DOUBLE BLACK_BROCHURE - Clariant

DOUBLE BLACK_BROCHURE - Clariant

DOUBLE BLACK_BROCHURE - Clariant

- TAGS

- double

- clariant

- clariant.fr

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

www.textiles.clariant.com<br />

<strong>Clariant</strong> International Ltd<br />

Rothausstrasse 61<br />

4132 Muttenz<br />

Switzerland<br />

<strong>Clariant</strong> Ibérica Producción S.A<br />

PG Special Dyes<br />

Pol.Ind. Can Estapé S.N<br />

08755 Castellbisbal, Barcelona (Spain)<br />

Tel. +34 93 817 61 62<br />

Fax. +34 93 772 02 28<br />

For sales to customers located within United States and Canada: This information corresponds to the<br />

present state of our knowledge and is intended as a general description of our products and their possible<br />

applications. <strong>Clariant</strong> makes no warranties, express or implied, as to the information’s accuracy,<br />

adequacy, sufficiency or freedom from defect and assumes no liability in connection with any use of this<br />

information or of any product, method or apparatus mentioned. Any user of this product is responsible<br />

for determining the suitability of <strong>Clariant</strong>‘s products for its particular application. NO WARRANTY IS<br />

MADE OF THE MERCHANTABILITY OR FITNESS FOR USE OF ANY PRODUCT, AND NOTHING INCLUDED<br />

IN THIS INFORMATION WAIVES ANY OF CLARIANT’S GENERAL TERMS AND CONDITIONS OF SALE,<br />

WHICH CONTROL UNLESS IT AGREES OTHERWISE IN WRITING. Any existing intellectual/industrial<br />

property rights must be observed. Due to possible changes in our products and applicable national and<br />

international regulations and laws, the status of our products could change. Material Safety Data Sheets<br />

providing safety precautions, that should be observed when handling or storing <strong>Clariant</strong> products, are<br />

available upon request and are provided in compliance with applicable law. You should obtain and<br />

review the applicable Material Safety Data Sheet information before handling any of these products.<br />

For additional information, please contact <strong>Clariant</strong>.<br />

For sales to customers located outside the United States and Canada: This information corresponds to<br />

the present state of our knowledge and is intended as a general description of our products and their<br />

possible applications. <strong>Clariant</strong> makes no warranties, express or implied, as to the information’s accuracy,<br />

adequacy, sufficiency or freedom from defect and assumes no liability in connection with any use<br />

of this information. Any user of this product is responsible for determining the suitability of <strong>Clariant</strong>‘s<br />

products for its particular application. Nothing included in this information waives any of <strong>Clariant</strong>’s<br />

General Terms and Conditions of Sale, which control unless it agrees otherwise in writing. Any existing<br />

intellectual/industrial property rights must be observed. Due to possible changes in our products and<br />

applicable national and international regulations and laws, the status of our products could change.<br />

Material Safety Data Sheets providing safety precautions, that should be observed when handling or<br />

storing <strong>Clariant</strong> products, are available upon request and are provided in compliance with applicable<br />

law. You should obtain and review the applicable Material Safety Data Sheet information before<br />

handling any of these products. For additional information, please contact <strong>Clariant</strong>.<br />

The opinions provided herein related to ColorLok Technology solely belong to <strong>Clariant</strong> and are not the<br />

opinions of International Paper Company. International Paper Company is not responsible for the opinions<br />

expressed herein.<br />

® Product and service marks protected by <strong>Clariant</strong> in many countries<br />

© 2010 <strong>Clariant</strong> International Ltd, Rothausstrasse 61, 4132 Muttenz, Switzerland<br />

