Equipment YOU Need.sdr - PCI Magazine

Equipment YOU Need.sdr - PCI Magazine

Equipment YOU Need.sdr - PCI Magazine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

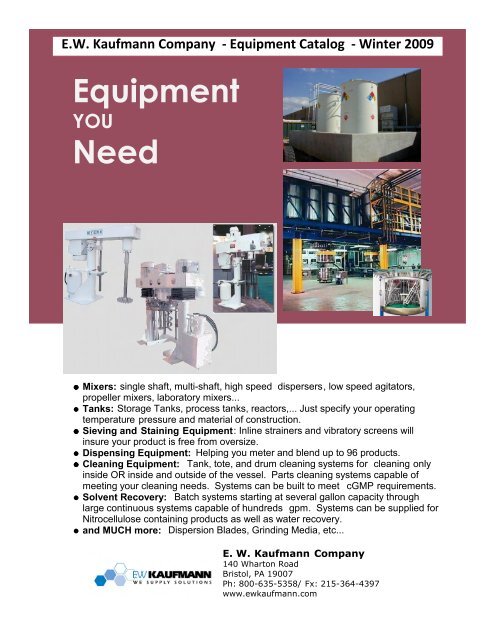

<strong>Equipment</strong><br />

<strong>YOU</strong><br />

<strong>Need</strong><br />

Mixers: single shaft, multi-shaft, high speed dispersers, low speed agitators,<br />

propeller mixers, laboratory mixers...<br />

Tanks: Storage Tanks, process tanks, reactors,... Just specify your operating<br />

temperature pressure and material of construction.<br />

Sieving and Staining <strong>Equipment</strong>: Inline strainers and vibratory screens will<br />

insure your product is free from oversize.<br />

Dispensing <strong>Equipment</strong>: Helping you meter and blend up to 96 products.<br />

Cleaning <strong>Equipment</strong>: Tank, tote, and drum cleaning systems for cleaning only<br />

inside OR inside and outside of the vessel. Parts cleaning systems capable of<br />

meeting your cleaning needs. Systems can be built to meet cGMP requirements.<br />

Solvent Recovery: Batch systems starting at several gallon capacity through<br />

large continuous systems capable of hundreds gpm. Systems can be supplied for<br />

Nitrocellulose containing products as well as water recovery.<br />

and MUCH more: Dispersion Blades, Grinding Media, etc...<br />

E. W. Kaufmann Company<br />

140 Wharton Road<br />

Bristol, PA 19007<br />

Ph: 800-635-5358/ Fx: 215-364-4397<br />

www.ewkaufmann.com

<strong>Equipment</strong><br />

High Speed<br />

Dispersers<br />

Multi-Shaft<br />

Mixers<br />

Media Mills<br />

Presses<br />

Low Speed<br />

Agitators<br />

Lab Mixers<br />

Storage Tanks<br />

Reactors<br />

Solvent<br />

Recovery<br />

Systems<br />

Dispensing<br />

Systems<br />

Tank & Parts<br />

Washing<br />

<strong>Equipment</strong><br />

Sieving and<br />

Straining<br />

equipment<br />

Dispersion<br />

Blades<br />

Grinding Media<br />

Service <strong>YOU</strong> expect<br />

E. W. Kaufmann Company has built a reputation for excellence in<br />

our industry. No one works harder to earn your business, or does<br />

more to keep it.<br />

Manufacturers<br />

<strong>YOU</strong><br />

Know<br />

A recognized<br />

leader in the<br />

industry. We<br />

partner with only<br />

the best suppliers.<br />

A Company <strong>YOU</strong> Count On<br />

Proudly Representing:<br />

E. W. Kaufmann Company is a Specialty Chemical and <strong>Equipment</strong><br />

Distributor focused on supporting our customers. Our experienced<br />

technical sales staff are always available to offer the latest<br />

technologies from our broad supplier base.<br />

For additional details on our <strong>Equipment</strong> Lines OR to review our<br />

extensive line of Specialty Chemicals:<br />

Phone 800-635-5358<br />

Visit our website: www.ewkaufmann.com

2009 <strong>Equipment</strong> Catalog ..................................................................... 1<br />

Laboratory <strong>Equipment</strong> ................................................ 1<br />

Dispersers ................................................................... 3<br />

Agitators ...................................................................... 5<br />

Multi Shaft Mixers ....................................................... 8<br />

Portable Mixers ........................................................... 10<br />

Dual Axis Mixers ......................................................... 12<br />

Ram Presses ............................................................... 13<br />

Media Mills ................................................................... 15<br />

Sieving & Straining ..................................................... 16<br />

Solvent Recovery Systems ........................................ 19<br />

Tank Cleaning <strong>Equipment</strong> .......................................... 21<br />

Dispensing ................................................................... 24<br />

Tanks ............................................................................ 29<br />

Disperser Blades ......................................................... 31<br />

Agitator Blades ........................................................... 34<br />

Grinding Media ............................................................ 36<br />

Used <strong>Equipment</strong> .......................................................... 38<br />

Engineering Services ................................................. 39<br />

Engineering Services.<br />

........................................................................... 39<br />

Material Metering System ........................................... 40<br />

Pre polymer Reactor ................................................... 42<br />

Raw Materials ..................................................................................... 43<br />

ii. Call: 800‐635‐5356 | visit: www.ewkaufmann.com<br />

Table of Contents<br />

THANK <strong>YOU</strong><br />

E.W. Kaufmann Company wishes<br />

to thank <strong>YOU</strong>, our customers and<br />

principals for their continued<br />

patronage.<br />

January 2009 Page | iii

DisperseTech<br />

<strong>Equipment</strong> Catalog<br />

1 1/4 Quart Stock Pots<br />

Made from non-porous 18-8, Type 304 stainless steel. These stainless stock pots<br />

feature a special conductive bottom to distribute heat evenly and reduce energy<br />

consumption, and they are equipped with strong welded loop handles for carrying<br />

ease. Covers are flat for convenient stacking and storage.<br />

1 1/4 Quart Stainless Steel Tank 4 1/8" Diameter x 5 3/4" Height<br />

MM Industries, Inc<br />

RBF 10<br />

The VORTI-SIV Lab ModelRBF-10 (10" screen diameter) is one of the most advanced small batch<br />

sieving machines on the market. The units are totally enclosed and heavily constructed. Weighing<br />

in at 80 lbs. each, they are driven by single or three phase, open construction, TENV, TEFC, or<br />

X.P., 1/3 or 1/2 HP motors. The TENV, TEFC or X.P. motor adds 3" to 6" in height to the standard<br />

21" tall single deck model. These models are extremely effective on many wet and dry products.<br />

Popular uses include quality control, "scalping" of powders, liquid straining, product reclamation,<br />

and particle size separation.<br />

Successfully processed products include:Paint, Inks, Cosmetics, Dental Materials,<br />

Pharmaceuticals, Paper Coatings, Powder Metals, Resins, Adhesives, Latexes, Grinding Media,<br />

Foods, Powder Coatings, and an unlimited number of highly specialized applications.<br />

Myers Engineering, Inc.<br />

Tri Shaft Lab Mixer<br />

Three shaft disperser mixer. This machine has added to the high viscosity<br />

capability of the 550 by adding a third shaft as an intermediate speed mixer inside<br />

the sweep impeller opposite the high speed shaft to provide more intermixing<br />

through the batch. This third agitator blade is shown here as a gate blade, but it<br />

can have other configurations usually 3 motors.<br />

Myers Engineering, Inc.<br />

Dual Shaft Lab Mixer<br />

The dual shaft, dual range disperser is the best-known machine in the Myers line.<br />

The high speed impeller (up to 5,500 feet per minute tip speed) disperses while<br />

the large slow speed open impeller (900 to 1200 feet per minute) keeps the extra<br />

viscous products flowing. This unit is available single or dual motors, variable belt<br />

transmission system, or variable frequency drives.<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #1<br />

