Effect of isothermal and migration process on knit - Pakistan Textile ...

Effect of isothermal and migration process on knit - Pakistan Textile ...

Effect of isothermal and migration process on knit - Pakistan Textile ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<str<strong>on</strong>g>Effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>isothermal</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>migrati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>process</str<strong>on</strong>g> <strong>on</strong> <strong>knit</strong> fabric<br />

dyeing with reactive dye especially <strong>on</strong> light colour<br />

by Md. Mahfuzur Rahman, Department <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>Textile</strong> Engineering,<br />

Faculty <str<strong>on</strong>g>of</str<strong>on</strong>g> Science & Informati<strong>on</strong> Technology, Daffodil Internati<strong>on</strong>al University.<br />

Abstract: This paper presents the effects <strong>on</strong> cott<strong>on</strong> fabric dyeing <str<strong>on</strong>g>process</str<strong>on</strong>g> (<str<strong>on</strong>g>isothermal</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>migrati<strong>on</strong></str<strong>on</strong>g>) with reactive dyes. cott<strong>on</strong><br />

fabric was dyed with reactive dyes with a analysis optimizing procedure by varying dyeing <str<strong>on</strong>g>process</str<strong>on</strong>g> (<str<strong>on</strong>g>isothermal</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>migrati<strong>on</strong></str<strong>on</strong>g>)<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> parameters. Dyes <str<strong>on</strong>g>and</str<strong>on</strong>g> chemicals are used for dyeing to achieve the appropriate effect. It was observed that dyeing<br />

<str<strong>on</strong>g>process</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> parameters are wide-ranging for using different types <str<strong>on</strong>g>of</str<strong>on</strong>g> reactive dyes <str<strong>on</strong>g>and</str<strong>on</strong>g> auxiliaries. It helps to find out the<br />

differentiati<strong>on</strong> between the two <str<strong>on</strong>g>process</str<strong>on</strong>g>es <str<strong>on</strong>g>and</str<strong>on</strong>g> provide a better result.<br />

Key words: chemicals <str<strong>on</strong>g>and</str<strong>on</strong>g> dyes, <str<strong>on</strong>g>process</str<strong>on</strong>g> parameters, after treatments, method analysis.<br />

Introducti<strong>on</strong><br />

Fabric dyeing usually requires three basic dyes in a mixture<br />

to achieve the desired hue <str<strong>on</strong>g>and</str<strong>on</strong>g> shade. Dyes with similar<br />

reactive groups <str<strong>on</strong>g>and</str<strong>on</strong>g> same exhausti<strong>on</strong> properties will be said<br />

to be compatible with each other <str<strong>on</strong>g>and</str<strong>on</strong>g> are ideal for use in<br />

such mixtures. Selecting compatible dyes is a part <str<strong>on</strong>g>of</str<strong>on</strong>g> ensuring<br />

an optimum dyeing recipe which will most efficiently utilize<br />

the dye, produce optimal dyeing results <str<strong>on</strong>g>and</str<strong>on</strong>g> will reduce<br />

the number <str<strong>on</strong>g>of</str<strong>on</strong>g> chemicals that enter the wastewater. [1] This<br />

research has been taken to describe the parameters like M:L,<br />

temperature, time, costing, scouring, bleaching, enzyme treatment,<br />

recipe, dyes, auxiliaries <str<strong>on</strong>g>and</str<strong>on</strong>g> two types <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>process</str<strong>on</strong>g> etc.<br />

Reactive dye has high affinity for <strong>knit</strong> fabric because <str<strong>on</strong>g>of</str<strong>on</strong>g> its<br />

very good fastness properties.<br />

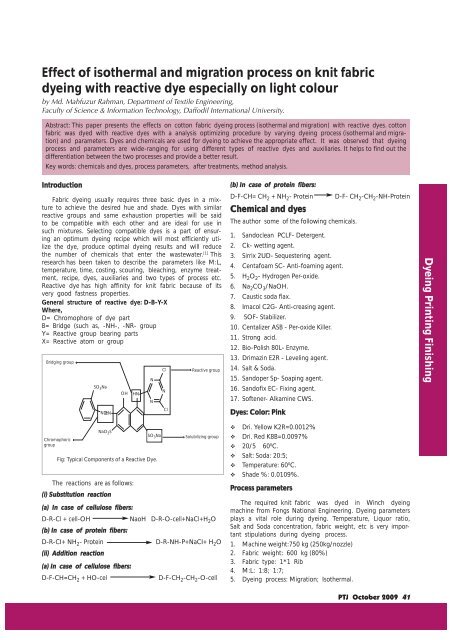

General structure <str<strong>on</strong>g>of</str<strong>on</strong>g> reactive dye: D-B-Y-X<br />

