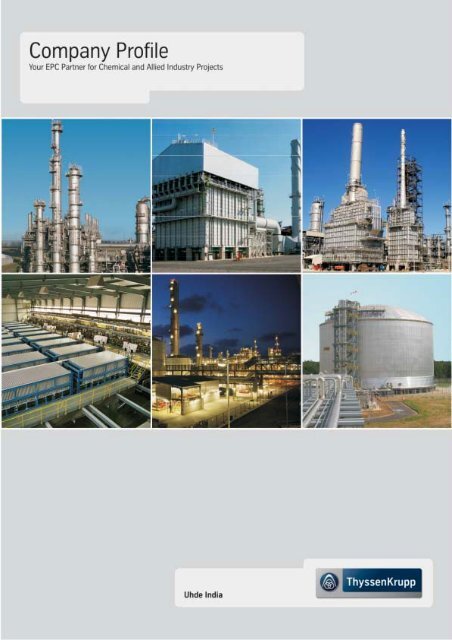

Profile - Final (Sachin).pmd - Uhde India Limited

Profile - Final (Sachin).pmd - Uhde India Limited

Profile - Final (Sachin).pmd - Uhde India Limited

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2<br />

<strong>Uhde</strong> Worldwide<br />

9 decades of service to the global Chemical industries and 2,000 plus plants worldwide

Contents<br />

<strong>Uhde</strong> Worldwide 2-3<br />

Portrait : <strong>Uhde</strong> <strong>India</strong>, <strong>Uhde</strong> GmbH 4-5<br />

Organisation 6-7<br />

Competence 8-9<br />

Resources 10-11<br />

Technology 12-13<br />

Quality, Health & Safety 14<br />

International Presence 15<br />

Experience & Major Projects 16-29<br />

Activities & Awards 30-31<br />

Contact 32<br />

3

4<br />

<strong>Uhde</strong> <strong>India</strong> : Your Complete EPC Partner<br />

Portrait<br />

Comprehensive EPC-LSTK / EPCM solutions from a world-class organisation<br />

We are a progressive Engineering Consultancy company committed to bringing you the entire<br />

range of services involved in the design and construction of plants for the chemical, petrochemical, fertiliser,<br />

refinery, metallurgical and pharmaceutical industries in <strong>India</strong> and abroad. We offer Engineering, Procurement,<br />

Construction Management Services and Lumpsum Turnkey (EPC-LSTK) plants.<br />

We are the largest international subsidiary of <strong>Uhde</strong> GmbH, a prominent company belonging to the Technologies<br />

Division of ThyssenKrupp AG of Germany.<br />

We have full-fledged modern engineering facilities in our Head Office in Mumbai and our Pune Office – with over<br />

1,000 qualified and well-trained technical experts. Our experience of over 500 contracts in <strong>India</strong> and abroad,<br />

annual capacity of over 1.5 million engineering hours, unique working methods, access to internationallyacclaimed<br />

process licensors and their advanced technologies, quality-certified systems and client-conscious<br />

approach make us the ideal and complete EPC partner, across a wide range of industries and sectors.

<strong>Uhde</strong> <strong>India</strong>’s Head Office in<br />

Vikhroli, Mumbai (left), and below,<br />

<strong>Uhde</strong> <strong>India</strong>’s Pune Office<br />

<strong>Uhde</strong> GmbH<br />

<strong>Uhde</strong> GmbH headquarters in Dortmund, Germany<br />

Our parent company <strong>Uhde</strong> GmbH is one of the world’s leading<br />

EPC contractors for chemical and allied industry process<br />

plants. Founded in 1921 and headquartered in Dortmund,<br />

Germany, <strong>Uhde</strong> has built in excess of 2,000 plants worldwide<br />

and has a combined workforce of approximately 5,000<br />

employees. Its network includes engineering offices in<br />

Germany, Australia, Brazil, China, Czech Republic, Egypt, <strong>India</strong>,<br />

Italy, Mexico, The Netherlands, Russia, Saudi Arabia, South<br />

Africa, Switzerland and Thailand, besides representative offices<br />

in Canada, China, Russia, UAE, USA and Vietnam.<br />

<strong>Uhde</strong>’s reputation of delivering mega-sized projects on LSTK<br />

basis is based on the successful application of its guiding<br />

principles, Engineering with ideas. <strong>Uhde</strong> belongs to the<br />

Technologies Division of the ThyssenKrupp AG Group of<br />

Germany, which is a Fortune 500 company with a turnover of<br />

Euro 41 billion (2008-09), and a world leader in its Materials<br />

and Technologies Divisions.<br />

5

6<br />

Organisation<br />

Commitment to prompt, cost-effective and technically sound solutions, across a<br />

wide range of services and contracts<br />

Executive Board<br />

Our organisation is divided into the following functional divisions: Sales, Engineering,<br />

