CR Manual CP L&M en - Creation Willi Geller

CR Manual CP L&M en - Creation Willi Geller

CR Manual CP L&M en - Creation Willi Geller

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

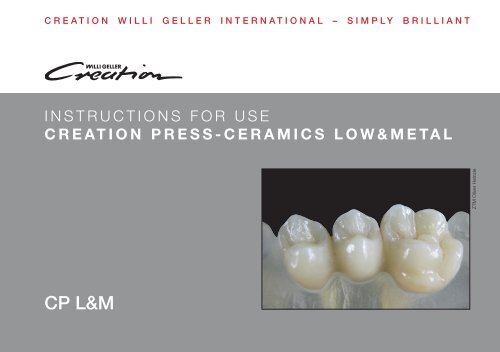

<strong>CR</strong>EATION WILLI GELLER INTERNATIONAL – SIMPLY BRILLIANT<br />

INSTRUCTIONS FOR USE<br />

<strong>CR</strong>EATION PRESS-CERAMICS LOW&METAL<br />

<strong>CP</strong> L&M<br />

1<br />

ZTM Oliver Heinzle

2<br />

CONTENT<br />

Introduction 3-4<br />

<strong>CP</strong> Low / Technique 5-16<br />

<strong>CP</strong> Low & Metal / Investing 9<br />

<strong>CP</strong> Low & Metal / Injecting 10, 30<br />

<strong>CP</strong> Low & Metal / Devesting 11<br />

<strong>CP</strong> Low & Metal / Colour Chart 17<br />

<strong>CP</strong> Low / Adhesively Cem<strong>en</strong>ting 18<br />

<strong>CP</strong> Metal / Introduction 19<br />

<strong>CP</strong> Metal / Cut Back Technique 20-26<br />

<strong>CP</strong> Metal / Cut Back Easy Technique 27-28<br />

<strong>CP</strong> Metal / Staining Posteriors 29<br />

<strong>CP</strong> Metal / Cut Back - Combination Charts 31<br />

<strong>CP</strong> Metal / Cut Back Easy - Combination Charts 32<br />

<strong>CP</strong> Metal / Staining Posteriors - Combination Charts 33<br />

Physical Properties 34<br />

Imprint<br />

Editor: <strong>Creation</strong> <strong>Willi</strong> <strong>Geller</strong> International AG<br />

Cont<strong>en</strong>t: ZTM Patrick Boche, ZTM Oliver Heinzle<br />

Picture credits: ZTM Oliver Heinzle<br />

Layout: hellblau. visuelle kommunikation

3<br />

I N T R O D U C T I O N<br />

<strong>Creation</strong> <strong>CP</strong> L & M is an injection moulded ceramic for fabricating<br />

inlays, onlays, v<strong>en</strong>eers and single crowns using the staining as well<br />

as the build-up technique. A further indication is the „Metal Overpress“<br />

technique. This technique op<strong>en</strong>s a new dim<strong>en</strong>sion both<br />

economically and aesthetically. Its physical properties, aesthetics<br />

and unique shade stability are impressive.

4<br />

I N T R O D U C T I O N<br />

BUILD-UP TECHNIQUE<br />

Inlays, onlays, v<strong>en</strong>eers and single crowns can be fabricated effici<strong>en</strong>tly<br />

and aesthetically using this technique. Units are waxed-up<br />

to their final shape on conv<strong>en</strong>tional section models and th<strong>en</strong> injected<br />

using the appropriate transluc<strong>en</strong>t pellet. After the injectionmoulded<br />

units have be<strong>en</strong> prepared, <strong>Creation</strong> CC.LF. Make Up<br />

Instant stains are used to add the finishing touches.<br />

STAINING TECHNIQUE<br />

This technique is used for restorations which require high-quality<br />

aesthetics. Fully anatomically waxed-up units can be injectedmoulded<br />

and th<strong>en</strong> reduced, or units can be waxed-up in reduced<br />

form and injected using appropriate pellet. <strong>Creation</strong> LF and <strong>Creation</strong><br />

CC.LF. Make Up Instant stains are used for facing (The stain can<br />

be mixed in or used on the surface). The d<strong>en</strong>tal technician’s creativity<br />

is unlimited using this combination of materials.

