detection of heavy metals by using a composite sensor ... - Lirmm

detection of heavy metals by using a composite sensor ... - Lirmm

detection of heavy metals by using a composite sensor ... - Lirmm

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DETECTION OF HEAVY METALS BY USING A COMPOSITE SENSOR<br />

BASED ON A BUILT-IN BISMUTH PRECURSOR<br />

M.T. Castañeda, 1, * B. Pérez, M. Pumera, M. del Valle, A.Merkoçi, S. Alegret<br />

Grup de Sensors i Bio<strong>sensor</strong>s, Departament de Química, Universitat Autònoma de Barcelona, 08193<br />

Bellaterra, Catalonia, Spain,<br />

1 On leave from: Departamento de Ciencias Básicas, Universidad Autónoma Metropolitana-Azcapotzalco, Av.<br />

San Pablo 180, Col. Reynosa Tamaulipas 022000, México, D. F., MÉXICO.<br />

* Corresponding author; email: tcb@correo.azc.uam.mx, tel: 34-93581 2118, fax: 34-93581 2379<br />

Abstract: A new graphite-epoxy <strong>composite</strong> electrode (GECE) containing Bi(NO3)3 as built-in bismuth precursor<br />

for simultaneous and individual anodic stripping analysis <strong>of</strong> <strong>heavy</strong> trace <strong>metals</strong> is reported. The developed<br />

Bi(NO3)3-GECE is compatible with bismuth film electrodes reported previously, including the <strong>composite</strong><br />

electrodes (Bi-GECE) recently reported <strong>by</strong> our group. The sensitive response, combined with the minimal<br />

toxicity <strong>of</strong> the Bi(NO3)3 allow its utilization in environmental quality monitoring as well as other applications.<br />

Keywords: bismuth nitrate, graphite-epoxy <strong>composite</strong> electrode, <strong>heavy</strong> <strong>metals</strong>.<br />

INTRODUCTION<br />

Mercury-modified electrodes coupled with stripping<br />

techniques have been recognised as the most<br />

sensitive methods for determination <strong>of</strong> <strong>heavy</strong><br />

