).<br />

After lots of planning rounds the preliminary<br />

planning was completed in<br />

summer 2011 and has been submitted<br />

to the financing local authorities for<br />

approval.<br />

In the meantime the preliminary planning<br />

is under further elaboration. The<br />

next milestone will be the completion<br />

and submission of the design documentation<br />

in order to apply for the<br />

construction permit. In the context of<br />

the project the demolition works on<br />

the site of VLB started at the end of<br />

2010 and are still in progress.<br />

Completion in 2014<br />

Based on the current schedule, the<br />

start of the construction works for<br />

the building excavation is expected in<br />

summer 2012. Depending on external<br />

influences (e.g. winter conditions) the<br />

ultimate completion and commissioning<br />

of the facility is expected for the<br />

second half of 2014.<br />

With the new training facility VLB will<br />

sustainably retain its top position as<br />

one of the leading institutes worldwide<br />

for the brewing and beverage<br />

industries.<br />

Design of the new VLB training centre: View from southwest

New international VLB members<br />

In 2011 again two renowned breweries and some companies from the supply side have joined the VLB<br />

network through a membership:<br />

The Spanish brewery Hijos<br />

de Rivera (Estrella<br />

Galicia) is a new member<br />

of VLB Berlin. The company is located<br />

in the north-west of Spain in the city<br />

of A Coruña. The brewery was founded<br />

in 1906 and its major brand is<br />

Estrella Galicia, a lager beer with 5.5<br />

%vol alcohol. The annual production<br />

is about 680,000 hl and there are 260<br />

employees. In addition to beer, Hijos<br />

de Rivera also produces wine, water,<br />

spirits and cider.<br />

Photo: José Luis Olmedo Nadal (3 rd<br />

from right) receives the Certificate of<br />

VLB Membership for Hijos de Rivera<br />

� www. estrellagalicia.es<br />

Tehran Govar Brewery from<br />

Iran also joined the VLB in<br />

January 2011. The brewery<br />

is located 120 km northeast<br />

of Tehran, the capital<br />

of Iran. The new greenfield<br />

plant went into operation in<br />

2009 and has a capacity of about 1.5<br />

mio. hl per year. Since alcoholic fermentation<br />

is prohibited in Iran, Tehran<br />

Govar focuses on non-alcoholic malt<br />

beverages which have become very<br />

popular in this country.<br />

Photo: Mansoor Nadjafi-Asl (Middle)<br />

receives the Certificate of VLB Membership<br />

for Tehran Govar<br />

� www.tehrangovar.com<br />

Companies from the supply industry which joined VLB in 2011:<br />

� www. voith.com � ww.thermofisher.com<br />

� www. ksb.com<br />

� www. grundfos.com � www. isp.com � www. rundmund.de<br />

Brauerei Forum – VLB International 2011<br />

®<br />

Specialty Malting<br />

Company<br />

since 1879<br />

Bamberg - Germany<br />

ABBEY MALT ®<br />

BOHEMIAN PILSNER MALT<br />

FLOOR-MALTED BOHEMIAN PILSNER MALT<br />

PILSNER MALT VIENNA MALT<br />

MUNICH MALT SMOKED MALT<br />

PALE ALE MALT<br />

MELANOIDIN MALT<br />

ACIDULATED MALT<br />

CARAMEL WHEAT MALT<br />

CHOCOLATE SPELT MALT<br />

RYE MALT:<br />

ROASTED - CARAMELIZED<br />

WHEAT MALT:<br />

PALE - DARK - ROASTED<br />

Our brew and special<br />

malts are also available in<br />

certified organic quality!<br />

Caramelized Malt :<br />

CARAPILS ® , CARAHELL ® , CARAMUNICH ® , CARARYE ® , CARARED ® ,<br />

CARAAROMA ® , CARAAMBER ® , CARAWHEAT ® , CARABOHEMIAN ® ,<br />

CARABELGE ® , CARAFA ® and SINAMAR ® are registered trademarks<br />

for Weyermann ® Specialty Malting Company, Bamberg<br />

CARAPILS ® CARAHELL ®<br />

CARAMUNICH ® CARARYE ®<br />

CARARED ® CARAAROMA ®<br />

CARAAMBER ® CARAWHEAT ®<br />

CARABOHEMIAN ® CARABELGE ®<br />

CARAFA ® CARAFA ® SPEZIAL<br />

(roasted malt from dehusked barley, gives the beer a smooth taste without burnt flavor)<br />

Malt Extract:<br />

VLB inside<br />

BAVARIAN PILSNER<br />

BAVARIAN HEFEWEIZEN<br />

MUNICH AMBER VIENNA RED<br />

BAVARIAN DUNKEL<br />

BAVARIAN MAIBOCK<br />

BAMBERG RAUCH<br />

MUNICH OCTOBER BEER<br />

All-Natural Liquid<br />

Malt Color<br />

SINAMAR ® and<br />

certified organic SINAMAR ®<br />

...gives your beer special taste<br />

and color, without burnt flavor !<br />

Meet Sabine and Thomas Weyermann<br />

at the „BRAU Beviale“ in Nuremberg,<br />

November 09 -11, 2011<br />

hall 1, booth # 403 and 405,<br />

and join the Weyermann ®<br />

Bavarian Party in Bamberg,<br />

November 12, 2011, 3:00 p.m. !<br />

For more information contact :<br />

e-mail: info@weyermann.de<br />

www.weyermann.de<br />

5

VLB inside<br />

VLB Berlin and SENAI Rio, Brazil,<br />

announcing cooperation<br />

Partnership signed in the field of education, further training and other projects<br />

for the Brazilian brewing sector.<br />

(oh) The competence of VLB Berlin<br />

is enjoying increasing appreciation<br />

worldwide: Further confirmation is the<br />

new cooperation agreement with the<br />

renowned SENAI Food and Beverage<br />

Technology Center from Vassouras, Rio<br />

de Janeiro, Brazil. The agreement was<br />

signed on 29 September 2011 in Berlin<br />

by Maria Lucia Telles, Director of SINAI<br />

Rio de Janeiro, Antõnio Tavares da Silva,<br />

Executive Manager of the SENAI<br />

Food and Beverage Technology Center,<br />

and Dr. Josef Fontaine, Managing<br />

Director of VLB Berlin.<br />

A focus of the agreement lies in close<br />

cooperation in the field of education<br />

and training for brewers in Brazil. It<br />

also includes the intention of joint<br />

development and consulting projects<br />

with relevance for the brewing<br />

and beverage sector.<br />

As a first step, the well-established<br />

SENAI brewers’ courses will be sup-<br />

6 Brauerei Forum – VLB International 2011<br />

ported by contributions from experts<br />

from VLB in the future. In addition<br />

joint excursions to Germany are planned.<br />

The upcoming 3 rd VLB Iberoamerica<br />

American Symposium Brewing<br />

and Filling Technology from 18<br />

to 21 June 2012 in Petropolis, Rio de<br />

Janeiro, Brazil, will include a session<br />

on raw materials and malt which will<br />

be organised together with SENAI.<br />

With this long-term agreement both<br />

institutes, SENAI and VLB, aim to further<br />

deepen the good relationships<br />

between the two great beer nations<br />

Brazil and Germany.<br />

The SENAI-RJ Food and Beverage<br />

Technology Center (CTS) is located<br />

in Vassouras in the State of Rio de<br />

Janeiro, Brazil. Amongst other things,<br />

CTS provides training courses for<br />

technicians from the brewing and<br />

food industry in Brazil.<br />

Looking forward to close cooperation: Antõnio Tavares da Silva, Executive<br />

Manager SENAI-RJ, Maria Lucia Telles, Director SENAI-RJ, and Dr. Josef Fontaine,<br />

