multifunctional powerhouse - Mercedes Benz

multifunctional powerhouse - Mercedes Benz

multifunctional powerhouse - Mercedes Benz

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

www.mercedes-benz.com September 2010<br />

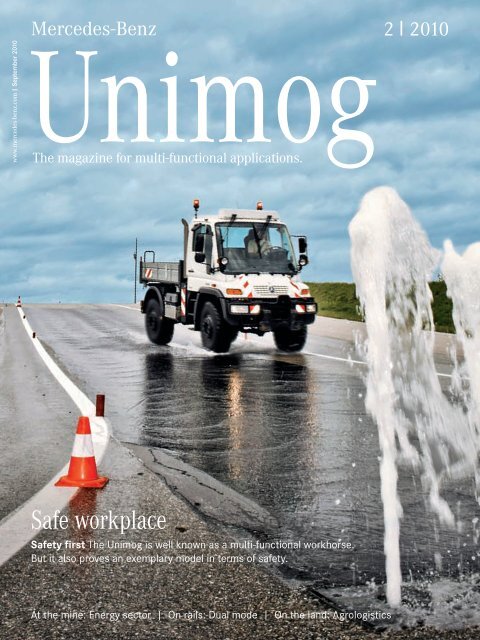

<strong>Mercedes</strong>-<strong>Benz</strong><br />

Unimog<br />

The magazine for multi-functional applications.<br />

Safe workplace<br />

Safety first The Unimog is well known as a multi-functional workhorse.<br />

But it also proves an exemplary model in terms of safety.<br />

At the mine: Energy sector | On rails: Dual mode | On the land: Agrologistics<br />

2 | 2010

2 EDITORIAL • UNIMOG 2 • 2010<br />

Dear friends of Unimog,<br />

appearances – and statistics – can be deceptive. We regularly hear news of<br />

falling accident rates, yet the figures mostly relate to cars and trucks. The<br />

situation with regard to farm tractors is sadly quite different. According to<br />

Germany’s Office of Statistics, the number of fatalities in accidents involving<br />

such vehicles rose by a dramatic 64 percent year-on-year in 2009.<br />

Consequently, it is incumbent upon operators to address road safety as a top<br />

priority: for their own good, for the sake of their employees, and to protect<br />

other road users. The safety of our vehicles and their occupants has always<br />

been a top priority for <strong>Mercedes</strong>-<strong>Benz</strong>. That is why we work to the now much<br />

more stringent standards applicable to commercial vehicles, deploying all the<br />

expertise and know-how of <strong>Mercedes</strong>-<strong>Benz</strong> in doing so. It is in keeping with<br />

those considerations, too, that the <strong>Mercedes</strong>-<strong>Benz</strong> Unimog is fitted as<br />

standard with extensive and innovative safety features. Safety and robustness<br />

are assured by the special running gear, permanent all-wheel drive, ABS brake<br />

system, compressed air brakes and portal axles, just for a start. And the safety<br />

features continue into the cab. It is not without reason that the Unimog has<br />

passed a variety of different safety and crash tests with ease. And another<br />

safety benefit which should not be forgotten is the extraordinarily good<br />

all-round view from the panoramic cab.<br />

A number of upcoming events including the IFAT, IAA Commercial Vehicles<br />

and InnoTrans shows promise great things for this Autumn. <strong>Mercedes</strong>-<strong>Benz</strong><br />

will once again be presenting its specialist vehicle solutions whenever and<br />

wherever the movers and shakers in the industry get together. The present<br />

mood is bright, and there is a great sense of anticipation. As one instance, the<br />

organiser of the 63rd IAA Commercial Vehicles show, German Automotive<br />

Industry Association VDA, is talking about the country’s economy enjoying a<br />

“strong impetus” which it believes will benefit its upcoming international show.<br />

The event of the year will doubtless be well attended once again, following on<br />

from the approximately 300,000 visitors from 110 countries who came two<br />

years ago to view close-up the new products and innovations on show from<br />

the over 2,000 exhibitors.<br />

The Autumn season of trade fairs marks one more step towards a very<br />

special year for the Unimog in 2011: its 60th birthday. So there will no doubt<br />

be much more to report about the exciting world of the Unimog in the near<br />

future!<br />

I very much hope you will enjoy reading this latest issue of Unimog Magazine.<br />

Yaris Pürsün<br />

<strong>Mercedes</strong>-<strong>Benz</strong> Wörth Plant Manager and<br />

Director of <strong>Mercedes</strong>-<strong>Benz</strong> Special Trucks Division<br />

Open-cast mining<br />

14 Extreme workhorses

News<br />

04 All the latest from the Special Trucks division<br />

Cover story<br />

06 Safety first Choosing a Unimog means keeping on the safe side.<br />

09 A misleading gut feeling Interview with Jürgen Freigang.<br />

Agrologistics<br />

10 A striking success in agrologistics The Wolf family’s Unimog U 500 is not<br />

just an attention-grabber – it is also a hard worker, which is rarely stood still.<br />

Fire-fighting<br />

13 A highly manoeuvrable fire-fighter The volunteer fire service in Wuppertal<br />

recently took delivery of a Unimog U 20 tank tender. And it’s a red hot hit.<br />

Open-cast mining<br />

14 Extreme workhorses The Hambach open-cast mine near Cologne is<br />

a place of superlatives. And Unimogs have been working there from the<br />

very beginning.<br />

16 “The Unimog is vital” Interview with Jörg Rübsteck.<br />

Transport<br />

18 Sunday driving ban? Not for the Unimog Eugen Betz uses his U 500 to<br />

transport construction machinery, among other purposes. And he profits<br />

from it in lots of ways.<br />

Dual-mode operation<br />

20 “Green Logistics” on road and rail For DB Schenker Rail the Unimog is<br />

proving an environmentally friendly alternative to marshalling locomotives.<br />

Engineering<br />

24 Flexible, manoeuvrable, agile – thanks to all-wheel steering Three<br />

practical examples demonstrating the great benefits of all-wheel steering.<br />

Service<br />

28 Being a king <strong>Mercedes</strong>-<strong>Benz</strong> customers can trust in the company’s reliable<br />

quality. All the time, everywhere.<br />

Uniscope<br />

30 Unimog exotic models collection/Unimog 2010 the star guest<br />

31 Shopping at the click of a mouse/World Tour, part I/Diary<br />

Publisher’s data<br />

Publisher: Daimler AG, <strong>Mercedes</strong>-<strong>Benz</strong> Special Trucks, Sales Marketing, D-76742 Wörth<br />

Responsible at publisher: Benjamin Syring, Special-Purpose Vehicles Product Division<br />

Editorial committee: Benjamin Syring, Marion Frank, Dieter Sellnau<br />

Authors: Martin Heying (13, 30 bottom), Richard Kienberger (4 bottom, 5 l.), Susanne Löw (4 top, 5 r., 9, 10 ff.,<br />

30 top, 31), Thomas Maier (20 ff.), Ralf Maile (18 f.), Saskia Meier (24 ff., 28 f.), Tanja Strauß (6 ff., 14 ff.)<br />

Photos: Aebi Schmidt (26 bottom), büro monaco (1, 3 no. 1+2, 6-8, 9 l., 10-12, 20 f., 22 r.), Daimler AG<br />

(Miscellaneous), Michael Ehritt (24, 26 top left/top right), Jürgen Freigang (9 r.), Martin Heying (3 no. 3, 13,<br />

22 l., 23, 30 bottom), Richard Kienberger (4 bottom, 5 l.), Susanne Löw (31 top right), Ralf Maile (18 f.),<br />

<strong>Mercedes</strong>-<strong>Benz</strong> Schweiz AG (3 no. 4, 27 top left/top right), Morlock Photography (2 r., 4 top, 14-17),<br />

Carl-Heinz Vogler (30 top)<br />

Production: Verlag Heinrich Vogel, Springer Fachmedien München GmbH, Corporate Publishing, Aschauer<br />

Straße 30, D-81549 Munich, Tel.: +49 (0)89 203043-1122; Art direction/graphics: Dierk Naumann; Editorial<br />

staff: Susanne Löw, Thomas Maier (Editor-in-chief); Project management: Susanne Löw, Matthias Pioro<br />

Printed by: F&W Mediencenter GmbH, Holzhauser Feld 2, D-83361 Kienberg<br />

Translation: beo Gesellschaft für Sprachen & Technologie mbH, Freischützstraße 9, D-81927 Munich<br />

Unimog Magazine is published twice a year, in English, German, French and Spanish. All rights<br />

reserved. Reproduction and electronic processing are only permitted with written authorisation from<br />

the publishers. No liability can be accepted for any unsolicited articles and images sent to us.<br />