Laboratory <strong>Equipment</strong>

Myers Engineering, Inc.<br />

<strong>Equipment</strong> Catalog<br />

High Speed Laboratory Disperser<br />

Single shaft lab disperser withvariable speed drive. Simple and sturdy, this unit is<br />

widely used for development and smallbatches.<br />

Myers Engineering, Inc.<br />

Laboratory Ram Press<br />

Laboratory version of the lager Myers presses. A heavy follower plate is lowered<br />

into the mixing tub by a hydraulic ram powered by an air or electric motor<br />

activating an oil pump. As it descends (under tremendous pressure), the plate<br />

pushes the viscous or thixotropic product out through a discharge valve. Seals or<br />

wipers clean the tank as the plate lowers.<br />

Myers hydraulic ram follower plate can discharge through many different valve<br />

configurations.<br />

State Mix<br />

VM200<br />

The VM200 with a maximum mixing capacity of 200 grams is the ideal machine for<br />

development work. The Vortex mixer is designed to mix difficult to blend materials<br />

over a range of viscosities. Materials including prepolymer resins, curatives,<br />

powdered additives, and epoxy systems are thoroughly mixed effectively and<br />

quickly. The centrifugal force created by spinning the material in two opposite axis'<br />

simultaneously produces a high shear blending effect, thus mixing the materials<br />

inside the pail. Compared to conventional hand mixing methods such as drills, or<br />

impeller type mixers, the Vortex mixer will give you an effective mix in fraction of<br />

the time without introducing any bubbles into mixed material.<br />

State Mix<br />

VM 2500<br />

The VM2500 with a maximum mixing capacity of 2500 grams is the ideal machine<br />

for development work and small batch production. The Vortex mixer is designed to<br />

mix difficult to blend materials over a range of viscosities. Materials including<br />

prepolymer resins, curatives, powdered additives, and epoxy systems are<br />

thoroughly mixed effectively and quickly. The centrifugal force created by spinning<br />

the material in two opposite axis' simultaneously produces a high shear blending<br />

effect, thus mixing the materials inside the pail. Compared to conventional hand<br />

mixing methods such as drills, or impeller type mixers, the Vortex mixer will give<br />

you an effective mix in fraction of the time without introducing any bubbles into<br />

mixed material.<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #2

Myers Engineering, Inc.<br />

<strong>Equipment</strong> Catalog<br />

Low Speed Tank Mount Agitator<br />

Slow speed tank mounted agitator mixes low to medium viscosity products.<br />

Square or round tanks can have vacuum or pressure. Low to medium viscosities.<br />

Each tank: 200 to 5,000 gallons. Single shaft with great variety of impeller designs,<br />

(Single, variable or 2-speeds). Used for let down (thinning), blending, tinting, solid<br />

suspension absorption, reaction, extraction, heat transfer hold tank (with mild<br />

agitation to prevent settling).<br />

Myers Engineering, Inc.<br />

High Speed Disperser<br />

Low to Medium Viscosities 5-25 H.P. Economic single shaft disperser has one<br />

wide belt variable speed drive. Simple and sturdy, this unit is widely used for small<br />

to medium size batches.<br />

Myers Engineering, Inc.<br />

High Speed Laboratory Disperser<br />

Single shaft lab disperser withvariable speed drive. Simple and sturdy, this unit is<br />

widely used for development and smallbatches.<br />

Myers Engineering, Inc.<br />

High Speed Disperser<br />

Medium to large batches 15-75 H.P. up to 200 HP with 2-speed motor. Heavy<br />

duty single shaft disperser has a compound drive utilizing one short wide belt and<br />

reduction through “V” belts. This unusual disperser is extra rugged to reduce down<br />

time. Take advantage of maximum capacity with minimum height and floor space.<br />

More dispersion in less time. Also available in multi-position<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #3<br />

Dispersers

Myers Engineering, Inc.<br />

<strong>Equipment</strong> Catalog<br />

Dual Shaft High Speed Disperser<br />

Dual shaft high speed disperser has two impellers on each shaft that pass over<br />

each other in opposite directions. Disperses so fine, sand milling often is not<br />

needed. Shafts spread apart for easier loading with less dust. A single motor has<br />

15 to 60 HP variable speed shafts. Dual motors for higher viscosities or larger<br />

batches. Available in different combinations of variable speeds, single speed or<br />

Two speeds.<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #4

Mix-Mor Incorporated<br />

<strong>Equipment</strong> Catalog<br />

Series "FD" Mixer<br />

FD Mixers are direct drive mixers furnished with standard ANSI flanges with shaft seals for use on<br />

closed vessels. Available shaft seals range from low pressure stuffing box to various types of<br />

mechanical seals including cartridge type double balanced, single and double dry running, metal<br />

bellows, tandem, water cooled, split and seals with sanitary containment glands.<br />

Mix-Mor Incorporated<br />

Series "FG" Mixer<br />

FG Gear Drive Mixers are furnished with standard ANSI flanges with shaft seals for use on<br />

closed vessels. Available shaft seals range from low pressure stuffing box to various types of<br />

mechanical seals including cartridge type double balanced, single and double dry running, metal<br />

bellows, tandem, water cooled, split and seals with sanitary containment glands.<br />

Mix-Mor Incorporated<br />

Series "J" Mixer<br />

The J & K series utilizes a double reduction helical/worm gear or single reduction worm gear reducer to provide<br />

a rugged, reliable drive with high shock load capacity for years of trouble-free service in the most challenging<br />

applications. Housings are close-grained cast iron with oversized output shafts for high torsional and bending<br />

stresses and includes drywell construction. Foot mounted or C face motors are used.<br />

Horsepower Range: 1 to 50Speed Range: 25 to 175 rpmReduction Type:<br />

Helical/Worm or Worm<br />

Mix-Mor Incorporated<br />

Series "M" Mixer<br />

The M series is a heavy duty all inclusive drive for applications requiring up to 100 horsepower. The drive uses<br />

a double of triple reduction combination helical/spiral bevel gear reducer. The low speed shaft has dry well<br />

construction to eliminate the possibility of lubricant leakage. Housings are made of fabricated steel and include<br />

easy gear ratio change capability. Foot mounted or C face motors are flexibly coupled to the reducer.<br />

Horsepower Range: 3 to 100Speed Range: 25 to 155 rpmReduction Type: Helical/Spiral Bevel<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #5<br />

Agitators

Mix-Mor Incorporated<br />

<strong>Equipment</strong> Catalog<br />

Series "N" Mixer<br />

The N series offers a mid range drive which features a double reduction, all helical gear reducer.<br />

Low speed shaft is provided with drywell construction and cast iron housings are horizontally split<br />

to eliminate the possibility of lubricant leakage. NEMA C face motors are directly coupled to the<br />

reducer by a flexible coupling.<br />

Horsepower Range: 1 to 25Speed Range: 37 to 155 rpmReduction Type: All Helical<br />

Myers Engineering, Inc.<br />

Line Mixer<br />

Battery of detachable shaft mixers has a series of hydraulic motors mounted on a<br />

heavy, overhead frame. one to ten tanks operate simultaneously Different length<br />

shafts and different size impellers are available for any size tank, (5 to 250<br />

gallons). Quick change couplings allow operator to change self aligning shafts in<br />

30 seconds for tanks of different product color.<br />

Myers Engineering, Inc.<br />

Low Speed Hoist Mount Mixer<br />

Heavy duty variable speed mixer thoroughly mixes the thinnest to most viscous<br />

products. Available in 5 through 60 H.P. models. Tip speed of impeller ranges from<br />

300 to 1200 feet per minute (Tip speed is velocity of outside edge of impeller). Dial<br />

exactly the speed you want. Shaft and impeller are designed to meet customer's<br />

needs with a great variety of impeller sizes and styles.<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #6

Myers Engineering, Inc.<br />

<strong>Equipment</strong> Catalog<br />

Low Speed Tank Mount Agitator<br />

Slow speed tank mounted agitator mixes low to medium viscosity products.<br />

Square or round tanks can have vacuum or pressure. Low to medium viscosities.<br />

Each tank: 200 to 5,000 gallons. Single shaft with great variety of impeller designs,<br />

(Single, variable or 2-speeds). Used for let down (thinning), blending, tinting, solid<br />

suspension absorption, reaction, extraction, heat transfer hold tank (with mild<br />

agitation to prevent settling).<br />

Myers Engineering, Inc.<br />

Portable Construction Mixer<br />

Single shaft portable construction mixer, fixed speed 230 rpm. Unit features a 9"<br />

turbine for use on materials up to 60,000 cps and batch sizes from 4 - 7 gallons.<br />