Managing Director VLB<br />

Photo: oh<br />

Deniz Bilge joins<br />

VLB‘s team of experts<br />

Since May 2011 Dr. Deniz Bilge has<br />

been new senior consultant at VLB‘s<br />

Department for Brewing and Beverage<br />

Science & Applications (BBSA).<br />

VLB Berlin has successfully expanded<br />

its team of experts: With Dr. Deniz Bilge<br />

VLB has been able to gain an experienced<br />

doctorate brewing engineer<br />

in order to strengthen its capacities.<br />

Deniz Bilge started his professional<br />

career with an apprenticeship as<br />

“Brewer and Maltster“ at the Beck´s<br />

Brewery in Bremen, Germany. After<br />

positions in Canada and Germany<br />

he started a study course in brewing<br />

technology at Technische Universität<br />

Berlin, where he obtained a degree<br />

in brewing engineering in 1999. In<br />

the following years he was a research<br />

assistant at the Institute for Brewing<br />

Science at TU Berlin under Prof. Karl<br />

Wackerbauer. There he also earned<br />

his Doctors degree.<br />

2005 Deniz Bilge moved to Sopura<br />

Chemie where he was responsible<br />

for the development and implementation<br />

of cleaning and disinfection<br />

concepts in the brewing industry.<br />

In 2008 he left Germany for Greece.<br />

As Technical Director of the Hellenic<br />

Breweries of Atalanti he was responsible<br />

for the management of production<br />

and filling including purchasing,<br />

maintenance and human resources.<br />

In 2011 he moved back to Berlin.<br />

At VLB Deniz Bilge contributes to the<br />

research, consultancy and training of<br />

VLB‘s Department for Brewing and<br />

Beverage Science & Applications<br />

(BBSA) with special focus on the international<br />

markets.

Pumps ■ Valves ■ Systems<br />

Visit us at Brau Beviale in Nuremberg!<br />

09 to 11 November 2011, hall 6, booth 221<br />

We set standards in industry.<br />

A worldwide leading manufacturer of pumps, valves and systems, we are a competent and reliable<br />

partner in many areas of the food and beverages industry. In the beginning of 2010, we extended<br />

our product range for sterile processes. Offering products for these core applications is KSB’s response<br />

to meeting the customers’ requirements and our guarantee to find the right solution for any<br />

demand. This is achieved with thorough know-how and an in-depth competence in materials to<br />

deliver solutions from a single source. Which is exactly what KSB is all about. www.ksb.com<br />

Brauerei Forum – VLB International 2011<br />

7

VLB inside<br />

VLB Alumni Meeting at the Craft Brewers Conference 2011<br />

The VLB booth at the Craft Brewers<br />

Conference in March 2011 in San<br />

Francisco, USA, again attracted a lot<br />

of interest. An additional highlight<br />

was provided by the first international<br />

VLB Alumni Meeting, which took<br />

place in the context of this event.<br />

8 Brauerei Forum – VLB International 2011<br />

Stay tuned to VLB: New website and social network<br />

The Internet has become one of the most important communication channels<br />

– also for VLB. With a web site relaunch in 2011 and a new community<br />

on LinkedIn VLB is well positioned within the world of new media.<br />

(oh) Since 1996 VLB Berlin has operated<br />

a web site at www.<strong>vlb</strong>-berlin.<br />

org. In 2011 the forth relaunch was<br />

completed: The new VLB page has<br />

the “look and feel” of an information<br />

portal. All current news, dates<br />

and information are displayed on<br />

the start page. In the submenus the<br />

user can find detailed information<br />

about all VLB departments, its service<br />

activities, the publications, training<br />

courses and other events. As special<br />

gimmick a small quiz about brewing<br />

specific expert know ledge is offered.<br />

The information on the VLB web site is<br />

available in German, English, Spanish<br />

and Russian.<br />

� www.<strong>vlb</strong>-berlin.org<br />

(oh) No doubt about it: The annual<br />

Craft Brewers Conference has developed<br />

into the biggest event for craft and<br />

microbrewers worldwide. With about<br />

4000 attendees the 2011 conference<br />

was again sold out. Since 2006 VLB Berlin<br />

has been attending this event with<br />

Social media networks have been growing<br />

very quickly and become more and<br />

more important – also on a professional<br />

level. In November 2011 VLB started to<br />

support an international community on<br />

the international network “LinkedIn”.<br />

Currently available is a company page<br />

and a group which will be managed and<br />

supported by several VLB experts. The<br />

group addresses international alumni,<br />

members, friends and partners of VLB.<br />

The language is English.<br />

� www.linkedin.com/company/<br />

<strong>vlb</strong>-berlin<br />

a booth. The aim is to continuously<br />

extend and maintain its international<br />

network – also with the US craft and<br />

microbrewers scene.<br />

In addition to a lot of other conference<br />

activities a special highlight for the VLB<br />

representatives Roland Folz and Burghard<br />

Meyer was the 1 st International<br />

VLB Alumni Meeting which took place<br />

on Thursday, 24 March 2011, at the Hilton<br />

San Francisco. The intention was to<br />

bring together the small but constantly<br />

growing community of VLB alumni<br />

based in North America. Thanks to the<br />

support of Ziemann USA, the Trumer<br />

Brewery, the Sierra Nevada Brewing<br />

Co and the New Holland Brewing Co<br />

it was a small but enthusiastic party<br />

with great beers and food. VLB would<br />

like to address special thanks to Oliver<br />

Wesseloh (Ziemann USA) for his great<br />

support!<br />

All attendees agreed that this was a<br />

successful kick-off which needs to be<br />

continued. The next international VLB<br />

Alumni Meeting is scheduled during<br />

the Craft Brewers Conference 2012 in<br />

May 2012 in San Diego, USA.<br />

� www.<strong>vlb</strong>-berlin.org/alumni<br />

Long time no see: Participants of the<br />

1 st International VLB Alumni Meeting in<br />

March 2011 in San Francisco (USA)

Wolfgang Kunze 85<br />

On 7 August 2011, Wolfgang Kunze,<br />

former Head of the Dresdner Brewers’<br />

School, manager of the VLB office in<br />

Dresden and author of the textbook<br />

“Technology Brewing and Malting“<br />

celebrated his 85 th birthday.<br />

(oh) Wolfgang Kunze, born in 1926,<br />

completed an apprenticeship as ”Brewer<br />

and Maltster“ at the Waldschlößchen<br />

Brauerei in Dresden, Germany. He<br />

graduated in brewing science at VLB<br />

Berlin in 1952. He moved back to Dresden<br />

and became teacher and head of<br />

the Dresden Brewer’s School, a position<br />

he held for 38 years. In this position he<br />

introduced generations of brewers and<br />

maltsters in Eastern Germany to the<br />

art of beer brewing. After the German<br />

reunification he founded and ran the<br />

VLB office in Dresden and rendered<br />

great service in re-uniting the German<br />

brewers community in East and West.<br />

He conveyed his comprehensive knowledge<br />

and his didactic experience in<br />

the famous textbook ”Technology<br />

Brewing and Malting“. His book – in<br />

brewers’ circles well-known as just the<br />

“Kunze”– has accompanied countless<br />

brewers and maltsters on their way<br />

into and through the professional<br />

practice since its first edition in 1961.<br />

Meanwhile more than 30,000 German,<br />

about 13,000 English, 6000 Chinese,<br />

3500 Russian and 1500 Spanish copies<br />

have been printed. It has also been<br />

translated into Polish, Serbian and<br />

Hungarian. The English Edition – last<br />

updated in 2009 – is available at VLB<br />

Berlin and other book stores.<br />

Today Wolfgang Kunze lives in Radebeul<br />

near Dresden. He has been<br />

married since 1948 to his wife Christa<br />

and has 3 children, 8 grandchildren,<br />

7 great-grandchildren and a dog.<br />

� www.<strong>vlb</strong>-berlin.org/en/kunze<br />

Tradition meets Innovation<br />

The Barth-Haas Group is the global market leader in all products and services derived from hops. As a<br />

successful family-run company, we have been developing innovative hop-based products to meet brewers’<br />

needs for over 100 years. We are setting new standards in hop-based applications. Our customers benefi t<br />

from our reliable partnership, extensive technical know-how and comprehensive service. We are the<br />