Printed on paper bleached without chlorine • Printed in the Federal Republic of Germany<br />

UNIMOG 2 • 2010 • CONTENTS 3<br />

06<br />

10<br />

20<br />

24

4 NEWS • UNIMOG 2 • 2010<br />

Meals on two axles<br />

At Stockholm Airport, caterer Gate Gourmet delivers its meals to the aircraft using the Econic. For good reasons.<br />

Luggage loading and unloading, refuelling, cleaning, catering<br />

– with so much going on, it’s important to keep a clear view.<br />

The panorama window of the Econic is a big help.<br />

Undemanding yet tough<br />

International caterer Gate Gourmet supplies leading airlines such<br />

as SAS and Delta with between 8,000 and 12,000 meals a day at<br />

Arlanda Airport in Stockholm. To ensure just-in-time delivery of the<br />

portioned, packed and trolley-stacked meals, plus drinks, duty-free<br />

goods and accessories to the aircraft on the nearby apron, Gate<br />

Gourmet relies on the Econic. The 10 low-floor units which have<br />

been serving the airport in this way since 2008 easily fit beneath all<br />

low passage-ways around the terminals. As a further benefit, the<br />

inward-opening front passenger door and the panorama window<br />

provide the necessary all-round visibility for the drivers when<br />

manoeuvring directly beneath the aircraft.<br />

The Mallaghan lift trucks mounted on the base units are capable<br />

of lifting a load capacity of 4,000 kilograms up to 5.70 metres. The<br />

refrigerated containers are manoeuvred directly to the aircraft doors<br />

for loading and unloading at the press of a button. Another comfort<br />

feature for drivers is the low entry and exit facility, thanks to the<br />

low-level cab floor. All in all, the Econic is a key factor in helping to<br />

ensure that air travellers flying from Arlanda will not be hungry<br />

when they arrive at their destination. r<br />

In exploring for new oil fields in Jordan, all-wheel vehicles from <strong>Mercedes</strong>-<strong>Benz</strong> are handling the tough jobs.<br />

They are undemanding, robust and can be deployed (almost)<br />

anywhere – just like the camels which are traditionally kept as<br />

beasts of burden around the region. All-wheel vehicles from<br />

<strong>Mercedes</strong>-<strong>Benz</strong> were the first<br />

choice when oil company Josco, a<br />

Jordanian-registered subsidiary<br />

of Shell, set about putting<br />

together a vehicle fleet to assist<br />

in exploring and exploiting new<br />

fields. What is special about this<br />

arrangement is that it represents<br />

the first time ever that Shell has<br />

run such a fleet under its own<br />

management, having previously<br />

relied on subcontractors.<br />

To handle the extreme conditions<br />

encountered in the Jordanian<br />

desert a range of different<br />

models are deployed, in a wide variety of configurations – primarily<br />

from the Zetros and Actros series. While the Zetros trucks are<br />

deployed to supply the various camps with equipment and material,<br />

the mobile drilling rigs are<br />

mounted on four-axled Actros<br />

trucks. The Unimog, which is<br />

scheduled to join the beigeliveried<br />

Josco desert fleet shortly,<br />

will provide specialist equipment<br />

to assist in handling of the pipes<br />

being sunk into the bore holes. r<br />

Actros, Zetros (see photo) and<br />

Unimog units are working under<br />

extreme conditions exploiting<br />

new oil fields in the Jordanian desert.

Unimog on show at the ski stadium<br />

Against an impressive backdrop, local dealer Autohaus Hornung together with<br />

Unimog distributor Henne-Unimog GmbH hosted a demonstration of public works<br />

and fire-fighting vehicles.<br />

A ski stadium is more normally associated<br />

with the Winter time and the cold, yet on this<br />

Summer’s day it is not just tourists who have<br />

come flocking to the Olympic Ski Stadium in<br />

Garmisch-Partenkirchen. In conjunction with<br />

the world’s largest Unimog distributor, Henne-<br />

Unimog GmbH, local <strong>Mercedes</strong>-<strong>Benz</strong> dealer<br />

Autohaus Hornung GmbH is hosting a major<br />

show, with large numbers of public works<br />

vehicles demonstrating their capabilities at<br />

the traditional wintersports venue. As the first<br />

spectators begin to arrive at the historic stadium,<br />

which was completely rebuilt in 2007,<br />

ski-jumpers are conducting their Summer<br />

training in the background.<br />

The <strong>Mercedes</strong>-<strong>Benz</strong> dealer regularly offers<br />

its customers an overview of the product<br />

portfolio and first sight of the latest releases<br />

by hosting special presentations. This time<br />

the focus was on public works and fire-fighting<br />

vehicles. Gerhard Lutz, Managing Director of<br />

Autohaus Hornung GmbH, sets out his corporate<br />

strategy: “In our catchment area there are<br />

very few freight forwarders. In fact, only one of<br />

our major customers operates a long-distance<br />

transport fleet. Consequently, we need to<br />

concentrate our commercial vehicle sales<br />

efforts on other market segments”. In pursuing<br />

its strategy, the dealership has put on a show<br />

about everything that <strong>Mercedes</strong>-<strong>Benz</strong> has to<br />

offer in the public works vehicles segment. A<br />

major feature of the show is a range of Unimog<br />

models from Henne-Unimog GmbH, based in<br />

Kirchheim-Heimstetten. The various equipment<br />

manufacturers have made their matching builton<br />

units available.<br />

The show features a U 500 tipper tractor unit<br />

as is widely used in farming, as well as maintenance<br />

vehicles, Winter gritters and snow-clearers<br />

and a cherry-picker. Two lovingly restored<br />

vintage models – one from the 1950s and a<br />

snow plough with a 54 hp engine and separate<br />

180 hp plough drive on its load space – arouse<br />

a strong sense of nostalgia among the older visitors<br />

especially. A new model among the fire<br />

service vehicles featured is based on the U 20,<br />

and is a product for which the <strong>Mercedes</strong>-<strong>Benz</strong><br />

dealership in Garmisch sees bright prospects.<br />

One of the reasons for that optimism is that the<br />

Unimog fire-fighting vehicle carries equipment<br />

which normally requires a much larger base<br />

unit. “The manoeuvrability and off-road capability<br />

of the U 20 are key attractions in view of the<br />

applications for which our fire services need to<br />

use it,” Lutz asserts. In terms of visitors, the<br />

dealership manager has focused on a closely targeted<br />

group: “You can’t expect to have thousands<br />

of people attending such an event. For us it is<br />

much more important to have professionals and<br />

decision-makers here, and to provide them with<br />

the expert information and assistance they<br />

expect.” r<br />

UNIMOG 2 • 2010 • NEWS 5<br />

Browse the <strong>Mercedes</strong>-<strong>Benz</strong> calendar<br />

The <strong>Mercedes</strong>-<strong>Benz</strong> Unimog is turning 60.<br />

That achievement calls for a very special gift<br />

for customers – something which is just as<br />

multi-functional as the “universal motor<br />

machine” itself: a ring-bound calendar that can<br />

be read like a book or used as a traditional wall<br />

calendar. Titled “Lebensräume” (living spaces),<br />

it portrays the many fields of application of<br />

the Unimog, including<br />

photos of historic models<br />

and the latest examples.<br />

The calendar will<br />

soon be available from<br />

www.shop.mercedesbenz.com/unimog<br />

(size: 31 x 43 cm, price:<br />

24.90 Euro).<br />

Get in gear fast<br />

Special offer weeks at your Unimog service<br />

partner. Come along and have a look, and<br />

save yourself money. From September 15th to<br />

December 31, 2010 you can get clutches for<br />

various Unimog models at a special offer<br />

price. And all in accustomed <strong>Mercedes</strong>-<strong>Benz</strong><br />

original parts quality. Talk to your Unimog<br />

service partner. They will be glad to help you.<br />

A real globetrotter!<br />

With the new Bocklet body, the U 4000 is<br />

capable of completing any expedition. Special<br />

features such as the heavy-duty running gear,<br />

the Tirecontrol tyre pressure control system<br />

and the vehicle’s high diesel capacity (290<br />

litres + two 20-litre reserve canisters) make it<br />

possible. In the cut-away shape live-in cab<br />

(standing height: 1.95, length: 4.35, interior<br />

width: 2.20 metres) sanitary facilities and a<br />

corner galley provide the necessary comforts.