Other configurations available.<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #7

Multi Shaft Mixers<br />

Myers Engineering, Inc.<br />

<strong>Equipment</strong> Catalog<br />

Dual Shaft Mixer<br />

The dual shaft, dual range disperser is the best-known machine in the Myers line.<br />

The high speed impeller (up to 5,500 feet per minute tip speed) disperses while<br />

the large slow speed open impeller (900 to 1200 feet per minute) keeps the extra<br />

viscous products flowing. This unit is available single or dual motors, variable belt<br />

transmission system, or variable frequency drives.<br />

Myers Engineering, Inc.<br />

Tri Shaft Mixer<br />

Three shaft disperser mixer. This machine has added to the high viscosity<br />

capability of the 550 by adding a third shaft as an intermediate speed mixer inside<br />

the sweep impeller opposite the high speed shaft to provide more intermixing<br />

through the batch. This third agitator blade is shown here as a gate blade, but it<br />

can have other configurations usually 3 motors.<br />

Myers Engineering, Inc.<br />

Tri Shaft Lab Mixer<br />

Three shaft disperser mixer. This machine has added to the high viscosity<br />

capability of the 550 by adding a third shaft as an intermediate speed mixer inside<br />

the sweep impeller opposite the high speed shaft to provide more intermixing<br />

through the batch. This third agitator blade is shown here as a gate blade, but it<br />

can have other configurations usually 3 motors.<br />

Myers Engineering, Inc.<br />

Dual Shaft Lab Mixer<br />

The dual shaft, dual range disperser is the best-known machine in the Myers line.<br />

The high speed impeller (up to 5,500 feet per minute tip speed) disperses while<br />

the large slow speed open impeller (900 to 1200 feet per minute) keeps the extra<br />

viscous products flowing. This unit is available single or dual motors, variable belt<br />

transmission system, or variable frequency drives.<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #8

Myers Engineering, Inc.<br />

<strong>Equipment</strong> Catalog<br />

Dual Shaft High Speed Disperser<br />

Dual shaft high speed disperser has two impellers on each shaft that pass over<br />

each other in opposite directions. Disperses so fine, sand milling often is not<br />

needed. Shafts spread apart for easier loading with less dust. A single motor has<br />

15 to 60 HP variable speed shafts. Dual motors for higher viscosities or larger<br />

batches. Available in different combinations of variable speeds, single speed or<br />

Two speeds.<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #9

Portable Mixers<br />

Mix-Mor Incorporated<br />

<strong>Equipment</strong> Catalog<br />

Portable Direct Drive Electric Mixer<br />

MixMor heavy duty direct drive mixers use standard NEMA C face motors mounted on aluminum<br />

drive housings. The housing encloses a double sealed ball bearing, with a lower lip seal for<br />

additional protection, to provide outboard support for the quill shaft which is subject to stresses<br />

from the mixer shaft. Mixer mounts with a heavy duty brass clamp with handwheels for fastening,<br />

thus eliminating the need for special tools or wrenches. The clamp and drive housing have a ball<br />

and socket assembly to allow 360° rotation on the horizontal plane and 100° on the vertical plane<br />

for optimum mixer shaft angle.<br />

MixMor heavy duty direct drive mixers use standard NEMA C face motors mounted on aluminum<br />

drive housings. The housing encloses a double sealed ball bearing, with a lower lip seal for<br />

additional protection, to provide outboard support for the quill shaft which is subject to stresses<br />

from the mixer shaft. Mixer mounts with a heavy duty brass clamp with handwheels for fastening,<br />

thus eliminating the need for special tools or wrenches. The clamp and drive housing have a ball<br />

and socket assembly to allow 360° rotation on the horizontal plane and 100° on the vertical plane<br />

for optimum mixer shaft angle.<br />

Mix-Mor Incorporated<br />

Portable Direct Drive Air Mixer<br />

MixMor heavy duty direct drive mixers use standard NEMA C face motors mounted on aluminum<br />

drive housings. The housing encloses a double sealed ball bearing, with a lower lip seal for<br />

additional protection, to provide outboard support for the quill shaft which is subject to stresses<br />

from the mixer shaft. Mixer mounts with a heavy duty brass clamp with handwheels for fastening,<br />

thus eliminating the need for special tools or wrenches. The clamp and drive housing have a ball<br />

and socket assembly to allow 360° rotation on the horizontal plane and 100° on the vertical plane<br />

for optimum mixer shaft angle.<br />

MixMor heavy duty direct drive mixers use standard NEMA C face motors mounted on aluminum<br />

drive housings. The housing encloses a double sealed ball bearing, with a lower lip seal for<br />

additional protection, to provide outboard support for the quill shaft which is subject to stresses<br />

from the mixer shaft. Mixer mounts with a heavy duty brass clamp with handwheels for fastening,<br />

thus eliminating the need for special tools or wrenches. The clamp and drive housing have a ball<br />

and socket assembly to allow 360° rotation on the horizontal plane and 100° on the vertical plane<br />

for optimum mixer shaft angle.<br />

Mix-Mor Incorporated<br />

Portable Gear Drive Electric Mixer<br />

MixMor heavy duty gear drive mixers use standard NEMA C face motors mounted on aluminum<br />

gear drive housings. Housings enclose helical gears with a double sealed ball bearing with upper<br />

and lower seals for or additional protection. Reducers are grease lubricated for life. Mixer mounts<br />

with a heavy duty brass clamp with handwheels for fastening, thus eliminating the need for special<br />

tools or wrenches. The clamp and drive housing have a ball and socket assembly to allow 360°<br />

rotation on the horizontal plane and 100° on the vertical plane for optimum shaft angle.<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #10

Mix-Mor Incorporated<br />

<strong>Equipment</strong> Catalog<br />

Portable Gear Drive Air Mixer<br />

MixMor heavy duty gear drive mixers use standard NEMA C face motors mounted on aluminum<br />

gear drive housings. Housings enclose helical gears with a double sealed ball bearing with upper<br />

and lower seals for or additional protection. Reducers are grease lubricated for life. Mixer mounts<br />

with a heavy duty brass clamp with handwheels for fastening, thus eliminating the need for special<br />

tools or wrenches. The clamp and drive housing have a ball and socket assembly to allow 360°<br />

rotation on the horizontal plane and 100° on the vertical plane for optimum shaft angle.<br />

Myers Engineering, Inc.<br />

Portable Construction Mixer<br />

Single shaft portable construction mixer, fixed speed 230 rpm. Unit features a 9"<br />

turbine for use on materials up to 60,000 cps and batch sizes from 4 - 7 gallons.<br />

Other configurations available.<br />

State Mix<br />

VM200<br />

The VM200 with a maximum mixing capacity of 200 grams is the ideal machine for<br />

development work. The Vortex mixer is designed to mix difficult to blend materials<br />

over a range of viscosities. Materials including prepolymer resins, curatives,<br />

powdered additives, and epoxy systems are thoroughly mixed effectively and<br />

quickly. The centrifugal force created by spinning the material in two opposite axis'<br />

simultaneously produces a high shear blending effect, thus mixing the materials<br />

inside the pail. Compared to conventional hand mixing methods such as drills, or<br />

impeller type mixers, the Vortex mixer will give you an effective mix in fraction of<br />

the time without introducing any bubbles into mixed material.<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #11