Where,<br />

D= Chromophore <str<strong>on</strong>g>of</str<strong>on</strong>g> dye part<br />

B= Bridge (such as, -NH-, -NR- group<br />

Y= Reactive group bearing parts<br />

X= Reactive atom or group<br />

Bridging group<br />

Chromophoric<br />

group<br />

SO 3 Na<br />

N N<br />

NaO 3 S<br />

OH HN<br />

The reacti<strong>on</strong>s are as follows:<br />

(i) Substituti<strong>on</strong> reacti<strong>on</strong><br />

SO 3 Na<br />

Fig: Typical Comp<strong>on</strong>ents <str<strong>on</strong>g>of</str<strong>on</strong>g> a Reactive Dye.<br />

(a) In case <str<strong>on</strong>g>of</str<strong>on</strong>g> cellulose fibers:<br />

D-R-Cl + cell-OH NaoH D-R-O-cell+NaCl+H2O (b) In case <str<strong>on</strong>g>of</str<strong>on</strong>g> protein fibers:<br />

D-R-CI+ NH2- Protein D-R-NH-P+NaCI+ H2O (ii) Additi<strong>on</strong> reacti<strong>on</strong><br />

(a) In case <str<strong>on</strong>g>of</str<strong>on</strong>g> cellulose fibers:<br />

D-F-CH=CH2 + HO-cel D-F-CH2-CH2-O-cell N<br />

N<br />

Cl<br />

N<br />

Cl<br />

Reactive group<br />

Solubilizing group<br />

(b) In case <str<strong>on</strong>g>of</str<strong>on</strong>g> protein fibers:<br />

D-F-CH= CH2 + NH2- Protein D-F- CH2-CH2-NH-Protein Chemical <str<strong>on</strong>g>and</str<strong>on</strong>g> dyes<br />

The author some <str<strong>on</strong>g>of</str<strong>on</strong>g> the following chemicals.<br />

1. S<str<strong>on</strong>g>and</str<strong>on</strong>g>oclean PCLF- Detergent.<br />

2. Ck- wetting agent.<br />

3. Sirrix 2UD- Sequestering agent.<br />

4. Centafoam SC- Anti-foaming agent.<br />

5. H2O2- Hydrogen Per-oxide.<br />

6. Na2CO3 /NaOH.<br />

7. Caustic soda flax.<br />

8. Imacol C2G- Anti-creasing agent.<br />

9. SOF- Stabilizer.<br />

10. Centalizer ASB - Per-oxide Killer.<br />

11. Str<strong>on</strong>g acid.<br />

12. Bio-Polish 80L- Enzyme.<br />

13. Drimazin E2R - Leveling agent.<br />

14. Salt & Soda.<br />

15. S<str<strong>on</strong>g>and</str<strong>on</strong>g>oper Sp- Soaping agent.<br />

16. S<str<strong>on</strong>g>and</str<strong>on</strong>g><str<strong>on</strong>g>of</str<strong>on</strong>g>ix EC- Fixing agent.<br />

17. S<str<strong>on</strong>g>of</str<strong>on</strong>g>tener- Alkamine CWS.<br />

Dyes: Color: Pink<br />

� Dri. Yellow K2R=0.0012%<br />

� Dri. Red K8B=0.0097%<br />

� 20/5 60 0 C.<br />

� Salt: Soda: 20:5;<br />

� Temperature: 60 0 C.<br />

� Shade %: 0.0109%.<br />

Process parameters<br />

The required <strong>knit</strong> fabric was dyed in Winch dyeing<br />

machine from F<strong>on</strong>gs Nati<strong>on</strong>al Engineering. Dyeing parameters<br />

plays a vital role during dyeing. Temperature, Liquor ratio,<br />

Salt <str<strong>on</strong>g>and</str<strong>on</strong>g> Soda c<strong>on</strong>centrati<strong>on</strong>, fabric weight, etc is very important<br />

stipulati<strong>on</strong>s during dyeing <str<strong>on</strong>g>process</str<strong>on</strong>g>.<br />