Implementation & Commercial, and geared to effectively rendering our services for the<br />

implementation of your plants.<br />

Bottom Row Left to Right:<br />

Left to Right:<br />

Dr. M. Thiemann, Chairman (also<br />

Chairman of <strong>Uhde</strong> GmbH)<br />

Dr. B. Lueke, Managing Director<br />

T. K. Vijayan - Executive Director, Commercial is responsible for Commercial & Administration,<br />

Finance & Taxation, Personnel & HRD, Legal and Secretarial<br />

Dr. I. Dayasagar - Executive Director, Engineering is responsible for Process, Plant Design,<br />

Mechanical, Electrical, Civil, Instrumentation and Information Technology<br />

P. D. Samudra - Executive Director, Sales is responsible for Sales & Business Development,<br />

Proposals and Marketing & Public Relations<br />

R. Sethuraman - Executive Director, Implementation is responsible for Projects (Planning,<br />

Project Management and Construction) and Procurement (Procurement & Estimation, Logistics<br />

and Inspection & Expediting)<br />

S. Rudra - Executive Director, Pune Operations is responsible for EPC Contracting, Pune Office

Corporate Philosophy<br />

We operate as a project-driven company for EPCM services<br />

and LSTK contracts. Our philosophy is expressed in our<br />

mission statements – and borne out by our technical<br />

expertise, ethical standards and commitment to clients /<br />

business associates. In keeping with our desire to<br />

continue being recognised as ‘the best EPC-LSTK<br />

company’, we distinguish ourselves with our :<br />

� Value-added technical services<br />

� Innovative engineering solutions<br />

� Quality-certified systems and high engineering<br />

standards<br />

� Conformity to safety, health and environmental<br />

norms<br />

� Flexible, client-oriented approach<br />

� Commitment to budgets and time schedules<br />

Range of Services<br />

� Pre-project Activities<br />

� Engineering<br />

� Project Implementation, Procurement, Construction<br />

� Start-up, Commissioning, Training of Client personnel<br />

Specialised Services<br />

� Feasibility Reports / Cost Estimation Reports<br />

� Front End Engineering Design (FEED Package)<br />

� Project Management Consultancy<br />

� Procurement / Inspection & Expediting Services<br />

� Construction & Commissioning Supervision<br />

� Asset Evaluation Studies<br />

Types of Contracts<br />

� Engineering Procurement Construction (EPC) /<br />

Lumpsum Turnkey (LSTK)<br />

� Engineering Services (EPCM)<br />

� Project Management Consultancy (PMC)<br />

� Front End Engineering Design (FEED)<br />

� Reimbursable Services<br />

7

8<br />

Competence<br />

Ensuring our vast experience helps our Clients<br />

Our experience covers projects for the chemical and allied industries, spans 4<br />

decades and comes with our trademark quality and commitment to engineering<br />

excellence. The plants implemented by us are based on technologies from worldfamous<br />

licensors. They cover :<br />

Fertilisers<br />

Petrochemicals & Organic Chemicals<br />

Refinery Units<br />

Ammonia<br />

Urea<br />

Nitric Acid<br />

Ammonium Nitrate<br />

Ammonium Nitrophosphate<br />

Ethylene Dichloride<br />

Vinyl Chloride Monomer<br />

Polyvinyl Chloride<br />

Propylene<br />

Polypropylene<br />

Propylene Oxide / Glycol<br />

Polyols<br />

Ethylene Oxide / Glycol<br />

High Density Polyethylene<br />

Low Density Polyethylene<br />

Linear Low Density Polyethylene<br />

Ethyl Benzene<br />

Styrene Butadiene Rubber<br />

Phosphoric Acid<br />

Di-Ammonium Phosphate, NPK<br />

Triple Super Phosphate<br />

Mono Ammonium Phosphate<br />

Styrene Monomer<br />

Polystyrene<br />

Polyamide / Nylon<br />

Polyesters<br />

Vinyl Acetate Monomer<br />

Linear Alkyl Benzene<br />

Adipic Acid<br />

Formaldehyde<br />

Caprolactam<br />

n-Butanol<br />

Detergent Alcohol<br />

Epichlorohydrine<br />

Methyl Isobutyl Ketone<br />

Crude Distillation Unit<br />

Vacuum Distillation Unit<br />

Hydrocracker<br />

Diesel Hydrotreater Unit<br />

Naphtha Hydrotreater<br />

Continuous Catalytic Regeneration Reformer<br />

Aromatics Extraction<br />

Diesel Hydro Desulphurisation Unit<br />

Gas Oil Hydro Desulphurisation Unit<br />

Visbreaker<br />

Sulfur Recovery Unit<br />

Motor Spirit Quality Upgradation Projects<br />

Hydrogen plants<br />

Hydrogen Compression & Distribution System<br />

Residue Upgradation (VGO-HDT, ATF, FCC LPG Merox)<br />

Gasification (based on Coal / Petcoke / Biomass)<br />

Integrated Gasification Combined Cycle Plant (IGCC)