Dual Axis Mixers<br />

State Mix<br />

<strong>Equipment</strong> Catalog<br />

VM200<br />

The VM200 with a maximum mixing capacity of 200 grams is the ideal machine for<br />

development work. The Vortex mixer is designed to mix difficult to blend materials<br />

over a range of viscosities. Materials including prepolymer resins, curatives,<br />

powdered additives, and epoxy systems are thoroughly mixed effectively and<br />

quickly. The centrifugal force created by spinning the material in two opposite axis'<br />

simultaneously produces a high shear blending effect, thus mixing the materials<br />

inside the pail. Compared to conventional hand mixing methods such as drills, or<br />

impeller type mixers, the Vortex mixer will give you an effective mix in fraction of<br />

the time without introducing any bubbles into mixed material.<br />

State Mix<br />

VM 2500<br />

The VM2500 with a maximum mixing capacity of 2500 grams is the ideal machine<br />

for development work and small batch production. The Vortex mixer is designed to<br />

mix difficult to blend materials over a range of viscosities. Materials including<br />

prepolymer resins, curatives, powdered additives, and epoxy systems are<br />

thoroughly mixed effectively and quickly. The centrifugal force created by spinning<br />

the material in two opposite axis' simultaneously produces a high shear blending<br />

effect, thus mixing the materials inside the pail. Compared to conventional hand<br />

mixing methods such as drills, or impeller type mixers, the Vortex mixer will give<br />

you an effective mix in fraction of the time without introducing any bubbles into<br />

mixed material.<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #12

Myers Engineering, Inc.<br />

<strong>Equipment</strong> Catalog<br />

Floor Level Surface Mount Press<br />

The baseplate of the press is mounted to the plant floor. Your tank is rolled or<br />

placed within the press frame at floor level. A heavy follower plate is lowered into<br />

the mixing tub by a hydraulic ram powered by an air or electric motor activating an<br />

oil pump. As it descends (under tremendous pressure), the plate pushes the<br />

viscous or thixotropic product out through a discharge valve. Seals or wipers clean<br />

the tank as the plate lowers.<br />

Myers’ hydraulic ram follower plate can discharge through many different valve<br />

configurations.<br />

Myers Engineering, Inc.<br />

Lift to Discharge Press<br />

Your tank is rolled or placed within the press frame at floor level. The press raised<br />

the tank to a predetermined discharge height. A heavy follower plate is lowered<br />

into the mixing tub by a hydraulic ram powered by an air or electric motor<br />

activating an oil pump. As it descends (under tremendous pressure), the plate<br />

pushes the viscous or thixotropic product out through a discharge valve. Seals or<br />

wipers clean the tank as the plate lowers.<br />

Myers’ hydraulic ram follower plate can discharge through many different valve<br />

configurations.<br />

Myers Engineering, Inc.<br />

Laboratory Ram Press<br />

Laboratory version of the lager Myers presses. A heavy follower plate is lowered<br />

into the mixing tub by a hydraulic ram powered by an air or electric motor<br />

activating an oil pump. As it descends (under tremendous pressure), the plate<br />

pushes the viscous or thixotropic product out through a discharge valve. Seals or<br />

wipers clean the tank as the plate lowers.<br />

Myers hydraulic ram follower plate can discharge through many different valve<br />

configurations.<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #13<br />

RAM PRESSES

Myers Engineering, Inc.<br />

<strong>Equipment</strong> Catalog<br />

Platform Ram Press<br />

Your Forklift is utilized to place tank on a platform at a height apprpriate for your<br />

discharge needs. A heavy follower plate is lowered into the mixing tub by a<br />

hydraulic ram powered by an air or electric motor activating an oil pump. As it<br />

descends (under tremendous pressure), the plate pushes the viscous or<br />

thixotropic product out through a discharge valve. Seals or wipers clean the tank<br />

as the plate lowers.<br />

Myers’ hydraulic ram follower plate can discharge through many different valve<br />

configurations.<br />

Myers Engineering, Inc.<br />

Floor Level Sub Surface Press<br />

The baseplate of the press is mounted to the plant floor. Your tank is rolled or<br />

placed within the press frame at floor level. A heavy follower plate is lowered into<br />

the mixing tub by a hydraulic ram powered by an air or electric motor activating an<br />

oil pump. As it descends (under tremendous pressure), the plate pushes the<br />

viscous or thixotropic product out through a discharge valve. Seals or wipers clean<br />

the tank as the plate lowers.<br />

Myers’ hydraulic ram follower plate can discharge through many different valve<br />

configurations.<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #14

Myers Engineering, Inc.<br />

<strong>Equipment</strong> Catalog<br />

Basket Mill<br />

A basket mill can help simplify your process. This unique piece of equipment<br />

allows you to charge your materials and process them all in one tank thus<br />

elimination the need for additional hard to clean tanks and hoses. With<br />

independent speed control on each shaft you can use a variety of tank sizes while<br />

maintaining maximum batch control. The dual-shaft basket mill has eliminated<br />

high maintenance seals and foot bearings in contact with product allowing for a<br />

more reliable piece of equipment. A jacketed baffle around the output of the grind<br />

chamber creates an additional cooling zone where it is needed most.<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #15<br />

MILLS

SIEVING AND STRAINING<br />

MM Industries, Inc<br />

<strong>Equipment</strong> Catalog<br />

InLine Strainer (High Pressure)<br />

Airpel/Vorti-Siv self-cleaning filters have been designed specifically to provide<br />

efficient filtration while minimizing both disruption to flow and liquid loss during the<br />

element cleaning process. The high quality stainless steel wedge-wire element is<br />

highly effective in removing contaminant particles as small as 25 microns.<br />

Cleaning is carried out by rotating the element against fixed scraper blades which<br />

remove debris from the surface of the element, this is in turn drained from the<br />

base of the filter. The filter is available for either manual or fully automatic<br />

operation. The range of optional control devices makes it particularly suitable for<br />

continuous processes and for service with high contamination levels.<br />

An in-line filter of all cast construction where the main body of the filter is fixed in<br />

the pipeline. The filter cover is bolted to the main body. Attached to the filter cover<br />

is the element and scraper blade assembly. Clearance is required above the filter<br />

to permit the removal of the cover/element/blade assembly for inspection or<br />

maintenance.<br />

Maximum Working Pressures:Cast Iron - 290 psi(g) @ 212° FCast Steel - 580<br />

psi(g) @ 212° F316 Stainless Steel - 580 psi(g) @ 212° FMinimum working<br />

pressure 15 psi(g)<br />

Sizes:1-1/4" to 2" NPT2" to 12" ANSI flangedSizes: 1-1/4" to 6" are castings (cast<br />

iron, cast steel, cast 316 stainless steel)Sizes 8" thru 12" are fabricated steel or<br />

fabricated 316 stainless steel<br />

MM Industries, Inc<br />

InLine Strainer<br />

Airpel/Vorti-Siv self-cleaning filters have been designed specifically to provide<br />

efficient filtration while minimizing both disruption to flow and liquid loss during the<br />

element cleaning process. The high quality stainless steel wedge-wire element is<br />

highly effective in removing contaminant particles as small as 25 microns.<br />

Cleaning is carried out by rotating the element against fixed scraper blades which<br />

remove debris from the surface of the element, this is in turn drained from the<br />

base of the filter. The filter is available for either manual or fully automatic<br />

operation. The range of optional control devices makes it particularly suitable for<br />

continuous processes and for service with high contamination levels.<br />

An in-line filter where the cast head of the filter is fixed in the pipeline and a spun<br />

stainless steel bowl is attached to the head by a quick release "VEE" band clamp<br />

arrangement. Removal of the bowl to access the scraper blades and element is a<br />

"no-tools" operation. Removal of the blades is also "no-tools" by means of quick<br />

release rods. Clearance is required below the filter to permit access for inspection<br />

or maintenance.<br />

Maximum Working Pressure 200 psi(g) @ 212° F<br />

Minimum working pressure 15 psi(g)<br />

Sizes:<br />

3/4" to 2" NPT<br />

3/4" to 4" ANSI flanged<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #16

MM Industries, Inc<br />

<strong>Equipment</strong> Catalog<br />

RBF 8<br />

The VORTI-SIV Lab Models RBF-8 (8" screen diameter) is one of the most advanced small batch<br />

sieving machines on the market. The units are totally enclosed and heavily constructed. Weighing<br />

in at 80 lbs. each, they are driven by single or three phase, open construction, TENV, TEFC, or<br />

X.P., 1/3 or 1/2 HP motors. The TENV, TEFC or X.P. motor adds 3" to 6" in height to the standard<br />

21" tall single deck model. These models are extremely effective on many wet and dry products.<br />

Popular uses include quality control, "scalping" of powders, liquid straining, product reclamation,<br />

and particle size separation. The model RBF-8 is adaptable to standard 8" diameter stainless<br />

steel or brass test sieves.<br />

Successfully processed products include:Paint, Inks, Cosmetics, Dental Materials,<br />

Pharmaceuticals, Paper Coatings, Powder Metals, Resins, Adhesives, Latexes, Grinding Media,<br />

Foods, Powder Coatings, and an unlimited number of highly specialized applications.<br />

