Valtra - Hanki-Ker Kft.

Valtra - Hanki-Ker Kft.

Valtra - Hanki-Ker Kft.

- TAGS

- valtra

- www.hanki-ker.hu

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

4<br />

<strong>Valtra</strong> Provides<br />

Continuity of Supply<br />

Like most agricultural producers, Valley Pro- Pro-<br />

duce run by Colin Hill has, in recent years,<br />

had to contend with rising costs coupled to<br />

stagnant returns. However, despite income<br />

stagnation this salad, herb and speciality<br />

vegetable growing and marketing business<br />

has increased its profi tability.<br />

Based near Reading, Valley Produce either tenant<br />

or occupy on short term rental some 554 produc-<br />

tive acres (228ha). Baby leaf salads include spin-<br />

ach, red chard, mizuna and baby greens while<br />

the herb crop embraces coriander, fl at and curly<br />

leaf parsley, dill, mint and fenugreek. Speciality<br />

vegetables, aimed mostly at the Chinese mar-<br />

ket, encompasses green and white pak choi, choi<br />

sum and gai choy. There is also an area of runner<br />

beans.<br />

Production is aimed at the high value end of<br />

the market embracing the ever increasing stand-<br />

ards of supermarkets and their packers. Other<br />

Valley Produce customers include food servicing<br />

companies supplying the catering trade while any<br />

excess is sent to wholesale markets in London,<br />

Manchester, Birmingham and Bristol. While open<br />

market prices may fl uctuate, its supermarket<br />

standards and prices that ultimately control Val-<br />

ley’s profi tability.<br />

The land utilised by Valley Produce includes<br />

a gravel loam, organic loam, green sands and a<br />

sandy loam all of which is irrigable. Growing sea-<br />

sons differ according to soil type and early seed<br />

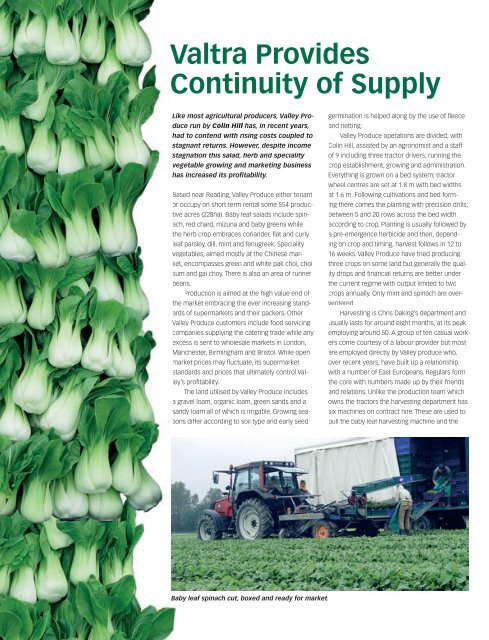

Baby leaf spinach cut, boxed and ready for market.<br />

germination is helped along by the use of fl eece<br />

and netting.<br />

Valley Produce operations are divided, with<br />

Colin Hill, assisted by an agronomist and a staff<br />

of 9 including three tractor drivers, running the<br />

crop establishment, growing and administration.<br />

Everything is grown on a bed system; tractor<br />

wheel centres are set at 1.8 m with bed widths<br />

at 1.6 m. Following cultivations and bed form-<br />

ing there comes the planting with precision drills;<br />

between 5 and 20 rows across the bed width<br />

according to crop. Planting is usually followed by<br />

a pre-emergence herbicide and then, depend-<br />

ing on crop and timing, harvest follows in 12 to<br />

16 weeks. Valley Produce have tried producing<br />

three crops on some land but generally the qual-<br />

ity drops and fi nancial returns are better under<br />

the current regime with output limited to two<br />

crops annually. Only mint and spinach are over-<br />

wintered.<br />

Harvesting is Chris Daking’s department and<br />

usually lasts for around eight months, at its peak<br />

employing around 50. A group of ten casual work-<br />

ers come courtesy of a labour provider but most<br />

are employed directly by Valley produce who,<br />

over recent years, have built up a relationship<br />

with a number of East Europeans. Regulars form<br />

the core with numbers made up by their friends<br />

and relations. Unlike the production team which<br />

owns the tractors the harvesting department has<br />

six machines on contract hire. These are used to<br />

pull the baby leaf harvesting machine and the