1. Machine weight:750 kg (250kg/nozzle)<br />

2. Fabric weight: 600 kg (80%)<br />

3. Fabric type: 1*1 Rib<br />

4. M:L: 1:8; 1:7;<br />

5. Dyeing <str<strong>on</strong>g>process</str<strong>on</strong>g>: Migrati<strong>on</strong>; Isothermal.<br />

PTJ October 2009 41<br />

Dyeing Printing Finishing

Dyeing Printing Finishing<br />

6. Color: Pink.<br />

7. Scouring temperature: 980C 8. Bleaching temperature: 800C 9. Scouring acid temperature: 600C 10. Enzyme temperature: 550C to 700C 11. Leveling temperature: 600C 12. Dyeing temperature: Varying due to <str<strong>on</strong>g>process</str<strong>on</strong>g><br />

13. Salt : Soda : 20:5<br />

14. S<str<strong>on</strong>g>of</str<strong>on</strong>g>tener.<br />

Process study<br />

Exhausti<strong>on</strong> & Fixati<strong>on</strong> study<br />

The dye-bath exhausti<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> fixati<strong>on</strong> was studied by<br />

known methods by collecting the samples <str<strong>on</strong>g>of</str<strong>on</strong>g> exhausted liquor<br />

at various intervals <str<strong>on</strong>g>and</str<strong>on</strong>g> studying the absorbancy by diluting<br />

the exhausted liquor up to various folds. [2]<br />

Solubility<br />

Due to the presence <str<strong>on</strong>g>of</str<strong>on</strong>g> the OH <str<strong>on</strong>g>and</str<strong>on</strong>g> NH functi<strong>on</strong>al group<br />

in the dye molecule, a dissociati<strong>on</strong> resulted in a higher solubility<br />

during the dyeing <str<strong>on</strong>g>process</str<strong>on</strong>g> at low liquor ratio. Also, the<br />

presence <str<strong>on</strong>g>of</str<strong>on</strong>g> the sulf<strong>on</strong>ic chromophores (two to three) <str<strong>on</strong>g>and</str<strong>on</strong>g> the<br />

novel sulphatoethyl sulph<strong>on</strong>e groups promoted the solubility<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> the new bifuncti<strong>on</strong>al (MCT/SES) dyes. [2]<br />

pH value <str<strong>on</strong>g>of</str<strong>on</strong>g> dye bath<br />

The pH <str<strong>on</strong>g>of</str<strong>on</strong>g> dye bath during exhaust dyeing method was<br />

widely taken into c<strong>on</strong>siderati<strong>on</strong>, where, we first used the neutral<br />

pH <str<strong>on</strong>g>and</str<strong>on</strong>g> gradually increased the alkalis by dosing the<br />

Na2CO3 /NaOH to a pH <str<strong>on</strong>g>of</str<strong>on</strong>g> 11.5 to differentiate the probable<br />

exhausti<strong>on</strong> in both cases. Both SES <str<strong>on</strong>g>and</str<strong>on</strong>g> MCT groups functi<strong>on</strong>ed<br />

as the reactive sites. However, we recommend a<br />

dyeing <str<strong>on</strong>g>process</str<strong>on</strong>g> for this type <str<strong>on</strong>g>of</str<strong>on</strong>g> dye exhaust dyeing method<br />

set at 60°C with a c<strong>on</strong>trol dye bath pH. [2]<br />

Color measurements<br />

The (%R) percent reflectance <str<strong>on</strong>g>of</str<strong>on</strong>g> the dyed material was<br />

measured at different wavelengths in the visible regi<strong>on</strong> (400-<br />

700 nm) using a ACS-600 color c<strong>on</strong>trol system. [2]<br />

Shade evaluati<strong>on</strong><br />

The hue over the <strong>knit</strong>ted cott<strong>on</strong> fabric as checked by<br />

matching it with st<str<strong>on</strong>g>and</str<strong>on</strong>g>ard shade cards. The shade appeared at<br />

a somewhat higher wavelength <str<strong>on</strong>g>of</str<strong>on</strong>g> the dye. [2]<br />

