You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Back to Contents pages<br />

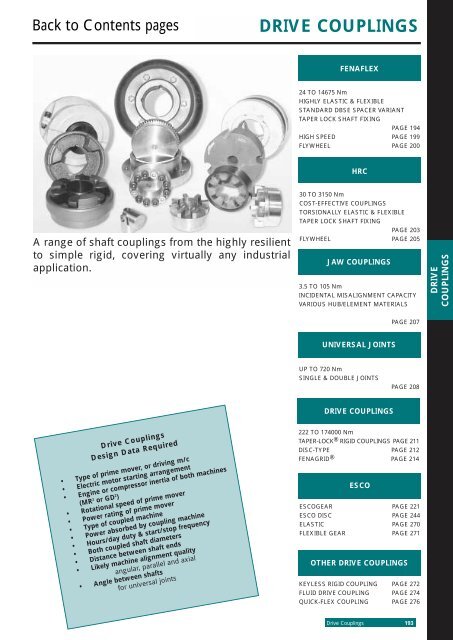

A range of shaft couplings from the highly resilient<br />

to simple rigid, covering virtually any industrial<br />

application.<br />

<strong>Drive</strong> <strong>Couplings</strong><br />

Design Data Required<br />

• Type of prime mover, or driving m/c<br />

• Electric motor starting arrangement<br />

• Engine or compressor inertia of both machines<br />

(MR 2 or GD 2 )<br />

• Rotational speed of prime mover<br />

• Power rating of prime mover<br />

• Type of coupled machine<br />

• Power absorbed by coupling machine<br />

• Hours/day duty & start/stop frequency<br />

• Both coupled shaft diameters<br />

• Distance between shaft ends<br />

• Likely machine alignment quality<br />

angular, parallel and axial<br />

• Angle between shafts<br />

for universal joints<br />

DRIVE COUPLINGS<br />

FENAFLEX<br />

24 TO 14675 Nm<br />

HIGHLY ELASTIC & FLEXIBLE<br />

STANDARD DBSE SPACER VARIANT<br />

TAPER LOCK SHAFT FIXING<br />

PAGE 194<br />

HIGH SPEED PAGE 199<br />

FLYWHEEL PAGE 200<br />

HRC<br />

30 TO 3150 Nm<br />

COST-EFFECTIVE COUPLINGS<br />

TORSIONALLY ELASTIC & FLEXIBLE<br />

TAPER LOCK SHAFT FIXING<br />

PAGE 203<br />

FLYWHEEL PAGE 205<br />

JAW COUPLINGS<br />

3.5 TO 105 Nm<br />

INCIDENTAL MISALIGNMENT CAPACITY<br />

VARIOUS HUB/ELEMENT MATERIALS<br />

UNIVERSAL JOINTS<br />

UP TO 720 Nm<br />

SINGLE & DOUBLE JOINTS<br />

DRIVE COUPLINGS<br />

PAGE 207<br />

PAGE 208<br />

222 TO 174000 Nm<br />

TAPER-LOCK ® RIGID COUPLINGS PAGE 211<br />

DISC-TYPE PAGE 212<br />

FENAGRID ® PAGE 214<br />

ESCO<br />

ESCOGEAR PAGE 221<br />

ESCO DISC PAGE 244<br />

ELASTIC PAGE 270<br />

FLEXIBLE GEAR PAGE 271<br />

OTHER DRIVE COUPLINGS<br />

KEYLESS RIGID COUPLING PAGE 272<br />

FLUID DRIVE COUPLING PAGE 274<br />

QUICK-FLEX COUPLING PAGE 276<br />

<strong>Drive</strong> <strong>Couplings</strong> 193<br />

DRIVE<br />

COUPLINGS

DRIVE<br />

COUPLINGS<br />

Fenaflex<br />

194 <strong>Drive</strong> <strong>Couplings</strong><br />

<strong>Couplings</strong><br />

Fenaflex couplings provide all the desirable features of an ideal flexible coupling, including Taper-Lock ® fixing.<br />

The Fenaflex coupling is a "torsionally elastic" coupling offering versatility to designers and engineers with a<br />

choice of flange combinations to suit most applications.<br />

The flanges are available in either F or H Taper-Lock ® fitting or pilot bored, which can be bored to the required size.<br />

With the addition of a spacer the coupling can be used to accommodate standard distances between shaft<br />

ends and thereby facilitate pump maintenance.<br />

Fenaflex couplings can accommodate simultaneous maximum misalignment in all planes without imposing<br />

undue loads on adjacent bearings and the excellent shock-absorbing properties of the flexible tyre reduce<br />

vibration and torsional oscillations.<br />

Fenaflex tyres are available in natural rubber compounds for use in ambient temperatures between –50OC and +50OC. Chloroprene rubber compounds are available for use in adverse operating conditions (e.g. oil or<br />

grease contamination) and can be used in temperatures of –15OC to +70OC. The chloroprene compound<br />

should also be used when fire-resistance and anti-static (F.R.A.S.) properties are required.<br />

SELECTION<br />

(a) Service Factor<br />

Determine the required Service Factor<br />

from table below.<br />

(b) Design Power<br />

Multiply the normal running power by<br />

the service factor. This gives the design<br />

power which is used as a basis for<br />

selecting the coupling.<br />

(c) Coupling Size<br />

Refer to Power Ratings table<br />

(page 195) and from the appropriate<br />

speed read across until a power greater<br />

than that required in step (b) is found.<br />

The size of Fenaflex coupling required<br />

is given at the head of that column.<br />

(d) Bore Size<br />

Check from Dimensions table<br />

(page 196) that chosen flanges can<br />

accommodate required bores.<br />

SERVICE FACTORS<br />

R<br />

SPECIAL CASES<br />

For applications where substantial shock, vibration and torque<br />

fluctuations occur, and for reciprocating machines (e.g. internal<br />

combustion engines, piston pumps and compressors) refer to<br />

Fenner Power Transmission Distributor with full machine details<br />

for analysis.<br />

EXAMPLE<br />

A Fenaflex coupling is required to transmit<br />

45kW from an A.C. electric motor which<br />

runs at 1440 rev/min to a rotary screen for<br />

12 hours per day. The motor shaft is 60mm<br />

diameter and the screen shaft is 55mm<br />

diameter. Taper Lock is required.<br />

(a) Service Factor<br />

The appropriate service factor is 1,4.<br />

(b) Design Power<br />

Design power = 45 x 1,4 = 63kW.<br />

(c) Coupling Size<br />

By reading across from 1440 rev/min in<br />

the power ratings table the first power<br />

figure to exceed the required 63kW in<br />

step (b) is 75,4kW. The size of coupling<br />

is F90 Fenaflex.<br />

(d) Bore Size<br />

By referring to the dimensions table it<br />

can be seen that both shaft diameters<br />

fall within the bore range available.<br />

Electric Motors<br />

Steam Turbines<br />

Type of Driving Unit<br />

Internal Combustion Engines†<br />

Steam Engines<br />

Water Turbines<br />

Hours per day duty Hours per day duty<br />

10 and over 10 over 10 and over 10 over<br />

Type of <strong>Drive</strong>n Machine<br />

CLASS 1<br />

Brewing machinery, Centrifugal compressors and pumps.<br />

under to 16 incl. 16 under to 16 incl. 16<br />

Belt conveyors, Dynamometers, Lineshafts, Fans up to 7,5kW<br />

Blowers and exhausters (except positive displacement),<br />

Generators.<br />

CLASS 2*<br />

Agitators, Clay working machinery, General machine tools,<br />

0,8 0,9 1,0 1,3 1,4 1,5<br />

paper mill beaters and winders, Rotary pumps, Rubber extruders,<br />

Rotary screens,Textile machinery, Marine propellors and Fans<br />

over 7,5kw.<br />

CLASS 3*<br />

Bucket elevators, Cooling tower fans, Piston compressors and<br />

1,3 1,4 1,5 1,8 1,9 2,0<br />

pumps, Foundry machinery, Metal presses, Paper mill calenders,<br />

Hammer mills, Presses and pulp grinders, Rubber calenders,<br />

Pulverisers and Positive displacement blowers.<br />

CLASS 4*<br />

1,8 1,9 2,0 2,3 2,4 2,5<br />

Reciprocating conveyors, Gyratory crushers, Mills (ball, pebble<br />

and rod), Rubber machinery (Banbury mixers and mills) and<br />

Vibratory screens.<br />

2,3 2,4 2,5 2,8 2,9 3,0<br />

* It is recommended that keys (with top clearance if in Taper-Lock ® bushes) are fitted on application where load fluctuation is expected.<br />

† <strong>Couplings</strong> for use with internal combustion engines may require special consideration, refer to pages 200 and 205.

POWER RATINGS (kW)<br />

R<br />

Fenaflex <strong>Couplings</strong> – Power Ratings<br />

Coupling Size<br />

Speed<br />

rev/min F40 F50 F60 F70 F80 F90 F100 F110 F120 F140 F160 F180 F200 F220 F250<br />

100 0,25 0,69 11,33 2,62 113,93 5,24 7,07 9,16 113,9 124,3 139,5 165,7 97,6 121 154<br />

200 0,50 1,38 12,66 5,24 117,85 110,5 114,1 118,3 127,9 148,7 179,0 131 195 243 307<br />

300 0,75 2,07 13,99 7,85 111,8 115,7 121,2 127,5 141,8 173,0 118 197 293 364 461<br />

400 1,01 2,76 15,32 10,5 15,7 120,9 128,3 136,6 155,7 197,4 158 263 1391 486 615<br />

500 1,26 3,46 16,65 13,1 19,6 126,2 135,3 145,8 169,6 122 197 328 1488 607 768<br />

600 1,51 4,15 17,98 15,7 23,6 131,4 142,4 155,0 183,6 146 237 394 1586 729 922<br />

700 1,76 4,84 19,31 18,3 27,5 136,6 149,5 164,1 197,5 170 276 460 1684 850 1076<br />

720 1,81 4,98 19,57 18,8 28,3 137,7 150,9 166,0 100 175 284 473 1703 875 1106<br />

800 2,01 5,53 10,6 20,9 31,4 141,9 156,5 173,3 111 195 316 525 1781 972 1229<br />

900 2,26 6,22 12,0 23,6 35,3 147,1 163,6 182,5 125 219 355 591 1879 1093 1383<br />