Caustic Soda - Chlorine<br />

Caustic Soda - Chlorine<br />

Conversion to Membrane Cells<br />

Caustic Potash<br />

Inorganic Chemicals & Metallurgy<br />

Storages<br />

Chlorine Dioxide<br />

Bleaching Powder<br />

Polyaluminium Chloride<br />

Hydrochloric Acid<br />

Spray Dried Silica<br />

Sulfuric Acid<br />

Petrochemical Tank Farms<br />

Cryogenic Ammonia, LPG, Ethylene, Propylene Tanks & Terminals<br />

Terminal Automation<br />

Refrigeration Systems<br />

Pharmaceuticals & Industrial Plants<br />

Bulk Drugs<br />

Formulation<br />

Antibiotics<br />

Excipients<br />

Fine & Speciality Chemicals<br />

Dyestuffs & Intermediates<br />

Offsites & Utility Facilities<br />

Zinc Smelting<br />

Alumina<br />

Air Separation Units<br />

Hydrogen-Nitrogen Generation Units<br />

Glycerine / Fatty Alcohol<br />

Cosmetics<br />

Coke Oven Gas Treatment plants<br />

BOPP for large Power Generation Units<br />

Cement plants<br />

Gelatin plants<br />

Ion Resin plants<br />

Iron Oxide Pigment plants<br />

Polyester Resin plants<br />

9

10<br />

People<br />

At <strong>Uhde</strong> <strong>India</strong>, our engineering experience<br />

and systems are perfectly complemented by<br />

people – our best assets. Our contingent of<br />

over 1,000 qualified employees account for<br />

an annual capacity of 1.5 million<br />

engineering hours. Augmenting their<br />

engineering skills and distinguishing<br />

abilities are a network of modern<br />

communication systems, advanced<br />

electronic tools and a working environment<br />

that is conducive to excellence.<br />

Resources<br />

We believe in providing Clients with the best talents and tools for their projects

Systems & Working Concepts<br />

Our systems and working concepts revolve around UTE<br />

(<strong>Uhde</strong> Total Engineering) – the unique and time-tested<br />

working concepts of our parent company <strong>Uhde</strong> GmbH.<br />

We firmly believe your project deserves nothing but the<br />

best from us. Consequently, our specialists are organised<br />

into Task Forces or Production Units, depending on the<br />

size of your project. The Task Force is dedicated to your<br />

project over all the phases of engineering and<br />

implementation, and comprises the Project Manager /<br />

Engineering Manager, Lead Engineers and a carefullyassembled<br />

complement of engineering and commercial<br />

specialists from our central business disciplines.<br />

For relatively smaller projects, we adopt the Production<br />

Unit concept, where lead team members working on your<br />

project, draw support from the centralised disciplines and<br />

engineering pools.<br />

Design Tools & Communication Facilities<br />

Your plant is designed using advanced electronic tools and<br />

systems such as ACAD, PDMS, PDS, Autoplant, IRP, Smart<br />

Plant P&IDs and Microstation, and a host of state-of-the-art<br />

design software over modern computerised set-ups. Our<br />

communication facilities cover the gamut of communication<br />

tools including high-speed / high-volume data transfer, and<br />

deploy dedicated communication lines. Our systems have<br />

been successfully put to test, while implementing a number<br />

of <strong>India</strong>n and international engineering assignments.<br />

11

12<br />

Integrated EDC-VCM /<br />

Caustic Soda-Chlorine complex<br />

Technology<br />

Professionally-rewarding opportunities to work on technologies from the world’s best licensors<br />

In our endeavour to bring you the best in reliable, economical, environmentfriendly<br />

and modern technology, we have built up an impressive record of<br />

projects based on technologies from the world’s best licensors / engineering<br />

contractors including <strong>Uhde</strong> GmbH, signifying our flexibility in handling various<br />

types of technologies, Basic Engineering Packages and international Codes /<br />