6 COVER STORY • UNIMOG 2 • 2010<br />

Safety first<br />

The Unimog is the right choice when it comes to ensuring safety. Its unique design protects vehicle occupants<br />

and other road users thanks to optimum all-round visibility, efficient braking and lots of other safety features.<br />

CLIMB ABOARD, DRIVE OFF – and arrive safely. Whether the U 20,<br />

U 300 to U 500 or U 4000 to U 5000, with a Unimog you can be sure<br />

of always being on the safe side – and also enhancing general levels<br />

of safety on the road. That is certainly not something to be taken for<br />

granted. Every year there are numerous serious collisions between<br />

utility vehicles and other road users. Often they are caused by human<br />

error, and as such will never be completely eliminated. The dangers are<br />

not restricted merely to other road users however: According to<br />

Germany’s Office of Statistics, the risk of farm tractor drivers being<br />

fatally injured in an accident is on the increase. There was a 64 percent<br />

year-on-year rise in such fatalities in 2009. The Unimog offers a wide<br />

range of driver safety features which no tractor can match.<br />

All-round protection for driver and passengers<br />

The cab of the Unimog is a safe, ergonomic workplace for the driver and<br />

other occupants. Occupant protection is enhanced by the seat construction<br />

in conformance to EU Directives 74/408/EEC and 76/115/EEC<br />

(relating to seat and seat belt anchorage testing). The integrated head<br />

restraints and three-point automatic seat belts provide effective<br />

protection in the event of a rear-end impact especially. And the Unimog<br />

also sets standards in terms of low vibration, falling within the<br />

vibration limits stipulated in section 5 of the German Occupational<br />

Health and Safety regulations in mowing and Winter works. In tests<br />

carried out by the Institute for Occupational Health and Safety of the<br />

Association of German Statutory Accident Insurers, the Unimog demonstrated<br />

that the vibration impact on the driver during mowing and in offroad<br />

driving was below the trigger threshold laid down in noise and<br />

vibration protection regulations. Thanks to its fully sprung running<br />

gear, cab suspension and air-sprung comfort seating, the Unimog promises<br />

stress-free working conditions which alleviate the risk of tiring.<br />

A clear view in all directions<br />

The Unimog also scores highly thanks to the good all-round visibility it<br />

provides. The panoramic cab ensures a clear view of the road and of the<br />

Direct field of view in compliance with section 35b of the German<br />

§<br />

road vehicle licensing regulations (StVZO)<br />

1) The systems used to control the vehicles must be easy and safe<br />

to operate.<br />

2) The vehicle driver must be guaranteed an adequate field of view<br />

under all operating and weather conditions.<br />

vehicle’s built-on units at all times. The low-slung windscreen provides<br />

a 12 metre visibility radius even with the mowing, gritting and snow clearing<br />

units dismounted. Including the heated and electrically adjustable<br />

large-area rear-view mirror, the vehicle features a total of five mirrors on<br />

On the safety training course near Salzburg the sales staff<br />

themselves had the chance to get behind the wheel.

UNIMOG 2 • 2010 • COVER STORY 7<br />

“Thanks to ABS the driver is able to maintain control<br />

of the Unimog under full braking.”<br />

Robert Ramsauer, product manager special-purpose vehicles, <strong>Mercedes</strong>-<strong>Benz</strong> Austria<br />

the driver and passenger sides to assure good rear visibility. This greatly<br />

reduces the risk posed by blind-spots and resultant hazard situations<br />

such as on pedestrian crossings. The seating position also helps:<br />

“Because the driver is seated closely behind the front axle and so in the<br />

front end of the vehicle, he can judge traffic situations, such as at crossings,<br />

earlier than would be the case if the position were set farther<br />

back,” explains Robert Ramsauer, product manager special-purpose<br />

vehicles with <strong>Mercedes</strong>-<strong>Benz</strong> Austria.<br />

§<br />

According to section 23(1) of the German road traffic regulations<br />

(StVO), the vehicle driver is responsible for ensuring that his or<br />

her view and hearing are not impaired by the other occupants,<br />

animals, load, equipment or machinery, or the condition of the<br />

vehicle.<br />

Unimog vehicles with built-on units also retain outstanding visibility.<br />

All units approved for mounting on a Unimog are within the legal limits<br />

in terms of forward visibility. They are matched to the Unimog so as to<br />

ensure all legal requirements regarding visibility are met. In concrete<br />

terms, for example, this means that when operating front-mounted<br />

equipment the legally permissible 3.5 metre distance from the middle<br />

of the steering wheel to the front of the equipment is not exceeded.<br />

As a result, no special permit is required. The driver and the vehicle<br />

owner can relax, because with the Unimog they are complying with all<br />

legal requirements regarding operation with mounted equipment and<br />

have critical situations more effectively under control.<br />

Safe braking to avoid danger<br />

If a Unimog encounters a potentially hazardous situation, the driver is<br />

able to rely on the vehicle’s high levels of braking safety, guaranteed<br />

by its dual-circuit service brake system with four disk brakes directly<br />

on the wheels. The four-channel ABS additionally keeps the Unimog<br />

controllable in the event of danger. “Even under full braking, thanks<br />

to ABS the driver is able to maintain control of the Unimog and avoid<br />

hitting any obstacles. Without ABS, the driver would have to decide<br />

whether to brake or steer,” Ramsauer points out. Braking is further<br />

aided by the two-stage engine brake, delivering over 100 kW of<br />

braking power. The automatic load-sensitive brake (ALB) controls<br />

the distribution of braking force between the front and rear axles,<br />

while the ABS socket assures safe trailer operation. ü<br />

ü

8 COVER STORY • UNIMOG 2 • 2010<br />

The Unimog remains on track even on wet and icy roads thanks to ABS.<br />

Changes of season pose a particular hazard to road users. Fog hinders<br />

visibility and vision, and Autumn leaves make roads slippery. So it is<br />

good that the rear lighting on the Unimog makes it so clearly visible to<br />

the traffic behind: with four tail lights, two indicators, two rear headlights,<br />

two reflectors, a fog tail light and two brake lights. In addition,<br />

two side-marker lamps as well as outline and periphery marker lamps<br />

ensure that the Unimog is clearly seen in every situation. The front headlights<br />

feature a range control system. Wild animals on German roads<br />

caused 2,412 accidents entailing personal injury last year (Destatis,<br />

Advertisement<br />

Road maintenance equipment for Unimog U300 - U500 and U20<br />

July 1, 2010). In such cases, and others in which abrupt braking is<br />

required, ABS prevents the vehicle from breaking away in various road<br />

conditions. Optional anti-skid or snow chains can be fitted in Winter to<br />

enhance traction and track control.<br />

Safety training: The Unimog shows what it can do<br />

Full braking on a wet road, cornering on a slippery surface and evading<br />

obstacles – 20 members of staff from the Unimog Austria sales organisation<br />

had the opportunity to experience for themselves the outstanding<br />

safety features and top-class handling of the Unimog over the course of<br />

a two-day event. “It’s the best way to get to know all the benefits and<br />

key features of the product you are selling. There is nothing more persuasive<br />

than getting behind the wheel yourself and managing to keep<br />

your vehicle on track under full braking on a mirror-like icy surface,”<br />

Ramsauer asserts.<br />

The driving technical centre of the Austrian Automobile, Motorcycle<br />

and Touring Club (ÖAMTC) in Marchtrenk in Upper Austria provided<br />

the perfect setting for the safety training course, with its computercontrolled<br />

water obstacles, inclines and slide surfaces. After all, the<br />

whole point of the event was for the Unimog to show what it can do.<br />

And it did just that. The result was clear: the Unimog is well ahead of<br />

the rest when it comes to safety. r<br />

Our comprehensive range<br />

of front and rear mounted<br />

mowing equipment with a<br />

versatile range of working<br />

attachments is the optimum solution for an allyear<br />

use of the Unimog. Please ask for our general<br />

folder about professional mowing equipment.<br />

International Unimog System-Partner<br />

Innovation and quality –<br />

we are committed to<br />

our reputation.

