The EC-630PP HMC - Haas - Haas Automation, Inc.

The EC-630PP HMC - Haas - Haas Automation, Inc.

The EC-630PP HMC - Haas - Haas Automation, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

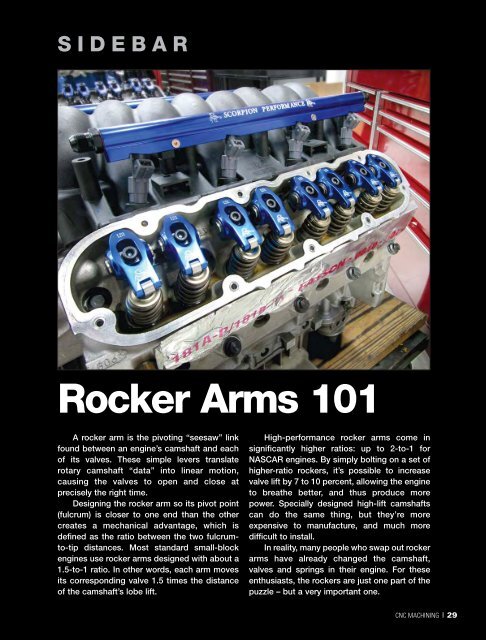

SIDEBAR<br />

Rocker Arms 101<br />

A rocker arm is the pivoting “seesaw” link<br />

found between an engine’s camshaft and each<br />

of its valves. <strong>The</strong>se simple levers translate<br />

rotary camshaft “data” into linear motion,<br />

causing the valves to open and close at<br />

precisely the right time.<br />

Designing the rocker arm so its pivot point<br />

(fulcrum) is closer to one end than the other<br />

creates a mechanical advantage, which is<br />

defined as the ratio between the two fulcrumto-tip<br />

distances. Most standard small-block<br />

engines use rocker arms designed with about a<br />

1.5-to-1 ratio. In other words, each arm moves<br />

its corresponding valve 1.5 times the distance<br />

of the camshaft’s lobe lift.<br />

High-performance rocker arms come in<br />

significantly higher ratios: up to 2-to-1 for<br />

NASCAR engines. By simply bolting on a set of<br />

higher-ratio rockers, it’s possible to increase<br />

valve lift by 7 to 10 percent, allowing the engine<br />

to breathe better, and thus produce more<br />

power. Specially designed high-lift camshafts<br />

can do the same thing, but they’re more<br />

expensive to manufacture, and much more<br />

difficult to install.<br />

In reality, many people who swap out rocker<br />

arms have already changed the camshaft,<br />

valves and springs in their engine. For these<br />

enthusiasts, the rockers are just one part of the<br />

puzzle – but a very important one.<br />

CNC MACHINING | 29