Substantivity<br />

The dyes showed medium-to-good substantivity which<br />

can be detected by the exhausti<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> fixati<strong>on</strong> study. This<br />

can be due also to the presence <str<strong>on</strong>g>of</str<strong>on</strong>g> the two pi<strong>on</strong>eer<br />

groups as the reactive sites involved in the dye substrate.<br />

The substantivity <str<strong>on</strong>g>of</str<strong>on</strong>g> the hydrolyzed byproduct can be<br />

readily detected from the amount <str<strong>on</strong>g>of</str<strong>on</strong>g> unfixed dye <str<strong>on</strong>g>and</str<strong>on</strong>g> can<br />

easily be removed after three or four washes at different<br />

temperatures. [2]<br />

Experimental Procedure<br />

Knit fabric dyeing procedure c<strong>on</strong>sists <str<strong>on</strong>g>of</str<strong>on</strong>g> five steps; scouring,<br />

bleaching, enzyme treatment, dyeing <str<strong>on</strong>g>and</str<strong>on</strong>g> s<str<strong>on</strong>g>of</str<strong>on</strong>g>tener treatment.<br />

These five steps are necessary for completing the whole<br />

dyeing <str<strong>on</strong>g>process</str<strong>on</strong>g>. F<strong>on</strong>gs dyeing machine is used for this experiment<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> subsequent steps are given as under.<br />

42 PTJ October 2009<br />

Scouring<br />

In this experiment, 1*1 rib fabric <str<strong>on</strong>g>of</str<strong>on</strong>g> weight 600 kg (Grey<br />

fabric) is used, with NOF, 2UD, PCLF, FFC <str<strong>on</strong>g>and</str<strong>on</strong>g> Caustic chemical<br />

used for scouring <str<strong>on</strong>g>process</str<strong>on</strong>g>. The required amount <str<strong>on</strong>g>of</str<strong>on</strong>g> chemical<br />

used for this <str<strong>on</strong>g>process</str<strong>on</strong>g> are as follows:<br />

(i) NOF: 0.5 g/l<br />

(ii) 2UD: 0.5 g/l<br />

(iii) PCLF : 0.6 g/l<br />

(iv) 2UD: 0.3 g/l<br />

(v) FFC: .05 g/l<br />

(vi) Caustic: 2.5 g/l<br />

(vii) Process temperature: 700C. Both the <str<strong>on</strong>g>process</str<strong>on</strong>g>es given as above are satisfactory, but first<br />

<str<strong>on</strong>g>process</str<strong>on</strong>g> is preferable because in this <str<strong>on</strong>g>process</str<strong>on</strong>g>, fabrics are<br />

better cleaned <str<strong>on</strong>g>and</str<strong>on</strong>g> absorbency power will be increased. The<br />

first <str<strong>on</strong>g>process</str<strong>on</strong>g> also removes the natural impurities, dirt or grease<br />

from cloth more efficiently.<br />

First Process:<br />

40 0 C<br />

5 min<br />

(NOF+2UD)<br />

10 min<br />

10 min<br />

Sec<strong>on</strong>d Process:<br />

55 0 C, 5 min<br />

(PCLF+2UD+FFC)<br />

80 0 C<br />

10 min<br />

(PCLF+2UD+FFC)<br />

70 0 C<br />

55 0 C<br />

5 min<br />

5 min Caustic<br />

70 0 C<br />

5 min<br />

Caustic<br />

Bleaching<br />

Normally scouring <str<strong>on</strong>g>and</str<strong>on</strong>g> bleaching is d<strong>on</strong>e simultaneously<br />

in the dyeing machine. Bleaching creates a permanent whiteness<br />

in the fabric which is helpful for dyeing <strong>knit</strong> fabrics. Acid<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> peroxide killer are added in the bath for this light color<br />

dyeing. Str<strong>on</strong>g acid is more beneficial than Acetic acid<br />

because str<strong>on</strong>g acid c<strong>on</strong>trols the PH values more strictly. The<br />

chemicals used for this <str<strong>on</strong>g>process</str<strong>on</strong>g>:<br />

i) H2O2 : 4.0 g/l<br />

ii) Centalizer ASB (Per-oxide destroyer): 0.6 g/l<br />

iii) Stabilizer SOF: 0.25 g/l<br />

iv) Str<strong>on</strong>g acid: 0.6 g/l<br />

98 o C<br />

70 o C 40 min<br />

35 o C<br />

5 min 10 min<br />

(H2O2 +SOF) (ASB & acid)<br />

Process flowchart<br />

for Scouring<br />

80 o C<br />

10 min<br />

10 min<br />

60 o C<br />

Process flowchart<br />

for bleaching

Enzyme treatment<br />

Enzyme removes the hairiness from the fabric surface which<br />

is helpful for fabric dyeing. Normally enzyme percentage varies<br />

from 0.9-1.0 <str<strong>on</strong>g>and</str<strong>on</strong>g> following two <str<strong>on</strong>g>process</str<strong>on</strong>g>es are applied. The<br />