<strong>metals</strong> [1]. However, the potential dangers<br />

associated with mercury have led to developing<br />

mercury-free <strong>sensor</strong>s. Unmodified electrodes like<br />

bare carbon, gold or iridium [2-4], graphite-epoxi<br />

<strong>composite</strong>s [5-7], recordable CD [8] or silver-plated<br />

rotograved carbon electrodes [9] have been used<br />

as an alternative to mercury based electrodes.<br />

One <strong>of</strong> the excited alternatives to mercury based<br />

electrodes is that based on bismuth [10]. Our group<br />

have configured Bi-GECE [11], based on graphiteepoxy<br />

<strong>composite</strong> electrode (GECE) without<br />

modification but bismuth film formation due to the<br />

presence <strong>of</strong> bismuth in the measuring solution. In<br />

the present work we present a novel configuration,<br />

Bi(NO3)3-GECE that represents GECE modified<br />

internally with bismuth nitrate salt which serves as<br />

built-in bismuth precursor for bismuth film<br />

formation. This represents an integrated<br />

configuration <strong>of</strong> bismuth based GECEs for stripping<br />

analysis. The low toxicity <strong>of</strong> bismuth makes it an<br />

alternative material to mercury in terms <strong>of</strong> trace<br />

metal determination.<br />

EXPERIMENTAL<br />

The lead and cadmium stock solutions were<br />

prepared <strong>by</strong> dissolving the corresponding nitrates<br />

in water obtained from an ion-exchange system<br />

Milli-Q (Millipore). Acetate buffer (0.1 M, pH 4.5) or<br />

HCl 0.5 M were used as supporting electrolyte. The<br />

Bi(NO3)3GECE were prepared <strong>using</strong> graphite<br />

powder with a particle size <strong>of</strong> 50 µm (BDH, UK),<br />

Epotek H77 (epoxy resin), hardener (both from<br />

Epoxy Technology, USA) and Bi(NO3)3 (Aldrich).<br />

Graphite powder and Bi(NO3)3 salt were first mixed<br />

together. The obtained dried mixture was mixed<br />

well with epoxy resin (mixed with hardener) in a<br />

ratio <strong>of</strong> 1:4 (w/w) as described in a previous work<br />

[12,13]. The percentage <strong>of</strong> Bi(NO3)3 in the prepared<br />

paste was varied being 0.1, 0.5, and 2.0 % (w/w).<br />

The resulting Bi(NO3)3 containing graphite-epoxy<br />

paste was placed into a PVC cylindrical sleeve<br />

body (6 mm i. d.), which has an inner electrical<br />

copper contact, to a depth <strong>of</strong> 3 mm. The conducting<br />

<strong>composite</strong> material glued to the copper contact was<br />

cured at 40 ºC during one week. Before each use,<br />

the surface <strong>of</strong> the electrode was wet with doubly<br />

distilled water and then thoroughly smoothed, first<br />

with abrasive paper and then with alumina paper<br />

(polishing strips 301044-001, Orion).<br />

A platinum auxiliary electrode (model 52-67 1,<br />

Crison, Spain) and double junction Ag/AgCl<br />

reference electrode (Orion 900200) with 0.1 M KCl<br />

as external reference solution and the Bi(NO3)3-<br />

GECE as working electrode were used. The square<br />

wave anodic stripping voltammetry (SWASV)<br />

experiments were performed <strong>using</strong> an Autolab<br />

PGSTAT 20 System (Eco-chemie, The<br />

Netherlands). A Hitachi S-570, Japan Scanning<br />

Electron Microscope (SEM) was used to observe<br />

the surface <strong>of</strong> the working electrodes.<br />

SWASV measurements were carried out in the<br />

presence <strong>of</strong> dissolved oxygen. The three<br />

electrodes were immersed into the electrochemical<br />

cell containing 25 mL 0.1 mL 0.1 M acetate buffer<br />

(pH 4.5). The deposition potential <strong>of</strong> -1.3 V was<br />

applied to Bi(NO3)3-GECE while the solution was<br />

stirred. Following 120 s deposition step, the stirring<br />

was stopped and after 15 s equilibration, the<br />

voltammogram was recorded <strong>by</strong> applying a squarewave<br />

potential scan between -1.3 and -0.3 V with a<br />

frequency <strong>of</strong> 50 Hz, amplitude <strong>of</strong> 20 mV and<br />

potential step <strong>of</strong> 20 mV.<br />

Aliquots <strong>of</strong> the target metal standard solution were<br />

introduced after recording the background<br />

voltammograms. A 60 s conditioning step at +0.6 V<br />

(with solution stirring) was used to remove the<br />

remaining reduced target <strong>metals</strong> and bismuth, prior<br />

to the next cycle. The electrodes were washed<br />

thoroughly with deionized water between each test.

