FleetBoard Temperature Management - Daimler FleetBoard GmbH

FleetBoard Temperature Management - Daimler FleetBoard GmbH

FleetBoard Temperature Management - Daimler FleetBoard GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

A <strong>Daimler</strong> company<br />

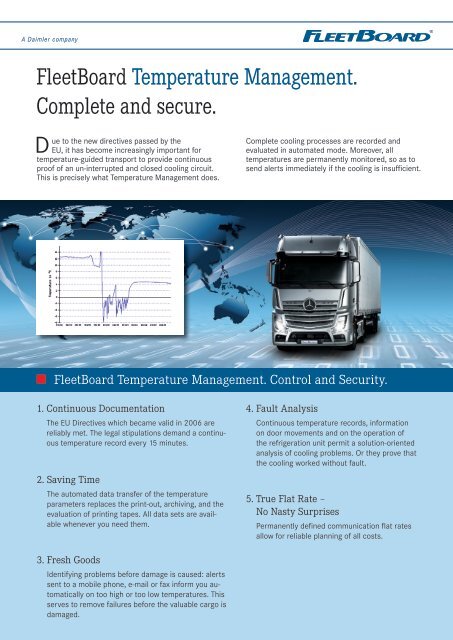

<strong>FleetBoard</strong> <strong>Temperature</strong> <strong>Management</strong>.<br />

Complete and secure.<br />

ue to the new directives passed by the<br />

D EU, it has become increasingly important for<br />

temperature-guided transport to provide continuous<br />

proof of an un-interrupted and closed cooling circuit.<br />

This is precisely what <strong>Temperature</strong> <strong>Management</strong> does.<br />

Complete cooling processes are recorded and<br />

evaluated in automated mode. Moreover, all<br />

temperatures are permanently monitored, so as to<br />

send alerts immediately if the cooling is insufficient.<br />

<strong>FleetBoard</strong> <strong>Temperature</strong> <strong>Management</strong>. Control and Security.<br />

1. Continuous Documentation<br />

The EU Directives which became valid in 2006 are<br />

reliably met. The legal stipulations demand a continuous<br />

temperature record every 15 minutes.<br />

2. Saving Time<br />

The automated data transfer of the temperature<br />

parameters replaces the print-out, archiving, and the<br />

evaluation of printing tapes. All data sets are available<br />

whenever you need them.<br />

3. Fresh Goods<br />

Identifying problems before damage is caused: alerts<br />

sent to a mobile phone, e-mail or fax inform you automatically<br />

on too high or too low temperatures. This<br />

serves to remove failures before the valuable cargo is<br />

damaged.<br />

4. Fault Analysis<br />

Continuous temperature records, information<br />

on door movements and on the operation of<br />

the refrigeration unit permit a solution-oriented<br />

analysis of cooling problems. Or they prove that<br />

the cooling worked without fault.<br />

5. True Flat Rate –<br />

No Nasty Surprises<br />

Permanently defined communication flat rates<br />

allow for reliable planning of all costs.

Documentation and Monitoring of the <strong>Temperature</strong> Parameters.<br />

Functions<br />

<strong>Temperature</strong> measurement every 10 minutes by<br />

means of up to 8 temperature sensors.<br />

Additional capturing of door movements, switching<br />

on and out processes of the refrigeration unit, as<br />

well as optional set points (target temperatures),<br />

defrosting cycles, and operating hours of the<br />

refrigeration unit.<br />

Consistent creation and transfer of reports with<br />

cooling processes via e-mail: the reports are<br />

directly configured in the portal (file format:<br />

Adobe Acrobat (pdf) or Microsoft Excel (xls)).<br />

Data transfer via GPRS: When selecting the national<br />

flat rate, the home country can be chosen from a<br />

Europe-wide selection list. Here, the data transfer<br />

is performed every 10 minutes. The temperature<br />

parameters are recorded abroad and are transferred<br />

when re-entering the home network.<br />

About Us<br />

Stuttgart-based <strong>Daimler</strong> <strong>FleetBoard</strong> <strong>GmbH</strong> offers<br />

market-leading standard devices and telematicssupported<br />

Internet services at one stop. All truck<br />

manufacturers are set to profit from the vehicle and<br />

transport management services, which include an<br />

international flat rate.<br />

Technology<br />

For further information about <strong>FleetBoard</strong> call<br />

+49 (0)7 11 / 17 - 9 19 99 or visit us online: www.fleetboard.com<br />

<strong>Daimler</strong> <strong>FleetBoard</strong> <strong>GmbH</strong>, 70546 Stuttgart 01/1105 Printed in Federal Republic of Germany/Imprimè en Répulique fédérale d‘Allmagne<br />

When selecting the international flat rate, the<br />

temperature is measured every 10 minutes.<br />

The data is transferred every 30 minutes.<br />

Optional feature: tracking the refrigeration unit with<br />

GPS position data: the position is directly displayed<br />

on a digital road map.<br />

<strong>Temperature</strong> <strong>Management</strong> consists of two components:<br />

The cooling data computer (see above figure)<br />

is a rugged device which is interconnected with the<br />

temperature scanner of the refrigeration unit. The<br />

computer is connected to the on-board power supply<br />

or the battery of the engine and possesses its own<br />

GPRS module and – optionally – a GPS receiver.<br />

The system supports temperature scanners from<br />

manufacturers TranScan, Euroscan, Carrier, Thermo<br />

King, Engelmann Sensor, and Mensch + Technik.<br />

The <strong>Temperature</strong> <strong>Management</strong> Portal (see figure to<br />

the left) is an Internet-based service linked to the<br />

<strong>FleetBoard</strong> Portal, which provides all functions of<br />

<strong>Temperature</strong> <strong>Management</strong> in a bundle.<br />

The co-operation with renowned system partners<br />

ensures the consistent adherence to top-level<br />

quality standards. Forwarding companies and<br />

hauliers invest into a reliable tool which pays off<br />

within a minimum time interval.