Preferential thermal nitridation to form pin-hole free - Oak Ridge ...

Preferential thermal nitridation to form pin-hole free - Oak Ridge ...

Preferential thermal nitridation to form pin-hole free - Oak Ridge ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1020 M.P. Brady et al. / Scripta Materialia 50 (2004) 1017–1022<br />

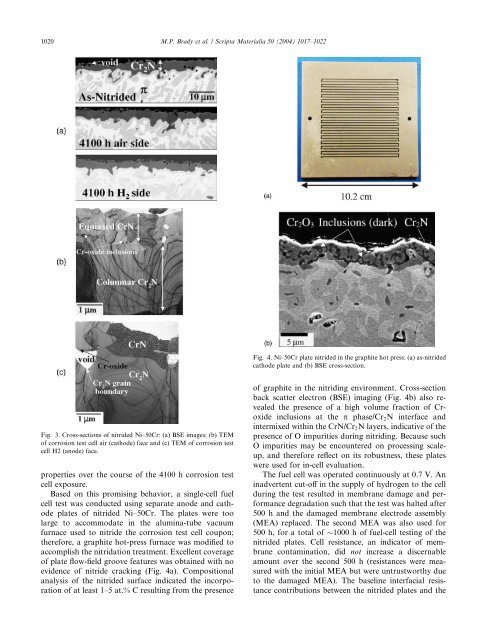

Fig. 3. Cross-sections of nitrided Ni–50Cr: (a) BSE images; (b) TEM<br />

of corrosion test cell air (cathode) face and (c) TEM of corrosion test<br />

cell H2 (anode) face.<br />

properties over the course of the 4100 h corrosion test<br />

cell exposure.<br />

Based on this promising behavior, a single-cell fuel<br />

cell test was conducted using separate anode and cathode<br />

plates of nitrided Ni–50Cr. The plates were <strong>to</strong>o<br />

large <strong>to</strong> accommodate in the alumina-tube vacuum<br />

furnace used <strong>to</strong> nitride the corrosion test cell coupon;<br />

therefore, a graphite hot-press furnace was modified <strong>to</strong><br />

accomplish the <strong>nitridation</strong> treatment. Excellent coverage<br />

of plate flow-field groove features was obtained with no<br />

evidence of nitride cracking (Fig. 4a). Compositional<br />

analysis of the nitrided surface indicated the incorporation<br />

of at least 1–5 at.% C resulting from the presence<br />

Fig. 4. Ni–50Cr plate nitrided in the graphite hot press: (a) as-nitrided<br />

cathode plate and (b) BSE cross-section.<br />

of graphite in the nitriding environment. Cross-section<br />

back scatter electron (BSE) imaging (Fig. 4b) also revealed<br />

the presence of a high volume fraction of Croxide<br />

inclusions at the p phase/Cr2N interface and<br />

intermixed within the CrN/Cr2N layers, indicative of the<br />

presence of O impurities during nitriding. Because such<br />

O impurities may be encountered on processing scaleup,<br />

and therefore reflect on its robustness, these plates<br />

were used for in-cell evaluation.<br />

The fuel cell was operated continuously at 0.7 V. An<br />

inadvertent cut-off in the supply of hydrogen <strong>to</strong> the cell<br />

during the test resulted in membrane damage and per<strong>form</strong>ance<br />

degradation such that the test was halted after<br />

500 h and the damaged membrane electrode assembly<br />

(MEA) replaced. The second MEA was also used for<br />

500 h, for a <strong>to</strong>tal of 1000 h of fuel-cell testing of the<br />

nitrided plates. Cell resistance, an indica<strong>to</strong>r of membrane<br />

contamination, did not increase a discernable<br />

amount over the second 500 h (resistances were measured<br />

with the initial MEA but were untrustworthy due<br />

<strong>to</strong> the damaged MEA). The baseline interfacial resistance<br />

contributions between the nitrided plates and the