Barth-Haas Group and Hops are our World!<br />

www.barthhaasgroup.com<br />

Brauerei Forum – VLB International 2011<br />

VLB inside<br />

9

ReseaRCh & deVeLopment<br />

� Brewing Technology<br />

Fermentation tests with improved<br />

EBC fermentation modules<br />

Small-scale tests of yeast properties can give valuable insight to optimise or modify the fermentation process<br />

or to develop new products. During recent years the so called EBC test tubes made from glass were the method<br />

of choice when running tests for beer fermentation. The Department for Brewing and Beverage Science &<br />

Application of VLB Berlin has now introduced a further development of this method which shows significant<br />

advantages in terms of handling and reliability.<br />

Roland Folz and<br />

Thomas Tyrell<br />

in front of the<br />

new fermentation<br />

module for<br />

fermentation test<br />

according to EBC<br />

(oh) Testing of yeast properties on a<br />

small-scale is mainly performed in so<br />

called EBC fermentation test tubes.<br />

This test was published in 1977 as<br />

method 2.5.4 “Tubes E.B.C.” within<br />

the Analytica of the European Brewery<br />

Convention (EBC). The reactors<br />

are described as glass tubes with an<br />

internal diameter of 50 mm and a<br />

height of 150 cm. In order to control<br />

the temperature they are equipped<br />

with a cooling jacket. The volume of 2<br />

litres of fermenting substrate allows a<br />

head of liquid of 110 cm. Samples are<br />

supposed to be taken from the top of<br />

the fermenter at a level of 30 cm below<br />

the surface of the liquid. The aeration<br />

of wort is recommended within<br />

this method by inverting the tube 20<br />

times after filling and yeast pitching.<br />

In comparison to other fermentation<br />

10 Brauerei Forum – VLB International 2011<br />

methods in laboratory scale, the EBC<br />

tubes allow a relatively high liquid<br />

column with only 2 litres of volume.<br />

This simulates a certain sedimentation<br />

height and static pressure to the yeast.<br />

As a result this fermentation comes<br />

closer to a large-scale process than fermentations<br />

in other laboratory setups.<br />

This method has been used for decades<br />

within the brewing industry and<br />

works quite well but has some serious<br />

disadvantages.<br />

Due to the material properties of glass<br />

the tubes are quite sensitive in handling.<br />

Also, the maximum internal pressure<br />

of a glass tube is limited. The aeration<br />

method by “shaking” the tubes<br />

is neither reproducible nor controllable.<br />

An oxygen free processing of the<br />

fermented beer is almost impossible<br />

and the range of adjustable CO 2 con-<br />

Photos: oh<br />

centrations is very limited. Taking into<br />

account all of these disadvantages,<br />

this EBC method shows some room<br />

for improvement.<br />

Modified test tubes made from<br />

stainless steel<br />

The basic targets for the development<br />

of the new test tubes were to increase<br />

the reproducibility, to optimise the<br />

handling and to bring the test environment<br />

closer to conditions in industrial<br />

practice. The figure on the right shows<br />

the basic setup of the new fermentation<br />

module containing 10 test tubes.<br />

They are made from stainless steel<br />

with an inner diameter of 65 mm. This<br />

increases the volume from 2 l to 3,65 l.<br />

Each tube has 3 cooling zones and is<br />

equipped with 2 Varivent® connectors<br />

provided by GEA Brewery Systems.<br />

The construction offers two sampling<br />

points per column and allows the inline<br />

connection of measuring devices<br />

for turbidity or other parameters. A<br />

view into the test tube for technological<br />

observation of the fermentation<br />

process is possible by a sight glass.<br />

The pressure is controlled by a bunging<br />

device on the top of each test<br />

tube. The cleaning process has also<br />

been improved. The new installation<br />

is suitable for cleaning in place (CIP).<br />

All columns are connected in parallel<br />

into the same CIP loop. This assures<br />

an easy cleaning and sanitising of the<br />

1,5 m long tubes within only one hour.<br />

An important aspect when it comes<br />

to screening a large amount of yeast<br />

strains on their fermentation properties.<br />

In comparison to the conventional<br />

EBC test tubes, the modified tubes<br />

show several significant advantages.<br />

Improved sampling: A reproducible<br />

sampling can be done at two sampling<br />

valves at the same liquid level. The upper<br />

one at 30 cm below liquid level as<br />

described in the original EBC method.<br />

The fixed point avoids irregularities<br />

due to different handling by different<br />

operators. Inline measurement can be<br />

applied with the installed Varivent®<br />

connections as well. This also allows<br />

the validation of new measurement<br />

devices and other applications.<br />

Fermentation under pressure: The<br />

new tubes allow the application of<br />

an overpressure up to 3 bar during<br />

fermentation. This has several advantages.<br />

It improves the wort aeration<br />

and allows checking yeast properties<br />

under higher CO 2 concentrations. Another<br />

positive effect is that the oxygen<br />

intake can be reduced significantly<br />

when the fermented beer is filled into<br />

bottles for further analysis.