TOOTH PREPARATION<br />

1,5<br />

2,0<br />

1,5<br />

1,5<br />

2,0<br />

2,0 2,0<br />

1,5<br />

0,7<br />

0,5<br />

1,5 - 2,0<br />

0,5<br />

1,5<br />

5 | L O W<br />

I N L AY S<br />

Inner walls should not be prepared parallel, but op<strong>en</strong> out approx.<br />

15 ° towards the occlusal surface. Occlusal preparations<br />

should be approx. 2 mm deep. Box preparations should have<br />

rounded corners and edges with no contact to the opposing bite<br />

at the junction of the tooth and inlay and no feather edges.<br />

<strong>CR</strong>OWNS<br />

Reduce the incisal edge by 2 mm and labial and buccal walls by<br />

1 – 1,5 mm. Prepare a well-formed deep chamfer or 90° shoulder.<br />

There should be no sharp edges and a minimum space of 1 mm<br />

palatally.<br />

L A M I N AT E V E N E E R S<br />

Prepare labially to a minimum of 0,5 mm at the gingival deep<br />

chamfer and up to 1 mm at the incisal edge. All preparation margins<br />

should be deep chamfers.

WA X I N G - U P - B U I L D - U P T E C H N I Q U E<br />

6 | L O W<br />

M E T H O D A<br />

The restoration is waxed-up fully anatomically and th<strong>en</strong> reduced<br />

using appropriate cutting instrum<strong>en</strong>ts. The pattern can be used<br />

as a diagnostic wax-up.<br />

METHOD B<br />

The restoration is waxed-up in reduced form and th<strong>en</strong> injected.<br />

Important: - Minimum thickness 0,8 mm!<br />

- 2/3 of the anatomical form must be made<br />

of press material!

WA X I N G - U P - S TA I N I N G T E C H N I Q U E<br />

7 | L O W<br />

The restoration is fully waxed-up. The pattern does not show any<br />

dim<strong>en</strong>sional changes during the injection.

S P R U E I N G<br />

8 | L O W<br />

The wax wire with 3 – 3,5 mm in diameter should be 5 – 6 mm<br />

long and should not taper towards the pattern. Wax the pattern<br />

in an angle of 35 – 45 ° on the edge of the crucible former. The<br />

distance betwe<strong>en</strong> the patterns should be 3 mm.<br />

Note: Maximum of 0,6 g wax weight for 1 pellet 2 g<br />

Maximum of 1,4 g wax weight for 2 pellets 2 g<br />

Maximum 2,8 g wax weight with 2 pellets 5 g

INVESTING<br />

9 | LOW & M E TA L<br />

Push the silicone ring on the crucible former. Fill to just below<br />

the edge of the silikon ring with special investm<strong>en</strong>t for injection<br />

moulded ceramics. Put on the mould base former turning g<strong>en</strong>tly<br />

(investm<strong>en</strong>t should exude easily through the op<strong>en</strong>ing). After the<br />

investm<strong>en</strong>t has set, turn the mould base former and mould former<br />

carefully to remove them. Smooth the underside with a plaster<br />

knife. Follow the directions for preheating in the instructions for<br />

use for the investm<strong>en</strong>t.<br />

Important: Do not preheat the pellets!<br />

Preheat the aluminium plunger!<br />

Do not preheat the one-way plunger!

I N J E C T I N G<br />

KLEMA Press 100g Mould 200g Mould 300g Mould<br />

Stand-by Temperature 800 °C 800 °C 800 °C<br />

Sealing Time 00:00 min. 00:00 min. 00:00 min.<br />

Heat Rate 60 °C/min. 60 °C/min. 60 °C/min.<br />

Vacuum Start 800 °C 800 °C 800 °C<br />

Vacuum Hold 30:00 min. 30:00 min. 37:00 min.<br />

Vacuum Limit 730 mm 730 mm 730 mm<br />

Firing Temperature 930 °C 940 °C 975 °C<br />

Holding Time 20:00 min. 20:00 min. 25:00 min.<br />

Injection Temperature 930 °C 940 °C 975 °C<br />

Injection Time 10:00 min. 10:00 min. 12:00 min.<br />

These firing parameters repres<strong>en</strong>t standard values and have to be adjusted to respective situation.<br />