using chemicals for this <str<strong>on</strong>g>process</str<strong>on</strong>g> are as follows:<br />

i. Bio-Polish 80L : 0.9 % (<strong>on</strong> the weight <str<strong>on</strong>g>of</str<strong>on</strong>g> the fabric)<br />

ii. Acetic acid: 0.6 g/l.<br />

iii. PH: 4.5 – 5.5<br />

First <str<strong>on</strong>g>process</str<strong>on</strong>g> c<strong>on</strong>sists <str<strong>on</strong>g>of</str<strong>on</strong>g> two steps. At temperature 550C, 0.6% enzyme c<strong>on</strong>centrati<strong>on</strong> is used in the machine, with a runtime<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> 30 minutes. The fabric sample is then take for hairiness<br />

checking, <str<strong>on</strong>g>and</str<strong>on</strong>g> then 0.3% enzyme is added with a running time<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> 20 minutes, with another fabric sample to check the hairiness.<br />

In order to ensure better fabric performance the temperature<br />

is increased upto 700C, with further 10 minutes runtime in<br />

the bath.<br />

The sec<strong>on</strong>d <str<strong>on</strong>g>process</str<strong>on</strong>g> entails a single step, at bath temperature<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> 550C, with 0.9% enzyme ratio, with running time <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>on</strong>e hour.<br />

The first <str<strong>on</strong>g>process</str<strong>on</strong>g> is comparatively better, because in this <str<strong>on</strong>g>process</str<strong>on</strong>g><br />

hairiness <str<strong>on</strong>g>of</str<strong>on</strong>g> fibers is smoothly removed which is helpful for<br />

the next dyeing <str<strong>on</strong>g>process</str<strong>on</strong>g>.<br />

Method analysis<br />

For this experiment, two methods are being used, <strong>on</strong>e is<br />

<str<strong>on</strong>g>migrati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>process</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> another is <str<strong>on</strong>g>isothermal</str<strong>on</strong>g> <str<strong>on</strong>g>process</str<strong>on</strong>g>.<br />

Process curve (Migrati<strong>on</strong>)<br />

In <str<strong>on</strong>g>migrati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>process</str<strong>on</strong>g>, color (300C), salt (600C), then runtime<br />

30 minutes at 800C, soda (600C), then again temperature rises<br />

up to 800C, to be completed in the dye bath.<br />

Dye<br />

30 0 C<br />

60 0 C 80 0 C X 30 min<br />

Salt<br />

Process curve (Migrati<strong>on</strong>)<br />

Vietnam reports rising dem<str<strong>on</strong>g>and</str<strong>on</strong>g> for<br />

br<str<strong>on</strong>g>and</str<strong>on</strong>g>ed clothes<br />

Soda<br />

20 min<br />

With growing br<str<strong>on</strong>g>and</str<strong>on</strong>g> awareness, fashi<strong>on</strong> c<strong>on</strong>sciousness <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

rising dem<str<strong>on</strong>g>and</str<strong>on</strong>g> for quality clothes, sales <str<strong>on</strong>g>of</str<strong>on</strong>g> clothes in Vietnam are<br />

projected to grow at a CAGR <str<strong>on</strong>g>of</str<strong>on</strong>g> around 15% by the end <str<strong>on</strong>g>of</str<strong>on</strong>g> 2012,<br />

according to a new research report by Vietnam Retail Analysis<br />

(2008-2012).<br />

The report further says that while Vietnam’s domestic garment<br />

market is largely export-oriented, local dem<str<strong>on</strong>g>and</str<strong>on</strong>g> for better<br />

quality clothing is also keeping pace with rising br<str<strong>on</strong>g>and</str<strong>on</strong>g> awareness<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> c<strong>on</strong>sumer-oriented society.<br />

As Vietnam has recently acquired the WTO membership,<br />

growth prospects for its textiles <str<strong>on</strong>g>and</str<strong>on</strong>g> garments industry have<br />

shown more promise as it has a potential to increase exports to<br />

the US <str<strong>on</strong>g>and</str<strong>on</strong>g> Europe (the biggest export markets for Vietnam)<br />

without any quota limitati<strong>on</strong>s. Besides, rise in textile exports will<br />

also enable Vietnam to generate more jobs <str<strong>on</strong>g>and</str<strong>on</strong>g> increase foreign<br />

exchange. In the backdrop <str<strong>on</strong>g>of</str<strong>on</strong>g> these factors, the Vietnamese<br />

apparel industry is expected to grow at a CAGR <str<strong>on</strong>g>of</str<strong>on</strong>g> 9.95% from<br />