Measurements in phosphate buffer for the study <strong>of</strong><br />

pH effect as well as in HCl medium were also<br />

performed in the same experimental conditions as<br />

described above.<br />

RESULTS AND DISCUSSION<br />

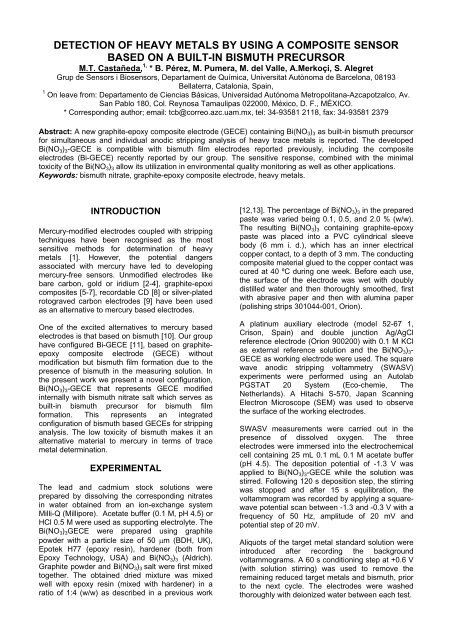

The surface morphologies <strong>of</strong> Bi(NO3)3-GECEs<br />

(containing different quantities <strong>of</strong> Bi(NO3)3 salt)<br />

before and after the preconcentration step<br />

(electrolysis at -1.3 V during 120 s) were observed<br />

<strong>by</strong> Scanning Electron Microscopy (SEM).<br />

As can be seen, the surfaces <strong>of</strong> Bi(NO3)3-GECE,<br />

with different concentration <strong>of</strong> Bi(NO3)3, before<br />

preconcentration step (Fig. 1 A) appears to have<br />

clusters <strong>of</strong> conducting material gathered in random<br />

areas. This is due to the graphite particles<br />

randomly distributed and randomly oriented in the<br />

epoxy resin [14]. Microcrystalline Bi(NO3)3 particles<br />

should be also distributed randomly but due to the<br />

very low percentage (0.1 to 2.0 %, w/w) were not<br />

visible. The darker coverage <strong>of</strong> the same Bi(NO3)3-<br />

GECEs after preconcentration step (Fig. 1 B)<br />

compared to Bi(NO3)3-GECE before<br />

preconcentration (Fig. 1 A) is clearly visible. This is<br />

due to the bismuth film formation coming from the<br />

Bi(NO3)3 salt inside the <strong>sensor</strong> matrix.<br />

The quantity <strong>of</strong> Bi(NO3)3 didn’t have any visible<br />

effect on the <strong>sensor</strong> surface. The images 1 B (a-c)<br />

have similar darkness. Seems that for the Bi(NO3)3<br />

quantities used the bismuth film has the same<br />

configuration.<br />

For all the Bi(NO3)3-GECEs after the<br />

preconcentration step there can be also seen<br />

dimensional fibril-like networks onto their surfaces<br />

which is in correlation with the early report <strong>of</strong> Bi-film<br />

at carbon surface [10]. The black and thick<br />

appearances <strong>of</strong> bismuth deposit can be attributed<br />

to carbon substrate that has positive effect on the<br />

nucleation and growth <strong>of</strong> the bismuth film. The<br />

same deposition <strong>of</strong> bismuth was clearly observed<br />

for GECE used in connection with bismuth in<br />

measuring solution.<br />

The characteristics <strong>of</strong> the electrodes must be very<br />

dependent on the amounts <strong>of</strong> Bi(NO3)3 used for the<br />

Bi(NO3)3-GECEs preparation.<br />

The effect <strong>of</strong> Bi(NO3)3 loadings (0.1-2.0 %, w/w) in<br />

the SWASV <strong>of</strong> the resulting Bi(NO3)3-GECEs were<br />

studied for a 70 ppb solution <strong>of</strong> Pb 2+ at 0.1 M<br />

acetate buffer pH 4.5. The increase <strong>of</strong> Bi(NO3)3<br />

content in the <strong>composite</strong> electrode increase the<br />

bismuth ion release during the contact with the<br />

measuring solution, and consequently the bismuth<br />

film formation capability. On the other hand, the<br />

higher Bi(NO3)3 content may reduce the<br />

conductivity <strong>of</strong> the Bi(NO3)3–GECE. A maxim<br />

response was observed for Bi(NO3)3-GECE<br />

containing 0.1 % Bi(NO3)3.<br />

The stripping performance <strong>of</strong> Bi(NO3)3-GECE was<br />

tested for lead and cadmium and the resulting<br />

voltammograms are showed in Fig.2. The Figure<br />

demonstrates the square wave stripping<br />

voltammograms for increasing concentration <strong>of</strong><br />

cadmium (A) in 10 µg L -1 steps (b–j) and lead (B) in<br />

10 µg L -1 steps (b–h). Also shown are the<br />

corresponding blank voltammograms (a) and the<br />

calibration plots (right) over the ranges 10 – 90 µg<br />

L -1 cadmium and 10 – 70 µg L -1 lead. The Bi(NO3)3-<br />

GECE displays well-defined and single peaks for<br />

