Autoflow-Mod DS 11-05 - Quasys

Autoflow-Mod DS 11-05 - Quasys

Autoflow-Mod DS 11-05 - Quasys

- TAGS

- quasys

- www.quasys.ch

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

hermetic sealing<br />

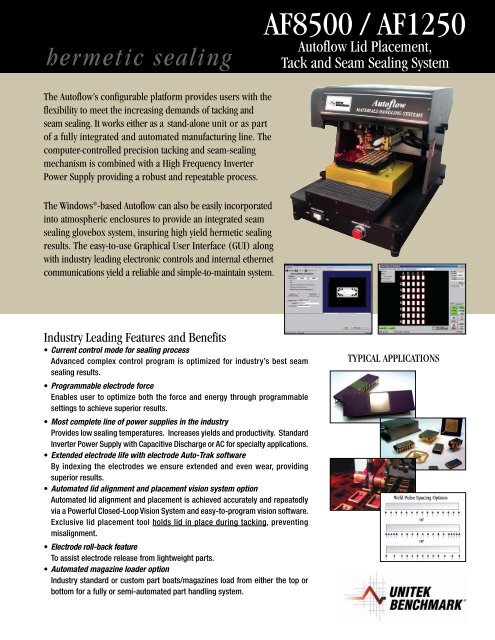

The <strong>Autoflow</strong>’s configurable platform provides users with the<br />

flexibility to meet the increasing demands of tacking and<br />

seam sealing. It works either as a stand-alone unit or as part<br />

of a fully integrated and automated manufacturing line. The<br />

computer-controlled precision tacking and seam-sealing<br />

mechanism is combined with a High Frequency Inverter<br />

Power Supply providing a robust and repeatable process.<br />

The Windows ® -based <strong>Autoflow</strong> can also be easily incorporated<br />

into atmospheric enclosures to provide an integrated seam<br />

sealing glovebox system, insuring high yield hermetic sealing<br />

results. The easy-to-use Graphical User Interface (GUI) along<br />

with industry leading electronic controls and internal ethernet<br />

communications yield a reliable and simple-to-maintain system.<br />

Industry Leading Features and Benefits<br />

• Current control mode for sealing process<br />

Advanced complex control program is optimized for industry’s best seam<br />

sealing results.<br />

• Programmable electrode force<br />

Enables user to optimize both the force and energy through programmable<br />

settings to achieve superior results.<br />

• Most complete line of power supplies in the industry<br />

Provides low sealing temperatures. Increases yields and productivity. Standard<br />

Inverter Power Supply with Capacitive Discharge or AC for specialty applications.<br />

• Extended electrode life with electrode Auto-Trak software<br />

By indexing the electrodes we ensure extended and even wear, providing<br />

superior results.<br />

• Automated lid alignment and placement vision system option<br />

Automated lid alignment and placement is achieved accurately and repeatedly<br />

via a Powerful Closed-Loop Vision System and easy-to-program vision software.<br />

Exclusive lid placement tool holds lid in place during tacking, preventing<br />

misalignment.<br />

• Electrode roll-back feature<br />

To assist electrode release from lightweight parts.<br />

• Automated magazine loader option<br />

Industry standard or custom part boats/magazines load from either the top or<br />

bottom for a fully or semi-automated part handling system.<br />

AF8500 / AF1250<br />

<strong>Autoflow</strong> Lid Placement,<br />

Tack and Seam Sealing System<br />

TYPICAL APPLICATIONS

<strong>Autoflow</strong> Optional Features<br />

<strong>Autoflow</strong> Configurations and Options<br />

• Stand Alone Tacking Station (vision optional)<br />

• Stand Alone Seam Sealing<br />

• Combined Tacking and Sealing Station (vision optional)<br />

Sealing Motions: Linear and/or Rotary<br />

Working Envelope: 203 mm or 304 mm (8” or 12”)<br />

Part Holding: Part nest (pallet), industry standard part boats or custom fixtures<br />

Lid Handling: Bowl feeder, pallet pickup or lid magazine with auto-locator<br />

Automated Handling: Industry standard magazines or integrated as part of<br />

an automated production process<br />

Higher Yields With Advanced<br />

HF25 Inverter Power Supply<br />

• 25 kHz feedback rate for closed<br />

loop electrical current control<br />

• Automatically compensates for<br />

variations in lid-to-part dimensions<br />

and electrical properties<br />

• Conditioning weld pulse brings each<br />

part to same resistance prior to<br />

application of welding current<br />

• Weld pulse shaping feature ramps<br />

energy up or down to reduce<br />

cracking and leaks<br />

• Energy output is independent of<br />

input line voltage fluctuations<br />

SPECIFICATIONS<br />

Part Size: 3mm – 203mm (0.1 inches – 8 inches)<br />

Positioning Accuracy: ±0.<strong>05</strong>0mm (±0.002 inches)<br />

Weld Force (Programmable): 500 to 5000 grams (standard)<br />

200-500 grams Low Force option available<br />

Weld Linear Speed: 38mm/sec Max. (1.5 inches/sec Max.)<br />

Rotary Position (Optional): ±12 arc minutes<br />

Rotary Speed (Optional): 0 to 28.8°/second – 1800° rotation Max.<br />

Compressed Air Requirements: 60 psi minimum<br />

Vacuum Requirements 950 mbars<br />

for Pickup Head: (optional venturi pump available)<br />

Your Local Representative<br />

Specifications subject to change without notice.<br />

Copyright© 2006 Miyachi Unitek Corporation. The material contained herein<br />

cannot be reproduced or used in any other way without the express written<br />

permission of Miyachi Unitek Corporation. All rights reserved.<br />

<strong>Mod</strong>el AF1250, shown<br />

with optional magazine handler for<br />

automated pallet loading and unloading.<br />

Leading Edge Software Options<br />

Batch Reporting Software option records lot number, operator,<br />

time, date, sealing schedule name, part serial number<br />

• Provides process and part traceability<br />

• Exportable via .CSV format<br />

WM3000 Weld Monitor Software option provides real-time and<br />

historical process analysis<br />

• Compares actual measurements to entered process setpoints<br />

• Informative graphical analysis screens<br />

Input Power – 120VAC 50/60 Hz, 15 amps<br />

<strong>Autoflow</strong> Mechanism:<br />

Calibration: To NIST standards<br />

HF25 Current Output: 50 to 2400 amps, ±2 amps<br />

HF25 Pulse Width: 0.3 to 2000 milliseconds<br />

Input Power – HF25: 192-264VAC, 50/60 Hz, 25 amps, 3 PH or<br />

320-440VAC, 50/60 Hz, 13 amps, 3 PH<br />

Miyachi Unitek Corporation<br />

1820 S. Myrtle Ave.<br />

P.O. Box 5033 • Monrovia, CA 91017-7133 USA<br />

Tel: (626) 303-5676 • FAX: (626) 359-7930<br />

E-Mail: sales@unitekbenchmark.com<br />

Internet http://www.miyachiunitek.com Optional Rotary Table<br />

991-017 02/06