CIP Cleaning: Due to the stainless<br />

steel construction, the new test<br />

tubes can be easily hooked up<br />

to a CIP loop. This allows reliable<br />

cleaning and disinfection and saves<br />

time and cost.<br />

Greater diameter and stainless<br />

steel instead of glass: The modified<br />

tubes are made of stainless<br />

steel with an inner diameter of<br />

65 mm. This leads to a larger volume<br />

of each tube (3,65 litres). A<br />

typical experience with the conventional<br />

tubes was that in fermentations,<br />

where many samples<br />

had to be taken the liquid level<br />

decreased significantly in the<br />

course of the fermentation. As a<br />

result the volume of the beer was<br />

too low to run a complete beer<br />

analysis, especially including sensory<br />

tasting at the end of the test.<br />

With the extended volume of the<br />

new tubes this problem has been<br />

solved. Of course, VLB is aware<br />

that gaining adequate sampling<br />

at a volume of 3,65 l is still a problem.<br />

However, this approach<br />

demonstrates a close connection<br />

to VLBs strategical investment in<br />

cutting edge analytical devices<br />

during the recent years in order<br />

to be able to gain as many results<br />

as possible out of smallest<br />

amount of sample volume. The<br />

combination of a modern small<br />

scale fermentation set up combined<br />

with leading analytical developments<br />

can therefore serve<br />

as a reference in today’s fermentation<br />

modelling.<br />

Fields of application<br />

New selection of yeast strains<br />

and screening of fermentation<br />

properties: It has been shown<br />

in several publications that culture<br />

yeast strains are usually not<br />

identical clones. Consequently it<br />

is not uncommon to find yeast<br />

cells with genetic differences<br />

within one brewery yeast culture.<br />

These mixed populations are not<br />

necessarily negative for industrial<br />

brewery fermentations. But in<br />

some cases one genotype within<br />

a mixed population performs<br />

better than others in terms of<br />

fermentation speed, flocculation,<br />

diacetyl reduction and others. To<br />

find genetically different yeasts<br />

in a batch it is necessary to separate<br />

single cells. At the VLB this is<br />

done with a micromanipulator.<br />

In a second step these yeast cells<br />

are propagated and checked to<br />

see if they are identical clones or<br />

different in their genetic properties.<br />

If different yeasts are present<br />

they need to be tested on their<br />

fermentation properties and on<br />

their genetic stability. Our improved<br />

EBC test tubes are perfectly<br />

adapted for reliably conducting<br />

those types of small scale fermentations.<br />

Screening of fermentation<br />

additives: Besides a general<br />

screening of yeast strains, the EBC<br />

test tubes are suitable to check<br />

the optimal dosage and the effects<br />

of fermentation additives.<br />

Testing of new inline measurement<br />

systems for control of fermentation:<br />

The test tubes also<br />

allow the validation of analytical<br />

inline control devices during fermentation.<br />

The equivalent offline<br />

control sample can be taken<br />

on the other side of the tube.<br />

With this improved EBC method<br />

process optimisation and product<br />

development of fermentet<br />

beverages will be more efficient<br />

and reliable.<br />

Contact<br />

Dr.-Ing. Roland Folz<br />

folz@<strong>vlb</strong>-berlin.org<br />

Dipl.-Ing. Thomas Tyrell<br />

Tyrell@<strong>vlb</strong>-berlin.org<br />

Origin of great beers.<br />

Focus on green brewing<br />

technology.<br />

GEA Brewery Systems lays the focus on conser vation of<br />

natural resources, yield increase in the brewing process<br />

and significant reduction of operational expenses.<br />

Reduce your environmental footprint and go green<br />

– our equipment and processes are optimized for longterm<br />

sustainability and designed for your successful<br />

economic future. We develop innovative solutions<br />

considering your local conditions and your economic<br />

and ecological requirements.<br />

■ Minimized consumption of natural resources like<br />

water, energy and raw materials<br />

■ Making the brewing process as efficient and<br />

predictable as possible<br />

■ Reduced odour emissions by up to 100 %<br />

■ Recycling of by-products or waste products<br />

■ Tailored energy management<br />

GEA Process Engineering<br />

GEA Brewery Systems GmbH<br />

Huppmann Tuchenhagen<br />

Nuremberg, 9 – 11 November<br />

hall 7 / stand 602<br />

Heinrich-Huppmann-Str. 1, 97318 Kitzingen, Germany<br />

Tel +49 9321 303-0, Fax +49 9321 303-603<br />

Am Industriepark 2–10, 21514 Büchen, Germany<br />

Tel +49 4155 49-0, Fax +49 4155 49-2770<br />

info@gea-brewery.com, www.gea-brewery.com<br />

ReseaRCh & deVeLopment<br />

Brauerei Forum – VLB International 2011<br />

GEA_BS_GreenImage_92x240mm_engl_RZ.indd 1 24.10.11 11:09<br />

11

ReseaRCh & deVeLopment<br />

� Raw materials<br />

New analytical method for determination of<br />

high molecular arabinoxylan content in wort<br />

Henrike Vorwerk, registered food chemist, Research Institute for Raw Materials (FIR) of VLB Berlin<br />

In the past, successful attempts were made in cultivation and malting technologies to reduce the content of β-glucans in brewing barley and malt and thus<br />

prevent technological problems in the brewing process caused by these substances. Arabinoxylans occur mainly together with β-glucans in the grain and<br />

show very similar properties. Nonetheless they have not been included in most of these studies. An analytical method for the determination of high molecular<br />

arabinoxylan was established at the Research Institute for Raw Materials in order to monitor their content in wort and beer.<br />

Henrike Vorwerk<br />

Prof. Dr. Frank Rath<br />

Arabinoxylans as a factor contributing<br />

to beer viscosity and filterability<br />

Arabinoxylans are important non-starch<br />

polysaccharides in barley and represent<br />

a major structural constituent of cell<br />

walls in various tissues. While β-glucan<br />

enriched endosperm cell walls contain<br />

only small amounts of arabinoxylan<br />

(20 %), aleurone cell walls are built up<br />

mainly of arabinoxylans (70 %). The<br />

chemical structure of arabinoxylans<br />

consists of a linear backbone of β-(1,4)-<br />

D-xylopyranosyl residues to which<br />

α-L-arabinofuranosyl residues can be<br />

attached in O-2 and/or O-3 position. The<br />

distribution of the resulting structural<br />

elements of unsubstituted, monosubstituted<br />

and disubstituted xylose residues<br />

varies depending on the origin of the<br />

arabinoxylans [1]. A unique characteristic<br />

of arabinoxylans is the presence of<br />

hydroxycinnamic acids, especially ferulic<br />

acid, which can be linked to the O-5<br />

position of arabinose residues.<br />

12 Brauerei Forum – VLB International 2011<br />

Arabinoxylans are only partially soluble<br />

in water. Higher amounts of substituted<br />

xylose residues improve the<br />

solubility of the molecules [2]. Under<br />

oxidative conditions feruloyl units can<br />

dimerize into dehydrodiferulate esters,<br />

cross-linking arabinoxylan molecules<br />

covalently with arabinoxylans and<br />

other cell wall components and thereby<br />

contributing to the insolubility<br />

of arabinoxylans [1]. Due to their high<br />

molecular weight and cross-linking capacity,<br />

arabinoxylans are able to form<br />

viscous solutions and stabilized gels,<br />

thereby displaying characteristics normally<br />

associated with β-glucans.<br />

During malting, water-soluble arabinoxylan<br />

levels in malt increase to twice<br />

the amount found in barley [3]. Enzyme<br />

activities during mashing cause<br />

a further solubilization of arabinoxylan<br />

from malt with wort arabinoxylans representing<br />

10-14 % of the total barley<br />

malt arabinoxylan (6.4-6.9 %) [4]. Pa-<br />

Fig. 1: Mean values of AX content in one congress wort prepared repeatedly over<br />

5 consecutive days<br />

rameters such as kilning and mashing<br />

temperatures, steeping degree and<br />

grist coarseness influence the formation<br />

and extractability of water-soluble<br />

arabinoxylans during malting and mashing<br />

[5]. In the past, filtration difficulties<br />

in the brewing process were generally<br />

attributed to β-glucan contents<br />

in raw materials. Recently, it has been<br />

reported that arabinoxylans might<br />

have a larger effect on filterability than<br />

β-glucans [6]. Evidence was found that<br />

arabinoxylans may influence wort and<br />

beer viscosity to a higher extent than<br />

known for β-glucans [7]. Furthermore<br />

the impact of arabinoxylans on extract<br />

yield, haze formation and foam stability<br />

is discussed. Considering that those<br />

effects can be attributed mostly to high<br />

molecular, water-soluble fractions of<br />

arabinoxylans, further studies should<br />

concentrate on these substances.<br />

High molecular arabinoxylans<br />

At the FIR an analytical method for the<br />

measurement of high molecular arabinoxylans<br />

from wort and beer was established<br />

as an adaptation of a method<br />

previously published by Obrecht [8].<br />

High molecular arabinoxylans are<br />

precipitated from wort by addition of<br />

alcohol. The precipitate is hydrolysed<br />

with sulphuric acid to break down the<br />

polysaccharides into their single sugar<br />

residues. After a neutralisation step<br />

with calcium carbonate, the supernatant<br />

is lyophilized, reconstituted in an<br />

eluent mixture and the xylose concentration<br />

measured by high performance<br />

liquid chromatography (HPLC) with<br />

refractive index detection (RID). The<br />

high molecular arabinoxylan content is<br />

calculated from the determined xylose<br />

concentration, assuming that barley<br />

malt arabinoxylan contains 56.3 % xylose<br />

[9]. The arabinose concentration in<br />

the lyophilisate is not considered in the

Fig. 2: AX concentration in congress worts of malts from different barley varieties<br />