Standards.<br />

Geographical spread of some of the Major International Licensors<br />

Germany<br />

BASF<br />

Basell<br />

Basell Poliolefine<br />

Bayer<br />

Caloric<br />

Dynamit Nobel<br />

Degussa<br />

Henkel<br />

Vin Tec (earlier Hoechst)<br />

Lurgi<br />

Madaus<br />

Outo Kumpu<br />

Plinke<br />

<strong>Uhde</strong><br />

Brazil<br />

Petrobras<br />

Canada<br />

Alcan Int.<br />

Nova Chemicals<br />

France<br />

Atochem<br />

IFP<br />

CdF Chemie<br />

Italy<br />

Conser<br />

Montedipe<br />

Pressindustria<br />

Radici

Japan<br />

Mitsubishi Heavy Industries<br />

Mitsubishi Chemical Corpn.<br />

Shin-Etsu<br />

The Netherlands<br />

Shell<br />

Stamicarbon (DSM)<br />

Norway<br />

Norsk Hydro<br />

Sunde Plastics<br />

Poland<br />

Ciech Icso<br />

Polservice<br />

Spain<br />

Incro<br />

Sweden<br />

Perstorp<br />

Switzerland<br />

Alesa Alusuisse<br />

Bertrams<br />

Enco<br />

Taiwan<br />

TSRC<br />

United Kingdom<br />

Fordell<br />

Johnson Matthey<br />

United States<br />

CB & I Lummus<br />

Haldor Topsoe<br />

Celanese<br />

Huntsman<br />

Monsanto<br />

Parsons<br />

UOP<br />

13

14<br />

Quality, Health & Safety<br />

World-class plants. Implemented with high regard to quality and international safety norms<br />

We are convinced our Clients return with repeat orders<br />

because their expectations are fully met – and because<br />

they see us as a truly quality and safety-conscious<br />

company. Quality for us, is as much a culture as it is a<br />

system – a system that critically ascertains, identifies and<br />

evaluates norms specified in our Quality Manuals. And our<br />

commitment to Health and Safety finds expression in our<br />

workplaces and plants that are optimised with regard to<br />

reliability, performance, safety and environment.<br />

Accredited with the ISO:9001:2008 certification, our QA<br />

systems cover all aspects of plant engineering and<br />

implementation.<br />

Client commendation for<br />

Safety record at site

International Presence<br />

We cater to the international markets, as well<br />

Our experience includes a number of overseas assignments, either independently or together with<br />

our parent company / group companies. With exports accounting for over a third of our business<br />

volumes, and our reputation as a global engineering partner being consolidated, we are wellequipped<br />

to handle international engineering assignments and LSTK contracts, either independently<br />

or together with our parent company / other business partners. Our major overseas projects :<br />

Fertilisers<br />

Ammonia / Ammonia-Urea : Algeria, Belgium, Egypt, Malaysia, Qatar, Saudi Arabia<br />

Ammonium Nitrate : Chile, Egypt, Thailand<br />

Hydrogen Plant : Turkmenistan<br />

Nitric Acid / Weak Nitric Acid : Chile, Egypt, Myanmar, Thailand, Greece<br />

Triple Super Phosphate / Mono Ammonium Phosphate / Di-Ammonium Phosphate : Morocco<br />

Urea Synthesis, Urea Granulation : Abu Dhabi, The Netherlands, Saudi Arabia<br />

Urea Formaldehyde Concentrate : Qatar, Saudi Arabia<br />

Petrochemicals & Organic Chemicals<br />

Adipic Acid : Germany<br />

Bisphenol-A : Taiwan<br />

Detergent Alcohol, n-Butanol : South Africa<br />

Ethyl Benzene, Styrene Monomer : Indonesia<br />

Ethylene Dichloride, Vinyl Chloride Monomer : Oman, Qatar<br />

Formaldehyde : Germany<br />

High Density Polyethylene / Low Density Polyethylene : Germany, Qatar<br />

Methyl Isobutyl Ketone : South Africa<br />

n-Paraffin, Linear Alkyl Benzene : Saudi Arabia<br />

Polyester Tyre Cord : Turkey<br />

Propylene / Polypropylene : Egypt, Philippines<br />

Refinery<br />

Aromatics Extraction : Belgium, Malaysia<br />

Benzene Mitigation : Saudi Arabia<br />

Hydrogen Plant : Belarus, China, Finland<br />

Mild Hydrocracker : Italy<br />

Refinery Facilities : Kuwait<br />

Caustic Soda – Chlorine<br />

Belgium, China, Czech Republic, Egypt, Germany, Iran, Jordan, Mexico, Norway, Poland, Qatar,<br />

Saudi Arabia, Taiwan, Thailand, Ukraine<br />

Inorganic Chemicals<br />

Hydrogen Peroxide : Indonesia, Israel<br />

Potassium Hydroxide : Mexico<br />

Sulfuric Acid : South Africa<br />

Cryogenic Storages<br />

Egypt, Hungary, Iran, Lithuania, Malaysia, Qatar, Saudi Arabia, Taiwan, Thailand, Turkmenistan<br />