MM Industries, Inc<br />

RBF 10<br />

The VORTI-SIV Lab ModelRBF-10 (10" screen diameter) is one of the most advanced small batch<br />

sieving machines on the market. The units are totally enclosed and heavily constructed. Weighing<br />

in at 80 lbs. each, they are driven by single or three phase, open construction, TENV, TEFC, or<br />

X.P., 1/3 or 1/2 HP motors. The TENV, TEFC or X.P. motor adds 3" to 6" in height to the standard<br />

21" tall single deck model. These models are extremely effective on many wet and dry products.<br />

Popular uses include quality control, "scalping" of powders, liquid straining, product reclamation,<br />

and particle size separation.<br />

Successfully processed products include:Paint, Inks, Cosmetics, Dental Materials,<br />

Pharmaceuticals, Paper Coatings, Powder Metals, Resins, Adhesives, Latexes, Grinding Media,<br />

Foods, Powder Coatings, and an unlimited number of highly specialized applications.<br />

MM Industries, Inc<br />

RBF 12<br />

The VORTI-SIV Lab Models RBF-12 (12" screen diameter) is one of the most advanced small<br />

batch sieving machines on the market. The units are totally enclosed and heavily constructed.<br />

Weighing in at 80 lbs. each, they are driven by single or three phase, open construction, TENV,<br />

TEFC, or X.P., 1/3 or 1/2 HP motors. The TENV, TEFC or X.P. motor adds 3" to 6" in height to the<br />

standard 21" tall single deck model. These models are extremely effective on many wet and dry<br />

products. Popular uses include quality control, "scalping" of powders, liquid straining, product<br />

reclamation, and particle size separation. The model RBF-12 is adaptable to standard 12"<br />

diameter stainless steel or brass test sieves.<br />

Successfully processed products include:Paint, Inks, Cosmetics, Dental Materials,<br />

Pharmaceuticals, Paper Coatings, Powder Metals, Resins, Adhesives, Latexes, Grinding Media,<br />

Foods, Powder Coatings, and an unlimited number of highly specialized applications.<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #17

MM Industries, Inc<br />

<strong>Equipment</strong> Catalog<br />

RBF 15<br />

The VORTI-SIV pilot model RBF-15 is one of the most efficient sieving and straining machines on<br />

the market. The side-discharge is totally enclosed, heavily constructed and driven by a standard<br />

explosion proof, single or three-phase 1 H.P. motor. An optional air-operated unit is also available.<br />

The standard discharge height is 30", however, the electric version is available down to 23" and<br />

the pneumatic version to 18". The RBF-15 is extremely effective on many wet and dry<br />

applications. Popular uses include: quality control check screening of powders, liquid straining,<br />

product reclamation, and particle size separation.<br />

Successfully processed products include:lactose, sugar, nuts, dental powders, antibiotics, powder,<br />

flour, cosmetics, pharmaceuticals, chocolate, powdered milk, tablets, vitamins, aspirin, spices,<br />

media, food powder, hormones, paint, ink, paper coatings, powdered metals, resins, adhesives,<br />

latex, grinding media, powder coatings, solder paste and an unlimited number of highly<br />

specialized applications.<br />

MM Industries, Inc<br />

RBF-2<br />

The VORTI-SIV RBF®-2 is one of the most efficient sieving and straining<br />

machines on the market. These totally enclosed units are heavily constructed,<br />

driven by explosion proof 5HP (Single or Variable) speed drives utilizing adjustable<br />

off-balanced flywheels. Heavy-Duty Bearing Systems enable the units to achieve<br />

flywheel speeds of up to 3200 RPM. Quick-release clamps allow easy in-plant<br />

dismounting and color changes.<br />

• All product contact parts are 316 grade stainless steel or PVC plastic.•<br />

Noncontact parts are available painted, epoxy and teflon powder coated, or in<br />

stainless steel.<br />

MM Industries, Inc<br />

RBF-3<br />

The VORTI-SIV RBF®-3 is one of the most efficient sieving and straining<br />

machines on the market. These totally enclosed units are heavily constructed,<br />

driven by explosion proof 5HP (Single or Variable) speed drives utilizing adjustable<br />

off-balanced flywheels. Heavy-Duty Bearing Systems enable the units to achieve<br />

flywheel speeds of up to 3200 RPM. Quick-release clamps allow easy in-plant<br />

dismounting and color changes.<br />

• All product contact parts are 316 grade stainless steel or PVC plastic.•<br />

Noncontact parts are available painted, epoxy and teflon powder coated, or in<br />

stainless steel.<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #18

Disti-Kleen, Inc<br />

<strong>Equipment</strong> Catalog<br />

Distillation Unit Model DW<br />

Treatment of contaminated solvents, concentration of rest inks, recovery of clean solvent and reduction of waste to be disposed.<br />

Cylindrical distillation boiler that features an electrically heated double jacket filled with thermal oil. Designed for batch operation and<br />

continuous. Residue discharge conveniently through the open flap at the front of the unit or through open lid with plastic discharge bag<br />

hooked in before distillation starts. Distillation under vacuum to lower boiling point and heating temperature. Automatic shut-off when<br />

reaching desired densification. Various options to meet respective task, Ex-proof category 1/2 according to ATEX.<br />

Disti-Kleen, Inc<br />

Distillation Unit Model M<br />

Treatment of contaminated solvents, concentration of restinks, recovery of clean solvent and reduction of waste to be disposed.<br />

Polygonal distillation boiler that features and electrically heated double jacket filled with therm al-oil. Designed for batch operation and<br />

continuous operation. Residue discharge conveniently through manhole at the front of the unit. Distillation under vacuum to lower<br />

boiling point and heating temperature. Automatic shut-off when reaching desired densification. Various options to meet respective<br />

task, Ex-proof category 1/2 according to ATEX.<br />

Disti-Kleen, Inc<br />

Nitrocellulose Kit<br />

Whenever varnish residues or solutions containing nitrocellulose are distilled, there<br />

is a danger of the nitrocellulose being decomposed in a more or less violent<br />

reaction that creates certain amounts of gas.<br />

Disti-Kleen supplies distillation units specifically modified for the distillation of<br />

Nitrocellulose containing compounds. These units operate under vacuum to<br />

reduce the overall temperature of the solvent and include controls to closely<br />

monitor the process.<br />

Contact us with your distillation needs. We can assist in providing a safe<br />

alternative for your solvent recovery.<br />

Disti-Kleen, Inc<br />

Distillation Unit Model Roto<br />

Treatment of contaminated solvents, concentration of rest-inks and wastewater, high recovery rate, low amount of residue. Designed<br />

for batch operation and continuous operation. Heating with thermal oil or steam provided by customer or with electrically heated<br />

thermal oil. Discharge of residue and effective self cleaning of heating surface by scraper system with wiper. Distillation under vacuum<br />

to lower boiling point and heating temperature. Automatic distillation with low attendance, automatic shut-off when reaching desired<br />

densification. Various options to meet respective task, Ex-proof category 1/2 according to ATEX.<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #19<br />

SOLVENT RECOVERY SYSTEMS

Disti-Kleen, Inc<br />

<strong>Equipment</strong> Catalog<br />

Distillation Unit RotoMAX<br />

Treatment of contaminated solvents, concentration of rest-inks and wastewater, maximal recovery rate, minimal amount of residue.<br />

Heating only via steam heated bottom: Very good heat carriage and constantly high heating power unattached from fill level.<br />

Discharge of residue and effective self cleaning of the heated bottom by scraper system with wiper. Monitoring of fill level through<br />

load cells. No malfunction of any level sensors in the distillation kettle, adjustment of first fill amount, refill amount and residue amount,<br />

for various requirements display of filling amount, distillation output, distillate amount, fully automation distillation without supervision.<br />

Limiting of emissions through enclosure of discharge area. Dis tillation under vacuum to lower boiling point and heating temperature.<br />

Ex-proof category 1/2 according to ATEX<br />

Disti-Kleen, Inc<br />

Water Distillation Unit RotoMAX<br />

Treatment of contaminated wastewater, maximal recovery rate, minimal amount of residue. Heating only via steam heated bottom:<br />