cadmium (Ep = -0.76 V) and lead (Ep = -0.54 V).<br />

Detection limits <strong>of</strong> 7.23 and 11.81 µg L -1 can be<br />

estimated for cadmium and lead respectively based<br />

on the upper limit approach (ULA) [15]. Also in the<br />

concentration ranges mentioned above, the<br />

calibration plots (right) were linear exhibiting the R<br />

values <strong>of</strong> 0.9968 and 0.9953 for cadmium and lead<br />

respectively.<br />

As in the case <strong>of</strong> Bi-GECE the bismuth film<br />

formation onto Bi(NO3)3-GECE is shown to be a<br />

homogenous and uniform one due to the novel<br />

supporting material. The rich microstructure <strong>of</strong><br />

Bi(NO3)3-GECE, composed <strong>of</strong> a mixture <strong>of</strong> carbon<br />

microparticles forming internal microarrays might<br />

have a pr<strong>of</strong>ound effect upon the bismuth film<br />

structural features. The obtained peak widths <strong>of</strong> 20<br />

mV for lead and cadmium were similar to other<br />

bismuth film electrodes reported previously.<br />

The simultaneous measuring <strong>of</strong> lead and cadmium<br />

with Bi(NO3)3-GECE was also performed as shown<br />

at Fig.3. This figure displays square wave stripping<br />

voltammograms for cadmium (Ep= -0.72 V) and<br />

lead (Ep= -0.54 V) for increasing concentrations in<br />

10 µg L -1 steps (Pb) and 20 µg L -1 steps (Cd) (b–e).<br />

The well resolved peaks increase linearly with the<br />

metal concentration. The voltammogram clearly<br />

indicates that these <strong>metals</strong> can be measured<br />

simultaneously following a short deposition time <strong>of</strong><br />

2 min. In the concentration range from 10-40 µg Pb<br />

L -1 and 20-80 µg Cd L -1 the stripping signals<br />

remained undistorted and the resulting calibrating<br />

plots <strong>of</strong> this concentration range are linear<br />

exhibiting the R values <strong>of</strong> 0.9562 and 0.9762<br />

respectively, for lead and cadmium. Detection limits<br />

<strong>of</strong> around 19.1 and 35.8 µg L -1 can be estimated for<br />

lead and cadmium respectively based on the same<br />

method [15].<br />

A more sensitive measurement was observed for<br />

lead at 0.5 M HCl as measuring solution. Fig.4<br />

represent typical subtractive square-wave stripping<br />

voltammograms (removing blanks) for increasing<br />

concentration <strong>of</strong> lead ranging from 1 to 10 µg L -1<br />

steps (a–h). Also the calibration plot (right) over the<br />

studied range, is shown. This highly sensitive<br />

response in HCl medium, as expected also from

a<br />

b<br />

c<br />

the study <strong>of</strong> the pH effect is probably related to an<br />

improved bismuth release and alloy formation in<br />

this medium.<br />

The stability <strong>of</strong> the Bi(NO3)3-GECEs in 10<br />

consecutive measurements for 50 ppb cadmium in<br />

0.1 M acetate buffer <strong>of</strong> pH 4.5 and <strong>using</strong> the same<br />

surface was tested. It was observed that the<br />

reproducibility <strong>of</strong> the obtained current peak was<br />

comparable with that <strong>of</strong> the Bi-GECE [11]<br />

developed previously, that uses bismuth solution. It<br />

seems that the Bi precursor in the Bi(NO3)3-GECEs<br />

surface keeps ensuring the same <strong>heavy</strong> metal<br />

preconcentration. The relative standard deviation <strong>of</strong><br />

this measurement was 9.33 %.<br />

Although the Bi(NO3)3 particles were not uniform in<br />

size they were expected to be exposed in a<br />

reproducible way onto the freshly obtained<br />

Bi(NO3)3-GECE surfaces after each mechanical<br />

polishing procedure. This was confirmed <strong>by</strong><br />

checking the reproducibility <strong>of</strong> the measurements<br />

for a series <strong>of</strong> 10 different surfaces <strong>of</strong> the same<br />