Industrial Plants<br />

Cement Plant : UAE<br />

Fatty Alcohol : Thailand<br />

Infrastructure Project : Morocco<br />

Multi-product Pipeline : South Africa<br />

Spent Bleached Earth : Malaysia<br />

15

16<br />

Ammonia - Urea plant<br />

Experience & Major Projects<br />

EPCM services and LSTK assignments covering a wide range of plants & projects

Fertilisers<br />

We have earned a reputation of being one of the leading EPC companies for the design and<br />

construction of Fertiliser plants, including revamp of existing units. With contracts for the major<br />

fertiliser companies in <strong>India</strong> and abroad, and our ability to implement a wide range of plants, based<br />

on technologies from <strong>Uhde</strong> GmbH and other group companies / business partners, we are ideally<br />

placed to implement your Fertiliser projects, either on an LSTK or EPCM-services basis.<br />

Some of our major projects :<br />

Abu Qir Fertilizer Co., Egypt Ammonia-Urea, Nitric Acid, Ammonium Nitrate*<br />

Asean Bintulu Fertilizer, Malaysia Ammonia-Urea Revamp<br />

BASF, Belgium Ammonia*<br />

Bunge Maroc Phosphore, Triple Super Phosphate, Mono Ammonium<br />

(Incro cooperation) Morocco Phosphate, Di-Ammonium Phosphate<br />

Coromandel International, <strong>India</strong> NPK Complex<br />

Enaex, Chile Weak Nitric Acid, Ammonium Nitrate *<br />

Godavari Fertilisers and Chemicals, <strong>India</strong> Di-Ammonium Phosphate Revamp<br />

Gujarat Narmada Valley Fertilizers, <strong>India</strong> Nitric Acid, Weak Nitric Acid, Calcium<br />

Ammonium Nitrate, Ammonium Nitrophosphate<br />

Gujarat State Fertilizers & Chemicals, <strong>India</strong> Di-Ammonium Phosphate<br />

QAFCO, Qatar Ammonia-Urea*, Urea Formaldehyde Concentrate<br />

Rashtriya Chemicals & Fertilizers, <strong>India</strong> Weak Nitric Acid<br />

SAFCO, Saudi Arabia Ammonia-Urea*, Urea Formaldehyde Concentrate<br />

SORFERT, Algeria Ammonia-Urea*<br />

Yara Sluiskil B. V. Urea Synthesis*<br />

*<strong>Uhde</strong> GmbH main contractor<br />

Please ask for our Project Reference List of over 500 projects<br />

17<br />

Weak Nitric Acid - Ammonium Nitrate complex

18 Experience & Major Projects<br />

EPCM services and LSTK assignments covering a wide range of plants & projects<br />

Integrated EDC - VCM plant

Petrochemicals & Organic Chemicals<br />

With several major contracts dating back to the seventies and covering a wide range of chemicals,<br />

we are ideally placed to offer our services to implement your Petrochemical, Polymer, Plastic and other<br />

Organic Chemical plants. Our specific experience in working with certain processes for a number of our<br />

reputed Clients, makes us the preferred partner for your Petrochemical projects.<br />

Some of our major projects :<br />

Egyptian Propylene &<br />

Polypropylene Co., Egypt<br />

Propylene - Polypropylene*<br />

Finolex Industries, <strong>India</strong> Vinyl Chloride Monomer, S-PVC, E-PVC<br />

Gulf Farabi (SNC-Lavalin cooperation / n-Paraffin, Linear Alkyl Benzene<br />

direct contract), Saudi Arabia (including duplication)<br />

Gujarat State Fertilizers & Chemicals, <strong>India</strong> Caprolactam (Expansion)<br />

Haldia Petrochemicals, <strong>India</strong> Polypropylene, LLDPE - HDPE Swing Unit<br />

Hoecsa, Turkey Polyester Tyre Cord<br />

<strong>India</strong>n Oil Corporation, Gujarat / Linear Alkyl Benzene (PMC Services) / HDPE,<br />

Panipat Refinery, <strong>India</strong> LLDPE - HDPE Swing Unit<br />

<strong>India</strong>n Petrochemicals Corporation, <strong>India</strong> High Density Polyethylene<br />

<strong>India</strong>n Synthetic Rubber Styrene Butadiene Rubber<br />

Qatar Petrochemicals (QAPCO), Qatar Low Density Polyethylene*<br />

Nirma, <strong>India</strong> Linear Alkyl Benzene<br />

P. T. Styrindo Mono (MHI cooperation), Indonesia Ethyl Benzene - Styrene Monomer<br />

Qatar Vinyl Company, Qatar Ethylene Dichloride - Vinyl Chloride Monomer*<br />

Radici, Germany Adipic Acid*<br />

SABIC Polyolefine, Germany High Density Polyethylene*<br />

SASOL (TKE South Africa cooperation), n-Butanol, Detergent Alcohol, Methyl<br />

South Africa Isobutyl Ketone<br />

Supreme Petrochem, <strong>India</strong> Polystyrene<br />

Tamilnadu Petroproducts, <strong>India</strong> Linear Alkyl Benzene<br />

*<strong>Uhde</strong> GmbH main contractor<br />

*<strong>Uhde</strong> GmbH main contractor<br />

Please ask for our Project Reference List of over 500 projects<br />

19<br />

LLDPE - HDPE Swing plant

20 Experience & Major Projects<br />

EPCM services and LSTK assignments covering a wide range of plants & projects<br />