960 2,41 6,63 12,8 25,1 37,7 150,3 167,9 188,0 134 234 379 630 1937 1166 1475<br />

1000 2,51 6,91 13,3 26,2 39,3 152,4 170,7 191,6 139 243 395 657 1976 1215 1537<br />

1200 3,02 8,29 16,0 31,4 47,1 162,8 184,8 110 167 292 474 788 1172<br />

1400 3,52 9,68 18,6 36,6 55,0 173,3 199,0 128 195 341 553 919<br />

1440 3,62 9,95 19,1 37,7 56,5 175,4 102 132 201 351 568 945<br />

1600 4,02 11,1 21,3 41,9 62,8 183,8 113 147 223 390 632<br />

1800 4,52 12,4 23,9 47,1 70,7 194,2 127 165 251 438<br />

2000 5,03 13,8 26,6 52,4 78,5 105,5 141 183 279<br />

2200 5,53 15,2 29,3 57,6 86,4 115 155 202<br />

2400 6,03 16,6 31,9 62,8 94,2 126 170<br />

2600 6,53 18,0 34,6 68,1 102 136 184<br />

2800 7,04 19,4 37,2 73,3 110 147<br />

2880 7,24 19,9 38,3 75,4 113 151<br />

3000 7,54 20,7 39,9 78,5 118 157<br />

3600 9,05 24,9 47,9 94,2<br />

PHYSICAL CHARACTERISTICS – FLEXIBLE TYRES<br />

Coupling Size<br />

The figures in heavier type are for standard<br />

motor speeds. All these power ratings are<br />

calculated at constant torque. For speeds<br />

below 100 rev/min and intermediate<br />

speeds use nominal torque ratings.<br />

Characteristics F40 F50 F60 F70 F80 F90 F100 F110 F120 F140 F160 F180 F200 F220 F250<br />

Maximum speed rev/min 4500 4500 4000 3600 3100 3000 2600 2300 2050 1800 1600 1500 1300 1100 1000<br />

Nominal Torque Nm TK N 24 66 127 250 375 500 675 875 1330 2325 3770 6270 9325 11600 14675<br />

Maximum Torque Nm TK MAX 64 160 318 487 759 1096 1517 2137 3547 5642 9339 16455 23508 33125 42740<br />

Torsional Stiffness Nm/ O 5 13 26 41 63 91 126 178 296 470 778 1371 1959 2760 3562<br />

Max, parallel misalignment mm 1,1 1,3 1,6 1,9 2,1 2,4 2,6 2,9 3,2 3,7 4,2 4,8 5,3 5,8 6,6<br />

Maximum end float mm ± 1,3 1,7 2,0 2,3 2,6 3,0 3,3 3,7 4,0 4,6 5,3 6,0 6,6 7,3 8,2<br />

Approximate mass, kg<br />

Alternating Torque ± Nm<br />

0,1 0,3 0,5 0,7 1,0 1,1 1,1 1,4 2,3 2,6 3,4 7,7 8,0 10 15<br />

@ 10Hz TKW 11 26 53 81 127 183 252 356 591 940 1556 2742 3918 5521 7124<br />

Resonance Factor V R 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7<br />

Damping Coefficient Ψ 0,9 0,9 0,9 0,9 0,9 0,9 0,9 0,9 0,9 0,9 0,9 0,9 0,9 0,9 0,9<br />

Maximum torque figures should be regarded as short duration overload ratings for use in such circumstances as direct-on-line starting.<br />