Very good heat carriage and constantly high heating power unattached from fill level. Discharge of residue and effective self cleaning<br />

of the heated bottom by scraper system with wiper. Monitoring of fill level through load cells. No malfunction of any level sensors in<br />

the distillation kettle, adjustment of first fill amount, refill amount and residue amount, for various requirements display of filling<br />

amount, distillation output, distillate amount, fully automation distillation without supervision. Limiting of emissions through enclosure of<br />

discharge area. Distillation under vacuum to lower boiling point and heating temperature. Ex-proof category 1/2 according to ATEX<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #20

Disti-Kleen, Inc<br />

<strong>Equipment</strong> Catalog<br />

Model 120<br />

The Washing Unit 120 cleans hobbocks and hobbock lids with solvent jets. A<br />

particularly effective inside cleaning of the hobbocks is achieved by means of the<br />

rotating spray heads. With the type-examined spraying systems and other<br />

safety-related details, the machine meets ATEX requirements.<br />

Disti-Kleen, Inc<br />

B3D IBC Cleaner<br />

The RioBeer Tote Cleaning System features a rotating articulating brush assembly<br />

for unsurpassed cleaning of tote and IBC's.<br />

The introduction of the three dimensional brush technology (3D) was a crucial<br />

progress within the brush cleaning sector. Concerning the cleaning of the blind<br />

spots on the top and bottom of the IBC, this technology has been improved<br />

substantially and its cleaning efficiency exceeds all expectations.<br />

Depending on the phase of the cleaning process, a certain movement dominates<br />

(movements can also be combined). The brushs various lengths of bristles and<br />

the reversal of its rotating direction ensure a perfect interior cleaning of the<br />

containers.<br />

Due to the rotating unit inside of the 3D head swivelling upwards (fully rotating<br />

brush spindle, reverse and slow rotation of the brush tube), the lateral radius, the<br />

beading in the floor and top as well as further form elements of the top can be<br />

cleaned.<br />

The unit can be supplied with outside cleaning and drying stations, to automate<br />

the entire IBC cleaning process.<br />

Disti-Kleen, Inc<br />

cGMP Washing Units<br />

The Pharmaceutical Grade washers provide cleaning as a fundamental part of the<br />

production process in the pharmaceutical industry as well as in the food and<br />

cosmetic industries.<br />

Parts in contact with product such as containers, drums, funnels, and piping as<br />

well as the components of the machinery and tools are thoroughly cleaned of<br />

residuals.<br />

The cleaning process is well-defined, programmable, and validable.<br />

Disti-Kleen, Inc<br />

COP Cleaning System<br />

The field of application is the inside cleaning of various materials and components<br />

used in the food, cosmetic and pharmaceutical manufacturing industries. Typical<br />

hollow bodies include IBC, vessels, fermenters and any containers. Optionally<br />

available is a drying unit, automatic handling of top and bottom valves as well as<br />

direct rinse and steam down.<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #21<br />

TANK CLEANERS

Disti-Kleen, Inc<br />

<strong>Equipment</strong> Catalog<br />

Disti Super Cleaner<br />

The Type DSC 750 washing system is designed for the interior cleaning of<br />

portable vessels and fixed tanks by high pressure spray. A pneumatically driven,<br />

dual axis, rotating spray-head is supplied with a pressure up to 1200 PSI by an<br />

electrically driven diaphragm pump of unique design. The resulting powerful spray<br />

reaches every point of the inner surface of the tank being cleaned. The system is<br />

intended for use with various cleaning solutions.<br />

Disti-Kleen, Inc<br />

Washing unit HP<br />

Washing unit HP is used for manual cleaning of small parts, valves, fittings,<br />

strainers, pans and doctor blades. The units features a closed floor tank with<br />

automatic runback for storage of the washing agent, horizontal air curtain guidance<br />

over the working area and a hand brush through which washing agent flows<br />

ensure sanitary and ergonomic working conditions with low solvent emissions.<br />

Disti-Kleen, Inc<br />

PCC Container Cleaning System<br />

The field of application is the inside and outside cleaning of various materials and<br />

components used in the food, cosmetic and pharmaceutical manufacturing<br />

industries. Typical components include IBC, drums, glassware, vessels, trays,<br />

hoppers, tools as well as components of tabletting, filling, and packaging<br />

machines. Optionally available is a drying unit, automatic handling of top and<br />

bottom valves as well as direct rinse and steam down.<br />

Disti-Kleen, Inc<br />

PDC Parts Cleaning System<br />

The field of application is the inside and outside cleaning of various equipment and<br />

components used in the food, cosmetic and pharmaceutical manufacturing<br />

industries. Typical components include drums, glassware, vessels, trays, hoppers,<br />

tools as well as components of tabletting, filling, and packaging machines.<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #22

Disti-Kleen, Inc<br />

<strong>Equipment</strong> Catalog<br />

Robus Tank Cleaner<br />

The Robus cleans the inside of shipping and other containers by means of a brush<br />

and simultaneous rinsing with washing agent. The rotating brush is equipped with<br />

arms that open by centrifugal force, thereby adapting to the size of the container;<br />

at the same time, the brush moves up and down, ensuring an effective cleaning of<br />

the inside surfaces. With nitrogen inerting and other safety-related details, the<br />

machine meets ATEX requirements when it is used with solvent.<br />

Disti-Kleen, Inc<br />

SKM Tank Cleaner<br />

The SKM cleans containers on the in- and outside with jets of washing agent. The<br />

spraying system consists of a part that moves around the container and another<br />

part that rotates within the container; this ensures a very effective cleaning of all<br />

container surfaces. With the type examined spraying systems and other<br />

safety-related details, the machine meets ATEX requirements.<br />

Disti-Kleen, Inc<br />

SPF Tank Cleaner<br />

The SPF Tank Cleaner cleans the inside of shipping and other containers with<br />

high pressure. Two types of spray head are available: one fixed spray head<br />

rotating around two perpendicular axes and a spray head oscillating up and down<br />

and rotating around the vertical axis. Both spray heads clean the inside surfaces<br />

very effectively. With the type-examined spray heads and other safety-related<br />

details, the machine meets ATEX requirements when it is used with solvent.<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #23

DISPENSING<br />

Disti-Kleen, Inc<br />

<strong>Equipment</strong> Catalog<br />

A16<br />

The A16 / A32 dispensing system is a small unit with very limited floor occupation.<br />

Ideal for small quantities to dispense. The scale height is self-adjusting, depending<br />

of the pail size. The system is very versatile thanks to the different valve options.<br />

* Maximum number of components: 16 for the solvent base configuration, 32 for<br />

the water base configuration.* Drawing from 25 or 200 kg barrels or different size<br />

containers.* Gravimetric/fixed valves* Completely automatic Inkmaker INKPRO<br />

software* Dispensing precision: 0.1 gr* pumps with anti-pulsation dampeners*<br />

Dispensing into 125 kg pails* Dispensing valves available are: DN6, DN14, DN18.*<br />

Recirculation through valve* Automatic washing system for valves* Modem and<br />

on-line technical assistance* Production time for a 5 Kg pail: 2-3 minutes<br />

Disti-Kleen, Inc<br />

Compasso<br />

The Compasso is a compact unit dedicated for the UV flexo inks. Ideal for small<br />

quantities to dispense. The valves are sliding to a central dispensing point. At the<br />

end of production, the scale is sliding out.* Maximum number of components: 20<br />

valves * UV flexo inks configuration available only. Atex not available * Drawing<br />

from 25 or 200 kg barrels or different containers. * Gravimetric sliding valves *<br />

Completely automatic Inkmaker INKPRO software * Dispensing precision: 0.1 gr *<br />

pumps with anti-pulsation dampers * Dispensing in 115 kg pails * Dispensing<br />

valves available are DN18. * Recirculation through valve * Automatic washing<br />

system for valves * Modem and on-line technical assistance * Production time for<br />

a 5 Kg pail: 2-3 minutes<br />

Disti-Kleen, Inc<br />

ECO14<br />

The ECO14 dispensing system is a compact system and very simple to use. The<br />

dispensing process is obtained through push-buttons. The installation can be done<br />

by the customer himself.* Maximum number of components: 14 * Drawing from 25<br />

or 200 kg barrels or from different containers * Gravimetric/fixed valves *<br />

