Featuring: 1996 Amada HFBO 170-40 CNC Press - Cincinnati ...

Featuring: 1996 Amada HFBO 170-40 CNC Press - Cincinnati ...

Featuring: 1996 Amada HFBO 170-40 CNC Press - Cincinnati ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TUESDAY, DECEMBER 19TH<br />

LATE MODEL PRECISION FABRICATING & POWDER COATING EQUIPMENT<br />

187 Ton X 168” <strong>Amada</strong> Promecam Model <strong>HFBO</strong>-<strong>170</strong>-<strong>40</strong><br />

Multi-Axis <strong>CNC</strong> Downacting Hydraulic <strong>Press</strong> Brake<br />

NEW AS<br />

1999<br />

NEW<br />

<strong>1996</strong><br />

5<br />

AVAILABLE<br />

(5) Steelman Model 8812 and 8816 Natural Gas Drive-Thru<br />

Cure Ovens<br />

NEW<br />

1990’s<br />

6’W X 15’L X 9’H Wagner Stainless Steel Modular Panel<br />

Cross Draft Drive-Thru Powder Coat Booth<br />

NEW<br />

LATE 90’s<br />

NEW<br />

1999<br />

Partial View Late Model Miller Welding Systems 8 Ton Haeger Model 824 Plus-IH Hardware<br />

Insertion <strong>Press</strong><br />

SALE UNDER THE MANAGEMENT OF<br />

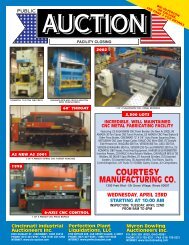

<strong>Featuring</strong>: <strong>1996</strong> <strong>Amada</strong> <strong>HFBO</strong> <strong>170</strong>-<strong>40</strong> <strong>CNC</strong> <strong>Press</strong> Brake, 1999 Haeger 824<br />

<strong>Press</strong>, (5) Steelman Drive-Thru Ovens to 8’ X 8’ X 16’ (New as 1999),<br />

Lewco Drive-Thru Oven, (3) Drive-Thru Powder Coat Booths, (3) Torit &<br />

IWI Drive-In Grinding Booths, Miller Welding Robot, (15) Late Model<br />

Welders, Welding Accessories, Toolroom Machinery, Misc. Machinery,<br />

Tapping & Drilling Machines, Lift Trucks, Material Handling,<br />

Late Model Shop Equipment, Most Equipment New 1990’s<br />

PLANT CLOSED - FORMER ASSETS OF<br />

CROWN NORTH<br />

AMERICA<br />

3101 Summit Avenue – Plano, Texas 75074<br />

(25 Miles North of Dallas, TX)<br />

SALE DATE:<br />

Tuesday,<br />

December 19th<br />

Starting at 9:00 AM<br />

INSPECTION:<br />

Monday, December 18th<br />

10:00 AM to 4:00 PM<br />

NEW & IMPROVED WEBSITE<br />

www.cia-auction.com<br />

New Features:<br />

Photo Gallery, Recent Auction<br />

Results, Staff Profiles<br />

& Reference Information<br />

Also Features:<br />

Upcoming Sale Information,<br />

Printable Color Brochures,<br />

Printable Lot Listing Catalogs,<br />

Downloadable Forms,<br />

Complete Terms of Sale<br />

1999 Faro “Silver Series” Model S12-02<br />

Portable Flex-Arm Coordinate Measuring<br />

Machine<br />

<strong>Cincinnati</strong> Industrial Auctioneers Inc.<br />

2020 DUNLAP ST., CINCINNATI, OHIO 45214 PHONE (513) 241-9701 / FAX (513) 241-6760<br />

INTERNET: cia-auction.com for printable brochures, catalog, terms and pre-bidding<br />

NEW<br />

1999

NEW<br />

2000<br />

10’W X 16’L X 9’H JBI Model PC2048 Drive-Thru Cross<br />

Draft Powder Coat Spay Booth<br />

6’W X 15’L X 8’H SDA Modular Panel Cross Draft Drive-<br />

Thru Powder Coat Booth<br />

Partial View Large Quantity <strong>Amada</strong> <strong>Press</strong> Brake<br />

Tooling<br />

NEW<br />

1990’s<br />

Miller Model MRH-5 Five-Axis <strong>CNC</strong> Welding Robot<br />

9” X 9” Comaca Hydraulic<br />

Corner Notcher<br />

TUESDAY, DECEMBER 19TH – 9:00 AM<br />

NEW<br />

1995<br />

NEW<br />

1999<br />

39” X 78” X 8” Thick Demmeler<br />

Type 3D-2000-1000-850 Precision<br />

Modular Fixturing System Table<br />

NEW<br />

<strong>1996</strong><br />

187 Ton X 168” <strong>Amada</strong> Promecam Model <strong>HFBO</strong>-<strong>170</strong>-<strong>40</strong> Multi-Axis<br />