Bi(NO3)3-GECE. The relative standard deviations <strong>of</strong><br />

these measurements performed in the same<br />

experimental conditions as for the stability study<br />

was 10.69% for cadmium measurements.<br />

A B<br />

50 µm<br />

Fig.1 Scanning electron microscopy images for Bi(NO3)3-<br />

GECE before (A) and after (B) the preconcentration step<br />

from solutions <strong>of</strong> 0.1 M acetate buffer (pH 4.5) at -1.3 V<br />

during 120 s. All electrode surfaces have been polished<br />

in the same way as explained in the text. The same<br />

accelerated voltage (10 kV) and resolution (10 µm) were<br />

used. The Bi(NO3)3 concentrations in the prepared<br />

<strong>sensor</strong>s were 0.1 (a), 0.5 (b) and 2.0 % (c) (w/w).<br />

A<br />

B<br />

5µA<br />

Fig2. Square-wave stripping voltammograms for<br />

increasing concentration <strong>of</strong> cadmium (A) in 10 µg L -1<br />

steps (b – h) and lead (B) in 10 µg/L steps (b – j). Also<br />

are shown the corresponding blank voltammograms<br />

(a) and the calibration plots (right) over the ranges 10<br />

– 90 µg L -1 cadmium and 10 – 70 µg L -1 lead.<br />

Solutions 0.1 M acetate buffer (pH 4.5). Square-wave<br />

voltammetric scan with a frequency <strong>of</strong> 50 Hz, potential<br />

step <strong>of</strong> 20 mV and amplitude <strong>of</strong> 20 mV. Deposition<br />

potential <strong>of</strong> -1.3 V during 120 s.<br />

10µA<br />

Cd<br />

Pb<br />

d<br />

c<br />

b<br />

a<br />

e<br />

-0.9 -0.7 -0.5<br />

j<br />

i<br />

h hh<br />

g gg<br />

f<br />

e<br />

d<br />

c<br />

b bb<br />

a<br />

-1.0 -0.8 -0.6 -0.4<br />

10µA<br />

d<br />

c<br />

h<br />

g<br />

f<br />

e<br />

b<br />

b<br />

a<br />

-0.7 -0.6 -0.5 -0.4 -0.3<br />

e<br />

I (µA)<br />

I (µA)<br />

14.0<br />

10.0<br />

40 40.0<br />

20 20.0<br />

00.0<br />

16<br />

12<br />

Cd<br />

10 30 50 70<br />

Fig. 3 Determination <strong>of</strong> cadmium and lead for increasing<br />

concentrations in 10 µg L -1 steps (Pb) and 20 µg L -1<br />

steps (Cd); concentration ranges <strong>of</strong> 10 – 40 (Pb) and 20<br />

– 80 (Cd) µg L -1 . Also is shown the blank (a) and the<br />

corresponding calibration plots. Experimental conditions<br />

as in Fig. 2.<br />

6.0<br />

2.0<br />

50<br />

30<br />

10<br />

8<br />

4<br />

0<br />

0 20 40 60 80 100<br />

E (V) [Cd 2+ ] (µg L -1 )<br />

I (µA)<br />

0 20 40 60<br />

E (V) [Pb 2+ ] (µg L -1 )<br />

Pb<br />

E (V) [Pb 2+ ], [Cd 2+ ] (µg L -1 )

10µA<br />

h<br />

g<br />

f<br />

e<br />

d<br />

c<br />

b<br />

a<br />

I (µA)<br />

-0.7 -0.6 -0.5 -0.4 -0.3<br />

20<br />

15<br />

10<br />

Fig. 4 Square-wave stripping voltammograms for<br />

increasing concentration <strong>of</strong> lead: (a) 1, (b) 2, (c) 3, (d) 4,<br />