All flexible tyres have an angular misalignment capacity up to 4 o .<br />

FLEXIBLE TYRE CODE NUMBERS<br />

Unless otherwise specified Fenaflex<br />

flexible tyres will be supplied in a<br />

natural rubber compound which is<br />

suitable for operation in temperatures –<br />

50 O C to +50 O C. A chloroprene compound<br />

is available which is Fire Resistant and<br />

Anti-Static (F.R.A.S) and has greater<br />

resistance to heat and oil.<br />

This is suitable for operation in<br />

temperatures –15 O C to +70 O C. For<br />

temperatures outside these ranges –<br />

consult Fenner Power Transmission<br />

Distributor.<br />

Coupling<br />

Size<br />

F40*<br />

F50*<br />

F60*<br />

F70<br />

F80<br />

F90<br />

F100<br />

F110<br />

F120<br />

F140<br />

F160<br />

F180<br />

F200<br />

F220<br />

F250<br />

M<br />

Dimension<br />

(mm)<br />

11<br />

12,5<br />

16,5<br />

11,5<br />

12,5<br />

13,5<br />

13,5<br />

12,5<br />

14,5<br />

16<br />

15<br />

23<br />

24<br />

27,5<br />

29,5<br />

Gap<br />

Between<br />

Tyre Ends<br />

(mm)<br />

2<br />

2<br />

2<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

5<br />

5<br />

6<br />

6<br />

6<br />

6<br />

Clamping<br />

Screw<br />

Torque<br />

(Nm)<br />

15<br />

15<br />

15<br />

24<br />

24<br />

40<br />

40<br />

40<br />

50<br />

55<br />

80<br />

105<br />

120<br />

165<br />

165<br />

Screw<br />

Size<br />

M6<br />

M6<br />

M6<br />

M8<br />

M8<br />

M10<br />

M10<br />

M10<br />

M12<br />

M12<br />

M16<br />

M16<br />

M16<br />

M20<br />

M20<br />

*Hexagonal socket caphead clamping screws on these sizes.<br />

<strong>Drive</strong> <strong>Couplings</strong> 195<br />

DRIVE<br />

COUPLINGS

DRIVE<br />

COUPLINGS<br />

R<br />

Fenaflex <strong>Couplings</strong> – Dimensions<br />

FLANGES<br />

DIMENSIONS OF FENAFLEX FLANGES TYPES B, F & H<br />

Bush<br />

Max Bore Types F & H Type B<br />

Screw<br />

Size Type No.<br />

# Metric Inch L E J† L E<br />

over<br />

Key<br />

A C D F G§ M Mass*<br />

(kg)<br />

Inertia*<br />

(kgm2 )<br />

F40 B – 32 – – – 29 33 22 M5 104 82 – – – 11 0,8 0, 00074<br />

F40 F 1008 25 1 " 33 22 29 – – – 104 82 – – – 11 0,8 0, 00074<br />

F40 H 1008 25 1 " 33 22 29 – – – 104 82 – – – 11 0,8 0, 00074<br />

F50 B – 38 – – – 38 45 32 M5 133 100 79 – – 12 ,5 1,2 0, 00115<br />

F50 F 1210 32 1 1 F50 H 1210 32<br />

/4"<br />

1<br />

38 25 38 – – – 133 100 79 – – 12 ,5 1,2 0, 00115<br />

1 /4" 38 25 38 – – – 133 100 79 – – 12 ,5 1,2 0, 00115<br />

F60<br />

F60<br />

B<br />

F<br />

–<br />

1610<br />

45<br />

42<br />

–<br />

1<br />

– – 38 55 38 M6 165 125 70 – – 16 ,5 2,0 0, 0052<br />

5 /8" 42 25 38 – – – 165 125 103 – – 16 ,5 2,0 0, 0052<br />

F60 H 1610 42 1 5 /8" 42 25 38 – – – 165 125 103 – – 16 ,5 2,0 0, 0052<br />

F70 B – 50 – – – – 47 35 M10 187 144 80 50 13 11 ,5 3,1 0, 009<br />

F70<br />

F70<br />

F<br />

H<br />

2012<br />

1610<br />

50<br />

42<br />

2 "<br />

1<br />

44 32 42 – – – 187 144 80 50 13 11 ,5 3,1 0, 009<br />

5 /8" 42 25 38 – – – 187 144 80 50 13 11 ,5 3,0 0, 009<br />

F80<br />

F80<br />

B<br />

F<br />

–<br />

2517<br />

60<br />

60<br />

–<br />

2<br />

– – – 55 42 M10 211 167 98 54 16 12 ,5 4,9 0, 018<br />

1 /2" 58 45 48 – – – 211 167 97 54 16 12 ,5 4,9 0, 018<br />

F80 H 2012 50 2 " 45 32 42 – – – 211 167 98 54 16 12 ,5 4,6 0, 017<br />

F90 B – 70 – – – – 63,5 49 M12 235 188 112 60 16 13 ,5 7,1 0, 032<br />

F90 F 2517 60 2 1 /2" 59,5 45 48 – – – 235 188 108 60 16 13 ,5 7,0 0, 031<br />

F90 H 2517 60 2 1 /2" 59,5 45 48 – – – 235 188 108 60 16 13 ,5 7,0 0, 031<br />

F100 B – 80 – – – – 70,5 56 M12 254 216 125 62 16 13 ,5 9,9 0, 055<br />

F100<br />

F100<br />

F<br />

H<br />

3020<br />

2517<br />

75<br />

60<br />

3 "<br />

2<br />

65,5 51 55 – – – 254 216 120 62 16 13 ,5 9,9 0, 055<br />

1 /2" 59,5 45 48 – – – 254 216 113 62 16 13 ,5 9,4 0, 054<br />

F110<br />

F110<br />

B<br />

F<br />

–<br />

3020<br />

90<br />

75<br />

–<br />

3 "<br />

–<br />

63,5<br />

–<br />

51<br />

–<br />

55<br />

75,5<br />

–<br />

63<br />

–<br />

M12<br />

–<br />

279<br />

279<br />

233<br />

233<br />

128<br />

134<br />

62<br />

62<br />

16<br />

16<br />

12 ,5<br />

12 ,5<br />

12,5<br />

11,7<br />

0, 081<br />

0, 078<br />

F110 H 3020 75 3 " 63,5 51 55 – – – 279 233 134 62 16 12 ,5 11,7 0, 078<br />

F120 B – 100 – – – – 84,5 70 M16 314 264 143 67 16 14 ,5 16,9 0, 137<br />

F120 F 3525 100 4 " 79,5 65 67 – – – 314 264 140 67 16 14 ,5 16,5 0, 137<br />

F120 H 3020 75 3 " 65,5 51 55 – – – 314 264 140 67 16 14 ,5 15,9 0, 130<br />

F140 B – 130 – – – – 110,5 94 M20 359 311 178 73 17 16 22,2 0, 254<br />

F140<br />

F140<br />

F<br />

H<br />

3525<br />

3525<br />

100<br />

100<br />

4 "<br />

4 "<br />

81,5<br />

81,5<br />

65<br />

65<br />

67<br />

67<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

359<br />

359<br />

311<br />

311<br />

178<br />

178<br />

73<br />

73<br />

17<br />

17<br />

16<br />

16<br />

22,3<br />

22,3<br />

0, 255<br />

0, 255<br />

F160<br />

F160<br />

B<br />

F<br />

–<br />

4030<br />

140<br />

115<br />

–<br />

4<br />

– – – 117 102 M20 402 345 187 78 19 15 35,8 0, 469<br />

1 /2" 92 77 80 – – – 402 345 197 78 19 15 32,5 0, 380<br />

F160 H 4030 115 4 1 /2" 92 77 80 – – – 402 345 197 78 19 15 32,5 0, 380<br />

F180 B – 150 – – – – 137 114 M20 470 398 200 94 19 23 49,1 0, 871<br />

F180 F 4535 125 5 " 112 89 89 – – – 470 398 205 94 19 23 42,2 0, 847<br />

F180 H 4535 125 5 " 112 89 89 – – – 470 398 205 94 19 23 42,2 0, 847<br />

F200 B – 150 – – – – 138 114 M20 508 429 200 103 19 24 58,2 1, 301<br />

F200<br />

F200<br />

F<br />

H<br />

4535<br />

4535<br />

125<br />

125<br />

5 "<br />

5 "<br />

113<br />

113<br />

89<br />

89<br />

89<br />

89<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

508<br />

508<br />

429<br />

429<br />

205<br />

205<br />

103<br />

103<br />

19<br />

19<br />

24<br />

24<br />

53,6<br />

53,6<br />

1, 281<br />

1, 281<br />

F220<br />

F220<br />

B<br />

F<br />

–<br />

5040<br />

160<br />

125<br />

–<br />

5 "<br />

–<br />

129,5<br />

–<br />

102<br />

–<br />

92<br />

154,5<br />

–<br />

127<br />

–<br />

M20<br />

–<br />

562<br />

562<br />

474<br />

474<br />

218<br />

223<br />

118<br />

118<br />

20<br />

20<br />

27 ,5<br />

27 ,5<br />

79,6<br />

72,0<br />

2, 142<br />

2, 104<br />

F220 H 5040 125 5 " 129,5 102 92 – – – 562 474 223 118 20 27 ,5 72,0 2, 104<br />

F250 B – 190 – – – – 161,5 132 M20 628 532 254 125 25 29 ,5 104,0 3, 505<br />

Dimensions in millimetres unless otherwise stated.<br />

§ G is the amount by which clamping screws need to be withdrawn to release tyre.<br />

† J is the wrench clearance to allow for tightening/loosening the bush on the shaft and the clamp ring screws on sizes F40, F50 and F60. The use of a shortened<br />

wrench will allow this dimension to be reduced.<br />

M is half the distance between flanges. Shaft ends, although normally located twice M apart, can project beyond the flanges as shown. In this event<br />

allow sufficient space between shaft ends for end float and misalignment.<br />

* Mass and inertia figures are for single flange with mid range bore and include clamping ring, screws and washers and half tyre.<br />

‡ For pilot bore 'B' flange code as listed.<br />

Flanges are also available finish bored with keyway if required.<br />

Bore must be specified on order.<br />

# Note: On sizes F70, 80, 100 and 120 the 'F' direction bush is larger than that in the 'H'direction.<br />

196 <strong>Drive</strong> <strong>Couplings</strong>

Comprising a Fenaflex tyre coupling (size<br />

F40–F140) complete with a spacer flange<br />

designed for use on applications where it is<br />

an advantage to be able to move either<br />

shaft axially without disturbing the driving or<br />

driven machine (e,g, centrifugal pump<br />

rotors), Fenaflex spacer couplings are<br />

primarily designed for standard distance<br />

between shaft end dimensions 100, 140 and<br />

180mm.<br />

DISTANCE BETWEEN SHAFT ENDS<br />

R<br />

Fenaflex Spacer <strong>Couplings</strong><br />

SELECTION<br />

1. Select a suitable size of Fenaflex<br />

coupling using the method shown on<br />

page 194. Read down the first column<br />

in table below and locate the size of<br />

coupling selected.<br />

2. Read across until the required distance<br />

between shaft ends can be<br />

accommodated.<br />

3. Note the required spacer coupling<br />

designation at head of column.<br />

4. Check from the Spacer Coupling<br />

Dimensions table below that the<br />

selected spacer/coupling combination<br />

can accommodate the machine shaft<br />

size.<br />

Note<br />

Typical order consists of<br />

1 x Spacer 3 x Taper Lock bushes<br />

2 x Fenaflex flanges 1 x Fenaflex tyre<br />

SM12 SM16<br />

Distance between Shaft Ends (mm)<br />

SM25 SM30 SM35<br />

Size 80 (100) 100 140 100 140 180 140 180 140 180<br />

Min Max Min Max Min Max Min Max Min Max Min Max Min Max Min Max Min Max Min Max<br />

F40 80 100 100 113 140 150<br />

F50 100 116 140 156<br />

F60 100 124 140 164<br />

F70 100 114 140 154 180 194<br />

F80 100 117 140 157 180 197<br />

F90 140 158 180 198<br />

F100 140 158 180 198<br />

F110 140 156 180 196<br />

F120 140 160 180 200<br />

F140<br />

Note: Alternative distances between shaft ends may be accommodated. Consult Fenner Power Transmission Distributor.<br />

140 163 180 203<br />

SPACER COUPLING DIMENSIONS<br />

Spacer Max. Bore Fenaflex Max. Bore<br />

Nom Bush Bush<br />

Spacer DBSE Fenaflex Size mm Inch Size mm Inch A B C D E F G H J K L M S T<br />

SM12 80 F40 1210 32 1 1 /4" 1008 25 1 " 104 82 118 83 134 25 14 15 14 6 65 22 77 25<br />

SM12 100 F40 1210 32 1 1 /4" 1008 25 1 " 104 82 118 83 140 25 14 15 14 22 77 22 77 25<br />

SM16 100 F40* 1610 42 1 5 /8" 1008 25 1 " 104 82 127 80 157 25 18 15 14 9 88 22 94 32<br />

SM16 140 F40* 1610 42 1 5 /8" 1008 25 1 " 104 82 127 80 187 25 18 15 14 9 128 22 134 32<br />

SM16 100 F50 1610 42 1 5 /8" 1210 32 1 1 /4" 133 79 127 80 160 25 18 15 14 9 85 25 94 32<br />

SM16 140 F50 1610 42 1 5 /8" 1210 32 1 1 /4" 133 79 127 80 200 25 18 15 14 9 125 25 134 32<br />

SM16 100 F60 1610 42 1 5 /8" 1610 42 1 5 /8" 165 70 127 80 161 25 18 15 14 9 78 33 94 32<br />

SM16 140 F60 1610 42 1 5 /8" 1610 42 1 5 /8" 165 70 127 80 201 25 18 15 14 9 118 33 134 32<br />

SM25 100 F70† 2517 60 2 1 /2" 2012 50 2 " 187 80 178 123 180 45 22 16 14 9 80 23 94 48<br />

SM25 140 F70† 2517 60 2 1 /2" 2012 50 2 " 187 80 178 123 220 45 22 16 14 9 120 23 134 48<br />

SM25 180 F70† 2517 60 2 1 /2" 2012 50 2 " 187 80 178 123 260 45 22 16 14 9 160 23 174 48<br />

SM25 100 F80 2517 60 2 1 /2" 2517 60 2 1 /2" 211 95 178 123 193 45 22 16 14 9 78 25 94 48<br />

SM25 140 F80 2517 60 2 1 /2" 2517 60 2 1 /2" 211 95 178 123 233 45 22 16 14 9 118 25 134 48<br />

SM25 180 F80 2517 60 2 1 /2" 2517 60 2 1 /2" 211 95 178 123 273 45 22 16 14 9 158 25 174 48<br />

SM25 140 F90 2517 60 2 1 /2" 2517 60 2 1 /2" 235 108 178 123 233 45 22 16 14 9 116 27 134 48<br />

SM25 180 F90 2517 60 2 1 /2" 2517 60 2 1 /2" 235 108 178 123 273 45 22 16 14 9 156 27 174 48<br />

SM30 140 F100 3020 75 3 " 3020 75 3 " 254 120 216 146 245 51 29 20 17 9 116 27 134 60<br />

SM30 180 F100 3020 75 3 " 3020 75 3 " 254 120 216 146 285 51 29 20 17 9 156 27 174 60<br />

SM30 140 F110 3020 75 3 " 3020 75 3 " 279 134 216 146 245 51 29 20 17 9 118 25 134 60<br />

SM30 180 F110 3020 75 3 " 3020 75 3 " 279 134 216 146 285 51 29 20 17 9 158 25 174 60<br />

SM35 140 F120† 3525 100 4 " 3525 100 4 " 314 140 248 178 272 63 34 20 17 9 114 29 134 80<br />

SM35 180 F120† 3525 100 4 " 3525 100 4 " 314 140 248 178 312 63 34 20 17 9 154 29 174 80<br />

SM35 140 F140 3525 100 4 " 3525 100 4 " 359 178 248 178 271 63 34 20 17 9 111 32 134 80<br />

SM35 180 F140 3525 100 4 " 3525 100 4 " 359 178 248 178 312 63 34 20 17 9 151 32 174 80<br />

Note: Larger sizes of spacer coupling can be manufactured to order. Consult Fenner Power Transmission Distributor.<br />