<strong>CNC</strong> Downacting Hydraulic <strong>Press</strong> Brake<br />

<strong>CNC</strong> PRESS BRAKE<br />

187 Ton X 168” <strong>Amada</strong> Promecam Model <strong>HFBO</strong>-<strong>170</strong>-<strong>40</strong><br />

Multi-Axis <strong>CNC</strong> Downacting Hydraulic <strong>Press</strong> Brake; S/N<br />

<strong>HFBO</strong>-<strong>170</strong>-<strong>40</strong>-H61118, 166 1/2” Overall Length of Bed & Ram, 148”<br />

Max. Between Housings, 7” Bed Width, 17” Throat, <strong>Amada</strong> Operateur<br />

Six-Axis Back Gauge & Control System, Light Curtains, Floor Mount,<br />

(21) <strong>Amada</strong> Quick Change Punch Holders (New <strong>1996</strong>)<br />

SEE PHOTO<br />

<strong>Amada</strong> <strong>Press</strong> Brake Tooling Consisting of; (18) <strong>Amada</strong> Punch<br />

Holders, <strong>Amada</strong> Protractor Type Angle Gauge, <strong>Amada</strong> Segmented<br />

Punches & Dies of All Styles, 4’ X 6’ X 1’ Deep Crate 1/2 Full, Spare<br />

ISB Light Curtain Set<br />

HARDWARE INSERTION PRESS<br />

8 Ton Haeger Model 824 Plus-IH Hardware Insertion <strong>Press</strong>;<br />

S/N 8PL-10501, 8 Ton Capacity, 24” Throat, Haeger Automatic<br />

Vibratory Bowl Feed, Foot Pedals, Haeger TPS Stroke Control (New<br />

1999) SEE PHOTO<br />

WELDING ROBOT<br />

Miller Model MRH-5 Five-Axis <strong>CNC</strong> Welding Robot; S/N<br />

KA80R149, Miller MRH Control System, Deltaweld 451 Power Supply,<br />

Miller Computer Interface Control, Display Module, Teach Pendant,<br />

ISB Light Curtains, Wire Feed SEE PHOTO<br />

WELDING EQUIPMENT<br />

(5) 300 Amp Miller XMT304 CC/CV DC Inverter Arc<br />

Welding Power Sources; Miller XR-W Extended Reach Wire Feed,<br />

Optima Remote Pulsing Pendant, XR-30W Guns, Coolmate 4 &<br />

Watermate 1 Systems, Portable Cart Mounted (New Late 90’s)<br />

(2) 300 Amp Miller XMT-300 CC/CV Auto-Link DC Inverter<br />

Arc Welders; Miller XRM Wire Feeds, XRM-15W Guns, Portable Cart<br />

Mounted (New Late 90’s)<br />

(2) 450 Amp Miller Deltaweld 452 CV DC Welding Power<br />

Source; (1) w/ Miller XR Wire Feed, Miller 24-Volt Wire Feed, (1-Out<br />

of Service)<br />

(2) 300 Amp Miller CP-302 CV DC Arc Welding Power<br />

Sources; (1) w/ Millermatic S-52E Wire Feed, (1) w/ XR Wire Feed<br />

(3) 350 Amp OTC Turbo Pulse CPDP-350 OF Mig Welding<br />

Systems; Model CMH-147 Wire Feeds (New 1998)<br />

Pro-Weld Model CD-312 Stud Welding System; S/N 322-1810-<br />

504, Complete w/ Gun & Leads<br />

(2) Miller S-64 Wire Feeds<br />

SPOT WELDER<br />

200 KVA Sciaky McReery Model W-653 Pneumatic <strong>Press</strong><br />

Type Spot Welder; S/N 21506, 100 KVA at 50% Rating, <strong>40</strong>” Throat,<br />