2007 to 2011.�<br />

Dye (20 min) Salt (20 min) Soda ash (20 min)<br />

60 0 C 60 0 C 60 0 C<br />

Process curve (Isothermal)<br />

Process curve (Isothermal)<br />

At first the dye bath is prepared by adding chemicals <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

auxiliaries, with temperature raised to 600C. The dyestuff are<br />

added slowly into a bath over a period <str<strong>on</strong>g>of</str<strong>on</strong>g> 20 mins. After the<br />

additi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> dyestuff, the required amount <str<strong>on</strong>g>of</str<strong>on</strong>g> salt is added in<br />

two porti<strong>on</strong>s or in some case slowly over the durati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> 20 mins.<br />

Afterwards the soda ash is added to the bath in two porti<strong>on</strong>s or<br />

over a period <str<strong>on</strong>g>of</str<strong>on</strong>g> 20 mins.<br />

S<str<strong>on</strong>g>of</str<strong>on</strong>g>tener<br />

After matching the shade, the CWS s<str<strong>on</strong>g>of</str<strong>on</strong>g>tener is added <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

for pink color dyeing.<br />

Results <str<strong>on</strong>g>and</str<strong>on</strong>g> discussi<strong>on</strong><br />

In <str<strong>on</strong>g>isothermal</str<strong>on</strong>g> <str<strong>on</strong>g>process</str<strong>on</strong>g> dyeing <str<strong>on</strong>g>process</str<strong>on</strong>g> has been completed at<br />

60 0 C (for light color dyeing). In <str<strong>on</strong>g>migrati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>process</str<strong>on</strong>g>, dyeing is<br />

being completed at 60 0 C-80 0 C-60 0 C <str<strong>on</strong>g>process</str<strong>on</strong>g>. In <str<strong>on</strong>g>migrati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>process</str<strong>on</strong>g>,<br />

the value added time remains 90 mins, whereas at <str<strong>on</strong>g>isothermal</str<strong>on</strong>g><br />

<str<strong>on</strong>g>process</str<strong>on</strong>g> this time remains 60 mins that’s why total time saving <str<strong>on</strong>g>of</str<strong>on</strong>g> 30<br />

mins is observed for <strong>on</strong>e batch. Fixati<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> exhausti<strong>on</strong> has been<br />

completed at same temperature during <str<strong>on</strong>g>isothermal</str<strong>on</strong>g> <str<strong>on</strong>g>process</str<strong>on</strong>g> for<br />

light color dyeing. In <str<strong>on</strong>g>migrati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>process</str<strong>on</strong>g>, Fixati<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> exhausti<strong>on</strong><br />

has been completed at various temperatures, so that chemical<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> dyes c<strong>on</strong>sumpti<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> energy expenditure also increases the<br />

cost <str<strong>on</strong>g>of</str<strong>on</strong>g> producti<strong>on</strong>. Therefore, it can be c<strong>on</strong>cluded from this experiment<br />

that for light color dyeing, <str<strong>on</strong>g>isothermal</str<strong>on</strong>g> <str<strong>on</strong>g>process</str<strong>on</strong>g> is much better<br />

alternative to <str<strong>on</strong>g>migrati<strong>on</strong></str<strong>on</strong>g> dyeing <str<strong>on</strong>g>process</str<strong>on</strong>g>.<br />

References<br />

[1] Razia Sultana <str<strong>on</strong>g>and</str<strong>on</strong>g> M. Zulhash Uddin “Compatibility Testing <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

Reactive dyes”Journal <str<strong>on</strong>g>of</str<strong>on</strong>g> Mechanical Engineering, Vol. Me38, Dec.<br />

2007. transacti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the Mech. Eng. Div., The Instituti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

Engineers, Bangladesh.<br />

[2] M.M. Dalal, K.R. Desai “Dyeing effects <str<strong>on</strong>g>of</str<strong>on</strong>g> Bi-functi<strong>on</strong>al Reactive<br />

Dyes <strong>on</strong> Knitted Cott<strong>on</strong> Fabrics”. �<br />

Come <str<strong>on</strong>g>and</str<strong>on</strong>g> visit us at ITMA ASIA +CITME 2010<br />

PTJ October 2009 43<br />

Dyeing Printing Finishing