Aromatics Extraction plant

Refinery Units<br />

Our experience of working on the Refinery Units of some of the world’s largest refineries, makes us a worthy<br />

engineering partner for specialised units in the Refinery Sector.<br />

Some of our major projects :<br />

BASF, Belgium Benzene-Toluene Extraction Unit*<br />

Bharat Petroleum Corporation, Naphtha Hydrotreater, Continuous Catalytic<br />

Mumbai, <strong>India</strong> Regeneration Reformer<br />

<strong>India</strong>n Oil Corporation, <strong>India</strong><br />

Bongaigaon Refinery Fractionation, Isomerisation Reformer, Reformer De-<br />

Heptaniser, Parex Unit - for Motor Spirit Quality<br />

Upgradation<br />

Digboi Refinery Naphtha / Reformate Splitter, Isomerisation Unit - for<br />

Motor Spirit Quality Upgradation<br />

Gujarat Refinery VGO-HDT, ATF & FCC LPG Merox for Motor Spirit<br />

Quality Upgradation / Residue Upgradation<br />

Sulfur Recovery Unit (Petrofac, Sharjah cooperation)<br />

Guwahati Refinery Indmax Gasoline Splitter, Light Naphtha Splitter,<br />

Isomerisation Unit – for Motor Spirit Quality<br />

Upgradation<br />

Panipat Refinery Diesel Hydro Desulphurisation Unit (L&T cooperation)<br />

Paradip Refinery DHDT, VGO-HDT, Hydrogen Compression &<br />

Distribution System<br />

Kuwait National Petroleum Corpn., Kuwait Enhancement of local marketing & distribution<br />

services (Detailed Engineering), Hazop Studies (both<br />

with International Services WLL cooperation)<br />

Mangalore Refinery and Petrochemicals, <strong>India</strong> Visbreaker Unit (incl duplication), Crude Distillation<br />

Unit, Vacuum Distillation Unit, Gas Oil Hydro<br />

Desulphurisation Unit<br />

Nagarjuna Oil Corporation, <strong>India</strong> Hydrogen plant, Sulfur Recovery Unit, AO2 – AO4<br />

Units, Offsites & Utilities, Refinery Refurbishment<br />

Praxair <strong>India</strong>, <strong>India</strong> Hydrogen plant (for <strong>India</strong>n Oil Corporation,<br />

Paradip Refinery)<br />

Reliance Industries, <strong>India</strong> Offsites & Utilities Upgradation<br />

Saras Refinery, Italy Mild Hydrocracker Unit (Parsons cooperation)<br />

Titan Petrochemicals, Malaysia Aromatics Extraction plant*<br />

*<strong>Uhde</strong> GmbH main contractor<br />

Please ask for our Project Reference List of over 500 projects<br />

21<br />

Visbreaker Unit

22 Experience & Major Projects<br />

EPCM services and LSTK assignments covering a wide range of plants & projects<br />

Membrane Cell House view of<br />

Caustic Soda-Chlorine plant

Caustic Soda-Chlorine<br />

Our reputation and experience in Caustic Soda-Chlorine plants precedes us. On a global level, <strong>Uhde</strong><br />

accounts for approximately 50% of the installed capacities of new-age Membrane Cell plants, while in <strong>India</strong><br />

<strong>Uhde</strong> <strong>India</strong> has installed nearly 70% of the Membrane Cell capacities over the past 2 decades. Our plants<br />

are designed using bipolar electrolysers of single-vessel design and state-of-the-art proprietary 5 th<br />

generation Membrane Cells. This means a lower investment and operating expense outlay, and a higher<br />

degree of reliability, safety and trouble-free operation. We also offer Basic Engineering services for your<br />

Caustic Soda-Chlorine plants.<br />

Some of our major projects in <strong>India</strong> :<br />

Andhra Sugars Capacity Expansion<br />

Bihar Caustic & Chemicals Capacity Expansion<br />

Chemplast Sanmar Capacity Expansion<br />

DCW Expansion / Conversion to Membrane Cell<br />

Grasim Industries Conversion to Membrane Cell, Membrane Cell<br />

Upgradation<br />

Gujarat Alkalies and Chemicals Conversion to Membrane Cell,<br />

Grassroots Complex, Capacity Expansions<br />

<strong>India</strong>n Petrochemicals Corporation Grassroots Complex<br />

<strong>India</strong>n Rayon and Industries Grassroots Complex, Capacity Expansion<br />