A misleading gut feeling<br />

Jürgen Freigang, an expert on transportation of hazardous goods and<br />

load securing, knows what is important when safety is at stake.<br />

In a comparison between a tractor and a Unimog, the “universal motor machine” comes out impressively on top.<br />

Unimog Magazine: You recently gave a presentation<br />

to a customer event at Minufa, the<br />

Unimog distributor in Herborn in the state of<br />

Hesse. What was the purpose of the event?<br />

Jürgen Freigang: It was intended to compare<br />

two different systems: a tractor and a Unimog.<br />

Minufa clearly demonstrated that the Unimog<br />

is safer to handle in some situations – even<br />

for the unpractised driver. When braking<br />

with ABS, for example, the Unimog remains<br />

well on track, even on a road surface with<br />

varying grip on the left and right sides of<br />

the vehicle and when driving at 50 km/h,<br />

whereas the tractor breaks away at just<br />

30 km/h on such a surface, because it has no<br />

ABS. The test also compared load securing.<br />

It demonstrated that a tonne weight on a<br />

vehicle moves around under full braking at<br />

20 km/h just the same as a light load. Many<br />

of the people attending the event expected<br />

that the crate holding the tonne weight<br />

would barely move on the load space. Yet<br />

when they saw that both crates were catapulted<br />

forward against the front bulkhead<br />

even at such a low speed at the same rate<br />

– the heavy object merely with much greater<br />

impact energy than the empty one – there was<br />

widespread astonishment. Their gut feeling<br />

had told them the outcome would be very<br />

different!<br />

Unimog Magazine: The issue of safety is also<br />

always linked to the question of responsibility<br />

– who is liable in the event of an accident?<br />

Jürgen Freigang: Many people are not sufficiently<br />

aware of their responsibility in this<br />

respect. According to StVZO regulations<br />

sections 30 and 31, a vehicle’s owner is<br />

fundamentally responsible for its operation.<br />

He/she must ensure that a vehicle is only<br />

ever used when it is safe. That includes, in<br />

particular, ensuring compliance with traffic<br />

safety regulations as well as rules governing<br />

safety when operating equipment and<br />

carrying passengers, etc. And the units builton<br />

to a carrier vehicle – such as a Unimog –<br />

must also be joined together so as to technically<br />

ensure safe operation on the road.<br />

UNIMOG 2 • 2010 • COVER STORY 9<br />

Jürgen Freigang:<br />

“A vehicle’s owner<br />

is fundamentally<br />

responsible for<br />

its operation.”<br />

Unimog Magazine: What role do vehicle,<br />

body and built-on unit manufacturers play in<br />

that?<br />

Jürgen Freigang: Vehicle manufacturers<br />

such as <strong>Mercedes</strong>-<strong>Benz</strong>, and the associated<br />

body manufacturers, maintain close mutual<br />

links and coordinate their products to an<br />

optimum degree. The issues of product safety<br />

and – where appropriate – product liability<br />

are key considerations for both parties, just<br />

as they are for the company which fits<br />

the built-on units and then supplies the<br />

complete system.<br />

With regard to load securing for example:<br />

StVO section 22, paragraph 1 stipulates that,<br />

on taking evasive action under full braking,<br />

the load must not slide, roll, tip, make noise<br />

or fall down – meaning that lashing points<br />

or other load securing aids and systems are<br />

essential. That is to say, body manufacturers<br />

should work out in advance and advise the<br />

vehicle manufacturer of the locations at<br />

which lashing points or other facilities need<br />

to be fitted, and how they need to be dimensioned.<br />

In concrete terms, this means: How<br />

many deca-Newtons (= daN; see also, for<br />

example, the blue lashing point identifiers<br />

on flat-bed truck) need to be held in what<br />

direction? The standard stipulations for<br />

trucks over 3.5 tonnes gross vehicle weight<br />

rating are as follows: 80 percent of the force<br />

due to weight must be secured against<br />

sliding forward, and 50 percent respectively<br />

against sliding to the rear and side. Put<br />

simply: Of a tonne load weight, as much as<br />

800 kilograms is forced towards the cab<br />

under full braking; of 10 tonnes, 8 is forced<br />

forward, etc. Once the load has started<br />

sliding, enormous impacts can occur representing<br />

many times the force due to weight<br />

of the load! In the case of a gritter vehicle or<br />

the like, this can result in a few tonnes’<br />

impact in a very short space of time … r

10 AGROLOGISTICS• UNIMOG 2 • 2010<br />

A striking success in agrologistics<br />

The Wolf family has been running a farm near Ulm for the last 18 years. Since 2006 the farm has<br />

been employing a Unimog U 500 in pretty much continuous operation – primarily to transport<br />

animals, whey and grain. The vehicle has notched up an impressive 220,000 kilometres to date!

UNIMOG 2 • 2010 • AGROLOGISTICS 11<br />

THE RAIN WAS BADLY NEEDED. Not a drop fell for weeks. The abnormally<br />

high July temperatures placed a strain on the people, the crops<br />

and the animals alike. “17 millilitres per square metre”, is how relieved<br />

farmer Gerhard Wolf quantifies the rain when it eventually came. But, as<br />

he comments: “It was nowhere near enough.” Whatever the weather, the<br />

day had begun early on the Wolf family farm, which is home to Gerhard<br />

and his wife Sigrid, their three sons as well as Sigrid’s parents. It was<br />

3.30 a.m. when son Martin started up the engine of the green Unimog<br />

U 500, with its 7,500 litre mounted tanker and 18,500 litre trailer, to<br />

drive the 60 kilometres to Oberschönegg in order to fetch whey as feed<br />

for the farm’s 1,500 fattening pigs.<br />

Apart from keeping the pigs and 60 dairy cows, the Wolfs farm a total<br />

of some 100 hectares in Börslingen and on a second farm 50 kilometres<br />

away which they leased in 2004. But even normally, the U 500 is rarely<br />

stood still. “Well, we didn’t buy it for fun, or because it’s nice to look at,”<br />

Gerhard Wolf comments. Quite the contrary: Three times a week the<br />

U 500 fetches whey; twice a week it runs overnight taking pigs to the<br />

slaughterhouse; and once a month the Wolfs use it to collect piglets and<br />

feed respectively. To handle the different kinds of transport, Wolf is able<br />

to quickly exchange the Unimog’s tanker body for a flat-bed tipper.<br />

Accordingly, after a total of 5,100 hours in operation since first being<br />

registered the vehicle’s clock already shows an impressive 220,000 kilometres.<br />

That kind of duty makes it essential to have reliable service backup<br />

for the entire fleet, which also includes a MB-trac 900, a MB-trac 1600<br />

and a Unimog 2400. The Baden-Württemberg born farmer is full of praise<br />

for the service provided by Mayer Nutzfahrzeuge GmbH: “The U 500 has to<br />

be ready to run round the clock, seven days a week. In view of that, it is<br />

important for us to be able to rely on the well trained staff of our service<br />

partner, and to be sure of getting help quickly when we need it. Even if<br />

we occasionally need to replace a worn part on a weekend, they help us<br />

out.” The versatile functionality of the U 500 was a key factor in the decision<br />

to purchase it: “Quite simply, we need a vehicle with which we can<br />

do everything,” Gerhard Wolf states. “At the time it was a choice between<br />

a truck and a Unimog, to replace a Unimog U 1700.” We chose the U 500,<br />

Gerhard, Sigrid and Martin Wolf (from left) are happy with their U 500, which they use<br />

mainly for transportation purposes.<br />

ü

12 AGROLOGISTICS• UNIMOG 2 • 2010<br />

Tanker body, flat-bed tipper, tractor rig: The versatility of the U 500 was a key factor<br />

in the Wolfs’ decision to buy it.<br />

among other reasons, because it is not subject to road tolls and<br />

because of its 15 tonne load capacity. Son Martin cites “economy<br />

and reliability” as the main reasons for the acquisition. Particularly<br />

under the cost pressures faced by farmers at present, Martin Wolf’s<br />

appraisal highlights an aspect which must not be underestimated: “Its<br />

fuel consumption is much better than that of earlier models – 32 litres<br />

per 100 kilometres on average, which is around five litres less.”<br />

Economical and reliable in continuous use<br />

He likes sitting behind the wheel of the Unimog: “It’s a terrific<br />

vehicle, particularly with regard to all-round visibility, and also ride<br />

comfort.” As the Wolfs were undertaking more and more transports<br />

– including on the motorway – the safety aspect was another key<br />

factor. Sigrid and Martin Wolf recall: “In earlier times it was dangerous<br />

on the motorway, towing the big cattle trailer and carrying the<br />

pigs. You were constantly afraid that the big trucks would run into<br />

the back of you. With the U 500 it’s easy to keep up with the truck<br />

traffic.”<br />

The U 500 frequently gets the Wolfs noticed. “It is a striking<br />

design. Something a bit different”, says Gerhard Wolf with a grin.<br />

Martin Wolf loading up – a short break for the Unimog. But in Börslingen it is rarely<br />

stood still.<br />

Many people simply cannot imagine Unimog and agricultural transports<br />

being mentioned in the same breath. Martin can only smile.<br />

He knows better. That afternoon he will be off again, fetching whey.<br />

Around one the following morning father Gerhard will be off driving<br />

pigs to the slaughterhouse in Schwäbisch Hall. Another plus point<br />

for the Unimog is its robustness: “The roads are sometimes quite<br />

bad, especially in Winter. And I am on a tight schedule: I have to be<br />

at the slaughterhouse between half past two and half past three,<br />

whatever the weather. In fact, there have been times in the past<br />

when I got through with the Unimog but none of the other trucks<br />

did.” In such situations, Wolf is much helped by the all-wheel drive<br />

and the short wheelbase of the Unimog. Those benefits enable him<br />

to drive safely in difficult road conditions, and to manoeuvre easily<br />

around roads narrowed by snowfall.<br />

Unimog driving as relaxation<br />

The night trips are usually handled by Gerhard Wolf himself. “It’s a<br />

kind of relaxation for him,” says Sigrid Wolf with a laugh. “Well, it<br />

certainly doesn’t bother me,” the farmer himself comments. Martin<br />

Wolf sums it up: “He has the three-pointed star in his heart.” r<br />

The Wolfs also use<br />

their U 500 to collect grain<br />

from the fields.