10 | LOW & M E TA L

DEVESTING<br />

11 | LOW & M E TA L<br />

Mark the l<strong>en</strong>gth of the plunger on the mould and separate along<br />

the l<strong>en</strong>gth of the mark. Th<strong>en</strong> carefully break apart the sections of<br />

the mould. The pressings should be roughly blasted with glass<br />

beads (50 μm) at 4 bars with a p<strong>en</strong> blaster, th<strong>en</strong> carefully with glass<br />

beads (50 μm) at 2 bars.<br />

Do not use aluminium oxide for blasting!

F I N I S H I N G<br />

12 | L O W<br />

Carefully remove the sprue pins with a suitable cut-off disc.<br />

Now fit the pressed parts onto the die and th<strong>en</strong> dep<strong>en</strong>ding on<br />

the technique used - carry out the finishing.<br />

BUILD-UP TECHNIQUE<br />

The fully anatomically modelled restoration should be reduced<br />

with finishing abrasives that are suitable for working porcelain or<br />

if the restoration was reduced before wax-up, prepare it for v<strong>en</strong>eering.<br />

Before layering, the surface should be blasted with aluminium<br />

oxide (50 μm) and very slight pressure (1bar). Layering can be<br />

started after through cleaning (steam blaster/ultrasonic cleaner).<br />

Minimum framework thickness 0,8 mm or rather 2/3 of the anatomical<br />

form must consist of pressable ceramic!

STAINING TECHNIQUE<br />

13 | L O W<br />

The objects are ready-finished (contact points, surface texture<br />

etc.). Wh<strong>en</strong> using silicone rubber polisher, blasting with aluminium<br />

oxide (50 μm) and slight pressure (1bar) are required. Any<br />

corrections can still be made with the <strong>Creation</strong> LF layering porcelain<br />

before staining. Individual characterisation is th<strong>en</strong> done with the<br />

<strong>Creation</strong> CC.LF. Make Up Instant stains. One or more stain firings<br />

may be carried out, dep<strong>en</strong>ding on the situation. Th<strong>en</strong> glaze the<br />

ready-stained restoration once or twice.

B U I L D - U P<br />

14 | L O W<br />

Layering with <strong>Creation</strong> LF. Before layering, a characterisation<br />

firing with <strong>Creation</strong> CC.LF. Make Up Instant stains can be fixed.<br />

Missing areas of d<strong>en</strong>tine can be added using d<strong>en</strong>tine porcelain.<br />

The incisal parts are added to the anatomical form, th<strong>en</strong> fired as<br />

specified in the firing chart. Firing is performed on firing cotton<br />

or thin metal firing pins (use platinfoil), but molars should only<br />

be fired on firing pad. A correction firing can be carried out, if<br />

necessary.<br />

A minimum thickness of 0,8 mm must be observed or 2/3 of the<br />

anatomical form must consist of pressable ceramic!

G L A Z E F I R I N G<br />

15 | L O W<br />

Small individual nuances can now be added with <strong>Creation</strong> CC.LF.<br />

Make Up Instant stains.<br />

Finally, carry out glazing or mechanical polishing.

F I R I N G I N S T R U C T I O N S<br />

STAINING TECHNIQUE<br />

Start Temp. Drying Time Raise of Temp. V 1 st Firing 2 nd Firing Holding Time<br />

Stains 450 °C 4 min. 45 °C/min. - 750 °C 750 °C 1 min.<br />

Glaze 450 °C 4 min. 45 °C/min. - 750 °C 740 °C 1 min.<br />

BUILD-UP TECHNIQUE<br />

16 | L O W<br />

Start Temp. Drying Time Raise of Temp. V Final Temp. Holding Time<br />

1 st D<strong>en</strong>tine Firing 450 °C 6 min. 45 °C/min. + 770 °C 1 min.<br />

2 nd D<strong>en</strong>tine Firing 450 °C 6 min. 45 °C/min. + 760 °C 1 min.<br />

Glaze Firing 480 °C 2 min. 45 °C/min. - 770 °C -<br />

Glaze Firing with Glaze Powder 480 °C 4 min. 45 °C/min. - 750 °C 1 min.<br />

These firing parameters repres<strong>en</strong>t standard values and have to be adjusted to respective situation. Decisive is the firing result.