Jayshree Chemicals Conversion to Membrane Cell<br />

Kanoria Chemicals & Industries Conversion to Membrane Cell, Capacity Expansion<br />

Punjab Alkalies & Chemicals Grassroots Complex, Conversion to Membrane Cell,<br />

Capacity Expansion<br />

Search Chem Industries / United Phosphorus Grassroots Complex / Relocation<br />

Sree Rayalaseema Alkalies & Allied Chemicals Capacity Expansion<br />

Please ask for our Project Reference List of over 500 projects<br />

23<br />

Membrane Cell Caustic Soda - Chlorine plant

24 Experience & Major Projects<br />

EPCM services and LSTK assignments covering a wide range of plants & projects<br />

Chlorine Dioxide plant

Inorganic Chemicals & Metallurgy<br />

Our experience extends to a significant number of interesting projects covering various Inorganic<br />

Chemicals like Chlorine Dioxide, Spray Dried Silica, Polyaluminium Chloride, Potassium Hydroxide and<br />

Hydrogen Peroxide.<br />

We offer Basic Engineering services for your Chlorine Dioxide plants.<br />

We are also associated with large scale Zinc smelting and Alumina projects.<br />

Some of our major projects :<br />

Andhra Sugars, <strong>India</strong> Polyaluminium Chloride<br />

Brasali, Indonesia Hydrogen Peroxide*<br />

Gujarat Alkalies and Chemicals, <strong>India</strong> Hydrogen Peroxide, Polyaluminium Chloride<br />

Hindustan Organic Chemicals, <strong>India</strong> Hydrogen Peroxide<br />

Hindustan Zinc, <strong>India</strong> Zinc Smelter (also duplication)<br />

Insilco, <strong>India</strong> Spray Dried Silica<br />

Kanoria Chemicals & Industries, <strong>India</strong> Polyaluminium Chloride<br />

MCW, Israel Hydrogen Peroxide*<br />

Sirpur Paper Mills, <strong>India</strong> Chlorine Dioxide<br />

Utkal Alumina, <strong>India</strong> Alumina<br />

West Coast Paper Mills, <strong>India</strong> Chlorine Dioxide<br />

*<strong>Uhde</strong> GmbH main contractor<br />

Please ask for our Project Reference List of over 500 projects<br />

25<br />

Zinc Smelter

26 Experience & Major Projects<br />

EPCM services and LSTK assignments covering a wide range of plants & projects<br />

Ammonia Storage Tank with associated facilities

Cryogenic Storages<br />

Our initiatives in plant design and construction are complemented by the special attention that we pay<br />

to the storage installations in and around your chemical manufacturing facilities. Involving critical safety<br />

and design considerations to account for their low operating temperature and atmospheric pressure<br />

requirements, these chemicals very often constitute the feedstock for your chemical plants. With over<br />

40 cryogenic installations in <strong>India</strong> and abroad, including some in the most challenging locations, and<br />

our state-of-the-art technology, we are easily one of the preferred partners for implementation of your<br />

storage requirements on an LSTK basis. We have engineered and implemented Cryogenic Storages<br />

for Ammonia, LPG, Propylene, Ethylene etc.<br />

Some of our major projects for Cryogenic Ammonia Storages :<br />

AB Achema, Lithuania*<br />

Deepak Fertilisers and Petrochemicals, <strong>India</strong><br />

EID Parry, <strong>India</strong><br />

Fertilizers & Chemicals Travancore, <strong>India</strong><br />

Formosa Chemicals and Fibre Corpn., Taiwan<br />

Godavari Fertilisers and Chemicals, <strong>India</strong><br />

Gujarat State Fertilizers & Chemicals, <strong>India</strong><br />

Indo Gulf Corporation, <strong>India</strong><br />

Mangalore Chemicals & Fertilizers, <strong>India</strong><br />

Paradeep Phosphates, <strong>India</strong> (largest <strong>India</strong>n installation in single location)<br />

QAFCO, Qatar*<br />

Rashtriya Chemicals & Fertilizers, <strong>India</strong><br />

Sanjana Cryogenics (for Hindustan Lever Chemicals), <strong>India</strong><br />

Dialog Holdings SDN BHD, Malaysia (Propylene Storage Tank)<br />

Tiszai Vegyi Kombinat RT., Hungary (Ethylene Storage Tank)<br />

Bharat Petroleum Corporation, <strong>India</strong> (LPG Storage with Refrigerated Pipelines)<br />