* F40 'B' Flange must be used to fit spacer shaft.<br />

† 'F' Flange must be used to fit spacer shaft.<br />

<strong>Drive</strong> <strong>Couplings</strong> 197<br />

DRIVE<br />

COUPLINGS

DRIVE<br />

COUPLINGS<br />

R<br />

Fenaflex Spacer <strong>Couplings</strong><br />

NB. To select the Fenaflex ® coupling size, this page must be used in conjunction with page 194, then check that spacer flange will suit<br />

required distance between shaft ends (D.B.S.E.).<br />

PHYSICAL DIMENSIONS:- F40 R12 to F60 R16 F70 R25 to F200 R50<br />

Spacer lengths<br />

The spacer lengths shown are the minimum<br />

possible. Longer spacers can be supplied to<br />

special order.<br />

Coupling<br />

Size<br />

Bush<br />

No.<br />

F40 RM12 1008 25 1210 32 105 118 163 104 – 22 37 – – 40 – 3<br />

F50 RM16 1210 32 1615 42 133 127 174 111 – 25 38 37 – 44 – 5<br />

F60 RM16 1610 42 1615 42 165 127 183 120 191 25 38 37 – 44 115 8<br />

F70 RM25 1610 42 2517 60 187 178 203 133 183 25 45 – – 56 106 11<br />

F70 RM25 F 2012 50 2517 60 187 178 210 133 183 32 45 – – 56 106 11<br />

F80 RM25 F 2517 60 2517 60 211 178 232 142 283 45 45 – – 59 200 12<br />

F80 RM25 2012 50 2517 60 211 178 219 142 283 33 45 – – 59 200 12<br />

F90 RM30 2517 60 3030 75 235 216 284 163 283 45 76 – – 71 191 21<br />

F100 RM30 2517 60 3030 75 254 216 290 169 282 45 76 – – 75 188 23<br />

F100 RM30 F 3020 75 3030 75 254 216 296 169 282 51 76 – – 75 188 23<br />

F110 RM30 3020 75 3030 75 279 216 298 170 282 51 76 – – 76 187 26<br />

F120 RM35 F 3525 100 3535 90 314 248 334 180 282 66 89 – – 78 187 35<br />

F120 RM35 3020 75 3535 90 314 248 320 180 282 51 89 – – 78 187 35<br />

F140 RM40 3525 100 4040 100 359 298 370 203 449 65 102 – 14 87 133 59<br />

F160 RM45 4030 115 4545 110 402 330 416 224 449 77 115 – 16 98 325 92<br />

F200 RM50 4535 125 5050 125 508 362 505 289 – 89 127 – 16 130 – –<br />

+ l6 Amount by which clamping screws need to be withdrawn to release tyre.<br />

§ l2 is the normal distance between shafts. End float which increases or decreases this distance by a slight amount is permissible.<br />

ø l2 Alternative spacer available ex-stock.<br />

* l5 is the wrench clearance necessary to tighten or slacken clamping ring screws.<br />

F Extended length when using F Flanges, (F70, 80, 100 & 120 sizes only).<br />

‡ These values include Rigid Half & Standard Spacer with Clamping Ring Only.<br />

Sizes F40 R12 through F100 R30 are normally carried in stock.<br />

198 <strong>Drive</strong> <strong>Couplings</strong><br />

Fenaflex End<br />

Max<br />

Bore<br />

Rigid End<br />

Bush<br />

No.<br />

Max<br />

§ ø<br />

Bore d 1 d 2 l 1 l 2 l 2 l 3 l 4<br />

*<br />

l 5<br />

+<br />

l 6 l 7 l 7<br />

‡<br />

mass kg

TABLE 4: POWER RATINGS (kW) FOR FLEXIBLE ELEMENTS<br />

R<br />

Fenaflex High Speed Coupling<br />

Speed<br />

Size<br />

(r/min) 87<br />

96 116 131 172 192 213 252<br />

100 2,5 3,4 6,2 7,9 20,1 36,6 67,2 116<br />

720 18,0 24,5 44,6 56,9 145 264 484 835<br />

960 24,0 32,6 59,5 75,8 193 351 645 1114<br />

1000 25,0 34,0 62,0 79,0 201 366 672 1160<br />

1200 30,0 40,8 74,4 94,8 241 439 806 1392<br />

1400 35,0 47,6 86,8 111 281 512 941 1624<br />

1440 36,0 49,0 89,3 114 289 527 968 1670<br />

1600 40,0 54,4 99,2 126 322 586 1075 1856<br />

1800 45,0 61,2 111 142 362 659 1210 2088<br />

2000 50,0 68,0 124 158 402 732 1344<br />

2200 55,0 74,8 136 174 442 805<br />

2400 60,0 81,6 149 190 482<br />

2600 65,0 88,4 161 205<br />

2800 70,0 95,2 174 221<br />

2880 72,0 98,0 179 228<br />

3000 75,0 102 186 237<br />

3200 80,0 109 198 253<br />

3400 85,0 116 211<br />

3600 90,0 122 223<br />

3800 95,0 129<br />

4000 100 136<br />

4200 105 143<br />

4400 110 150<br />

4600 115<br />

4800 120<br />

For speeds below 100 r/min and intermediate speeds use normal torque ratings.<br />

The figures in heavier type are for<br />

standard motor speeds.<br />

X FLANGES (Steel) — REVERSIBLE TO PROVIDE H or F TAPER-LOCK ® BUSH FITTINGS<br />

TABLE 4: POWER RATINGS (kW) FOR FLEXIBLE ELEMENTS<br />

‘X’<br />

Flange<br />

Size<br />

Max<br />

Speed<br />

(r/min)<br />

Torque<br />

(N.m)<br />

Normal Max<br />

Moment<br />

of<br />

Inertia<br />

m.r 2<br />

(kg.m 2 )<br />

Torsional<br />

Stiffness<br />

(N.m/ o )<br />

Max<br />

Mis-alignment<br />

Parallel<br />

End<br />

± Float<br />

87 4800 239 716 0,046 07 60 0,5 0,4 2012 50 240 90 90 32 26 20 42 20 6,0 0,6<br />

96 4400 325 974 0,089 77 81 0,6 0,4 2517 60 262 110 110 44 30 29 48 25 8,3 0,9<br />

116 3600 592 1776 0,016 98 148 0,7 0,5 2517 60 313 110 110 44 30 29 48 25 11,0 1,0<br />

131 3200 754 1263 0,360 23 189 0,8 0,6 2517 60 351 110 110 44 39 29 48 25 16,0 1,7<br />

172 2400 1919 5758 1,173 48 480 1,0 0,8 3525 90 465 180 180 65 41 40 67 40 34,0 3,3<br />

192 2200 3495 10485 1,951 70 874 1,2 0,9 4040 100 516 190 190 101 46 47 80 69 49,0 3,6<br />

ø213 2000 6417 19251 3,565 09 1604 1,3 1,0 4545 110 572 200 199 114 70 56 89 74 55,0 6,2<br />

ø252 1800 11405 33137 7,605 50 2.761 1,6 1,2 5050 125 673 230 220 127 60 56 92 87 78,0 13,0<br />

§ Mass is for X Flange with mid-range bore Taper-Lock ® Bush.<br />

All couplings have an angular mis-alignment capacity up to 1 o .<br />

Maximum torque figures should be regarded as short duration overload ratings for use in such circumstances as direct-on-line starting.<br />

ø Ex import only.<br />

Coupling<br />

Size<br />

Companion<br />

Flange<br />

Size<br />

Bush<br />

No.<br />

Dimensions - Assembled High Speed <strong>Couplings</strong><br />

H Flanges F Flanges B Flanges<br />

Bush No. Max Bore l 1 Bush No. Max Bore l 1<br />

Max<br />

Bore d 1 d 2 d 3 l 5 l 6 l 7 l 8 l 9<br />

Bore Min/<br />

Max<br />

Approx. Mass<br />

(kg)§<br />

X<br />

Flange Element<br />

D.B.S.E. Flange<br />

reversed<br />

l 2 l 3 l 4 H F<br />

87X F70 1610 42 65 2012 50 67 38/50 70 73 35 23 23<br />

96X F80 2012 50 72 2517 60 85 42/60 82 81 40 25 21<br />

116X F100 2517 60 86 3020 75 92 48/80 89 89 41 26 22<br />

131X F110 3020 75 106 3020 75 106 48/90 118 102 55 40 36<br />

172X F140 3525 90 133 3525 90 133 60/130 162 121 68 43 43<br />

192X F160 4030 115 153 4030 115 153 65/140 178 137 76 22 44<br />

213X F180 4535 125 193 4535 125 193 70/150 218 175 104 46 64<br />

252X F220 5040 125 234 5040 125 234 80/160 259 222 132 61 92<br />

<strong>Drive</strong> <strong>Couplings</strong> 199<br />

DRIVE<br />

COUPLINGS

DRIVE<br />

COUPLINGS<br />

R<br />

Fenaflex Flywheel <strong>Couplings</strong><br />

Designed to fit standard SAE and other popular flywheel configurations, these couplings use chloroprene<br />

flexible elements and employ standard B, F or H type driven flanges.<br />

DIMENSIONS<br />

Driving Flange — W (Bolt ring) <strong>Drive</strong>n Flanges — Through Bore and Taper-Lock ® — F & H<br />

Bolts†<br />

Thread Mass Inertia Max Screw Mass Inertia<br />

Size PCD Type A H (kg) (kg m 2 ) Size Type Bush Bore C D E F G J†† L M Over Key (kg) (kg m 2 )<br />

F70 B – 50 144 80 35 73 13 – 70 35 M10 3,1 0,009<br />

8XM8<br />

87 8,750" 240 26 1,41 0,016 F70 F 2012 50 144 80 32 73 13 42 67 35 – 3,1 0,009<br />

8x5/16UNC F70 H 1610 42 144 80 30 73 13 38 65 35 – 3,0 0,009<br />

F80 B — 60 167 97 42 81 16 — 82 40 M10 4,9 0,018<br />

6xM10<br />

96 9,625" 262 30 1,87 0,025 F80 F 2517 60 167 95 45 81 16 48 85 40 — 4,9 0,018<br />

6x3/8UNC F80 H 2012 50 167 95 32 81 16 42 72 40 — 4,6 0,017<br />

F100 B — 80 216 125 48 89 16 — 86 41 M12 9,9 0,055<br />

112 11,250" 8x 7/16UNF 305 32 2,49 0,048 F100 F 3020 75 216 120 51 89 16 55 89 41 — 7,0 0,031<br />

F100 H 2517 60 216 113 45 89 16 48 83 41 — 7,0 0,031<br />

8xM10 F100 B — 80 216 125 48 89 16 — 89 41 M12 9,9 0,055<br />

116 11,625" 8x 3/8UNC 313 30 2,51 0,051 F100 F 3020 75 216 120 51 89 16 55 92 41 — 9,9 0,055<br />

8x 3/8BSF F100 H 2517 60 216 113 45 89 16 48 86 41 — 9,4 0,054<br />

F110 B — 90 233 128 63 102 16 — 118 55 M12 12,5 0,081<br />

8xM10<br />

131 13,125" 351 39 3,71 0,094 F110 F 3020 75 233 134 51 102 16 55 106 55 — 11,7 0,078<br />