COLOUR CHART<br />

TRANSPARENT PELLETS 2g<br />

Labial V<strong>en</strong>eer 3 LV 1 LV 2 LV 3<br />

Occlusal Enamel 4 OC 1 OC 2 OC 3 OC 4<br />

Occlusal Opaque 4 OO 1 OO 2 OO 3 OO 4<br />

DENTINE PELLETS 2g<br />

Vita ® Shade A1 A2 A3 A3,5 A4 B1 B2 B3 B4 C1 C2 C3 C4 D2 D3 D4<br />

D<strong>en</strong>tine 16 A1 A2 A3 A3,5 A4 B1 B2 B3 B4 C1 C2 C3 C4 D2 D3 D4<br />

Transpar<strong>en</strong>t D<strong>en</strong>tine 9 TA1 TA2 TA3 - - TB1 TB2 TB3 - TC1 TC2 - - TD2 - -<br />

Bleach D<strong>en</strong>tine 3 BD-A BD-B BD-B0<br />

Transp. Bleach D<strong>en</strong>tine 3 TBD-A TBD-B TBD-B0<br />

DENTINE PELLETS 5g<br />

Vita ® Shade A1 A2 A3 A3,5 A4 B1 B2 B3 B4 C1 C2 C3 C4 D2 D3 D4<br />

D<strong>en</strong>tine 9 A1 A2 A3 - - B1 B2 B3 - C1 C2 - - D2 - -<br />

Transpar<strong>en</strong>t D<strong>en</strong>tine 9 TA1 TA2 TA3 - - TB1 TB2 TB3 - TC1 TC2 - - TD2 - -<br />

Bleach D<strong>en</strong>tine 3 BD-A BD-B BD-B0<br />

Transpar<strong>en</strong>t Bleach D<strong>en</strong>tine 3 TBD-A TBD-B TBD-B0<br />

Vita ® is a registered trademark of VITA Zahnfabrik H. Rauter GmbH & Co. KG, Bad Säcking<strong>en</strong>, Germany.<br />

17 |<br />

LOW & M E TA L

CEMENTING ALL-CERAMIC PRESSED <strong>CR</strong>OWNS<br />

The restoration fabricated from <strong>Creation</strong> <strong>CP</strong> Low has to be<br />

adhesively cem<strong>en</strong>ted!<br />

18 | L O W<br />

Pre-treatm<strong>en</strong>t of the restoration before bonding (please follow<br />

the manufacturer’s instructions):<br />

• Carefully sandblast the inside of the crowns with Al 2O 3 (50 μm)<br />

and 1 bar of pressure.<br />

• Sandblasted surface.<br />

• Etch the rough<strong>en</strong>ed surface with maximum 10 % hydrofluoric<br />

acid for two minutes, according to the manufacturer’s<br />

instructions.<br />

• Thoroughly remove the acid residues under running water.<br />

Th<strong>en</strong> clean with ultrasound or steam blaster. In the dry state,<br />

a milky white surface (fluorosilicate crystals) is visible.<br />

• Acidify the fluorosilicate crystals with phosphoric acid (39%)<br />

for one minute. Th<strong>en</strong> thoroughly clean under running water.<br />

• The microret<strong>en</strong>tive surface is ready for adhesive bonding.

19 | M E TA L<br />

I N T R O D U C T I O N<br />

PRESS OVER METAL<br />

The press over metal technique combines in an unique way<br />

economic effici<strong>en</strong>cy and aesthetics. This technique offers unlimited<br />

possibilities to the technician, perfect ceramic shoulders<br />

for crowns as well as for bridges. „Press over metal“ combines<br />

the b<strong>en</strong>efits of a metal ceramic with the possibilities of press<br />

ceramics.<br />

· Cut back technique: For highly aesthetic restorations.<br />

· Cut back easy technique: Effici<strong>en</strong>t and ev<strong>en</strong> aesthetical with<br />

perfect accordance to the Vita ® Classic shade guide.<br />

· Staining posteriors: Easy, fast and beautiful.