*<strong>Uhde</strong> GmbH main contractor<br />

Please ask for our Project Reference List of over 500 projects<br />

27<br />

Ethylene Storage Tank

28 Experience & Major Projects<br />

EPCM services and LSTK assignments covering a wide range of plants & projects<br />

Fatty Alcohol plant

Pharmaceutical & Industrial Plants<br />

In addition to our integrated design approach featuring specialised engineering services with<br />

appropriate validation for your Pharmaceutical projects, we regularly undertake assignments for a<br />

variety of Industrial plants and Offsites / Utilities. Our experience covers such diverse assignments as<br />

Captive Power plants, Air Separation units, plants for Fatty Alcohol, Glycerine Distillation, Hydrogen -<br />

Nitrogen, Cosmetics etc., as well as Offsites & Utilities for all mainstream chemical plants.<br />

Some of our major Pharmaceutical projects :<br />

Agrevo <strong>India</strong>, <strong>India</strong> Agrochemical plant<br />

Colorcon Asia, <strong>India</strong> Excipients facility<br />

Madaus Pharmaceuticals, <strong>India</strong> Agiolax Formulation plant<br />

Torrent Gujarat Biotech, <strong>India</strong> Penicillin G Formulation plant<br />

US Vitamins, <strong>India</strong> Bulk Drug plant<br />

Some of our major Industrial plants :<br />

Bombay Oxygen, <strong>India</strong> Air Separation Unit<br />

DCW, <strong>India</strong> Synthetic Iron Oxide Pigment plant<br />

Eco Oils SDN BHD, Malaysia Spent Bleached Earth<br />

Fujairah Cement Industries<br />

(Polysius AG cooperation)<br />

Cement plant<br />

LANXESS <strong>India</strong>, <strong>India</strong> Ion Resin plant<br />

L’Oreal <strong>India</strong>, <strong>India</strong> Cosmetics plant<br />

Maroc Phosphore, Morocco Infrastructure project, Electrical Engineering Services<br />

Rothe Erde, <strong>India</strong> Gear / Bearings factory<br />

Siemens (for Gujarat Torrent<br />

Energy Corpn.), <strong>India</strong><br />

Balance of plant facilities for Power plant<br />

Thai Oleochemicals, Thailand Fatty Alcohol*<br />

ThyssenKrupp Electrical Steel, <strong>India</strong> Hydrogen - Nitrogen plant<br />

VVF <strong>Limited</strong>, <strong>India</strong> Fatty Alcohol, Saponification, Glycerine Distillation<br />

*<strong>Uhde</strong> GmbH main contractor<br />

Please ask for our Project Reference List of over 500 projects<br />

29<br />

Hydrogen plant

30<br />

Trade Fairs & Exhibitions<br />

<strong>Uhde</strong> <strong>India</strong> at Petrotech & <strong>India</strong> Chem trade fairs<br />

Our presence at leading Chemical and allied<br />

industry trade fairs gives us the opportunity to<br />

showcase our capabilities and advances in the<br />

context of the world's chemical industries, our<br />

peers and business associates.<br />

Activities & Awards<br />

Staying in touch. Keeping you updated about our advances & activities,<br />

achievements & awards<br />

Technology Symposiums &<br />

Technical Presentations<br />

Caustic Soda-Chlorine Symposium 2010<br />

It is a privilege for us to update you with regard to<br />

developments in our organisation and group companies<br />

through our Technology Symposiums, and presentations<br />

on our technology and plant implementation experience<br />

by our experts.

Awards & Accolades<br />

A Star Export House, our progress has been acknowledged<br />

with a number of industry awards and citations from nodal<br />

and trade associations. In parallel, it is an honour to be<br />

bestowed with the continued trust, confidence and<br />

compliments of our Clients, whose plants we have been<br />

privileged to build.<br />

Federation of <strong>India</strong>n Export<br />

Organisations (FIEO) Award :<br />

2002-03, 2003-04, 2008-09<br />

Engineering Export Promotion<br />

Council (EEPC) Award : 2003-04,<br />

2005-06, 2007-08<br />

News<br />

www.uhdeindia.com<br />

It is our pleasure to bring you information about our<br />

organisation. Our website www.uhdeindia.com is<br />

regularly updated with our new projects, tenders and<br />

events, and our press releases ensure that you are<br />

kept abreast of our advances and developments.<br />

For more news about our organisation, activities and<br />

project requirements, contact our Marketing Department,<br />

<strong>Uhde</strong> <strong>India</strong> Private <strong>Limited</strong>, <strong>Uhde</strong> House, LBS Marg,<br />

Vikhroli (W), Mumbai 400 083, <strong>India</strong>.<br />

Tel : +91 22 6796 8014<br />

Fax : +91 22 2578 6187<br />

E-mail : uil.mktg@thyssenkrupp.com<br />

Website : www.uhdeindia.com<br />

31