A highly manoeuvrable fire-fighter<br />

The volunteer fire service in Wuppertal this Spring began using a Unimog U 20 tank tender.<br />

LAST YEAR, the local volunteer fire service<br />

in the Lagerfeld district of Wuppertal was<br />

faced with having to replace an ageing allwheel<br />

drive fire-fighting tank tender. The old<br />

one had always been a faithful servant, but<br />

it had some weaknesses too. In tight spaces<br />

and on steeply inclined terrain, especially,<br />

it quickly came up against its limits. This<br />

was problematic particularly in view of the<br />

fact that the Wuppertal municipal area is<br />

over 29 percent forest and fields, much of it<br />

extending over quite hilly terrain. That was<br />

reason enough for the fire service to focus on<br />

the ability to handle tough terrain when<br />

choosing their new vehicle.<br />

They soon found the ideal candidate: a<br />

Unimog U 20 configured as a TLF 10/20 firefighting<br />

tank tender with a Schlingmann<br />

body. Its short 2700 millimetre wheelbase<br />

provided the Wuppertal fire-fighters with the<br />

manoeuvrability they were looking for. And,<br />

of course, the superior off-road capability<br />

of the Unimog was a further benefit. The<br />

mounted body incorporates everything necessary<br />

for first-phase fire-fighting operations:<br />

a 2,400 litre tank, a pump with a throughput<br />

rate of 2,000 litres a minute, a front splash<br />

guard as a self-protection feature and for<br />

damping-down wide-area fires, and a water<br />

Christian Reeker (left), head of the Engineering and<br />

Logistics department, and fire chief Karl Grünewald<br />

are already convinced of the U 20’s merits.<br />

UNIMOG 2 • 2010 • FIRE-FIGHTING 13<br />

cannon mountable on the roof – all operable<br />

with the vehicle in motion.<br />

Rapid response in an emergency<br />

For fire chief Karl Grünewald the “little”<br />

Unimog has already proved its worth: “Last<br />

Monday we had a 500 square metre forest<br />

fire on a difficult-to-access slope. With our<br />

old tender we would not have got to it.”<br />

Thanks to the U 20 TLF 10/20, the firefighters<br />

did not have to lay their hoses laboriously<br />

across the surrounding scrub<br />

and then slowly follow the fire’s path. The<br />

Unimog U 20 reached the fire quickly, and<br />

the ground jets and roof-mounted cannon<br />

soon had it all under control.<br />

Christian Reeker, head of the Engineering<br />

and Logistics department and responsible<br />

for procurement, is just as certain that the<br />

Unimog U 20 will prove a hit: “At the moment<br />

our TLF forest tender is the only one of its<br />

kind in Germany. But the idea is so good that<br />

more are bound to follow.” r

14 Service OPEN-CAST • UNIMOG MINING 2 • 2010 UNIMOG 2 • 2010<br />

Extreme workhorses<br />

Extreme conditions at the Hambach open-cast mine demand<br />

maximum performance from personnel and machinery alike.<br />

The off-road capability and broad-ranging flexibility of the<br />

Unimog make it a highly respected partner.<br />

ROUND THE CLOCK, seven days a week, 365 days a year, the staff and<br />

vehicle fleet at the Hambach open-cast mine are on continuous duty. Its<br />

immense size alone, but especially the extreme ground conditions and<br />

the varying applications in which they need to be deployed at the mine,<br />

demand maximum performance from personnel and machinery alike.<br />

That is why operator RWE Power has for years relied on the Unimog –<br />

in a range of variants according to the application: from the U 400 up<br />

to the U 5000, all models are represented. Most of them, however, are<br />

the ultra-rugged off-road specialists of the Unimog U 4000 and U 5000<br />

series. The Unimog can cope with the most demanding of routes along<br />

muddy tracks and over rugged terrain, climbing huge inclines, and<br />

working their way down some extremely steep slopes, too.<br />

The broad range of applications of the Unimog on the site reflect the<br />

enormous dimensions of the open-cast mine located right on the outskirts<br />

of Cologne: As far as the eye can see, there are miles of terraced<br />

cuttings extending hundreds of metres down into the ground. But the<br />

main feature of the Hambach mine is the millions of tonnes of sand,<br />

clay and gravel. These so-called covering layers conceal the valuable<br />

lignite, or brown coal. The site looks like some fantastical moonscape,<br />

with gigantic excavators seemingly grazing across the unending barren<br />

plains of this artificial landscape like some species of colossal<br />

monster.<br />

In all weather and on any ground<br />

And among them, some 50 yellowish-gold coloured Unimog wend their<br />

way around the approximately 85 square kilometre site – in all weathers<br />

– with what seems almost stoic calmness. Thanks to their all-wheel<br />

drive, differential lock and heavy-duty thick-treaded tyres, they are able<br />

to handle even extremely slippery terrain in rain, snow and icy con -<br />

ditions. “If you want to drive around extreme terrain such as this, a<br />

Unimog is essential. Its off-road capability is simply unbeatable,” comments<br />

Jörg Rübsteck, a member of the RWE Power Vehicle Service staff.<br />

Another key factor for the company, which is provided with service<br />

backup by RKF-Bleses, is that vehicles can be tailored to specific operations.<br />

“The Unimog offers us lots of different body mounting options.<br />

That means we can use one vehicle model for a wide variety of purposes,”<br />

Rübsteck goes on. As a universal master of all tasks, the Unimog<br />

handles virtually every transport job at the mine: Fitted with a double<br />

cab, it is used to transport work crews; as a flat-bed truck, it carries<br />

materials and tools; and configured as a tanker it distributes water and<br />

Imposing dimensions:<br />

Alongside the gigantic excavators<br />

at the Hambach mine the Unimog<br />

looks quite tiny.

UNIMOG 2 • 2010 • OPEN-CAST MINING 15<br />

fuel. “The Unimog with diesel tanks mounted on them have to be<br />

particularly reliable, running round the clock, supplying diesel to<br />

construction machinery such as bulldozers. If the Unimog broke<br />

down, a lot of machines and vehicles would be forced to stop work.”<br />

There are also Unimog on-site mounted with Palfinger cranes and<br />

flat-bed load spaces, used primarily for repair and maintenance work,<br />

and there are also units fitted with box bodies, used for servicing of<br />

large-scale machinery. “They are our ‘workhorses’. Without them<br />

practically nothing would get done here,” asserts Rübsteck with a grin.<br />

The all-rounders from <strong>Mercedes</strong>-<strong>Benz</strong> also serve as fire-fighting and<br />

emergency vehicles, as well as providing Winter ice and snow clearing<br />

services. Because those vehicles, more than any other, have to get to<br />

their destination rapidly, however tough the conditions may be.<br />

In view of the difficult terrain on which the vehicles operate, RWE<br />

Power places great value in their safety features. Pendulum strike and<br />

roof load tests to the ECE R29 standard passed by the Unimog’s all-steel<br />

cab were powerful arguments in favour of the vehicles, alongside their<br />

reliable brake systems and seat-integrated safety belts. “We have to be<br />

able to rely on our vehicles. It is a reassuring feeling for us to send out<br />

our drivers in a Unimog,” says Herbert Töller, RWE Power’s head of<br />

Vehicle and Transport Service. “The Unimog is simply an exemplary<br />

model when it comes to safety.” The Unimog not only sets standards in<br />

terms of safety, but also with regard to low vibration. That was a key<br />

All-wheel drive and differential locks help the Unimog achieve outstanding off-road<br />

capability – an absolutely vital aspect of fire-fighting operations!<br />

ü

16 OPEN-CAST MINING • UNIMOG 2 • 2010<br />

The wide-ranging body and equipment mounting options exactly meet the needs<br />

of RWE Power: Here a Unimog configured as a tanker is supplying essential fuel.<br />

“The Unimog is vital”<br />

Jörg Rübsteck, from the RWE Power Vehicle Service staff, talking about vehicle outfitting options<br />

developed specially for open-cast mining and how the Unimog handles extreme situations.<br />