C U T B A C K T E C H N I Q U E - M E TA L PA R T<br />

1<br />

20 | M E TA L<br />

ALLOY<br />

Overpress technique: Alloys with a coeffici<strong>en</strong>t thermal expansion<br />

betwe<strong>en</strong> 13,8 – 14,2 (25 ° – 500 °C) can be used.<br />

This information is not obligatory. Please check the alloys suitabilities<br />

for the press over technique before you start using it.<br />

WAXING-UP<br />

It is recomm<strong>en</strong>ded to produce a diagnostic wax-up to position<br />

the framework pattern correctly. You wax-up a little reduced as<br />

with the MC technique with full shoulder. The pattern should<br />

correspond to the reduced tooth mould to guarantee constant<br />

layer thickness. The later metal part should be kept as small as<br />

possible to avoid t<strong>en</strong>sion with the press ceramics.

C U T B A C K T E C H N I Q U E - M E TA L PA R T<br />

2<br />

3<br />

4<br />

21 | M E TA L<br />

SPRUEING - CASTING - FINISHING - OXIDIZING<br />

Refer to the alloy manufacturer`s instructions.<br />

FIRST OPAQUE FIRING<br />

Use the <strong>Creation</strong> CC Paste or Powder Opaque. Apply the<br />

opaque ev<strong>en</strong>ly that the metal is masked 75%.<br />

SECOND OPAQUE FIRING<br />

The opaque should have a shiny surface after firing. The second<br />

coating of opaque should mask the metal completely. The fired<br />

surface should shine lightly.

C R E AT I O N C C O P A Q U E - F I R I N G I N S T R U C T I O N S<br />

PASTE OPAQUE<br />

Preheating Drying Time Raise of Temp. V Final Temp. Holding Time<br />

1 st Opaque Firing 550 °C 6 min. 80 °C/min. + 980 °C * 1 min.<br />

2 nd Opaque Firing 550 °C 6 min. 80 °C/min. + 950 °C 1 min.<br />

<strong>CR</strong>EATION CC POWDER OPAQUE<br />

Preheating Drying Time Raise of Temp. V Final Temp. Holding Time<br />

1 st Opaque Firing 600 °C 2 min. 80 °C/min. + 980 °C * 1 min.<br />

2 nd Opaque Firing 600 °C 2 min. 80 °C/min. + 950 °C 1 min.<br />

*Wh<strong>en</strong> firing non-precious alloy: final temperature 1.000°C.<br />

These firing parameters repres<strong>en</strong>t standard values and have to be adjusted to respective situation. Decisive is the firing result.<br />

22 | M E TA L

C U T B A C K T E C H N I Q U E<br />

23 | M E TA L<br />

WAXING-UP<br />

The model is isolated and th<strong>en</strong> the framework is put on the model<br />

without pressure. According to the technique used you can<br />

either wax-up completely or reduce. The minimum thickness of<br />

the restoration is 0,8 mm.<br />

Important: Check internally for wax, keeping wax free!<br />

SPRUEING<br />

The objekt is sprued directly. The wax wire should be 3 mm in<br />

diameter, 5 – 7 mm long and should not taper towards the pattern.<br />

The pattern is waxed onto the crucible former in a c<strong>en</strong>tral<br />

position.<br />

P E L L E T<br />

Use a d<strong>en</strong>tine pellet (e.g.: D-A2).

C U T B A C K T E C H N I Q U E - P R E S S PA R T<br />

24 | M E TA L<br />

INVESTING<br />

See low technique (p. 8 – 9).<br />

P R E S S I N G<br />

See press parameter (p. 10, 30).<br />

DEVESTING<br />

See low technique (p. 11).

C U T B A C K T E C H N I Q U E - P R E S S PA R T<br />

25 | M E TA L<br />

FINISHING<br />

Cut off the sprues carefully using a suitable cut-off-disc. Work<br />

with low pressure and low r.p.m. (revolutions per minute). After<br />

separating, the work is carefully fitted onto the die (caution in<br />

the area metal press ceramic. Int<strong>en</strong>se heat can cause breaks!).<br />

The fully anatomically modelled restoration should be reduced<br />

or prepare the already reduced restoration for v<strong>en</strong>eering.