8x3/8UNC F110 H 3020 75 233 134 51 102 16 55 106 55 — 11,7 0,078<br />

F110 B — 90 233 128 63 102 16 — 120 57 M12 12,5 0,081<br />

135 13,500" 6x 3/8UNC 364 37 4,16 0,113 F110 F 3020 75 233 134 51 106 16 55 108 57 — 11,7 0,078<br />

F110 H 3020 75 233 134 51 106 16 55 108 57 — 11,7 0,078<br />

F140 B — 130 311 178 94 121 17 — 162 68 M20 22,2 0,254<br />

8xM12<br />

172 17,250" 465 41 7,10 0,320 F140 F 3525 100 311 178 65 121 17 67 133 68 — 22,3 0,255<br />

8x1/2UNC F140 H 3525 100 311 178 65 121 17 67 133 68 — 22,3 0,255<br />

All dimensions in millimetres unless otherwise stated.<br />

Driving flange mass & inertia given are for the bolt ring, bolts and half of the element.<br />

<strong>Drive</strong>n flange mass & inertia given are for an assembled flange having a mid range bore or bush and half the element.<br />

†† J is the wrench clearance to allow for tightening/loosening the bush. A shortened wrench will allow this dimension to be reduced.<br />

200 <strong>Drive</strong> <strong>Couplings</strong><br />

†W FLANGE—<br />

bolt holes are equi-spaced except size<br />

135W shown

Example: Part No. = X87<br />

R<br />

Fenaflex Flywheel <strong>Couplings</strong><br />

FENAFLEX ELEMENTS—PHYSICAL CHARACTERISTICS AND POWER RATINGS<br />

Normal Maximum Maximum Damping Dynamic<br />

Coupling Torque Torque Alternating<br />

Resonance<br />

Energy Stiffness Power at * Power at *<br />

Size (Nm) (Nm) Torque (Nm)<br />

Factor<br />

Ratio (Nm/rad) 1500 rev/min 1800 rev/min<br />

VR ψ CTdyn (kW) (kW)<br />

T KN T KMAX ± T KW<br />

87 239 717 120 7 0,9 3427 37,5 45,0<br />

96 325 975 163 7 0,9 4653 51,0 61,2<br />

112 592 1776 158 7 0,9 3392 93,0 111,5<br />

116 592 1776 296 7 0,9 8480 93,0 111,5<br />

131 754 2262 377 7 0,9 10801 118 142<br />

135 754 2262 201 7 0,9 4320 118 142<br />

172 1919 5757 960 7 0,9 27492 301 362<br />

Selection of Fenaflex flywheel couplings should take account of design power (using Service Factors on page 194) and speed,<br />

and also the torsional characteristics of the coupled machines – consult Fenner Power Transmission Distributor.<br />

* Power ratings at other speeds directly proportional to these values.<br />

All Fenaflex <strong>Couplings</strong> – Ordering Instructions<br />

SHAFT TO SHAFT COUPLING<br />

USING FLEXIBLE TYRE.<br />

Consists of:<br />

2–Flanges<br />

T/L bushes for F and H flanges only<br />

1–Flexible tyre<br />

EXAMPLE ORDER<br />

Fenaflex coupling F90BH comprising:<br />

1–F90B flange bored 70mm (coded at<br />

time of order).<br />

1–F90H flange<br />

1–2517 T/L bush (bore 35mm)<br />

1–F90 Flexible tyre (Natural)<br />

FENAFLEX SPACER COUPLING<br />

Consists of a standard Fenaflex coupling<br />

(using B, F or H flanges as desired)<br />

together with a spacer flange and a third<br />

Taper Lock bush.<br />

EXAMPLE ORDER<br />

Fenaflex spacer assembly<br />

F110FF–SM30/140 comprising:<br />

2–F110F flanges<br />

1–F110 flexible tyre<br />

1–SM30 x 140mm spacer flange<br />

1–3020 T/L bush to suit motor shaft<br />

1–3020 x 60mm T/L bush<br />

1–3030 T/L bush to suit driven shaft<br />

FENAFLEX FLYWHEEL COUPLING<br />

Consists of:<br />

1–Driving (W) flange<br />

1–Bolt pack<br />

1–Flexible element (above)<br />

1–<strong>Drive</strong>n flange<br />

1–T/L bush to suit driven shaft (F & H driven<br />

flanges only)<br />

<strong>Drive</strong> <strong>Couplings</strong> 201<br />

DRIVE<br />

COUPLINGS

DRIVE<br />

COUPLINGS<br />

R<br />

Fenaflex Flywheel <strong>Couplings</strong><br />

INSTALLATION INSTRUCTIONS<br />

Note: Satisfactory performance depends on<br />

correct installation and maintenance. All<br />

instructions must therefore be followed<br />

carefully.<br />

1. Thoroughly clean all components, paying<br />

particular attention to the removal of the<br />

protective coating in the bore of the driven<br />

flange.<br />

2. Slip bolt ring, clamping, and then element<br />

(with large diameter facing flywheel) onto<br />

driven shaft. Fit flange to shaft. (Where a<br />

Taper Lock ® bush). Locate flange on shaft<br />

so that dimension M will be achieved on<br />

assembly (see paragraph 3).<br />

3. Bring driven shaft into line with flywheel<br />

until dimension M is correct (see table). If<br />

shaft end float is to occur, locate driven shaft<br />

at mid position of end float when checking<br />

dimension M. Note that driven shaft may<br />

project beyond the face of the flange if<br />

required. In this event, allow sufficient<br />

space between shaft end and flywheel for<br />

end float and misalignment.<br />

4. Accurately align driven shaft with flywheel.<br />

Check both parallel and angular alignment<br />

by mounting a dial indicator near the outside<br />

diameter of the flange (as shown) and<br />

rotating the flywheel through 360 o . Indicator<br />

readings for both parallel and angular<br />

alignment should not exceed the values<br />

given in the table overleaf. Then bolt driven<br />

machine in place.<br />

5. Place flexible element and bolt ring* in<br />

position, fit screws finger tight. Place<br />

clamping ring in position and fit screws<br />

finger tight.<br />

6. Working alternately and evenly round each<br />

flange, tighten each screw (approx. 1 / 2 turn)<br />

until the required screw torques are<br />

achieved – see table.<br />

Element Size<br />

M<br />

Lr<br />

Maximum<br />

Indicator<br />

Reading<br />

Flange Size<br />

Screw<br />

Bolt Ring Nm<br />

Torques<br />

Clamping Ring Nm<br />

† For 213W Flywheel coupling M - 104 mm when adaptor ring fitted, see diagram.<br />

Note: It may be necessary to back off the shaft to allow room to remove and replace the<br />

flexible element.<br />

202 <strong>Drive</strong> <strong>Couplings</strong><br />

mm<br />

mm<br />

mm<br />

Flywheel<br />

Flywheel<br />

M<br />

Ferrule<br />

Bolt Ring<br />

Flexible<br />

Element<br />

Clamping<br />

Ring<br />

Bolt Ring<br />

Adaptor Ferrule<br />

Bolt Ring<br />

213W only<br />

Flange<br />

Flange<br />

87 96 112 116 131 135 172 192 213 252<br />

35 40 42 42 53 57 69 76 86† 132<br />

– – – – 91 93 112 123 156 200<br />

0,51 0,63 0,76 0,76 0,89 0,89 1,14 1,27 1,40 1,52<br />

F70 F80 F100 F100 F110 F110 F140 F160 F180 F220<br />

24 32 32 32 32 32 35 35 54 75<br />

24 24 32 32 32 32 35 55 55 140<br />

WHR and WBR Configurations<br />

These flanges are available for use in<br />

applications where close-couplings is essential.<br />

It should be noted that the coupling must be<br />

assembled on the driven machine shaft before<br />

offering the driven machine up to the engine,<br />

i.e. First place bolt ring on driven shaft then fit<br />

driven flange, element and clamping ring. Take<br />

care to position the driven flange so that the<br />

correct dimension Lr will be achieved on<br />

assembly (see table). Tighten the clamping ring<br />

screws alternately and evenly ( 1 / 2 turn each) until<br />

the required screw torques are achieved. After<br />

the two machines are brought together the bolt<br />

ring screws should be inserted and tightened<br />

alternately are achieved.<br />

• On size 213W only, place bolt ring adaptor<br />

between flexible element and flywheel. Line up<br />

unthreaded holes in adaptor with threaded holes<br />

in flywheel and fit the 6 long screws into these<br />

holes. Fix the 6 short screws in the other holes.<br />

LR<br />

ASSEMBLY WHR<br />

LR<br />

ASSEMBLY WBR

These semi-elastic couplings designed for general purpose use, permit quick and easy assembly by means of Taper-<br />

Lock ® bush fixing.<br />

Fully machined outside diameters allow alignment by simple straight edge methods.<br />

Shaft connection is "fail safe" due to interacting dog design.<br />

SELECTION<br />

(a) Service Factor<br />

Determine appropriate Service Factor<br />

from table below<br />

(b) Design Power<br />

Multiply running power of driven<br />

machinery by the service factor. This<br />

gives the design power which is used<br />

as a basis for coupling selection.<br />

(c) Coupling Size<br />

Refer to Power Ratings table below<br />

and read across from the appropriate<br />

speed until a power equal to or greater<br />

than the design power is found. The<br />

size of coupling is given at the head of<br />

that column.<br />

SERVICE FACTORS<br />

(d) Bore Size<br />

From Dimensions table on page 204<br />

check that the required bores can be<br />

accommodated.<br />

EXAMPLE<br />

A shaft coupling is required to transmit<br />

70kW between a 1200 rev/min diesel<br />

engine and a hoist running over 16hrs/day.<br />

Engine shaft is 70mm and the hoist shaft is<br />

75mm.<br />

(a) Service Factor<br />

The appropriate service factor is 2,5.<br />

(b) Design Power<br />

Design power 70 x 2,5=175kW.<br />

SPECIAL CASES<br />

For applications where substantial shock, vibration and torque fluctuation occur, and<br />

for reciprocating machines e.g. internal combustion engines, piston type pumps and<br />

compressors, refer to Fenner Power Transmission Distributor with full machine details<br />

for torsional analysis.<br />

(c) Coupling Size<br />

Reading across from 1200 rev/min in<br />

the speed column of Power Ratings<br />

table below, 251kW is the first power<br />

to exceed the required 175kW (design<br />

power). The size of the coupling at the<br />

head of this column is 230.<br />

(d) Bore Size<br />

The Dimensions table (page 204)<br />

shows that both shaft diameters are<br />

within the bore range available.<br />

Type of Driving Unit<br />

Electric Motors<br />

Internal Combustion Engines<br />

Steam Engines<br />

Steam Turbines Water Turbines<br />

Hours per day duty Hours per day duty<br />

over 8 over 8<br />

8 and to 16 over 8 and to 16 over<br />

<strong>Drive</strong>n Machine Class under inclusive 16 under inclusive 16<br />

