datasheet high-performance extruders - SML

datasheet high-performance extruders - SML

datasheet high-performance extruders - SML

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>high</strong>-<strong>performance</strong> <strong>extruders</strong><br />

full range of single screw <strong>extruders</strong><br />

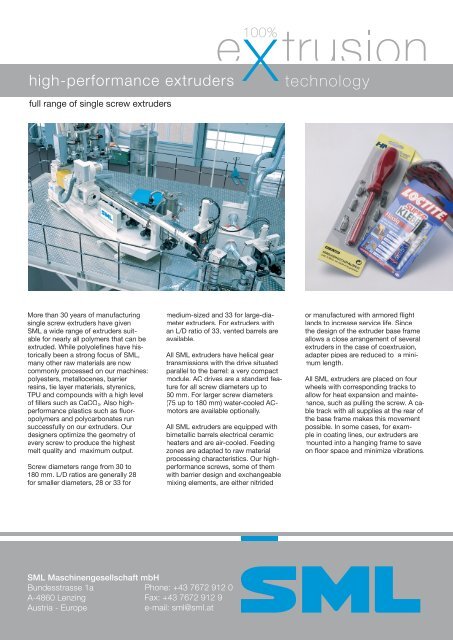

More than 30 years of manufacturing<br />

single screw <strong>extruders</strong> have given<br />

<strong>SML</strong> a wide range of <strong>extruders</strong> suitable<br />

for nearly all polymers that can be<br />

extruded. While polyolefines have historically<br />

been a strong focus of <strong>SML</strong>,<br />

many other raw materials are now<br />

commonly processed on our machines:<br />

polyesters, metallocenes, barrier<br />

resins, tie layer materials, styrenics,<br />

TPU and compounds with a <strong>high</strong> level<br />

of fillers such as CaCO3. Also <strong>high</strong><strong>performance</strong><br />

plastics such as fluoropolymers<br />

and polycarbonates run<br />

successfully on our <strong>extruders</strong>. Our<br />

designers optimize the geometry of<br />

every screw to produce the <strong>high</strong>est<br />

melt quality and maximum output.<br />

Screw diameters range from 30 to<br />

180 mm. L/D ratios are generally 28<br />

for smaller diameters, 28 or 33 for<br />

<strong>SML</strong> Maschinengesellschaft mbH<br />

Bundesstrasse 1a<br />

A-4860 Lenzing<br />

Austria - Europe<br />

medium-sized and 33 for large-diameter<br />

<strong>extruders</strong>. For <strong>extruders</strong> with<br />

an L/D ratio of 33, vented barrels are<br />

available.<br />

All <strong>SML</strong> <strong>extruders</strong> have helical gear<br />

transmissions with the drive situated<br />

parallel to the barrel: a very compact<br />

module. AC drives are a standard feature<br />

for all screw diameters up to<br />

60 mm. For larger screw diameters<br />

(75 up to 180 mm) water-cooled ACmotors<br />

are available optionally.<br />

All <strong>SML</strong> <strong>extruders</strong> are equipped with<br />

bimetallic barrels electrical ceramic<br />

heaters and are air-cooled. Feeding<br />

zones are adapted to raw material<br />

processing characteristics. Our <strong>high</strong>-<br />

<strong>performance</strong> screws, some of them<br />

with barrier design and exchangeable<br />

mixing elements, are either nitrided<br />

Phone: +43 7672 912 0<br />

Fax: +43 7672 912 9<br />

e-mail: sml@sml.at<br />

or manufactured with armored flight<br />

lands to increase service life. Since<br />

the design of the extruder base frame<br />

allows a close arrangement of several<br />

<strong>extruders</strong> in the case of coextrusion,<br />

adapter pipes are reduced to a minimum<br />

length.<br />

All <strong>SML</strong> <strong>extruders</strong> are placed on four<br />

wheels with corresponding tracks to<br />

allow for heat expansion and maintenance,<br />

such as pulling the screw. A cable<br />

track with all supplies at the rear of<br />

the base frame makes this movement<br />

possible. In some cases, for example<br />

in coating lines, our <strong>extruders</strong> are<br />

mounted into a hanging frame to save<br />

on floor space and minimize vibrations.

<strong>high</strong>-<strong>performance</strong> <strong>extruders</strong><br />

full range of single screw <strong>extruders</strong><br />

www.sml.at<br />

printed 02/2009<br />

We reserve the right to technical modifications.<br />

dimensions in mm power rating venting<br />

barrel<br />

Ø L/D B H1 H2 L<br />

rated drive<br />

power kW*)<br />

heating<br />

wattage kW<br />

30 28 510 698 808 1870 20 8 –<br />

45 28 572 490 955 2530 38 18 –<br />

60 28 600 920 1120 3340 60 28 –<br />

60 33 600 920 1120 3640 60 37 O<br />

75 28 700 920 1120 2775 90 40 –<br />

75 33 800 920 1120 3240 90 49 O<br />

90 28 970 940 1220 3280 132 50 –<br />

90 33 970 940 1220 3730 132 61 O<br />

105 33 1100 940 1305 4545 160 72 O<br />

120 33 1110 940 1305 5000 195 105 O<br />

135 33 1300 1144 1587 5880 250 134 O<br />

150 33 1300 1225 1665 6420 305 171 O<br />

180 33 1380 1225 1665 7410 474 237 O<br />

optional O<br />

*) depending on raw material<br />

H2<br />

B<br />

L<br />

H1<br />

available<br />

01