Jörg Rübsteck is thoroughly impressed by the Unimog.<br />

Unimog Magazine: Mr. Rübsteck, your<br />

company has been relying on the Unimog<br />

for a long time …<br />

Jörg Rübsteck: Yes, indeed. The Unimog has<br />

been working at the Hambach mine since its<br />

very beginnings. We even still have a really<br />

early Unimog still in operation: a U 900, built<br />

in 1978. It is the oldest in our field. We are<br />

still using it to transport material.<br />

Unimog Magazine: What makes the Unimog<br />

so attractive for open-cast mining specifi -<br />

cally?<br />

Jörg Rübsteck: We were convinced above all<br />

by its versatility. The Unimog is tops<br />

wher ever you need to get a vehicle across the<br />

toughest of terrain – whether with a diesel<br />

tanker or a crane mounted on it. A particular<br />

challenge is that the ground conditions<br />

on-site are continually changing. Yet the<br />

Unimog never lets us down.<br />

Unimog Magazine: How do the vehicles cope<br />

with the extreme conditions?<br />

Jörg Rübsteck: Very well. Our Unimog are<br />

fitted with special features which additionally<br />

protect them against dust and mud. We devel-<br />

selection criterion for RWE. Because only vehicles capable of minimising<br />

vibration will protect and preserve the health of their drivers.<br />

As part of its strong commitment to occupational health and safety,<br />

RWE Power conducts vibration measurements on all vehicles. These<br />

are applied to determine how long a driver can operate a vehicle without<br />

interruption before it poses a health risk. “The operating time of the<br />

Unimog is six hours per shift. That is a very good length of time given<br />

the conditions under which we operate,” Rübsteck states. Thanks to its<br />

helical-spring deformable chassis, rigid cab mounting and air-sprung<br />

comfort cab seat, the Unimog provides a workplace which not only falls<br />

well within stipulated vibration limits but also retains a very high<br />

degree of comfort and quiet even in extreme conditions.<br />

Just how extraordinary the Unimog’s operations at the Hambach<br />

mine are is also illustrated by the fact that <strong>Mercedes</strong>-<strong>Benz</strong> conducts<br />

vehicle testing at the site. “It provides us with an ideal test setting,<br />

because the brown coal, water and mud create really extreme conditions,”<br />

explains Unimog product manager Jan Debler. Those extreme<br />

conditions can be used to simulate scenarios which would otherwise<br />

take years to recreate. They enable <strong>Mercedes</strong>-<strong>Benz</strong> to test the Unimog<br />

in a kind of time-lapse environment. “We place great value in being<br />

oped the brake encapsulation installed in all<br />

our vehicles together with <strong>Mercedes</strong>-<strong>Benz</strong><br />

for example. It isolates the brakes behind a<br />

steel covering, so protecting them against<br />

dirtying. The brakes are much more durable<br />

as a result. The heavy-duty tractor tread on<br />

the tyres prevents dirt from getting trapped<br />

in them and additionally provides optimum<br />

traction on rugged terrain.<br />

Unimog Magazine: How long do the Unimog<br />

run for?<br />

Jörg Rübsteck: It depends on what job they<br />

are doing. On average, we run Unimog for<br />

between 7 and 13 years. During that time, they<br />

cover between 180,000 and 300,000 kilo -<br />

metres. That is a lot – especially given the<br />

extreme conditions on-site. 200,000 kilo -<br />

metres at an open-cast mine is almost comparable<br />

to twice or even three times the<br />

mileage on the road. r

able to conduct practical trials in real-life operation at a customer location<br />

and incorporate the results into the ongoing technical development<br />

of our vehicles,” says Debler. That works also thanks to partners<br />

such as RWE Power AG. r<br />

r Hambach mine<br />

Operations at the Hambach open-cast mine close to the village of the<br />

same name began in September 1978. It was six years before the first<br />

brown coal was extracted from a depth of 160 metres. The 700 million<br />

cubic metres of sand, clay and gravel above it – the so-called spoil – had<br />

to be moved first. Today the Hambach mine, with its workforce of some<br />

1,500 people, mines some 40 million tonnes of brown coal a year from<br />

depths of down to 370 metres, excavating some 250 million cubic metres<br />

of spoil in the process. The brown coal from the mine is used to generate<br />

electricity at the nearby power stations operated by RWE, which make up<br />

around 25 percent of Germany’s total energy mix.<br />

Advertisement<br />

Ehranger Straße 101<br />

D-54293 Trier<br />

Postfach 8051<br />

D-54181 Trier<br />

Unimogstraße 1<br />

76571 Gaggenau<br />

Tel.: +49 (0) 651 6867-124<br />

Fax.: +49 (0) 651 64146<br />

UNIMOG 2 • 2010 • OPEN-CAST MINING 17<br />

Some of the 50 Unimogs are fitted with a Palfinger crane. They are used primarily<br />

to carry out repair work.<br />

MULTIFUNCTIONAL<br />

POWERHOUSE<br />

Cable winches, compressors, hydraulic<br />

supports, flatbed body or crane? Or everything<br />

together? Werner makes sure that all<br />

your equipment is not only installed perfectly,<br />

but also that it fits together perfectly.<br />

vertrieb@werner-trier.com<br />

www.werner-trier.com

18 TRANSPORT• UNIMOG 2 • 2010<br />

Sunday driving ban? Not for the Unimog<br />

Eugen Betz from St. Johann near Reutlingen has been a self-employed transport operator serving the construction<br />

trade since 1975, and he is a convinced Unimog fan. He also uses his U 500 for Winter gritting and snow clearing.<br />

“MY U 500 IS simply the ideal vehicle for me<br />

– and not just as a tractor rig,” Eugen Betz comments<br />

enthusiastically. “I need it all year round.<br />

I supply machinery and building materials on<br />

the low-loader to construction sites around the<br />

district. During flat periods when that work is<br />

not available I can do transport jobs using different<br />

trailers without having to modify the<br />

vehicle itself. And in Winter, when there is no<br />

construction work going on, I can earn good<br />

money gritting and snow clearing.”<br />

That is why his U 500 additionally has a ballhead<br />

trailer hitch and on-spot tyre chains. The<br />

U 500 is his fourth Unimog in 30 years. In the<br />

early days he also drove trucks that were somewhat<br />

more powerful: “But after comparing the<br />

advantages and disadvantages, I stuck with the<br />

Unimog,” he recalls. He uses the 10 metre long<br />

low-loader to transport construction machinery<br />

to sites around the Schwäbische Alb hill areas.<br />

The manoeuvrability and compact design of<br />

the U 500, with its short wheelbase of just<br />

3350 millimetres, make the vehicle easy to<br />

handle: “I can easily get to sites in town centres,<br />

negotiating tight bends, narrow, winding<br />

streets and tricky one-way systems where a<br />

truck would often not be able to get,” Betz<br />

reports with a grin. Another important aspect<br />

for him is that the Unimog is registered as an<br />

agricultural tractor rig, which means he does<br />

not have to pay road tolls when travelling<br />

unladen. And he is not subject to the Sunday<br />

driving ban on motorways. The state-of-the-art<br />

With his 10 metre long low-loader Eugen Betz<br />

transports construction machinery quickly and reliably<br />

to sites around the Schwäbische Alb area.

The U 500 is a boon to Eugen Betz because of its registration as a tractor rig.<br />

As a result, he has no road tolls to pay, and is not subject to overtaking bans and<br />

driving restrictions which affect trucks.<br />

UNIMOG 2 • 2010 • TRANSPORT 19<br />

“I can easily get to sites in town centres,<br />

negotiating tight bends and narrow, winding streets.”<br />

Eugen Betz, self-employed transport operator serving the construction trade<br />