UNIFORM<br />

Brewing machinery, Centrifugal blowers, Centrifugal compressors†,<br />

Conveyors, Centrifugal fans and pumps, Generators, Sewage disposal equipment.<br />

MODERATE SHOCK*<br />

Agitators, Clay working machinery, Crane hoists, Laundry machinery, Wood working<br />

1,00 1,12 1,25 1,25 1,40 1,60<br />

machinery, Machine tools, Rotary mills, Paper mill machinery, Textile machinery,<br />

Non-unifomly loaded centrifugal pumps.<br />

HEAVY SHOCK*<br />

Reciprocating conveyors, Crushers, Shakers, Metal mills, Rubber machinery (Banbury<br />

1,60 1,80 2,00 2,00 2,24 2,50<br />

mixers and mills), Reciprocating compressors, Welding sets. 2,50 2,80 3,12 3,12 3,55 4,00<br />

* It is recommended that keys (with top clearance if in Taper-Lock ® bushes) are fitted for applications where load fluctuation is expected.<br />

† For Centrifugal Compressors multiply Service Factor by an additional 1,15.<br />

POWER RATINGS (kW)<br />

HRC <strong>Couplings</strong><br />

Speed<br />

rev/min<br />

Coupling Size<br />

70 90 110 130 150 180 230 280<br />

100<br />

200<br />

400<br />

0,33<br />

0,66<br />

1,32<br />

0,84<br />

1,68<br />

3,35<br />

1,68<br />

3,35<br />

6,70<br />

3,30<br />

6,60<br />

13,2<br />

6,28<br />

12,6<br />

25,1<br />

9,95<br />

19,9<br />

39,8<br />

20,9<br />

41,9<br />

83,8<br />

33,0<br />

65,0<br />

132<br />

600<br />

720<br />

800<br />

1,98<br />

2,37<br />

2,64<br />

5,03<br />

6,03<br />

6,70<br />

10,1<br />

12,1<br />

13,4<br />

19,8<br />

23,8<br />

26,4<br />

37,7<br />

45,2<br />

50,3<br />

59,7<br />

71,6<br />

79,6<br />

126<br />

151<br />

168<br />

198<br />

238<br />

264<br />

960<br />

1200<br />

1440<br />

3,17<br />

3,96<br />

4,75<br />

8,04<br />

10,1<br />

12,1<br />

16,1<br />

20,1<br />

24,1<br />

31,7<br />

39,6<br />

47,5<br />

60,3<br />

75,4<br />

90,5<br />

95,5<br />

119<br />

143<br />

201<br />

251<br />

302<br />

317<br />

396<br />

475<br />

1600<br />

1800<br />

2000<br />

5,28<br />

5,94<br />

6,60<br />

13,4<br />

15,1<br />

16,8<br />

26,8<br />

30,2<br />

33,5<br />

52,8<br />

59,4<br />

66,0<br />

101<br />

113<br />

126<br />

159<br />

179<br />

199<br />

335<br />

377<br />

419<br />

528<br />

594<br />

660<br />

2200<br />

2400<br />

2600<br />

7,26<br />

7,92<br />

8,58<br />

18,4<br />

20,1<br />

21,8<br />

36,9<br />

40,2<br />

43,6<br />

72,6<br />

79,2<br />

85,8<br />

138<br />

151<br />

163<br />

219<br />

239<br />

259<br />

461<br />

503<br />

545<br />

726<br />

2880<br />

3000<br />

3600<br />

9,50<br />

9,90<br />

11,9<br />

24,1<br />

25,1<br />

30,1<br />

48,3<br />

50,3<br />

60,3<br />

95<br />

99<br />

118<br />

181<br />

188<br />

226<br />

286<br />

298<br />

Nominal Torque (Nm) 31,5 80 160,30 315 600 950 2000 3150<br />

Max Torque (Nm) 72 180 360,30 720 1500 2350 5000 7200<br />

For speeds below 100 rev/min and intermediate speeds use nominal torque ratings.<br />

* Maximum coupling speeds are calculated using an allowable peripheral speed for the hub material. For selection of smaller sizes with speeds in excess of<br />

3600 rev/min – Consult Fenner Power Transmission Distributor.<br />

<strong>Drive</strong> <strong>Couplings</strong> 203<br />

DRIVE<br />

COUPLINGS

DRIVE<br />

COUPLINGS<br />

HRC <strong>Couplings</strong> – Dimensions<br />

Example: Part No. = HRC70<br />

PHYSICAL DIMENSIONS AND CHARACTERISTICS<br />

204 <strong>Drive</strong> <strong>Couplings</strong><br />

Common Dimensions Type F & H Type B<br />

Size A B E F ‡ 1 G<br />

Bush<br />

size<br />

Max. Bore<br />

mm ins. C D J†<br />

Bore Dia's<br />

Pilot<br />

Max. H9<br />

Screw<br />

over key C D<br />

70 69 60 31 25,5 18,5 1008 25 1" 20,0 23,5 29 32 8 M 6 20 23,5<br />

90 85 70 32 30,5 22,5 1108 28 11 /8 19,5 23,5 29 42 10 M 6 26 30,5<br />

110 112 100 45 45,5 29,5 1610 42 15 /8 18,5 26,5 38 55 10 M10 37 45,5<br />

130 130 105 50 53,5 36,5 1610 42 15 /8 18,0 26,5 38 60 15 M10 39 47,5<br />

150 150 115 62 60,5 40,5 2012 50 2 23,5 33,5 42 70 20 M10 46 56,5<br />

180 180 125 77 73,5 49,5 2517 60 21 /2 34,5 46,5 48 80 25 M10 58 70,5<br />

230 225 155 99 85,5 59,5 3020 75 3 39,5 52,5 55 100 25 M12 77 90,5<br />

280 275 206 119 105,5 74,5 3525 100 4 51,0 66,5 67 115 30 M16 90 105,5<br />

† 'J' is the wrench clearance required for tightening/loosening the bush on the shaft. A shortened wrench will allow this dimension to be reduced.<br />

‡ F 1 refers to combinations of flanges: FF, FH, HH, FB, HB, BB.<br />

Bore limits H7 unless specified otherwise.<br />

Assembled Length (L*) Dynamic Maximum Nominal<br />

Size Comprising Flange Types Mass Inertia Mr2 Stiffness Misalignment Torque<br />

(kg) (kgm2 ) (Nm/ O ) (Nm)<br />

FF, FH, HH FB,HB BB Parallel Axial<br />

70 65 65 65 1,00 0,00085 – 0,3 +0,2 31<br />

90 69,5 76 82,5 1,17 0,00115 – 0,3 +0,5 80<br />

110 82 100,5 119 5,00 0,00400 65 0,3 +0,6 160<br />

130 89 110 131 5,46 0,00780 130 0,4 +0,8 315<br />

150 107 129,5 152 7,11 0,01810 175 0,4 +0,9 600<br />

180 142 165,5 189 16,6 0,04340 229 0,4 +1,1 950<br />

230 164,5 202 239,5 26,0 0,12068 587 0,5 +1,3 2000<br />

280 207,5 246,5 285,5 50,0 0,44653 1025 0,5 +1,7 3150<br />

All dimensions in millimetres unless otherwise stated.<br />

All HRC Elements have an angular misalignment capacity of up to 1 o .<br />

Mass is for an FF, FH or HH coupling with mid range Taper-Lock Bushes.<br />

Standard element -40 o C / +100 o C.