(4 locations, 2 malting variants) (n = 8)<br />

calculation as varying amounts of arabinose<br />

can result from arabinogalactans.<br />

For validation purposes aliquots<br />

of one congress wort were prepared 10<br />

times during one day and several times<br />

per day for 5 consecutive days. The<br />

intraday measurements had a mean<br />

value of 307 mg/L with a relative standard<br />

deviation (RSD) of 4.9 %. For the<br />

interday measurements a mean of the<br />

daily mean values of 306 mg/L with a<br />

RSD of 1.4 % was calculated, showing<br />

a good repeatability of the sample preparation<br />

(Fig. 1).<br />

First Results<br />

6 spring barley varieties, cultivated at<br />

various locations in Germany, were<br />

malted under varying conditions and<br />

the concentration of high molecular<br />

arabinoxylans in the congress worts of<br />

these malts was measured. The calculated<br />

mean values for 4 locations and<br />

2 malting variants ranged from 183–<br />

308 mg/L, showing a distinct variation<br />

of the determined arabinoxylan levels<br />

(Fig. 2). High molecular arabinoxylan<br />

concentrations measured in congress<br />

worts of commercial barley malts were<br />

in a range from 206–371 mg/L. Comparing<br />

the determined arabinoxylan contents<br />

in the congress worts with their<br />

β-glucan content, it appears difficult<br />

to find a correlation between these<br />

compounds, seeing as worts with similar<br />

amounts of arabinoxylans contain<br />

strongly varying amounts of β-glucan<br />

(Fig. 3). But there seems to be a slight<br />

trend of increasing arabinoxylan concentrations<br />

with decreasing β-glucan<br />

concentrations. A reason for this effect<br />

could be an improved extractability of<br />

high molecular arabinoxylans caused<br />

by a stronger degradation of β-glucans<br />

in the cell wall material during malting.<br />

Taking these results into account<br />

it should be considered whether a<br />

strong degradation of β-glucans is<br />

useful to the brewing process if this<br />

results in larger amounts of high molecular<br />

arabinoxylan being released into<br />

the worts with the capacity to form<br />

viscous solutions and gels.<br />

Literature<br />

[1] Izydorczyk MS, Dexter JE (2008):<br />

Barley β-glucans and arabinoxylans:<br />

Molecular structure, physicochemical<br />

properties, and uses in food<br />

products – A Review, Food Research<br />

International, 41, 850–868<br />

[2] Viëtor RJ, Voragen AGJ, Angelino<br />

SAGF (1993): Composition of nonstarch<br />

polysaccharides in wort and<br />

spent grain from brewing trials with<br />

malt from a good malting quality<br />

barley and a feed barley, Journal of<br />

the Institute of Brewing, 99, 243–248<br />

[3] Dervilly G, Leclercq C, Zimmermann<br />

D, Roue C, Thibault JF, Saulnier L<br />

(2002): Isolation and characterization<br />

of high molar mass water-soluble<br />

arabinoxylans from barley and<br />

barley malt, Carbohydrate Polymers,<br />

47, 143–149<br />

[4] Debyser W, Derdelinckx G, Delcour<br />

JA (1997): Arabinoxylan and arabinoxylan<br />

hydrolysing activities in barley<br />

malts and worts derived from them,<br />

Journal of Cereal Science, 26, 67–74<br />

[5] Krahl M, Müller S, Back W, Kreisz S<br />

(2008): Arabinoxylan (Pentosan) in<br />

der Malz- und Bierbereitung, Brauwelt,<br />

10, 248–252<br />

[6] Sadosky P, Schwarz PB, Horsley<br />

RD (2002): Effect of arabinoxylans,<br />

β-glucans, and dextrins on the viscosity<br />

and membrane filterability<br />

of a beer model solution, Journal<br />

of the American Society of Brewing<br />

Chemists, 60(4), 153–162<br />

[7] Li Y, Lu J, Gu G, Shi Z, Mao Z (2005):<br />

Studies on water-extractable arabinoxylans<br />

during malting and brewing,<br />

Food Chemistry, 93, 33–38<br />

[8] Obrecht J (2009): A straightforward<br />

method for the determination of<br />

viscosity-inducing arabinoxylans in<br />

wort and beer, Poster Session EBC<br />

Congress Hamburg<br />

[9] Izydorczyk MS, MacGregor AW<br />

(2003): Identification of biochemical<br />

and functional properties of<br />

β-glucans and arabinoxylans in barley<br />

and malt that cause processing<br />

problems during malting and brewing,http://www.gov.mb.ca/agriculture/research/ardi/projects/98–187.<br />

html<br />

Contact<br />

Henrike Vorwerk<br />

vorwerk@<strong>vlb</strong>-berlin.org<br />

Prof. Dr. Frank Rath<br />

rath@<strong>vlb</strong>-berlin.org<br />

Brauerei Forum – VLB International 2011<br />

ReseaRCh & deVeLopment<br />

Fig. 3:<br />

Arabinoxylan<br />

and β-glucan<br />

concentration in<br />

congress worts of<br />

commercial malts<br />

13

ReseaRCh & deVeLopment<br />

� Analytical Services<br />

VLB laboratories achieved ISO/IEC17025 reaccreditation<br />

VLB Berlin has achieved the reaccreditation by the Deutsche Akkreditierungsstelle (DAkkS). The laboratories are now again accredited for a period of five years<br />

according to DIN EN ISO/IEC 17025. Compliance to international standards is essential for a professional analytical laboratory.<br />

Die Akkreditierung gilt für die in der<br />

Urkunde aufgeführtern Verfahren<br />

(WiK) VLB Berlin has renewed its accreditation<br />

according to DIN EN ISO/IEC<br />

17025. “New this year is the acceptance<br />

of VLB’s Central Laboratory as a conformity<br />

assessment body for consumer<br />

health protection including food safety”,<br />

says VLB’s Quality Management<br />

Representative Katharina Baron. This<br />

is an important precondition for the<br />

approval of Dr. Diedrich Harms (Head<br />

of Central Laboratory) as a private qualified<br />

expert for the testing of official<br />

samples according<br />

to § 3 Cross<br />

Checking Regulation.<br />

As a result,<br />

VLB is now able<br />

to analyse official<br />

samples taken by<br />

the food inspection<br />

authorities.<br />

Also new this<br />

(WiK) In close cooperation with<br />

DLG Dr. Harms together with<br />

VLB staff developed solutions<br />

for the future of the beverage<br />

sector. The DLG tests are very<br />

strict, but popular, because a DLG medal<br />

on the bottle label is still a unique<br />

selling proposition at the point of sale.<br />

Beer test<br />

In the beer test 2011, were 651 samples<br />

and given scores based on chemical<br />

technical and microbiological analyses<br />

and sensory evaluation.<br />

The beer was sent in from Austria, Germany,<br />

Italy, Namibia, Sweden, Switzerland,<br />

Tansania and the USA. In order to<br />

take part in the international DLG quality<br />

test for beer, the beers must have<br />

been brewed in accordance with the<br />

German Purity Law of 1516. Ten sensory<br />

experts examine two different-aged<br />

14 Brauerei Forum – VLB International 2011<br />

year is the external monitoring by the<br />

DAkkS GmbH. DAkkS (Deutsche Akkreditierungsstelle)<br />

is the national accreditation<br />

body of the Federal Republic<br />

of Germany. It is legally mandated to<br />

carry out accreditations of conformity<br />

assessment bodies. DAkkS was founded<br />

in 2010 based on EU Regulation<br />

765/2008 and its accreditations are<br />

within the scope of the multilateral<br />

agreements of the European Cooperation<br />

for Accreditation and the ILAC and<br />

IAF international accreditation organisations.<br />

Since 1 January 2010, DAkkS<br />

has taken on the role as the national accreditation<br />

body of Germany. DAkkS is<br />

entrusted by the Federal Government<br />

with its public authority tasks and is<br />

subject to the German administrative<br />

law and operates on a non-profit basis.<br />

The mutual recognition of accreditations<br />

among the member countries<br />

Dr. Diedrich Harms, DLG’s Authorised Beer Test Officer<br />

Dr. Diedrich Harms, head of VLB’s Central Laboratory, became Authorised Test Officer (Prüfbevollmächtigter) for DLG (Deutsche Landwirtschafts-Gesellschaft<br />