Completely manual system * pumps * Dispensing into 25 kg pails, or 50 kg. pails<br />

on option<br />

Disti-Kleen, Inc<br />

ECO18<br />

The ECO18 dispensing system is an economical automatic system. Available only<br />

for water base products. Ideal for up to 20 tons annual consumption.* Maximum<br />

number of components: 18 (+ 1 on/off * Drawing from 25 or 200 kg barrels or from<br />

different containers * Gravimetric/fixed valves * Completely automatic Inkmaker<br />

INKPRO software * Dispensing precision: 1 gr * pumps * Dispensing into 125 kg<br />

pails, in 50 kg. pails on option * Recirculation in DN 14 valves * Modem and on-line<br />

technical assistance * Production time for a 25 Kg pail: 4-5 minutes<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #24

Disti-Kleen, Inc<br />

<strong>Equipment</strong> Catalog<br />

Giottino<br />

This system has been designedt for printing offices with continual needs of<br />

peculiar colors, which require just in time service or which operate with base<br />

colors.The advantage of this machine is the fact that cans are compressed during<br />

the dispensing action and ultimately crushed flat when empty. There are no extra<br />

external pumps or devices necessary, which means very limited maintenance.<br />

maximum number of components: 14 taking from 1 or 2.5 Kg cans<br />

gravimetric/container on rotary plate dispensing precision: 0.1 gr minimal<br />

dispensing: 1 gr; maximum dispensing 5,000 gr. completely automatic Inkmaker<br />

INKPRO software modem and on-line assistance<br />

Disti-Kleen, Inc<br />

GT18<br />

The GT18 dispensing system is a compact system requiring limited space. Ideal<br />

for all small and medium size printers. A GT24 version is also available; capable to<br />

manage up to 24 components.* Maximum number of components: 18 (+ 1 on/off) *<br />

Drawing from 25 or 200 kg barrels or from different containers * Gravimetric/fixed<br />

valves * Completely automatic Inkmaker INKPRO software * Dispensing precision:<br />

1 gr * or 1 pumps with anti-pulsation dampeners * Dispensing into 125 kg pails, in<br />

50 kg. pails on option * Recirculation through DN 14 valves * Automatic washing<br />

system for valves included * Modem and on-line technical assistance * Production<br />

time for a 25 Kg pail: 4-5 minutes<br />

Disti-Kleen, Inc<br />

GT36<br />

Ideal for medium size printers, or with different ink series. The system can be<br />

equipped with an automatic conveyor line and with an automatic mixer (as option).<br />

Manual control panel included, useful in the event of a PC failure. On option, the<br />

system can be equipped with a 300kg scale and to dispense into drums.*<br />

Maximum number of components: 36 * Drawing from 25, 200 kg barrels or from<br />

different containers * Gravimetric/fixed valves * Completely automatic Inkmaker<br />

INKPRO software * Dispensing precision: 1 gr * or 1 pumps with anti-pulsation<br />

dampeners * Dispensing into 125 kg pails, in 50 kg. pails on option * Recirculation<br />

through DN 14 valves * Automatic washing system included * Modem and on-line<br />

technical assistance * Production time for a 25 Kg pail: 4-5 minutes<br />

Disti-Kleen, Inc<br />

IDA 25<br />

Thanks to the mobile table (pendulum movement) all the valves can be located in<br />

the same dispensing point.Very small quantities can be dispensed in very small<br />

can.The system can be equipped with an automatic conveyor line and with an<br />

automatic mixer (on option).Manual control panel included, useful in the event of a<br />

PC failure. maximum number of components: 25 (+ 4 ON/OFF) taking from 25 or<br />

200 kg drums. gravimetric/ mobile table completely automatic Inkmaker INKPRO<br />

software dispensing precision: 1 gr, 0.1 gr on option dispensing into 1060 kg<br />

containers, in 1500 kg containers on option high pressure pumps for 25 kg or<br />

200kg drums (type piston pump) dispensing valves valves cleaning system air<br />

blade cut modem and on-line technical assistance production time for a 25 Kg pail:<br />

3-5 minutes<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #25

Disti-Kleen, Inc<br />

<strong>Equipment</strong> Catalog<br />

IDA 32<br />

This system can dispense either offset products or liquid products, up to 32 x<br />

offset and 32 x liquids.Thanks to the mobile table all the valves can be located in<br />

the same dispensing point.Ability to dispense into almost any size can or<br />

containerThe system can be equipped with an automatic conveyor line and with an<br />

automatic mixer (as an option). maximum number of components: 32+ 32 taking<br />

from 25 or 200 kg drums gravimetric/mobile table completely automatic Inkmaker<br />

INKPRO software dispensing precision: 1 gr, 0.1 gr on option high pressure pumps<br />

for 25 kg or 200kg drums (type piston pump) dispensing into 1060 kg containers,<br />

in 1500 Kg containers on option dispensing valves valves cleaning system air<br />

blade cut modem and on-line assistance production time for a 25 Kg pail: 3-5<br />

minutes<br />

Disti-Kleen, Inc<br />

M48<br />

The M range can be equipped with up to48 or 96 valves + 5 on/off. Swinging arm<br />

system, single point dispensing, which means limited and easy maintenance.<br />

Ability to dispense into any size can or container. The system can be equipped<br />

with an automatic conveyor line and with an automatic mixer (as option). Manual<br />

control panel included, useful in the event of a PC failure.* Maximal number of<br />

components: 96 (+ 5 on/off * Taking from 25 or 200 kg. barrels or from different<br />

containers * Gravimetric/mobile valves * Completely automatic Inkmaker INKPRO<br />

software * Dispensing precision: 1 gr, 0.1 gr on option * 1 or bigger pumps with<br />

anti-pulsation dampeners * Dispensing in 160 kg pails, up to 3000 kg tubs on<br />

option * Recirculation through DN 20 valves * DN 35 or DN50 valves on option *<br />

Automatic washing system included * Modem and on-line technical assistance *<br />

Production time for a 25 Kg pail: 3-4 minutes<br />

Disti-Kleen, Inc<br />

O32<br />

Swinging arm system, single point dispensing, which means limited and easy<br />

maintenance.<br />

Ability to dispense into almost any size can or containerThe system can be<br />

equipped with an automatic conveyor line and with an automatic mixer (as<br />

option).Manual control panel included, useful in the event of a PC failure.<br />

maximum number of components: 32 (+ 1 on/off) taking from 25, 200 kg barrels or<br />

from different containers gravimetric/mobile valves completely automatic Inkmaker<br />

INKPRO software dispensing precision 1 gr high pressure pumps for 25 kg or<br />

200kg drums (type piston pump) dispensing into 160 kg pails, in 300 kg pails on<br />

option DN 18 dispensing valves automatic washing system included modem and<br />

on-line technical assistance production time for a 25 Kg pail: 3-5 minutes<br />

Disti-Kleen, Inc<br />

O48<br />

Swinging arm system, single point dispensing, which means limited and easy<br />

maintenance.Ability to dispense into almost any size can or containerThe system<br />

can be equipped with an automatic conveyor line and with an automatic mixer (as<br />

option).Manual control panel included, useful in the event of a PC failure.<br />

maximum number of components: 48 (+ 5 on/off) taking from 25, 200 kg. barrels<br />

or from different containers gravimetric/mobile valves completely automatic<br />

Inkmaker INKPRO software dispensing precision: 1 gr, high pressure pumps for<br />

25 kg or 200kg drums (type piston pump) dispensing into 160 kg pails, up to 1500<br />

kg pails on option DN 20 dispensing valves Automatic washing system included<br />

modem and on-line technical assistance production time for a 25kg pail: 3-5<br />

minutes<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #26

Disti-Kleen, Inc<br />

<strong>Equipment</strong> Catalog<br />

P32<br />

Swinging arm system, single point dispensing, which means limited and easy<br />

maintenance. Ability to dispense into almost any size can or container. The system<br />

can be equipped with an automatic conveyor line and with an automatic mixer (as<br />

option). Manual control panel included, useful in the event of a PC failure.*<br />