C U T B A C K T E C H N I Q U E - P R E S S PA R T<br />

1 2<br />

3 4<br />

5<br />

26 | M E TA L<br />

Layering with <strong>Creation</strong> LF. Additional staining with <strong>Creation</strong><br />

CC.LF. Make Up Instant can be carried out and fired before building-up.<br />

Build-up the incisal sections and fire according to the<br />

firing chart. D<strong>en</strong>tine porcelain can be used to build up sections<br />

with insuffici<strong>en</strong>t d<strong>en</strong>tine. A further add-on firing is carried out if<br />

required. Small acc<strong>en</strong>tuating high-lights can still be added using<br />

<strong>Creation</strong> CC.LF. Make Up Instant stains. Firing is carried out on<br />

pins, but be careful that the shoulder does not touch the firing pin.<br />

Restoration can be glazed or polished.

C U T B A C K E A S Y T E C H N I Q U E<br />

1<br />

2<br />

3<br />

27 | M E TA L<br />

METAL FRAMEWORK AND OPAQUE<br />

Follow the instructions „Cut back technique“.<br />

WAXING-UP<br />

Full contour wax-up.<br />

SPRUEING - INVESTING - PRESSING<br />

Follow the instructions for „Cut back technique“.<br />

Select a transpar<strong>en</strong>t d<strong>en</strong>tine pellet (e.g. TD-A1).

CUT BACK EASY TECHNIQUE<br />

1<br />

3<br />

5<br />

28 | M E TA L<br />

2<br />

4<br />

C U T B A C K<br />

Reduce the d<strong>en</strong>tine only in the upper third to provide space for<br />

the corresponding <strong>en</strong>amel (e.g.: E-58 for A2).<br />

E N A M E L B U I L D - U P<br />

Build-up the incisal area with a small amount of the corresponding<br />

<strong>en</strong>amel. You can make a correction if necessary.<br />

FINISHING<br />

Cut the crowns and finish them using glaze powder.

STAINING POSTERIORS<br />

1<br />

4<br />

7<br />

29 | M E TA L<br />

2<br />

5<br />

3<br />

6<br />

Use <strong>Creation</strong> CC past or powder<br />

opaque. Select a transpar<strong>en</strong>t<br />

d<strong>en</strong>tine pellet (e. g.: TD-A1).<br />

Finish with <strong>Creation</strong> CC.LF.<br />

Make Up Instant stains.<br />

Firing: See firing chart (p. 16).

INJECTING<br />

KLEMA Press 100g Mould 200g Mould 300g Mould<br />

Stand-by Temperature 800 °C 800 °C 800 °C<br />

Sealing Time 00:00 min. 00:00 min. 00:00 min.<br />

Heat Rate 60 °C/min. 60 °C/min. 60 °C/min.<br />

Vacuum Start 800 °C 800 °C 800 °C<br />

Vacuum Hold 30:00 min. 30:00 min. 37:00 min.<br />

Vacuum Limit 730 mm 730 mm 730 mm<br />

Firing Temperature 930 °C 940 °C 975 °C<br />

Holding Time 20:00 min. 20:00 min. 25:00 min.<br />

Injection Temperature 930 °C 940 °C 975 °C<br />

Injection Time 10:00 min. 10:00 min. 12:00 min.<br />

These firing parameters repres<strong>en</strong>t standard values and have to be adjusted to respective situation.<br />

30 | LOW & M E TA L

C U T B A C K - C O M B I N AT I O N C H A R T<br />

VITA ® SHADE<br />

Shade A1 A2 A3 A3,5 A4 B1 B2 B3 B4 C1 C2 C3 C4 D2 D3 D4<br />

Pellet A1 A2 A3 A3,5 A4 B1 B2 B3 B4 C1 C2 C3 C4 D2 D3 D4<br />

Opaque A1 A2 A3 A3,5 A4 B1 B2 B3 B4 C1 C2 C3 C4 D2 D3 D4<br />

Enamel E58 E58 E59 E59 E60 E57 E59 E59 E59 E60 E59 E59 E60 E60 E59 E59<br />

Vita ® is a registered trademark of VITA Zahnfabrik H. Rauter GmbH & Co. KG, Bad Säcking<strong>en</strong>, Germany.<br />