– German Agricultural Society). He is responsible for all tests which are performed in the beverage sector, from beer to fruit beverages and soft drinks. He is<br />

also a member of all DLG beverage commissions.<br />

Dr. Diedrich Harms<br />

harms@<strong>vlb</strong>-berlin.org<br />

samples of each beer. There<br />

must not be any significant<br />

deviation between the fresh<br />

sample and the older sample.<br />

The beer has also to prove its<br />

flavour stability during storage.<br />

Spirits, fruit beverages and water<br />

DLG‘s international quality test for distilled<br />

spirits, headed by Dr. Rolf Hardt<br />

(VLB Central Laboratory), in 2011<br />

checked and awarded scores to 563<br />

samples from 7 countries such as Austria,<br />

Germany, Greece, Italy, Lithuania,<br />

Luxemburg and even from Mongolia.<br />

The DLG tests fruit beverages and covers<br />

fruit juices, nectars and fruit juice<br />

beverages. Even soft drinks such as<br />

caffeinated, functional and innovative<br />

drinks are tested. The water test, headed<br />

by Dr. Alfons Ahrens (Head of VLB‘s<br />

Research Institute for Water and Waste-<br />

ensures the acceptance of conformity<br />

assessments in Europe and all over the<br />

world.<br />

The reaccreditation audit also included<br />

an evaluation of the QM system<br />

and technical audits of the analytical<br />

laboratories of VLB. Within the fiveyear<br />

validity of the reaccreditation, two<br />

supervising audits will be conducted.<br />

� www.<strong>vlb</strong>-berlin.org/en/services<br />

water), checks natural mineral, spring<br />

and table waters. All beverage tests<br />

are divided into a sensory and an analytical<br />

part. Depending on the scores<br />

achieved, the products are awarded<br />

DLG Medals in Bronze, Silver or Gold.

� Analytical Services<br />

“AHA Collaborative Trials”<br />

of the hop analytics work group<br />

For the 116 th time the hop analytics<br />

work group (Arbeitsgruppe<br />

Hopfenanalytik; AHA) met on 7 th<br />

and 8 th of July 2011 at the invitation<br />

of VLB Berlin’s in the guesthouse<br />

„Zur Linde“ in Krauschwitz,<br />

Germany.<br />

The AHA was founded in 1972<br />

and works on developing methods<br />

for the analysis of<br />

bitter substances in hops.<br />

Bitter substances represent<br />

the most important<br />

ingredient of hops and<br />

hop products. Over the<br />

past decades several<br />

other substance groups<br />

came into focus, e.g. hop<br />

oils, polyphenols or most<br />

recently pesticides. The work of<br />

the AHA is closely related to the<br />

activities of the analytical committee<br />

of the EBC. The implementation<br />

of International Calibration<br />

Extracts (ICE) for HPLC analysis<br />

of hop bitter substances (α- and<br />

β-acids) was forwarded by the<br />

AHA and the stability of the ICE<br />

is controlled on a regular basis.<br />

Furthermore, the AHA provides<br />

the opportunity to take part in<br />

collaborative trials. Several laboratories<br />

from the hop and beer<br />

industry already make use of<br />

the collaborative trials provided.<br />

These collaborative trials include<br />

analyses of bitter substances in<br />

different hop products (pellets<br />

and extract, downstream products,<br />

pre-isomerised pellets and<br />

extracts) or in beer according<br />

to the respective<br />

methods recommended<br />

in Analytica-EBC. A statistical<br />

evaluation of all results<br />

(including z-scores<br />

for every laboratory) is<br />

part of the ser vice (fig. 1).<br />

More than 30 laboratories<br />

in Europe, the US and<br />

Asia are already using the services<br />

provided to validate their<br />

analytical results. Participation is<br />

possible twice a year. Each round<br />

the participation fee is 180 €. For<br />

more detailed information please<br />

refer to Ruslan Hofmann.<br />

Contact<br />

VLB Berlin, Ruslan Hofmann<br />

hofmann@<strong>vlb</strong>-berlin.org<br />

Fig. 1: Example for the statistical evaluation of bitter units in a Pilsener<br />

beer sample. The outlier are not included in statistics. The outliers were<br />

detected from lab. 16 ( Cochran-Test) and lab. 13 (Grubbs-Test).<br />

mean 36,05 s r 0,048 CVS r 0,13 S R 0,760 CVS R 2,11<br />

S L 0,759 r 95 * 0,14 R 95 ** 2,13 n R 11 r 95 ** 0,15<br />

R 95 ** 2,40 *S r,R • 2,8 ** S r,R • F, F = f(n)<br />

Dicolube<br />

Sustain<br />

Sustainable Semi Dry<br />

Track Treatment<br />

Solutions<br />

� Line E� ciency<br />

� Conveyor Hygiene<br />

� Reduced Dilution Water Usage<br />

� Reduced E� uent Discharge Volumes<br />

� Reduced Water and E� uent Costs<br />

� Semi Dry Track Treatment<br />

Nürnberg, 09.-11.11.2011<br />

Please contact us in hall 4/231<br />

Diversey Deutschland GmbH & Co. oHG<br />

Mallaustraße 50-56 · 68219 Mannheim 0621-8757 0<br />

www.diversey.com

ReseaRCh & deVeLopment<br />

� Anaytical Services<br />

Stable isotope dilution assay:<br />

An outstanding tool in beer analysis<br />

Prof. Dr. Leif-Alexander Garbe and Dipl.-Ing. Nils Rettberg, VLB Research Institute for Special Analysis (also TU Chair of Bioanalytics)<br />

The VLB Research Institute for Special Analysis (FIS) offers long lasting competence in mass spectrometry (MS) and stable isotope dilution assay (SIDA). MS and<br />

SIDA are outstanding tools for trace analysis from complex matrices such as mash, wort and beer.<br />