Satisfactory performance depends on<br />

correct installation and maintenance. All<br />

instructions in this manual must therefore<br />

be followed carefully.<br />

1. Thoroughly clean all components, paying<br />

particular attention to the removal of the<br />

protective coating in the bore of the driven<br />

flange.<br />

2. Fit driven flange (with driving dogs facing<br />

flywheel) onto driven shaft. (Where a Taper<br />

Lock ® Flange is used, see separate fitting<br />

instructions supplied with the Taper Lock ®<br />

Bush). Locate flange on shaft so that<br />

dimension ‘M’ will be achieved on assembly<br />

(see paragraph 3).<br />

3. Bring driven shaft into line with flywheel<br />

until dimension ‘M’ is correct (see tables<br />

overleaf). If shaft end float is to occur, locate<br />

driven shaft at mid position of end float<br />

when checking dimension ‘M’. Note that<br />

driven shaft may project beyond the face<br />

of the flange if required. In this event, shaft<br />

diameter + key must be within the bore<br />

diameter ‘E’ of the element (see table<br />

overleaf). Allow sufficient space between<br />

shaft end and flywheel for end float and<br />

misalignment.<br />

4. Fit driving flange to flywheel, using screws<br />

from appropriate screw pack (to suit thread<br />

type in flywheel). Initially screws should be<br />

finger tight. Check location surface i.e.<br />

outside diameter or spigot in back face of<br />

flange are seating square with flywheel.<br />

Alternatively flange location can be achieved<br />

by using dowel pins. (2 at 180 o ).<br />

5. Working alternately and evenly round the<br />

flange, tighten each screw until the required<br />

screw torques are achieved – as below.<br />

Flywheel Size Screw Torque (Nm)<br />

096 to 135<br />

172<br />

32<br />

35<br />

6. With open assembly type drives check both<br />

parallel and angular alignment by placing<br />

straight edge across the coupling using<br />

setting diameter on flywheel flange and<br />

shroud on driven flange (as shown below).<br />

Re-check with straight edge after rotating<br />

the flywheel through 180 o .<br />

HRC Flywheel <strong>Couplings</strong><br />

FLYWHEEL COUPLING ASSEMBLY IMPORTANT<br />

When assembled there must be clearance<br />

between the metal halves of the coupling. A<br />

minimum 1,5 mm between the face of the dog<br />

and the inner face of the opposing coupling half<br />

Driving flange<br />

is recommended to prevent any preload of<br />

driver and driven bearings.<br />

<strong>Drive</strong>n flange<br />

Flexible<br />

element<br />

Parallel<br />

mis-alignment<br />

Straight edge<br />

1,5 mm<br />

<strong>Drive</strong> <strong>Couplings</strong> 205<br />

DRIVE<br />

COUPLINGS

DRIVE<br />

COUPLINGS<br />

HRC Flywheel <strong>Couplings</strong><br />

TABLE 4: DIMENSIONS – SAE STYLE COUPLING<br />

BOLTS<br />

Type Size pod<br />

S<br />

No. Size<br />

mm inch<br />

W<br />

W<br />

W<br />

W<br />

W<br />

W<br />

W<br />

W<br />

W<br />

W<br />

W<br />

W<br />

W<br />

W<br />

W<br />

W<br />

150-096<br />

150-112<br />

150-116<br />

150-131<br />

180-096<br />

180-112<br />

180-116<br />

180-131<br />

180-135<br />

230-112<br />

230-116<br />

230-131<br />

230-135<br />

280-131<br />

280-135<br />

280-172<br />

N<br />

Example: Part No. = HRP 230<br />

244<br />

286<br />

295<br />

333<br />

244<br />

286<br />

295<br />

333<br />

343<br />

286<br />

295<br />

333<br />

343<br />

333<br />

343<br />

438<br />

9 5 /8"<br />

11 1 /4"<br />

11 5 /8"<br />

13 1 /8"<br />

9 5 /8"<br />

11 1 /4"<br />

11 5 /8"<br />

13 1 /8"<br />

13 1 /2"<br />

11 1 /4"<br />

11 5 /8"<br />

13 1 /8"<br />

13 1 /2"<br />

13 1 /8"<br />

13 1 /2"<br />

17 1 /4"<br />

† J is the wrench clearance to allow for tightening and loosening the bush on the shaft. The use of a shortened key will allow this dimension to be<br />

reduced.<br />

LFH is the overall length when using F or H bushed flanges.<br />

LB is the overall length when using ‘B’ flanges.<br />

Mass and inertias are for a complete coupling, ie flywheel flange, F or H flange fitted with a mid range bush and the element.<br />

206 <strong>Drive</strong> <strong>Couplings</strong><br />

6<br />

8<br />

8<br />

8<br />

6<br />

8<br />

8<br />

8<br />

6<br />

8<br />

8<br />

8<br />

6<br />

8<br />

6<br />

8<br />

L<br />

M<br />

<strong>Drive</strong>n Flange Codes<br />

‘B’ Flange - Bored to size<br />

‘F’ Flange<br />

‘H’ Flange<br />

DRIVING FLANGE DRIVEN FLANGE<br />

3 /8"UNC<br />

7 /16"UNF<br />

3 /8"UNC<br />

3 /8"UNC<br />

3 /8"UNC<br />

7 /16"UNF<br />

3 /8"UNC<br />

3 /8"UNC<br />

3 /8"UNC<br />

7 /16"UNF<br />

3 /8"UNC<br />

3 /8"UNC<br />

3 /8"UNC<br />

3 /8"UNC<br />

3 /8"UNC<br />

1 /2"UNC<br />

Element Codes<br />

Nitrile Rubber (General Duty)<br />

G<br />

E<br />

263<br />

307<br />

314<br />

352<br />

263<br />

307<br />

314<br />

352<br />

370<br />

307<br />

314<br />

352<br />

370<br />

352<br />

370<br />

466<br />

LFH LB M N<br />

84,5<br />

84,5<br />

84,5<br />

84,5<br />

107,5<br />

107,5<br />

107,5<br />

107,5<br />

107,5<br />

127<br />

127<br />

127<br />

127<br />

157<br />

157<br />

157<br />

D<br />

111<br />

111<br />

111<br />

111<br />

131<br />

131<br />

131<br />

131<br />

131<br />

164,5<br />

164,5<br />

164,5<br />

164,5<br />

196<br />

196<br />

196<br />

51<br />

51<br />

51<br />

51<br />

61<br />

61<br />

61<br />

61<br />

61<br />

74,5<br />

74,5<br />

74,5<br />

74,5<br />

90,5<br />

90,5<br />

90,5<br />

J<br />

B A P S<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

17<br />

17<br />

17<br />

Total<br />

Mass<br />

kg<br />

Total<br />

Inertia<br />

kgm 2<br />

9,629 0,055<br />

11,622 0,098<br />

11,955 0,106<br />

13,607 0,157<br />

13.128 0,078<br />

15,191 0,121<br />

15,523 0,129<br />

17,788 0,191<br />

18,859 0,226<br />

22,301 0,187<br />

22,634 0,195<br />

24,774 0,255<br />

25,845 0,289<br />

41,889 0,484<br />

43,103 0,524<br />

47,737 0,782<br />

Size<br />

150<br />

150<br />

150<br />

150<br />

180<br />

180<br />

180<br />

180<br />

180<br />

230<br />

230<br />

230<br />

230<br />

280<br />

280<br />

280<br />

Type<br />

FH<br />

Bush<br />

2012<br />

2012<br />

2012<br />

2012<br />

2517<br />

2517<br />

2517<br />

2517<br />

2517<br />

3020<br />

3020<br />

3020<br />

3020<br />

3525<br />

3525<br />

3525<br />

Flywheel to Shaft Coupling<br />

Comprises:<br />

1 - Flywheel Flange.<br />

1 - Flexible element.<br />

1 - HRC <strong>Drive</strong>n Flange.<br />

1 - Taper-Lock ® Bush.<br />

Max Bore<br />

Type B Bore<br />

mm inch Max Min<br />

50<br />

50<br />

50<br />

50<br />

60<br />

60<br />

60<br />

60<br />

60<br />

75<br />

75<br />

75<br />

75<br />

90<br />

90<br />

90<br />

2,0<br />

2,0<br />

2,0<br />

2,0<br />

2,5<br />

2,5<br />

2,5<br />

2,5<br />

2,5<br />

3,0<br />

3,0<br />

3,0<br />

3,0<br />

3,5<br />

3,5<br />

3,5<br />

30 O<br />

70<br />

70<br />

70<br />

70<br />

80<br />

80<br />

80<br />

80<br />

80<br />

100<br />

100<br />

100<br />

100<br />

115<br />

115<br />

115<br />

42<br />

42<br />

42<br />

42<br />

48<br />

48<br />

48<br />

48<br />

48<br />

55<br />

55<br />

55<br />

55<br />

65<br />

65<br />

65<br />

+ 135 Flange<br />

A B DFH D6 E G J†<br />

150<br />

150<br />

150<br />

150<br />

180<br />

180<br />

180<br />

180<br />

180<br />

225<br />

225<br />

225<br />

225<br />

275<br />

275<br />

275<br />

30 O<br />

90 O 90 O<br />

BOLT HOLES ARE EQUI-SPACED<br />

EXCEPT SIZE 135 SHOWN<br />

115<br />

115<br />

115<br />

115<br />

125<br />

125<br />

125<br />

125<br />

125<br />

155<br />

155<br />

155<br />

155<br />

206<br />

206<br />

206<br />

33,5<br />

33,5<br />

33,5<br />

33,5<br />

46,5<br />

46,5<br />

46,5<br />

46,5<br />

46,5<br />

52,5<br />

52,5<br />

52,5<br />

52,5<br />

66,5<br />

66,5<br />

66,5<br />

30 O<br />

60<br />

60<br />

60<br />

60<br />

70<br />

70<br />

70<br />

70<br />

70<br />

90<br />

90<br />

90<br />

90<br />

105,5<br />

105,5<br />

105,5<br />

156.56<br />

156.50<br />

62<br />

62<br />

62<br />

62<br />

77<br />

77<br />

77<br />

77<br />

77<br />

99<br />

99<br />

99<br />

99<br />

119<br />

119<br />

119<br />

2<br />

40<br />

40<br />

40<br />

40<br />

49<br />

49<br />

49<br />

49<br />

49<br />

59,5<br />

59,5<br />

59,5<br />

59,5<br />

74,5<br />

74,5<br />

74,5<br />

42<br />

42<br />

42<br />

42<br />

48<br />

48<br />

48<br />

48<br />

48<br />

55<br />

55<br />

55<br />

55<br />

67<br />

67<br />

67

Jaw <strong>Couplings</strong> offer the choice of sintered iron hubs, standard nitrile elements and a range of stock bores to meet the<br />

demand for a low cost general purpose flexible coupling. They cater for incidental misalignment, absorb shock loads<br />

and damp small amplitude vibrations.<br />

SELECTION PROCEDURE<br />

(a) Service Factor<br />

Find service factor from table 1.<br />

(b) Design Power<br />

Multiply normal running power by the service factor.<br />

(c) Coupling Size<br />

Refer to table 2 and read across from the appropriate speed until a power equal to or<br />

greater than the design power is found. The coupling size is given at the head of the<br />

column.<br />

(d) Bore Size<br />

Check from dimension table 4 that the bore capacity of the coupling is adequate.<br />

TABLE 1: SERVICE FACTORS<br />

<strong>Drive</strong>n Load<br />

PRIME MOVER<br />

ELECTRIC MOTOR<br />

Uniform Load 1,0<br />

Moderate Shock 1,5<br />

Heavy Shock 2,0<br />

TABLE 2: POWER RATINGS - NITRILE ELEMENTS (kW)<br />

Speed<br />

r/min*<br />

100<br />

720<br />

960<br />

1440<br />

2880<br />

3600<br />

Torque N.m<br />

050<br />

0,037<br />

0,26<br />

0,35<br />

0,53<br />

1,05<br />

1,32<br />

3,51<br />

Coupling Size<br />

Jaw <strong>Couplings</strong><br />

070 075 090 095 100 110<br />

0,06<br />

0,43<br />

0,58<br />

0,87<br />

1,73<br />

2,17<br />

5,77<br />

TABLE 3: ELEMENT CHARACTERISTICS<br />

Type<br />

Nitrile<br />

Temp<br />

Range O C<br />

TABLE 4: DIMENSIONS<br />

Size<br />

050<br />

070<br />

075<br />

090<br />

095<br />

100<br />

110<br />

Max Displacement<br />

0,12<br />

0,90<br />

1,20<br />

1,80<br />

3,61<br />

4,51<br />

11,9<br />

Degrees Parallel<br />

-40 to 100 1 0,38 80A 1<br />

d1<br />

27,5<br />

35<br />

44,5<br />

53,5<br />

53,5<br />

65<br />

84,5<br />

Example: Part No. = L050<br />

d2<br />

Max<br />

14<br />

19<br />

24<br />

24<br />

28<br />

35<br />

42<br />

l1<br />

44<br />

51<br />

54<br />

54<br />

64<br />

90<br />

108<br />

l2 ø<br />

6,5<br />

9,5<br />

8,0<br />

8,7<br />

11,0<br />

11,0<br />

19,0<br />

0,20<br />

1,44<br />

1,93<br />

2,89<br />

5,78<br />

7,22<br />

19,2<br />

Shore<br />

Hardness<br />

l3<br />

16,5<br />

20<br />

21<br />

23,5<br />

25,5<br />

35,5<br />

43<br />

0,27<br />

1,95<br />

2,59<br />

3,89<br />

7,78<br />

9,73<br />

25,8<br />

Power<br />

Factor<br />

Set screw<br />

ø over<br />

key<br />

M6<br />

M6<br />

M6<br />

M6<br />

M8<br />

M8<br />

M10<br />

0,58<br />

4,18<br />

5,58<br />

8,36<br />

16,73<br />

20,91<br />

55,4<br />

Approx +<br />

mass<br />

(kg)<br />

Maximum speed 3 600 r/min. Maximum displacement all sizes: 0,38 mm radial, 1 o angular.<br />