BlueTec ® engine OM 906 LA, developing<br />

210 kW of power output and conforming to the<br />

Euro 5 emissions standard, is another key<br />

factor for Betz: “It gives me plenty of power<br />

and speed; the automatic transmission means<br />

I can concentrate fully on driving; and by<br />

meeting the high emissions standard I am<br />

allowed into any designated pollution control<br />

zone where other trucks are not. As a result,<br />

my consignments are guaranteed to be<br />

delivered punctually every time.”<br />

The all-round visibility offered by the Unimog’s<br />

cab provides Betz with a clear overview<br />

at all times – and that is especially important<br />

for his Winter work on the roads. “Only the<br />

U 500 allows me to control the snow plough so<br />

tightly and accurately.” He is assigned to keep<br />

clear some 180 kilometres of roads around<br />

Würtingen and St. Johann in the Winter, which<br />

means he is out and about from four in the<br />

morning, with a snow plough mounted on the<br />

front and a grit silo on the flat-bed load space.<br />

“My gritting and snow clearing contract with<br />

the local authority also means I pay no road tax<br />

between November and March,” he goes on.<br />

“A lot of other operating costs are much lower<br />

than for a truck too.” The insurance classification<br />

for the U 500 is also useful. “As a light<br />

industrial tractor rig, it runs with a black<br />

licence plate at the same rate of premium as<br />

an agricultural tractor.” And there are more<br />

benefits, as he outlines: “Incidentally, the<br />

U 500 also needs just four tyres of all the<br />

same size. To handle the identical transport<br />

capacity with a truck, I would need a doubletyred<br />

three-axle rig, which would mean buying<br />

10 in total.”<br />

All-round talent: working all year round<br />

The flat-bed load space is particularly valuable<br />

to Betz. “It is not only excellent for mounting<br />

the gritter, but is also useful in Summer for<br />

carrying ballast, occasionally also a fuel tank<br />

to refuel construction machinery on-site, but<br />

most of all for transporting gravel and excavated<br />

spoil.” This fills a gap which is often<br />

left between different types of construction<br />

machinery and trucks. The low-loader is then<br />

parked up, and a three-axle trailer is hitched<br />

in its place. The trailer has air suspension of<br />

course, because a trailer with leaf springs would<br />

be continuously bouncing, as Betz asserts. And<br />

he adds: “Thanks to the Unimog’s tight chassis<br />

setup, the trailer keeps nicely in line with the<br />

towing vehicle, and does not wobble around.”<br />

For his tandem-axle trailer he needs the additional<br />

hitch to DIN 74051 with the 40 mm bolt.<br />

“With that I can easily tow a 30 tonne load and<br />

still keep to the 40 tonne gross vehicle weight<br />

limit without having to get a special permit,<br />

which I would need for a truck towing such<br />

a load.”<br />

He has extra space on the flat-bed load space<br />

too, providing even greater flexibility. “Only<br />

the all-round capabilities of the Unimog allow<br />

me to keep busy all year round with a single<br />

vehicle. Thanks to it, I have virtually no flat<br />

periods in between.” He is also full of praise for<br />

the Unimog distributor Schmalz + Sohn in<br />

Oberndorf: “I will certainly be staying faithful<br />

to both: to the Unimog and to my local service<br />

centre.” r<br />

Eugen Betz and Unimog – a good partnership.<br />

Betz will definitely be sticking with his all-purpose<br />

workhorse in future.

20 DUAL-MODE OPERATION • UNIMOG 2 • 2010<br />

“Green Logistics”<br />

on road and rail<br />

Rail freight operator DB Schenker Rail Deutschland AG, a subsidiary of German national rail<br />

company Deutsche Bahn, has for approaching two years now been running a pilot project at<br />

three of its locations deploying the <strong>Mercedes</strong>-<strong>Benz</strong> Unimog as a railway marshalling vehicle.<br />

The results it has delivered have been outstanding in terms of economy and eco-friendliness.<br />

BOTH ON THE road and on the railways,<br />

DB Schenker is a leading international logistics<br />

company. As part of the landmark “Green<br />

Logistics Networks” project, the Deutsche<br />

Bahn subsidiary is interlinking its various<br />

modes of transport not only with a view to<br />

maximising commercial benefit but also,<br />

especially, according to ecological considerations,<br />

in order to provide its customers with<br />

a carbon-optimised transport chain. Within<br />

that remit, DB Schenker Rail, Europe’s largest<br />

rail freight operator, is also currently running<br />

a pilot project at three locations in Germany<br />

involving the use of a Unimog U 400 as an<br />

environmentally friendly railway marshalling<br />

vehicle. The company has been operating the<br />

Unimog for almost two years now in what is<br />

one of the largest and most efficient marshalling<br />

yards in Germany, at its Cargo Centre<br />

in the major rail hub city of Nuremberg. The<br />

two other dual-mode Unimog are being run<br />

under the control of DB Schenker Rail’s<br />

Hanover Cargo Centre. In contrast to the<br />

Nuremberg operation, in Hanover the company<br />

is running the vehicles as a service provider<br />

directly on behalf of its customers, on their<br />

own sidings – at Sappi GmbH in Alfeld and at<br />

Panopa GmbH in Wolfsburg-Vorsfelde.<br />

Environmentally friendly thanks to BlueTec ®<br />

technology<br />

“We were looking to adopt a new approach to<br />

marshalling, and we initially commissioned<br />

a degree thesis to investigate in detail alternative<br />

concepts for marshalling vehicles,”<br />

explains Werner Matz, manager of the<br />

Nuremberg Cargo Centre of DB Schenker Rail<br />

Deutschland AG. “The outcome of the study<br />

revealed the dual-mode Unimog to be the<br />

most suitable system for our needs. Following<br />

on from those findings, in 2008 we procured<br />

a Unimog U 400 with rail operation systems<br />

from Zwiehoff/Zagro as a replacement for

an ageing marshalling locomotive,” Werner<br />

Matz continues. The core task of the dualmode<br />

Unimog in Nuremberg is to transport<br />

freight cars into the maintenance shed. The<br />

serviced and repaired cars are then pulled<br />

out of the shed again by the Unimog into the<br />

marshalling yard where they are ready to be<br />

put back into operation. Claus Barth, group<br />

leader at DB Schenker Rail in Nuremberg,<br />

comments: “We are particularly impressed<br />

by the low consumption levels of the Unimog.<br />

Between 5 and 6 litres of diesel per hour in<br />

operation is a major savings potential compared<br />

to a locomotive.” And not just that: The<br />

locomotive’s engine is not usually switched<br />

off for brief periods of inactivity, whereas<br />

the Unimog can be. Werner Matz comments:<br />

“That is exactly the right kind of solution<br />

for a company such as ours, which takes the<br />

issue of Green Logistics very seriously and<br />

is looking to drive forward developments in<br />

the field. In fact, it is also something which<br />

transport companies using our services<br />

increasingly expect of us.” And the Unimog<br />

offers another major advantage over a<br />

locomotive: “Since we have been using the<br />

Unimog instead of a marshalling locomotive,<br />

we have had much better working conditions<br />

UNIMOG 2 • 2010 • DUAL-MODE OPERATION 21<br />

r TECHNICAL FEATURES AT A GLANCE<br />

� State-of-the-art, environmentally<br />

friendly Euro 5 diesel technology<br />

� Permanent all-wheel drive and<br />

differential locks for maximum<br />

pulling power<br />

� Torque converter clutch for smooth<br />

drive-off when pulling heavy loads<br />

� Full traction thanks to high friction<br />

coefficient between rubber tyre and rail<br />

� High-swinging rail guidance system<br />

for safe tracking<br />

� Rail car brake system for<br />

800 tonnes/52 axles<br />

� User-friendly remote control to<br />

safety class AK6<br />

� EBA approval, licensed to operate<br />

on DB network infrastructure<br />

r DB SCHENKER RAIL<br />

“The dual-mode Unimog has worked<br />

very well for us to date,” comments<br />

Werner Matz.<br />

With sales of some 3.7 billion Euros,<br />

25,000 employees and 3,300 rail heads<br />

served in Germany alone, DB Schenker Rail<br />

is Europe’s leading rail freight operator.<br />

Its range of services, working together with<br />

a number of European subsidiaries to provide<br />

cross-border transport services all from one<br />

source, incorporates complete trains, single-car<br />

transports and combination consignments.<br />

The focus of its rail freight operations is<br />

on bulk transports for the iron and steel,<br />

chemicals, oil, building materials and waste<br />

management industries.<br />

ü

22 DUAL-MODE OPERATION • UNIMOG 2 • 2010<br />

“The Unimog’s fuel consumption is astonishingly low,<br />

at 5.5 litres of diesel per operating hour on average.”<br />

Werner Matz, manager of the Nuremberg Cargo Centre of DB Schenker Rail Deutschland AG<br />