Prof. Dr.<br />

Leif-Alexander Garbe<br />

garbe@<strong>vlb</strong>-berlin.org<br />

Dipl.-Ing. Nils Rettberg<br />

n.rettberg@<strong>vlb</strong>-berlin.<br />

org<br />

Todays brewing technology and research<br />

relies on accurate data derived<br />

from analysis of raw materials, intermediate<br />

products and the packed beer<br />

itself. Fundamental parameters such as<br />

hop bitter acids or fermentation byproducts<br />

are frequently monitored by<br />

means of basic liquid chromatographic<br />

(LC) and gas chromatographic (GC)<br />

techniques. GC and LC setups are widely<br />

established and automated. In<br />

routine applications both create large<br />

data sets without an operator needed.<br />

In addition to fundamental beer parameters<br />

numerous trace concentrated<br />

substances are highly relevant. Volatile<br />

(off) flavour compounds, (hydroxy) fatty<br />

acids, hop oils or product contaminants<br />

are usually present in (sub) ppb<br />

(µg/L) levels. Their identification and<br />

quantification is often crucial. Low target<br />

concentrations require extensive<br />

sample preparation procedures, stable<br />

isotope standards and sensitive mass<br />

spectrometry.<br />

Disadvantages of conventional<br />

internal standard assays in trace<br />

analyses<br />

A precise and reliable analysis of trace<br />

substances from complex matrices is<br />

a challenging discipline in beer analysis.<br />

In brewing sugars, proteins, polyphenols,<br />

alcohols and organic acids<br />

frequently mask low concentrated target<br />

substances. Matrix effects interfere<br />

or even preclude definite target identification<br />

and precise quantification. In<br />

addition to an efficient instrumental<br />

setup, appropriate and reproducible<br />

techniques of sample preparation and<br />

target isolation are required. Analyte<br />

loss throughout sample preparation<br />

needs to be followed, therefore reliable<br />

standards have to be chosen. Many<br />

analytical problems can be solved by<br />

internal standards, however the accuracy<br />

of those methods is very much<br />

dependent on the structure of the in-<br />

16 Brauerei Forum – VLB International 2011<br />

ternal standard. In general analyte and<br />

standard should be as near identical<br />

as possible. Structural differences can<br />

cause severe differences in their chemical<br />

and physical properties. Equilibration<br />

of standard and matrix may<br />

not be reached and enrichment during<br />

sample preparation may be disproportionate.<br />

Also matrix effects can cause<br />

discrimination or enhancement of one<br />

or the other. That means substance<br />

quantification might be incorrect or<br />

at least imprecise. In addition many<br />

target substances are labile, reactive<br />

or volatile during analysis and quantification<br />

does not properly reflect reality.<br />

In case structurally different internal<br />

standards are combined with extensive<br />

sample preparation procedures,<br />

systematic errors cannot be excluded.<br />

The advantages of SIDA and MS in<br />

precise substance quantification<br />

Today chromatographic systems are<br />

increasingly coupled to mass spectro-<br />

Fig. 1: The autosampler of GC-MS operates day and night<br />

metry (MS). Compared to basic GC and<br />

LC detectors (e.g. flame ionization and<br />

UV-detectors) MS enables substance<br />

characterisation and identification. If<br />

employed properly, MS is a very powerful<br />

tool. In the mass spectrometer<br />

ions are generated by electron impact,<br />

chemical or electrospray ionization.<br />

In connection to chromatographic<br />

separation the occurrence and rate of<br />

characteristic ions can be assigned to<br />

chemical structures and compound<br />

identity can be proven. In MS marginal<br />

mass to charge differences of ions are<br />

measured and nearly identical molecules<br />

with similar GC or LC retention<br />

times can be distinguished. This fact<br />

offers the possibility of a special case of<br />

an internal standard assay: Stable isotope<br />

dilution assay (SIDA). SIDA is comprehensive<br />

and very reliable technique<br />

of (trace) substance quantification. It<br />

is an internal standard assay in which<br />

stable isotope labeled substances are<br />

used as internal standards. In SIDA the

internal standard is an isotopologue<br />

of the target compound. Isotopologues<br />

are molecules that differ only<br />

in their isotopic composition. Simply,<br />

the isotopologue of a chemical species<br />

has at least one atom with a different<br />

number of neutrons than the parent.<br />

Figure 2 shows two isotopologues of<br />

Linalool. Whereas substance a) contributes<br />

to hoppy beer flavour, substance<br />

b) is a chemically synthesized<br />

stable isotope labeled standard. Analyte<br />

and isotope standard are as near<br />

identical as possible and can be solely<br />

distinguished by MS. The highly similar<br />

physical and chemical properties of<br />

analyte and isotope standard assure<br />

equal behavior during extraction<br />

and chromatography. In either case<br />

the loss of isotope standard exactly<br />

equals the loss of analyte and vice versa.<br />

The lower the target concentration,<br />

the higher its volatility and reactivity,<br />

the more essential the use of stable<br />

isotope labeled internal standards. If<br />

spiking with standard is carried out<br />

precisely, SIDA excludes any systematic<br />

errors. With respect to the limit of<br />

detection and quantification SIDA is<br />

not directly dependent on sample volume.<br />

Therefore SIDA perfectly suits<br />

miniaturized analytical setups such as<br />

Ultra-HPLC-MS applications. In general<br />

all systematic errors that usually arise<br />

from external and internal calibration<br />

vanish when using SIDA.<br />

Why is SIDA not widely used?<br />

The fact SIDA is not widely used in<br />

quality assurance labs and research<br />

institutes is connected to its two major<br />

perquisites: Firstly SIDA requires<br />

GC-MS or LC-MS setups combined<br />

with MS-skilled staff, secondly stable<br />

isotope labeled standards are needed.<br />

Whereas prices for simple mass<br />

spectrometers are constantly decreasing,<br />

the appropriate application of<br />

MS techniques is not trivial at all. The<br />

availability of stable isotope labeled<br />

standards is the major disadvantage<br />

of SIDA. Only very limited substances<br />

are commercially available. In most<br />

cases isotope standards have to be<br />

chemically synthesized, however this<br />

is often anything but easy. A major prejudice<br />

obverse SIDA is its high price.<br />

Doubtless prices for labeled standards<br />

or precursors seem to be high on first<br />

view, but have to be judged with care.<br />

SIDA is mainly applied in trace analysis,<br />

that means commonly only a few ng<br />

or µg standard are needed per sample.<br />

In case 5 µg standard are needed<br />

per sample, almost 5,000 runs can be<br />

performed from 250 mg. Assuming<br />

250 mg labeled standard cost € 500,<br />

the costs for isotope standards add up<br />

to € 0.1 per sample. This investment<br />

appears to be insignificant compared<br />

to costs for solvents and manpower.<br />

Conclusion<br />

The routine analysis in brewery quality<br />

assurance labs and research institutes<br />

is often based on chromatographic<br />

methods. Routine protocols, e.g. the<br />

quantification of higher alcohols or<br />

hop bitter acids, may be sufficiently<br />

VLB-LaboTech GmbH<br />

carried out with basic GC and LC equipment<br />

and conventional internal or<br />

external standards. When it comes to<br />

trace analysis of e.g. hop oils or staling<br />

carbonyls GC-MS or LC-MS methods<br />

coupled to SIDA are needed. In trace<br />

analysis, where sample preparation is<br />

usually extensive, stable isotope standards<br />

significantly support a precise<br />

analysis. GC-MS and LC-MS techniques<br />

help to assure compound identity and<br />

enable a precise quantification even<br />

if target concentration is low. Doubtless<br />

the major challenge in SIDA is the<br />

synthesis of stable isotope standards.<br />

In this field the VLB Research Institute<br />

for Special Analysis (FIS), and especially<br />

Prof. L.-A. Garbe, offers long lasting<br />

competence. When it comes to mass<br />

spectrometry and SIDA he kindly offers<br />

his support. Do not hesitate to ask for<br />

on demand stable isotope standard<br />

synthesis, sophisticated support in<br />

terms of MS, SIDA and trace analysis<br />

in brewing.<br />

� Laboratory tools and<br />

equipment for the<br />

laboratory in breweries,<br />

malthouses, beverage<br />

industry and distillers<br />

� Microbiology equipment<br />

� Distilling apparatus<br />

� Sensoric glasses<br />

www.<strong>vlb</strong>-berlin.org/service<br />

Brauerei Forum – VLB International 2011<br />

ReseaRCh & deVeLopment<br />

Fig. 2:<br />

Analyte a) and<br />

stable isotope<br />

standard b) are as<br />

near identical as<br />

possible and can<br />

be solely distinguished<br />

by MS<br />

Analytical services<br />

� Water / waste water<br />

� Barley, malt, hops<br />

� Wort, beer<br />

� Microbiology<br />

� Special analytics<br />

e.g. off flavours,<br />

residues, toxines<br />

� Testing of packaging<br />

� Testing of gas<br />

permeation<br />

through plastic bottles<br />

17

tRaining & eVents<br />

� International Training<br />

VLB Berlin bids farewell to its<br />

Certified Brewmasters 2011<br />

After 6 months of intensive training, 36 successful graduates of VLB‘s Certified Brew master Course 2011 were<br />

bid farewell on Friday, 24 June. This year’s VLB Certifed Brewmaster Course was attended by students from 18<br />

nations – once more evidence of the clear international focus of this training course.<br />

