BUCKET WHEEL EXCAVATOR KWK-910 - SKW

BUCKET WHEEL EXCAVATOR KWK-910 - SKW

BUCKET WHEEL EXCAVATOR KWK-910 - SKW

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

GENERAL CHARACTERISTIC<br />

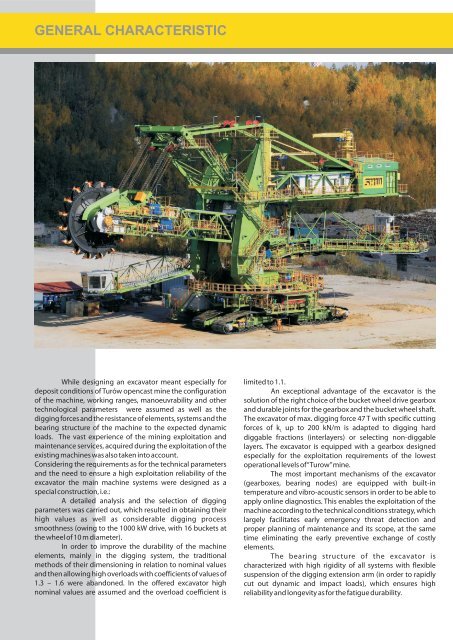

While designing an excavator meant especially for limited to 1.1.<br />

deposit conditions of Turów opencast mine the configuration An exceptional advantage of the excavator is the<br />

of the machine, working ranges, manoeuvrability and other solution of the right choice of the bucket wheel drive gearbox<br />

technological parameters were assumed as well as the and durable joints for the gearbox and the bucket wheel shaft.<br />

digging forces and the resistance of elements, systems and the The excavator of max. digging force 47 T with specific cutting<br />

bearing structure of the machine to the expected dynamic forces of k L up to 200 kN/m is adapted to digging hard<br />

loads. The vast experience of the mining exploitation and diggable fractions (interlayers) or selecting non-diggable<br />

maintenance services, acquired during the exploitation of the layers. The excavator is equipped with a gearbox designed<br />

existing machines was also taken into account. especially for the exploitation requirements of the lowest<br />

Considering the requirements as for the technical parameters operational levels of “Turow” mine.<br />

and the need to ensure a high exploitation reliability of the The most important mechanisms of the excavator<br />

excavator the main machine systems were designed as a (gearboxes, bearing nodes) are equipped with built-in<br />

special construction, i.e.: temperature and vibro-acoustic sensors in order to be able to<br />

A detailed analysis and the selection of digging apply online diagnostics. This enables the exploitation of the<br />

parameters was carried out, which resulted in obtaining their machine according to the technical conditions strategy, which<br />

high values as well as considerable digging process largely facilitates early emergency threat detection and<br />

smoothness (owing to the 1000 kW drive, with 16 buckets at proper planning of maintenance and its scope, at the same<br />

the wheel of 10 m diameter). time eliminating the early preventive exchange of costly<br />

In order to improve the durability of the machine elements.<br />

elements, mainly in the digging system, the traditional The bearing structure of the excavator is<br />

methods of their dimensioning in relation to nominal values characterized with high rigidity of all systems with flexible<br />

and then allowing high overloads with coefficients of values of suspension of the digging extension arm (in order to rapidly<br />

1.3 – 1.6 were abandoned. In the offered excavator high cut out dynamic and impact loads), which ensures high<br />

nominal values are assumed and the overload coefficient is reliability and longevity as for the fatigue durability.