Ø Bored or bored and keywayed hubs can be supplied against special order. Bores are to ISO .268 H7 tolerance (BS 4500, 1969).<br />

Keyways are to BS 4235 for metric bores and to BS46 Part 1:1958 for imperial bores.<br />

+ Masses are for a complete coupling with solid hubs which are normally supplied.<br />

*S -Sintered Iron.<br />

0,11<br />

0,26<br />

0,46<br />

0,55<br />

0,68<br />

1,58<br />

3,17<br />

1,10<br />

7,94<br />

10,59<br />

15,88<br />

31,77<br />

39,71<br />

105<br />

Hub<br />

Material<br />

*S<br />

<strong>Drive</strong> <strong>Couplings</strong> 207<br />

S<br />

S<br />

S<br />

S<br />

S<br />

S<br />

S<br />

DRIVE<br />

COUPLINGS

DRIVE<br />

COUPLINGS<br />

High Precision Universal Joints with Hardened Bushes<br />

Example: Part No. = UTS 100AL<br />

Singles max 45 o - Doubles max 90 o<br />

TABLE 1: DIMENSIONS<br />

TYPE<br />

108AD<br />

TYPE<br />

100AL<br />

102A<br />

103A<br />

104A<br />

105A<br />

106A<br />

108A<br />

109A<br />

110A<br />

111A<br />

111/1A<br />

113A<br />

114A<br />

SELECTION OF JOINTS<br />

TABLE 3 gives the maximum allowable torque (expressed in N.m) calculated on the basis<br />

with an angle of inclination of 10 o and continuous use.<br />

If the inclination angle is over 10 o the values shown will be reduced in accordance with the<br />

angle factors in TABLE 2.<br />

208 <strong>Drive</strong> <strong>Couplings</strong><br />

SINGLE JOINTS<br />

d l1 l2<br />

10<br />

16<br />

22<br />

25<br />

29<br />

32<br />

40<br />

47<br />

50<br />

58<br />

63<br />

80<br />

95<br />

DOUBLE JOINTS<br />

40<br />

58<br />

62<br />

86<br />

90<br />

95<br />

127<br />

127<br />

140<br />

178<br />

130<br />

160<br />

190<br />

13<br />

11<br />

10<br />

11<br />

13<br />

15<br />

19<br />

22<br />

26<br />

30<br />

30<br />

42<br />

54<br />

MAX BORE SIZES: ROUND, SQUARE, HEX<br />

dH7<br />

KEYWAY b t dH7 SH 8 SWH8<br />

–<br />

8<br />

10<br />

12<br />

14<br />

16<br />

20<br />

22<br />

25<br />

30<br />

32<br />

40<br />

50<br />

d1 l3<br />

l4<br />

l5<br />

40 128 46 20 6 22,8 25 20 20 20<br />

All dimensions are in mm's.<br />

NB Joints are solid and may not be dismantled for boring.<br />

–<br />

2<br />

3<br />

4<br />

5<br />

5<br />

6<br />

6<br />

8<br />

8<br />

10<br />

12<br />

14<br />

–<br />

9<br />

11,4<br />

13,8<br />

16,3<br />

18,3<br />

22,8<br />

24,8<br />

28,3<br />

33,8<br />

35,3<br />

43,3<br />

53,8<br />

dH7<br />

KEYWAY b t dH7 SH 8 SWH8<br />

5<br />

10<br />

12<br />

12<br />

16<br />

20<br />

25<br />

25<br />

32<br />

35<br />

40<br />

50<br />

55<br />

–<br />

–<br />

10<br />

12<br />

14<br />

16<br />

20<br />

22<br />

25<br />

30<br />

30<br />

–<br />

–<br />

TABLE 2: ANGLE FACTOR<br />

ANGLE UP TO<br />

5O 10O 20O 30O 40O All dimensions in millimetres.<br />

FACTOR F<br />

1,25<br />

1<br />

0,75<br />

0,45<br />

0,30<br />

–<br />

–<br />

10<br />

12<br />

14<br />

16<br />

20<br />

25<br />

25<br />

35<br />

35<br />

38<br />

38

High Precision Universal Joints with Hardened Bushes<br />

Example: Criteria for selection of joint after<br />

taking into account the power to be<br />

transmitted, speed and angle of inclination.<br />

Example: power P 2,2 kW<br />

speed n 200 r/min<br />

bore size<br />

angle � 20 o<br />

1. The corresponding torque moment is:<br />

M = 9550 x P = 9550 x 2,2 = 105,05 N.m<br />

n 200<br />

TABLE 3: TORSION MOMENTS FOR JOINTS IN N.m<br />

SIZE<br />

100AL<br />

102A<br />

103A<br />

104A<br />

105A<br />

106A<br />

108A<br />

109A<br />

110A<br />

111A<br />

113A<br />

114A<br />

100<br />

5,5<br />

13<br />

25<br />

43<br />

68,5<br />

86,5<br />

240<br />

300<br />

384<br />

432<br />

504<br />

720<br />

200<br />

5<br />

9<br />

17<br />

25<br />

43<br />

84<br />

168<br />

192<br />

240<br />

264<br />

336<br />

480<br />

300<br />

4,2<br />

8<br />

14,5<br />

20,5<br />

39,5<br />

72<br />

120<br />

144<br />

168<br />

192<br />

264<br />

336<br />

SPEED r/min<br />

For double joints use the value equivalent to 90% of the mentioned torsion moments.<br />

NOTES ON THE INSTALLATION OF<br />

UNIVERSAL JOINTS<br />

RECOMMENDED LUBRICANTS<br />

LUBRICATION<br />

For both intermittent and continuously<br />

rated joints where constant lubrication<br />

(such as an oil bath) is not available, joint<br />

covers suitable for grease packing are<br />

recommended. These are available for all<br />

sizes of single joint and can be used in pairs<br />

on double joints.<br />

Where the use of covers is not practical,<br />

the working areas of the joint must be oiled<br />

at least once a day.<br />

2. The torque to be transmitted is 105,05<br />

N.m but since the joint angle is 20 o one<br />

must select a joint of larger dimensions<br />

and torque carrying capacity to<br />

compensate.<br />

Since the torque factor for 20 o is 0,75<br />

(as indicated on the table 2) one divides<br />

the torque factor M by factor F.<br />

M = 105,05 = 140,07 N.m<br />

F 0,75<br />

Darmex<br />

Shell<br />

Mobil<br />

Caltex<br />

400<br />

3,8<br />

7<br />

13<br />

17<br />

36<br />

57,5<br />

96<br />

120<br />

144<br />

156<br />

216<br />

264<br />

GREASE<br />

3. The appropriate joint should have a<br />

torque capability of 140,07 N.m or<br />

greater, refer to TABLE 3.<br />

A Size 108A at 200 r/min will transmit<br />

168 N.m.<br />

4. Bore size, refer to TABLE 1 to ensure<br />

joint will accept the shaft diameters.<br />

500<br />

3,5<br />

6<br />

12<br />

15,5<br />

33,5<br />

51,5<br />

84<br />

96<br />

120<br />

132<br />

–<br />

–<br />

123<br />

Alvania EP2<br />

Mobilplex 46<br />

EP 00<br />

700<br />

–<br />

5,2<br />

11<br />

13<br />

28,5<br />

41<br />

60<br />

72<br />

96<br />

–<br />

–<br />

–<br />

OIL<br />

GB 1050<br />

Omala 320<br />

SHC 632<br />

Meropa 220<br />

800<br />

–<br />

4,7<br />

7,5<br />

12<br />

26,5<br />

36<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

Where constant angular velocity throughout each revolution of the connected shafts is<br />

required, the working angles must be equal - see Fig. 1. Where an intermediate shaft is<br />

used either telescopic (to accommodate lateral movement between the driving and<br />

driven shafts) or plain, the relationship of the joint ends must be as shown in Fig. 2.<br />

Applications involving tension or compression of the universal joint should be referred<br />

to Fenner Power Transmission Distributor.<br />

FIG. 2<br />

<strong>Drive</strong> <strong>Couplings</strong> 209<br />

DRIVE<br />

COUPLINGS

DRIVE<br />

COUPLINGS<br />

Rubber Boots for the Protection of the Universal Joints<br />

210 <strong>Drive</strong> <strong>Couplings</strong><br />

Example: Part No. = UJB 103G<br />

SIZE<br />

103G<br />

104G<br />

105G<br />

106G<br />

108G<br />

109G<br />

110G<br />

111G<br />

JOINT BORE<br />

10<br />

12<br />

14<br />

16<br />

20<br />

22<br />

25<br />

30<br />

A<br />

39<br />

47<br />

51<br />

56<br />

75<br />

83<br />

93<br />

105<br />

B C<br />

20,5<br />

24,5<br />

27,5<br />

30,5<br />

40<br />

45<br />

50<br />

56<br />

47<br />

52<br />

58<br />

67<br />

84<br />

97<br />

110<br />

124

Taper-Lock ® Rigid <strong>Couplings</strong> — Cast Iron<br />

Taper-Lock ® Rigid <strong>Couplings</strong> provide a convenient method of rigidly connecting ends of shafts. Taper-Lock ® Bushes permit easier and<br />