(e) 5, (f) 8, (g) 9, (h) 10 µg L -1 . Also is shown the<br />

corresponding calibration plot (right) over the range 1–10<br />

µg L -1 lead. The measuring solution was 0.5 M HCl.<br />

Other experimental conditions as in Fig. 2.<br />

CONCLUSIONS<br />

0 2 4 6 8 10<br />

A novel GECE that incorporates Bi(NO3)3 salt in the<br />

sensing matrix is developed. The resulted Bi(NO3)3-<br />

GECE is compatible with bismuth-film electrodes<br />

for use in stripping analysis <strong>of</strong> <strong>heavy</strong> <strong>metals</strong>. The<br />

built-in bismuth property is the distinctive feature <strong>of</strong><br />

this Bi(NO3)3 modified GECE which can be utilized<br />

for the generation <strong>of</strong> bismuth adjacent to the<br />

electrode surface.<br />

The developed Bi(NO3)3-GECE is related with an<br />

in-situ bismuth ions generation and film formation<br />

without the necessity <strong>of</strong> external addition <strong>of</strong> the<br />

bismuth in the measuring solution. The good<br />

stability (9.33 % for cadmium measurements) <strong>of</strong> the<br />

Bi(NO3)3-GECE is owing to the unique surface<br />

morphology resulting in enhanced contact between<br />

the GECE matrix and the electrochemically<br />

reduced bismuth. Moreover, the surface <strong>of</strong> the<br />

Bi(NO3)3-GECE could be renewed easily <strong>by</strong> simple<br />

polishing so that the utility <strong>of</strong> the <strong>sensor</strong> is<br />

improved.<br />

5<br />

0<br />

E (V) [Pb2+ ] (µg L-1 E (V) [Pb )<br />

2+ ] (µg L-1 )<br />

The convenience <strong>of</strong> this built-in bismuth <strong>sensor</strong> in<br />

voltammetric analysis will be greatly improved if<br />

this novel <strong>composite</strong> should be used <strong>by</strong> screen<br />

printed technology. The utilization <strong>of</strong> the Bi(NO3)3-<br />

GECE for real <strong>heavy</strong> metal samples along with<br />

other applications are underway in our laboratory.<br />

REFERENCES<br />

1. J. Wang, Stripping Analysis; VCH Publishers:<br />

Deerfield Beach, 1985.<br />

2. E. Achterberg, P.; Braungardt, Anal. Chim. Acta<br />

400 (1999) 381.<br />

3. J. Wang, B. Tian. Anal. Chem. 65 (1993) 1529.<br />

4. M. A Nolan, S. P Kounaves, Anal. Chem. 71<br />

(1999) 3567.<br />

5. M. Serradell, S., Izquierdo, L. Moreno, A.<br />

Merkoçi, S. Alegret. Electroanalysis 14 (2002)<br />

1281.<br />

6. L. Moreno, A. Merkoçi, S. Alegret, Electrochim.<br />

Acta 48 (2003) 2599.<br />

7. S. Carrégalo, A. Merkoçi, S. Alegret,<br />

Microchimica Acta 147(2004) 245.<br />

8. L Angnes, E.M Richter, M.A. Augelli, G.H.<br />

Kume, Anal.Chem. 72 (2000) 5503.<br />

9. P.R.M Silva, El. Khakami, M. Chaker, A.<br />

Dufrense, F. Courchesne, Sensors and<br />

Actuators B. 76 (2001) 250.<br />

10. J. Wang, J. Lu, S.B. Hocevar, P.A.Farias, B.<br />

Ogorevc; Analytical Chemistry, 72 (2000) 3218.<br />

11. Ü.A.Kırgöz,S.Marín, M.Pumera, A.Merkoçi, S.<br />

Alegret; Electroanalysis 17 (2004) 881.<br />

12. M. Santandreu, F. Céspedes, S. Alegret, E.<br />

Martínez-Fàbregas; Analytical Chemistry 69<br />

(1997) 2080.<br />

13. A.Merkoçi, S. Braga, E. Fàbregas, S. Alegret,<br />

Analytica Chimica Acta 391 (1999) 65.<br />

14. S. Ramírez-García, S. Alegret, F. Céspedes,<br />

R.J. Forster, Analyst 127 (2002) 1512.<br />

15. J.Mocak, A.M. Bond, S. Mitchell, G. Scollary;<br />

Pure & Applied Chemistry 69 (1997) 297.