betaseal1527

betaseal1527

betaseal1527

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

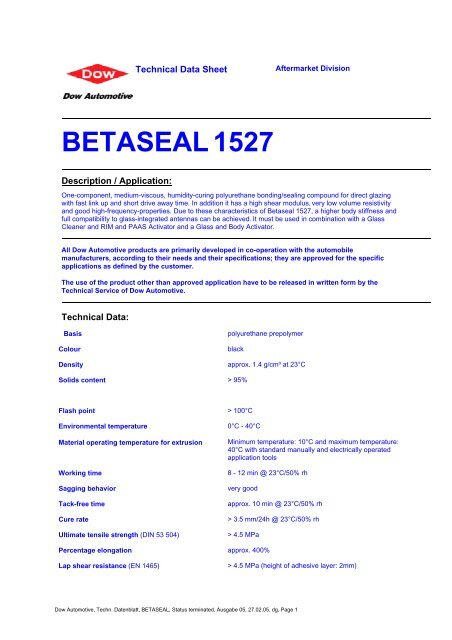

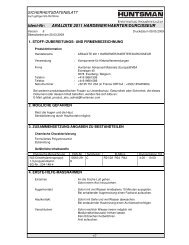

Technical Data Sheet<br />

BETASEAL 1527<br />

Description / Application:<br />

Aftermarket Division<br />

One-component, medium-viscous, humidity-curing polyurethane bonding/sealing compound for direct glazing<br />

with fast link up and short drive away time. In addition it has a high shear modulus, very low volume resistivity<br />

and good high-frequency-properties. Due to these characteristics of Betaseal 1527, a higher body stiffness and<br />

full compatibility to glass-integrated antennas can be achieved. It must be used in combination with a Glass<br />

Cleaner and RIM and PAAS Activator and a Glass and Body Activator.<br />

All Dow Automotive products are primarily developed in co-operation with the automobile<br />

manufacturers, according to their needs and their specifications; they are approved for the specific<br />

applications as defined by the customer.<br />

The use of the product other than approved application have to be released in written form by the<br />

Technical Service of Dow Automotive.<br />

Technical Data:<br />

Basis polyurethane prepolymer<br />

Colour black<br />

Density approx. 1.4 g/cm³ at 23°C<br />

Solids content > 95%<br />

Flash point > 100°C<br />

Environmental temperature<br />

Material operating temperature for extrusion<br />

0°C - 40°C<br />

Working time 8 - 12 min @ 23°C/50% rh<br />

Sagging behavior very good<br />

Minimum temperature: 10°C and maximum temperature:<br />

40°C with standard manually and electrically operated<br />

application tools<br />

Tack-free time approx. 10 min @ 23°C/50% rh<br />

Cure rate > 3.5 mm/24h @ 23°C/50% rh<br />

Ultimate tensile strength (DIN 53 504) > 4.5 MPa<br />

Percentage elongation approx. 400%<br />

Lap shear resistance (EN 1465) > 4.5 MPa (height of adhesive layer: 2mm)<br />

Dow Automotive, Techn. Datenblatt, BETASEAL, Status terminated, Ausgabe 05, 27.02.05, dg, Page 1

G-Modulus approx. 2.5 MPa at 10% strain after curing<br />

Recovery (EN 27 389) approx. 99%<br />

Shore A hardness (DIN 53 505) approx. 75<br />

Specific electrical volume resistivity > 10 9<br />

Ohm*cm<br />

Abrasion resistance High<br />

Temperature stability -40°C to 45°C; only for short period of time 46°C to 100.<br />

Resistance to chemicals Highly resistant to aqueous chemicals, petrol, alcohol and<br />

mineral oils.<br />

Conditionally resistant to esters, ketones, aromatics and<br />

chlorinated hydrocarbons<br />

Bonding surface preparation All bonding surfaces must be free of dirt, dust, water, oil,<br />

silicon and grease. Glass surfaces should be primed. Verify<br />

compatibility or consult our technical service department.<br />

Processing equipment Standard handapplicators and electrically operated<br />

dispensing equipment<br />

Cleaning Uncured Betaseal 1527 residues can easily be removed with<br />

BETACLEAN 3500. Hardened Betaseal 1527 residues can<br />

only be removed mechanically. Immerse equipment in<br />

BETACLEAN 3350.<br />

Shelf life Short time storage temperature: 0°C to 40°C<br />

9 months at 5°C to 25°C in unopened containers. (See "use<br />

before" date printed on container.)<br />

Containers 300 ml Bigmouth cartridges<br />

Protection measures See health and safety data sheet.<br />

Dow Automotive Quality Management<br />

Quality is our highest priority. Dow Automotive works with a highly modern Quality Management System which meets all international requirements<br />

of QS 9000, VDA-6 and ISO 9001.<br />

The above information implies no liability as to the usage of our products. Since the applications, utilisation and processing of our products are<br />

beyond our control, the information given is not intended to replace your own trials with the products to establish their suitability for your particular<br />

application.<br />

Our liability is limited to the value of the products supplied by us and used by you.<br />

The information on this data sheet corresponds to the latest findings and supersedes all previous versions.<br />

Dow Automotive Dow Automotive Dow Automotive (France) S.A.<br />

Dow Europe GmbH Dow Italy S.r.L F-60130 Saint-Just en chaussee<br />

Freienbach Branch I-20010 Bareggio (MI) Tel. +33(0) 3 44 77 61 00<br />

CH-8807 Freienbach Tel. +39(0)2 90 36 11 66 Fax. +33(0) 3 44 77 61 61<br />

Tel. +41(0)55416 81 11 Fax +39(0)2 90 27 66 98<br />

Fax +41(0)55416 82 20<br />

Dow Automotive (Deutschland) GmbH Dow Automotive (España) S.A. Dow Automotive<br />

D-35683 Dillenburg E-28816 Camarma de Esteruelas (Madrid) Dow Chemical Company Ltd.<br />

Tel. +49(0)2771 8 71 40 Tel. +34 (9)1 886 61 43 GB-Nuneaton-Warwickshire CV10 7QT<br />

Fax +49(0)2771 87 14 70 Fax +34 (9)1 885 75 60 Tel. +44 (0) 24 7635 72 00<br />

Fax. +44 (0) 24 7635 72 57<br />

Dow Automotive, Techn. Datenblatt, BETASEAL, Status terminated, Ausgabe 05, 27.02.05, dg, Page 2