Stewart Warner Performance Catalog - Auto Electric Service, Inc.

Stewart Warner Performance Catalog - Auto Electric Service, Inc.

Stewart Warner Performance Catalog - Auto Electric Service, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Technical Information<br />

<strong>Electric</strong>al Gauges Mechanical Gauges<br />

HOW THEY WORK:<br />

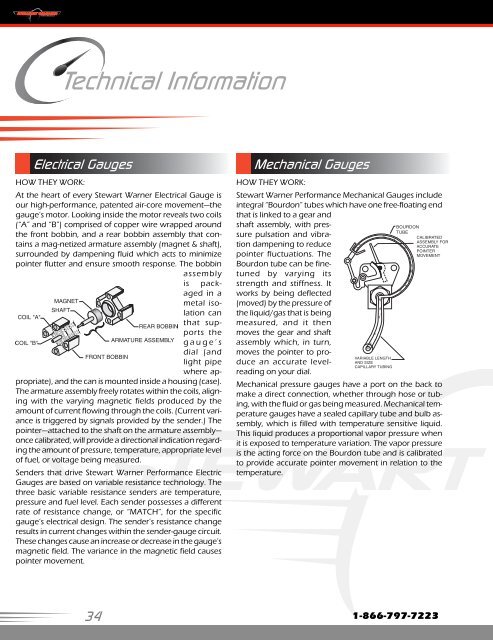

At the heart of every <strong>Stewart</strong> <strong>Warner</strong> <strong>Electric</strong>al Gauge is<br />

our high-performance, patented air-core movement—the<br />

gauge’s motor. Looking inside the motor reveals two coils<br />

(“A” and “B”) comprised of copper wire wrapped around<br />

the front bobbin, and a rear bobbin assembly that contains<br />

a mag-netized armature assembly (magnet & shaft),<br />

surrounded by dampening fluid which acts to minimize<br />

pointer flutter and ensure smooth response. The bobbin<br />

assembly<br />

is packaged<br />

in a<br />

metal isolation<br />

can<br />

that supports<br />

the<br />

gauge’s<br />

dial (and<br />

light pipe<br />

where appropriate),<br />

and the can is mounted inside a housing (case).<br />

The armature assembly freely rotates within the coils, aligning<br />

with the varying magnetic fields produced by the<br />

amount of current flowing through the coils. (Current variance<br />

is triggered by signals provided by the sender.) The<br />

pointer—attached to the shaft on the armature assembly—<br />

once calibrated, will provide a directional indication regarding<br />

the amount of pressure, temperature, appropriate level<br />

of fuel, or voltage being measured.<br />

Senders that drive <strong>Stewart</strong> <strong>Warner</strong> <strong>Performance</strong> <strong>Electric</strong><br />

Gauges are based on variable resistance technology. The<br />

three basic variable resistance senders are temperature,<br />

pressure and fuel level. Each sender possesses a different<br />

rate of resistance change, or “MATCH”, for the specific<br />

gauge’s electrical design. The sender’s resistance change<br />

results in current changes within the sender-gauge circuit.<br />

These changes cause an increase or decrease in the gauge’s<br />

magnetic field. The variance in the magnetic field causes<br />

pointer movement.<br />

34<br />

HOW THEY WORK:<br />

<strong>Stewart</strong> <strong>Warner</strong> <strong>Performance</strong> Mechanical Gauges include<br />

integral “Bourdon” tubes which have one free-floating end<br />

that is linked to a gear and<br />

shaft assembly, with pressure<br />

pulsation and vibration<br />

dampening to reduce<br />

pointer fluctuations. The<br />

Bourdon tube can be finetuned<br />

by varying its<br />

strength and stiffness. It<br />

works by being deflected<br />

(moved) by the pressure of<br />

the liquid/gas that is being<br />

measured, and it then<br />

moves the gear and shaft<br />

assembly which, in turn,<br />

moves the pointer to produce<br />

an accurate levelreading<br />

on your dial.<br />

Mechanical pressure gauges have a port on the back to<br />

make a direct connection, whether through hose or tubing,<br />

with the fluid or gas being measured. Mechanical temperature<br />

gauges have a sealed capillary tube and bulb assembly,<br />

which is filled with temperature sensitive liquid.<br />

This liquid produces a proportional vapor pressure when<br />

it is exposed to temperature variation. The vapor pressure<br />

is the acting force on the Bourdon tube and is calibrated<br />

to provide accurate pointer movement in relation to the<br />

temperature.<br />

1-866-797-7223