BLEACH<br />

Shade A B B0<br />

Pellet BD-A BD-B BD-B0<br />

Opaque 0-AB 0-AB 0-AB<br />

Enamel S-AB S-AB S-AB<br />

31

CUT BACK EASY - COMBINATION CHART<br />

VITA ® SHADE<br />

Shade A1 A2 A3 A3,5 A4 B1 B2 B3 B4 C1 C2 C3 C4 D2 D3 D4<br />

Pellet TA1 TA2 TA3 TA3 TA3 TB1 TB2 TB3 TB3 TC1 TC2 TC2 TC2 TD2 TD2 TD2<br />

Opaque A1 A2 A3 A3,5 A4 B1 B2 B3 B4 C1 C2 C3 C4 D2 D3 D4<br />

Enamel E58 E58 E59 E59 E60 E57 E59 E59 E59 E60 E59 E59 E60 E60 E59 E59<br />

Stains - - - A A - - - B - - C C - D D<br />

Vita ® is a registered trademark of VITA Zahnfabrik H. Rauter GmbH & Co. KG, Bad Säcking<strong>en</strong>, Germany.<br />

B L E A C H<br />

Shade A B B0<br />

Pellet TBD-A TBD-B TBD-B0<br />

Opaque 0-AB 0-AB 0-AB<br />

Enamel S-AB S-AB S-AB<br />

Stains - - -<br />

32

S TA I N I N G P O S T E R I O R - C O M B I N AT I O N C H A R T<br />

VITA ® SHADE<br />

Shade A1 A2 A3 A3,5 A4 B1 B2 B3 B4 C1 C2 C3 C4 D2 D3 D4<br />

Pellet TA1 TA1 TA2 TA3 TA3 TB1 TB1 TB2 TB3 TC1 TC1 TC2 TC2 TD2 TD2 TD2<br />

Opaque A1 A3,5 A3,5 A3,5 A4 B1 B3 B3 B3 C1 C3 C3 C4 D2 D3 D4<br />

Stains A A A A A B B B B B B C C D D D<br />

Vita ® is a registered trademark of VITA Zahnfabrik H. Rauter GmbH & Co. KG, Bad Säcking<strong>en</strong>, Germany.<br />

B L E A C H<br />

Shade A B B0<br />

Pellet TBD-A TBD-B TBD-B0<br />

Opaque 0-AB 0-AB 0-AB<br />

Stains - - -<br />

33

P H Y S I C A L P R O P E R T I E S<br />

Properties Measure Value Norm<br />

Coeffici<strong>en</strong>t Thermal Expansion (25 ° – 500 °C) 10 -6 xK -1<br />

13,1 ± 0,3<br />

Glass Transition Temperature °C 585 ± 10<br />

Solubility μg/cm 2<br />

20 max. 100<br />

Flexural Str<strong>en</strong>gth MPa (Nmm 2 ) 115 min. 100<br />

All tested materials conform to EN ISO 9693:2000. The technical and physical values quoted relate to samples produced in-house and to our own measuring<br />

instrum<strong>en</strong>ts.<br />

34 | L O W & M E TA L

36<br />

Distributor<br />

<strong>Creation</strong> <strong>Willi</strong> <strong>Geller</strong> International GmbH<br />

Koblacherstraße 3, 6812 Meining<strong>en</strong>, Austria<br />

Tel. +43 (0)5522 76784<br />

Fax. +43 (0)5522 73699<br />

info@creation-willigeller.com<br />

www.creation-willigeller.com<br />

Technical inquiries:<br />

technic@creation-willigeller.com<br />

Errors and printing errors exepted.<br />

Subject to changes at any time.<br />

Manufacturer<br />

KLEMA D<strong>en</strong>talprodukte GmbH<br />

Koblacherstr. 3a, 6812 Meining<strong>en</strong>, Austria<br />

0483<br />

910161 03/09<br />

© <strong>Creation</strong> <strong>Willi</strong> <strong>Geller</strong> International GmbH