9.10/e/2000<br />

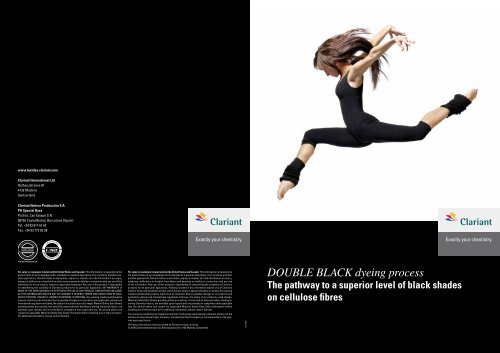

<strong>DOUBLE</strong> <strong>BLACK</strong> dyeing process<br />

The pathway to a superior level of black shades<br />

on cellulose fibres

<strong>DOUBLE</strong> <strong>BLACK</strong><br />

<strong>Clariant</strong> is pleased to present the new <strong>DOUBLE</strong> <strong>BLACK</strong><br />

dyeing process.<br />

<strong>DOUBLE</strong> <strong>BLACK</strong> is the synergy of two dyeing technologies,<br />

the sulphur black and the reactive black. It is carried out<br />

in one process resulting in a superior level of deep black<br />

shades and enhanced performance for cellulose fibres.<br />

Diresul Black RDT-2KS liq<br />

&<br />

Drimaren Black CL-S p<br />

<strong>DOUBLE</strong> <strong>BLACK</strong> represents a significant improvement in<br />

the field of black shades for cellulose. It combines the high<br />

performance of sulphur blacks in aspects such as<br />

perspiration/light fastness with the features of reactive<br />

blacks, in terms of shade flexibility and repetitive washing<br />

fastness, amongst other. As a result of this combined<br />

concept, a superior level of depths, tone flexibility and<br />

fastness is achieved.<br />

<strong>DOUBLE</strong> <strong>BLACK</strong> Superior Lightfastness:<br />

Light fastness, Atlas Ci35-A, ISO 105-B02: >6,0<br />

Perspiration wet light fastness, alkaline SZFP 15 h: 5,0<br />

<strong>DOUBLE</strong> <strong>BLACK</strong> advantages:<br />

■ Deepest obtainable black shades<br />

■ Shading flexibility<br />

■ Shade stability under different illuminates<br />

■ Excellent covering of immature/dead cotton<br />

■ Good perspiration light fastness<br />

■ Good repetitive washing fastness<br />

<strong>DOUBLE</strong> <strong>BLACK</strong> is achieved without an increase in<br />

processing time because scouring and Diresul black<br />

dyeing is carried out at the same time.<br />

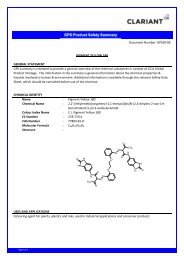

<strong>DOUBLE</strong> <strong>BLACK</strong> DYEING PROCESS<br />

<strong>DOUBLE</strong> <strong>BLACK</strong> DYEING PROCESS<br />

TEMP. (ºC)<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

10’<br />

A B C<br />

15’<br />

20’<br />

10’ overflow<br />

10’<br />

5’<br />

15’-20’ 20’ 10’ 30’<br />

70% progresive<br />

45’-60’<br />

0 50 100 150 200 250 300 350<br />

A - 10g/l Reductor D p.<br />

20 g/l NaOH 50%<br />

3 g/l Leonil EHC liq conc<br />

1 g/l Ladiquest 2005 liq c<br />

B - 8% Diresul Black RDT-2KS liq<br />

D<br />

10’<br />

E<br />

F G H<br />

C - 30 g/l Sodium Sulphate<br />

D - Neutralization with<br />

Sirrix NE liq<br />

(Untill pH=6-6,5)<br />

10’<br />

E - 1 g/l Ladiquest 2005 liq c<br />

PH 6,0-6,5<br />

80 g/l Sodium sulfate<br />

3 g/l Revatol S<br />

F - 5% Drimaren Black CL-S p<br />

I<br />

15’-20’<br />

J<br />

15’<br />

TIME<br />

(min.)<br />

G - 5 g/l Soda Ash<br />

H - 3,5 g/l NaOH 36ºBe<br />

I - 0,5 g/l Acetic acid<br />

J - 1 g/l Ladipur RSK