in the maintenance shed. The Unimog,<br />

with its state-of-the-art BlueTec ® technology,<br />

goes virtually unnoticed – both in terms of<br />

emissions and in terms of noise.”<br />

Economical: low fuel consumption<br />

The Unimog’s low emissions, based on its<br />

environmentally friendly engine technology,<br />

were also a key factor in the decision to deploy<br />

the vehicle at the Wolfsburg-Vorsfelde site.<br />

Ralf Peters, responsible for marshalling planning<br />

at the Hanover Cargo Centre, explains:<br />

“The marshalling vehicle frequently has to go<br />

into the shed. Our customer Panopa was no<br />

longer willing to accept the diesel locomotive<br />

we had previously been using for the job<br />

inside the shed because the soot emissions,<br />

in particular, were harmful to staff. By using<br />

the Unimog we have now regained our customer’s<br />

full acceptance – an absolutely vital<br />

factor for us as a service provider of course.”<br />

Panopa operates an interim storage facility<br />

for steel coils in Vorsfelde near Wolfsburg.<br />

Ralf Peters reports: “DB Schenker Rail supplies<br />

steel on behalf of Panopa to the VW<br />

press plant in Fallersleben on a just-in-time<br />

basis for the plant’s three-shift operations.<br />

The Unimog handles all the marshalling<br />

work on the Panopa site – unlinking the<br />

incoming trains and transferring cars to the<br />

appropriate loading and unloading points.<br />

It also assembles trains and makes available<br />

car groups for outgoing goods shipments.”<br />

Ralf Peters is likewise very happy with the<br />

performance of his Unimog: “Marshalling at<br />

this location is a particular challenge, as we<br />

pull around 500 tonnes on average, and at<br />

peak times occasionally even 800 tonnes.<br />

Moreover, the rail yard at Panopa features a<br />

considerable curve radius as well as a small<br />

incline, which poses more difficulties for the<br />

marshalling vehicle. But the Unimog is able<br />

to deal perfectly with those challenges too!”<br />

Wienhold Averbeck, deputy head of financial<br />

controlling at the Hanover Cargo Centre<br />

and responsible for the dual-mode Unimog<br />

project, is more impressed by the economy of<br />

the vehicle: “We have to date run the dualmode<br />

Unimog for almost 4,000 hours, and<br />

it has consumed just 5.5 litres of diesel per<br />

Finally cleaner air: Compared to locomotives, the emissions of a Unimog in the maintenance shed<br />

are barely noticeable. That represents a considerable improvement in working conditions for staff.<br />

hour on average. That represents an enormous<br />

saving compared to the diesel locomotive<br />

we had previously been using, and is<br />

in itself sufficient to make our use of the<br />

Unimog worthwhile.”<br />

Operator comfort highly appreciated<br />

DB Schenker Rail is also deploying a dualmode<br />

Unimog in its role as a service provider<br />

to Sappi GmbH in Alfeld, and has already<br />

succeeded in convincing the customer of its<br />

merits. Detlef Spyra, Sappi procurement<br />

manager and head of rail operations,<br />

explains: “To ensure our production operations<br />

run smoothly and efficiently, it is<br />

important for us that DB Schenker Rail is<br />

able to transport all the required rail cars<br />

punctuality and reliably to where they are<br />

needed. The transports primarily involve raw<br />

materials for the manu facture of high-grade<br />

special papers”. Detlef Spyra goes on: “Previously<br />

DB Schenker Rail did the job using a<br />

four-axle locomotive. The dual-mode Unimog<br />

has been operating at our plant for about<br />

18 months now, and we are very happy with<br />

The Unimog is dismounted quickly and easily from the rails and can be driven<br />

on the road around the plant to its next work location.

the new setup.” Egbert Henkel, marshalling<br />

vehicle driver at the Alfeld facility, greatly<br />

appreciates the comfort the Unimog offers.<br />

“After having undergone a short period of<br />

induction in use of the dual-mode Unimog,<br />

I am now a big fan of it. The ability to dismount<br />

the vehicle from the rails, drive it to<br />

another location around the plant and then<br />

mount it back on the rails there means I am<br />

Advertisement<br />

much more flexible than when using a railbound<br />

vehicle.”<br />

Maximum availability is assured<br />

The service backup offered for the Unimog<br />

system is also a hit: “The nearby <strong>Mercedes</strong>-<br />

<strong>Benz</strong> customer service centre is able to<br />

carry out most maintenance work on-site,<br />

so maximum availability of the vehicle is<br />

UNIMOG 2 • 2010 • DUAL-MODE OPERATION 23<br />

The U 400 offers very high performance<br />

capability: it is able to move as much as<br />

800 tonnes along the rails with ease.<br />

assured,” affirms Lothar Pallant, who was<br />

one of the first operators to drive the Unimog<br />

in Alfeld.Based on its positive experience<br />

with the dual-mode Unimog, the Hanover<br />

Cargo Centre is already planning ahead.<br />

Wienhold Averbeck reveals the thinking:<br />

“We are already looking into a number of<br />

other potential applications for the Unimog<br />

as a marshalling vehicle.” r

24 ENGINEERING • UNIMOG 2 • 2010<br />

Flexible,<br />

manoeuvrable,<br />

agile – thanks to<br />

all-wheel steering<br />

Handling any bend with all-wheel steering: auxiliary rear<br />

axle steering makes the Unimog even more adaptable and<br />

manoeuvrable. Three practical examples.<br />

59 METRES ABOVE NORMAL ZERO. 10 o’clock in the morning in a<br />

forest clearing 40 kilometres south of Potsdam. A heavy machine is<br />

parked on the cycle path. A prototype: the U 400 with all-wheel steering<br />

and a 3600 millimetre wheelbase. Mounted on its right-hand side<br />

is a special unit designed for root barrier cutting – the WSF 800. The<br />

machine is on operations for gardening and landscaping company Feind<br />

based in Lübben. The aim of the work is to protect the asphalt, which<br />

has already been pushed up by roots at many points, against further<br />

destruction. The WSF 800 was developed by Feind in conjunction with<br />

construction machinery company AS Baugeräte.<br />

Accessing the location through rough terrain and working on the narrow<br />

cycle paths with no side surfacing demands the right tools. And in<br />

that respect company proprietor Reinhardt Feind swears by the Unimog<br />

– and has been doing so for the last 20 years. “We have been relying on<br />

Unimog since the company was founded back in 1990. We have the full<br />

range in our fleet, from the U 2100 to the U 500,” he goes on. It is a relationship<br />

of trust which remains on a firm foundation to this day. Or on<br />

24 wheels, to be precise. Because the R. Feind gardening and landscaping<br />

business operates six Unimog as part of its basic portfolio. The sixcylinder,<br />

231 hp engine of the U 400 with all-wheel steering emits a<br />

reassuring brumming noise as its rotating cutter neatly chops away the<br />

roots. In the same pass it lays down a root-barrier membrane and then<br />

back-fills and seals the trench it has made. The company boss is particularly<br />

proud of this U 400. Its steerable rear axle is what made it possible<br />

to do today’s job in the first place. “This is the first instance of a<br />

U 400 with this special equipment configuration on cutting operations,”<br />

he reports.<br />

Round the bend with the cutter<br />

“The particularly tricky part about using this vehicle was cutting round<br />

bends,” the head of the root barrier department at Feind, Norman Fruth,<br />

recalls. The cutter disk mounted on the right-hand side of the vehicle<br />

parallel to the direction of travel at a height of 50 centimetres above the<br />

ground must be guided smoothly round bends. That is the only way to ü

UNIMOG 2 • 2010 • ENGINEERING 25<br />

On narrow, winding cycle paths the all-wheel steering of the<br />

U 400 operated by gardening and landscaping company<br />

R. Feind is very practical for root-barrier cutting.

26 ENGINEERING • UNIMOG 2 • 2010<br />

Maximum manoeuvrability – all-wheel steering makes it possible. This optimum<br />

starting position is a key criterion in favour of the U 400 for Reinhardt Feind.<br />

Low-slung side windows and large rear windows ensure a clear all-round overview<br />

even when faced by heavy snow drifts. Heated air driers additionally help keep the<br />

driver warm.<br />

The root cutter cuts a five centimetre wide trench next to the cycle path in which<br />

the RootBarrier ®<br />

membrane is laid. It is the ideal method of stopping roots.<br />

ensure a high-quality job. The solution found was a steerable rear axle.<br />

When the driver turns the front wheels to the left on a left-hand bend,<br />

the rear wheels move even further to the right. On tight left-hand bends,<br />

all four wheels are steered to the left, causing the Unimog to drive in a<br />

circle – a very tight circle. Because, despite the long wheelbase, the allwheel<br />

steering reduces the vehicle’s turning circle to just 13.2 metres.<br />

Steering with a flexible rear axle is possible up to a maximum speed<br />

of 30 km/h; the system then switches automatically to straight-ahead<br />

running with only the front axle controlling the steering. Consequently,<br />

neither the vehicle’s maximum speed nor its safety is affected. “The<br />

hydrostatic drive system was also very important for us,” company boss<br />

Feind adds. “It alone enables high levels of power transmission while<br />

maintaining consistent and precise vehicle movement, because the rate<br />

of working can be infinitely varied at a constant engine speed. It’s also<br />

ideal for cutting verges.” As if in agreement, the low-emission Euro 5<br />

standard engine of the U 400 growls away, working on metre by metre<br />

through the roots in the ground.<br />