Maximum number of components: 32 (+ 1 on/off * Drawing from 25 or 200 kg<br />

barrels or from different containers * Gravimetric/mobile valves * Completely<br />

automatic Inkmaker INKPRO software * Dispensing precision: 1 gr, 0.1 gr on<br />

option * or 1 pumps, with anti-pulsation dampeners * Dispensing into 160 kg pails,<br />

in 300 kg pails on option * Recirculation through DN 18 valves * DN28 valves on<br />

option * Automatic washing system included * Modem and on-line technical<br />

assistance * Production time for a 25 Kg pail: 3-4 minutes<br />

Disti-Kleen, Inc<br />

P96<br />

The P range can be equipped with up to 96 valves + 5 on/off. Swinging arm<br />

system, single point dispensing, which means limited and easy maintenance.<br />

Ability to dispense into almost any size can or container. The system can be<br />

equipped with an automatic conveyor line and with an automatic mixer (as option).<br />

Manual control panel included, useful in the event of a PC failure.* Maximum<br />

number of components: 96 (+ 5 on/off * Drawing from 25 or 200 kg. barrels or from<br />

different containers * Gravimetric/mobile valves * Completely automatic Inkmaker<br />

INKPRO software * Dispensing precision: 1 gr, 0.1 gr on option * 1 or bigger<br />

pumps with anti-pulsation dampers * Dispensing into 160 kg pails, up to 3000 kg<br />

tubs on option * Recirculation through DN 20 valves * DN 35 or DN50 valves on<br />

option * Automatic washing system included * Modem and on-line technical<br />

assistance * Production time for a 25 Kg pail: 3-4 minutes<br />

Disti-Kleen, Inc<br />

Piccolo<br />

Ideal for medium and large size printers. The system can be equipped with an<br />

automatic conveyor line and with an automatic mixer (as option). Manual control<br />

panel included, useful in the event of a PC failure. Optionally, the system can be<br />

equipped with a 300kg scale and to dispense into drums.* Maximum number of<br />

components: 18 (+ 1 on/off) * Drawing from 25 or 200 kg barrels or from different<br />

containers * Gravimetric/fixed valves * Completely automatic Inkmaker INKPRO<br />

software * Dispensing precision: 1 gr * or 1 pumps with anti-pulsation dampeners *<br />

Dispensing into 125 kg pails, in 50 kg. pails on option * Recirculation through DN<br />

14 valves * Automatic washing system for valves included * Modem and on-line<br />

technical assistance * Production time for a 25 Kg pail: 4-5 minutes<br />

Disti-Kleen, Inc<br />

Ring 21 + 3<br />

In this system the maximum number of components and the minimum dispensing<br />

head surface are combined in an optimal solution.This machine can be equipped<br />

on option with an automatic conveyor maximum number of components: 21 (+ 3<br />

on/off) taking from 25 or 200 kg drums gravimetric/fixed valves completely<br />

automatic Inkmaker INKPRO software dispensing precision: 1 gr, 0.1 gr on option<br />

high pressure pumps for 25kg or 200 kg drums (type piston pump) dispensing into<br />

525 kg containers, in 200 kg barrels on option DN18 dispensing valves valves<br />

cleaning system air blade cut included modem and on-line technical assistance<br />

production time for a 25 Kg pail: 3-5 minutes<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #27

Disti-Kleen, Inc<br />

<strong>Equipment</strong> Catalog<br />

Slider<br />

This machine advantage is the valves group displacement. Its movement allows<br />

always the location of 4 valves in a central dispensing point.It allows dispensing<br />

into small containers with a diameter of 120 mm. maximum number of<br />

components: 20 taking from 25 or 200 kg drums gravimetric/mobile valves group<br />

completely automatic Inkmaker INKPRO software dispensing precision: 1 gr, 0.1<br />

gr on option high pressure pumps for 25 kg or 200kg drums (type piston pump)<br />

dispensing into 125 kg containers, in 60 kg containers on option DN18 dispensing<br />

valves valves cleaning system air blade cut modem and on-line technical<br />

assistanceproduction time for a 25 Kg pail: 3-5<br />

Disti-Kleen, Inc<br />

Software<br />

The machine software is entirely designed in-house and has always been one of<br />

the genuine points of strength of the INKMAKER dispensing systems. Available in<br />

two versions: InkPro for inks and PaintPro for paints.A team of highly qualified<br />

professionals, who are constantly striving for perfection, allows us to offer a high<br />

degree of product customization and personalized solutions. The software can<br />

interface with various computerized systems, company networks and<br />

spectrophotometers. No matter how complex your application is, you have to think<br />

everything is possible with Inkmaker.List of main options: Base Component<br />

Management, with synoptic display of stock of bases Dispensing parameters with<br />

automatic adjustment Colour strength management Formulas management Work<br />

orders Production management of component, formula, design, work order.<br />

Production planning Designs management, with estimations of ink consumption<br />

based on printed surface Reports and statistics Traceability management for ISO<br />

9000 compliance Price management and stocks evaluation<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #28

DisperseTech<br />

<strong>Equipment</strong> Catalog<br />

1 1/4 Quart Stock Pots<br />

Made from non-porous 18-8, Type 304 stainless steel. These stainless stock pots<br />

feature a special conductive bottom to distribute heat evenly and reduce energy<br />

consumption, and they are equipped with strong welded loop handles for carrying<br />

ease. Covers are flat for convenient stacking and storage.<br />

1 1/4 Quart Stainless Steel Tank 4 1/8" Diameter x 5 3/4" Height<br />

E.W. Kaufmann Services, LLC<br />

Horizontal Storage Tank<br />

Storage Tanks can be fabricated to our customers requirements. We routinely<br />

supply Caron Steel, Stainless Steel, Fibergalss, Polyethylen and Polypropylene<br />

tanks. Other materials are available on request.<br />

E.W. Kaufmann Services, LLC<br />

Portable Tanks<br />

Portable tanks can be supplied on casters or forchannels to meet your inplant<br />

process requirements.<br />

E.W. Kaufmann Services, LLC<br />

PE Portable Tanks<br />

Portable tanks can be supplied on casters or forchannels to meet your inplant<br />

process requirements.<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #29<br />

TANKS

E.W. Kaufmann Services, LLC<br />

<strong>Equipment</strong> Catalog<br />

Reactors<br />

Reactors can be made your Specifications. Tanks can be designed to meet your<br />

pressure and temperature requirements. Material of construction, finish, and<br />

coatings can be applied if desired.<br />

E.W. Kaufmann Services, LLC<br />

Vertical Storage Tank<br />

Vertical Storage Tanks can be fabricated to our customers requirements. We<br />

routinely supply Caron Steel, Stainless Steel, Fibergalss, Polyethylen and<br />

Polypropylene tanks. Other materials are available on request.<br />

E.W. Kaufmann Services, LLC<br />

Fiberglass Storage Tank<br />

Vertical Storage Tanks can be fabricated to our customers requirements. We<br />

routinely supply Caron Steel, Stainless Steel, Fibergalss, Polyethylen and<br />

Polypropylene tanks. Other materials are available on request.<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #30

DisperseTech<br />

<strong>Equipment</strong> Catalog<br />

"CSI" Blade<br />

"CSI" Constant Shear Impeller A patented design using the Venturi principle to produce very fine<br />

grinds with laminar flow and less heat build-up. Also, excellent for emulsification when operated at<br />

low speeds. Has minimum heat build-up and longer life than any other design. Pat. No. 3486741.<br />

DisperseTech<br />

"D" Blade<br />

A high shear design accererates product through a series of rings to produce very fine grinds with<br />

laminar flow and less heat build-up. Also, excellent for emulsification when operated at low<br />

speeds.<br />

DisperseTech<br />

"E" Blade<br />

Known as the cutter blade because of its superiority for dissolving resins. Also utilized for high<br />

vehicle viscosities and/or solids loadings. Produces shear but with more turbulence than other<br />

designs.<br />

DisperseTech<br />

"F" Blade<br />

"F" Blade The most popular and versatile blade. The uniform teeth accelerate pigment particles<br />

and breakup agglomerates. High shear is quickly achieved with turbulent flow.<br />

n E.W. Kaufmann Company . 140 Wharton Rd. . Bristol . PA . 19072<br />

Tel: +1 215 364 0240 . Fax: +1 215 364 4397 . www.ewkaufmann.com<br />

Page #31<br />

Disperser Blades

DisperseTech<br />

<strong>Equipment</strong> Catalog<br />

"G" Blade<br />

This High-vaned blade is designed for turbulent flow to provide fast blending and agitation. It will<br />