(oh) Again a Certified Brewmaster<br />

Course has been completed in Berlin.<br />

Due to the strong demand, in 2011 it<br />

was necessary once again to conduct<br />

the course in two parallel classes. 37<br />

of the initially 38 participants who<br />

arrived in January in a wintry Berlin,<br />

completed the course successfully. The<br />

high number of participants from the<br />

Ibero-American area this year was noticeable.<br />

Awarded as best VLB Certified<br />

Brew master 2011 was Martin Alejandro<br />

Bernabeu from Cervecería y Maltería<br />

Quilmes in Zárate, Argentina. “Silver“<br />

went to André Gonzalez Hercoli, Am-<br />

Bev, Brazil followed in 3 rd place by Ingrid<br />

Vico, Mahou San Miguel, Spain,<br />

who was also the best female brewmaster<br />

this year.<br />

The course was attended by participants<br />

from Argentina, Austria, Belgium,<br />

Brazil, Chile, Germany, Guatemala,<br />

Italy, Japan, Korea, Mexico, Panama,<br />

Spain, Turkey, Uganda, Ukraine and<br />

the USA.<br />

18 Brauerei Forum – VLB International 2011<br />

From raw materials to quality<br />

assurance<br />

The six month course addresses persons<br />

who desire a professional qualification<br />

in brewing technology, either<br />

to enter the brewing industry or<br />

to advance within it. Split into three<br />

modules, the Certified Brewmaster<br />

Course covers practice-oriented and<br />

up-to-date knowledge in all brewingrelevant<br />

fields, from raw materials to<br />

quality control. Hands-on work in the<br />

labs in the fields of chemical technical<br />

analyses and microbiology increased<br />

the value of theoretical knowledge.<br />

During a week’s practical work in VLB’s<br />

pilot brewery, microbiological sample<br />

taking and work in the hop garden was<br />

performed.The course was supplemented<br />

by guest presentations from<br />

the supply industry, exercises in process<br />

control and classes in economics<br />

and logistics. Lectures on managing<br />

a pub brewery and dispensing techniques<br />

completed the course. The<br />

participants soon recognised that<br />

their stay in Berlin was not an extended<br />

holiday. Periodical tests and the<br />

extensive closing examinations made<br />

continual studies necessary. All graduates<br />

received a certificate at the end<br />

of the course. Those who had three or<br />

more months of work experience in<br />

a brewery also received the diploma<br />

“Certified Brewmaster VLB”. Because<br />

of their good practical experience in<br />

breweries, most graduates in 2011 received<br />

this diploma directly.<br />

Brewing and Engineering<br />

Conference and excursion<br />

Participation in VLB’s International Brewing<br />

and Engineering Conference in<br />

March 2011 in Bonn-Bad Godesberg<br />

(North Rhine-Westphalia), offered interesting<br />

presentations and technical<br />

visits. The final four-day excursion after<br />

the examinations included visits to renowned<br />

breweries, malt houses, hop<br />

processors, plant and label manufacturers<br />

throughout Germany.<br />

Farewell<br />

Before distributing the certificates, Dr.<br />

Josef Fontaine looked back on the past<br />

six months: “It was a great pleasure<br />

to have you here at VLB Berlin”, he<br />

stressed. “Please use the knowledge<br />

and competence you acquired which<br />

will be useful for prospective career<br />

moves! And please keep in touch with<br />

us, with the VLB Berlin!”<br />

A video from the farewell party is available<br />

at youtu.be/ZS-c3e-kXBM<br />

The next VLB Certified Brewmaster<br />

Course takes place in Berlin 9 January<br />

to 22 June 2012 and is fully booked<br />

Photos: oh

1.<br />

Martín Alejandro Bernabeu<br />

(Argentina)<br />

Juan Altamirano<br />

(Argentina)<br />

Alejandro Castillo Close<br />

(Guatemala)<br />

Soner Erduran<br />

(Turkey)<br />

Jason Barcelon<br />

(USA)<br />

Mireia Cisternas<br />

(Spain)<br />

Koen Feyen<br />

(Belgium)<br />

2.<br />

André Gonzalez Hercoli<br />

(Brazil)<br />

Pedro Bevilaqua<br />

(Brazil)<br />

Jack Colt<br />

(USA)<br />

Luciano Fonseca<br />

(Brazil)<br />

3..<br />

Ingrid Vico Diaz<br />

(Spain)<br />

Brauerei Forum – VLB International 2011<br />

tRaining & eVents<br />

André Buitoni<br />

(Brazil)<br />

Fernando Ventura<br />

Engelberg (Brazil)<br />

Alessandro Gorbi<br />

(Italy)<br />

19

tRaining & eVents<br />

Marco Filomeno Hundt<br />

(Deutschland)<br />

Matthew Manthe<br />

(USA)<br />

Enrique Alonso Montoya<br />

(Spain)<br />

Pedro Joaquin Icaza<br />

(Panama)<br />

Jace Marti<br />

(USA)<br />

José C.M. Neto<br />

(Brazil)<br />

20 Brauerei Forum – VLB International 2011<br />

Buyong Moon Kim<br />

(Korea)<br />

Pedro Henrique Buhatem<br />

Matos (Brazil)<br />

Juan Antonio de Oliveira<br />

Lopez (Chile)<br />

VLB Certified Brewmaster Course 2012 and 2013<br />

Once a year the VLB Berlin offers a 6-month full time course in Berlin. The course conveys all the<br />

knowledge necessary for the technical management of a brewery. In addition the participants attend<br />

VLB‘s International Brewing and Engineering Convention and join an excursion with technical visits to<br />

modern breweries, malt houses and companies of the allied industry. All lectures are given in English.<br />

Course 2012 is fully booked – enrolment has started for 2013<br />

The ”Certified Brewmaster Course 2013“ takes place from 14 January to 28 June 2013 at VLB Berlin<br />

Contact: VLB Berlin Ms. Heike Flohr, phone +49 30 450 80-267, fax +4930 450 80-187<br />

� brewmaster@<strong>vlb</strong>-berlin.org � www.<strong>vlb</strong>-berlin.org/training<br />

Tetsuya Koyama<br />

(Japan)<br />

Veronica Menzel<br />

(Brazil)<br />

Mayuko Onimura<br />

(Japan)

Jung Hun Park<br />

(Korea)<br />

Josef Sigl<br />

(Austria)<br />

Luis Suarez Blanco<br />

(Spain)<br />

Iliana Yanez Tirado<br />

(Mexico)<br />

Eric Jerome Ponce<br />

(USA)<br />

Issah Ssegawa<br />

(Uganda)<br />

Ryan Wibby<br />

(USA)<br />

Ievgen Zablotskyi<br />

(Ukraine)<br />

Moose Sanders<br />

(USA)<br />

Versuchs- und Lehranstalt für<br />

Brauerei in Berlin (VLB)<br />

VLB Certified<br />

Brewmaster<br />

Course 2013<br />

Brauerei Forum – VLB International 2011<br />

tRaining & eVents<br />

Comprehensive training course<br />

for prospective brewing professionals<br />