Intertron Model 302A Control System, Updated Electronics<br />

SEE PHOTO<br />

REBUILT<br />

1990’s<br />

200 KVA Sciaky McReery<br />

Model W-653 Pneumatic<br />

<strong>Press</strong> Type Spot Welder<br />

WELDING ACCESSORIES<br />

39” X 78” X 8” Thick Demmeler Type 3D-<br />

2000-1000-850 Precision Modular<br />

Fixturing System Table; Bolt Holes on 4”<br />

Centers, Various Clamps & Angle Fixtures (New<br />

1995)<br />

7’ X 8’ Custom Built Tilting Portable<br />

Welding Fixture; Portable A-Frame Support Tilts<br />

to 45 Degree Angle, Pin Type Locking System<br />

(3) 3’ X 3’ x 4 1/2” Thick Acorn Platens<br />

Cast Iron Welding Table; (2) Mounted on<br />

Heavy-Duty Portable Common Base, (1) Free-<br />

Standing w/ Heavy-Duty Base<br />

Welding Accessories & Supplies Consisting<br />

of; Misc. Guns & Leads, Torch Tips, Clamps,<br />

Safety Equipment, Welding Curtains, Clamps of All<br />

Types, Abrasives, Heavy-Duty Welding Tables &<br />

Related<br />

SQUARING SHEAR<br />

3/16” X 10’ <strong>Cincinnati</strong> Model 1410<br />

Mechanical Power Squaring Shear; S/N<br />

28719, 8’ Squaring Arm, Spare Blade Set<br />

HYDRAULIC NOTCHER<br />

9” X 9” Comaca Hydraulic Corner Notcher;<br />

Push Buttons, Foot Pedal SEE PHOTO<br />

POWDER COAT CURE OVENS<br />

(4) 8’W X 12’L X 8’H Steelman Model 8812 GPC-DE-R2<br />

Natural Gas Fired Drive-Thru Cure Ovens; S/N’s 97211, 97210,<br />

P990135, & P990134, 8’ X 12’L X 8’ High Inner Dimensions, (2) 4’<br />

Wide Swing Open Doors on Each End, Floor Panel w/ Cart Tracks on<br />

56” Centers, 500 Degree F Max. Temperature, 600,000 BTU/HR, 768<br />

Cu. Ft. Open Volume, Push Button Controls (New as 1999)<br />

SEE PHOTO<br />

8’W X 16’L X 8’H Steelman Model 8816 GPC-DR-R2<br />

Natural Gas Fired Drive-Thru Cure Oven; S/N P990106, 8’W X<br />

16’L X 8’ H Inner Dimensions, (2) 4’ Swing Open Doors on Each End,<br />

Floor Panel w/ Cart Tracks 56” on Centers, Fabricated Structural Push<br />

Type Conveyor Rails, 500 Degree F Max. Temperature, 1,024 Cu. Ft.<br />

Open Volume, 800,000 BTU/HR, Push Button Control (New 1999)<br />

SEE PHOTO<br />

8’W X 12’L X 8’H Lewco Heat-Pro Model WI5GTD-9614496<br />

Natural Gas Fired Drive-Thru Cure Oven; S/N 204195001C,<br />

8’W X 12’L X 8’ H Inner Chamber Dimensions, (2) 4’ Wide Swing<br />

Open Doors on Each End, Steel Plate Floor, 500 Degree F (Est.) Max.<br />

Temperature, Honeywell Digital Temperature Controls, Push Buttons<br />

SEE PHOTO<br />

POWDER COAT BOOTHS & RELATED<br />

10’W X 16’L X 9’H JBI Model PC2048 Drive-Thru Cross<br />

Draft Powder Coat Spay Booth; S/N 32298, 10’W X 16’L X 9’H<br />

Main Inner Booth Dimensions, 66”W X 8’H Windows, (2) JBI 44”<br />

Wide Filter Walls, Each w/ (6) 12” Dia. X 26” High Filters, Overhead<br />

Structural Frame Push Type Overhead Conveyor Rails, Push Button<br />

Controls (New 2000) SEE PHOTO<br />

6’W X 15’L X 9’H Wagner Stainless Steel Modular Panel<br />

Cross Draft Drive-Thru Powder Coat Booth; S/N N/A, 6’W X<br />

15’L X 9’H Overall Inner Booth Dimensions, 46”w X 8’H Windows,<br />

Wagner Cross-Draft Powder Recovery Filter Wall w/ (6) 52 1/2” X 11”<br />

Diameter Filters, (2) 36” X 72” Side Windows, Push Button Control,<br />

Fabricated Structural Push Type Overhead Conveyor Rail (New<br />

1990’s) SEE PHOTO<br />

6’W X 15’L X 8’H SDA Modular Panel Cross Draft Drive-<br />

Thru Powder Coat Booth; S/N 99167-1, 6’W X 10’L X 10’H Inner<br />

Booth Dimensions, 6’W X 8’H X 32’L Front & Rear Entry Sections w/<br />

Doors, Side Filter Powder Recovery System w/ (7) 1’ Dia. X 3’ High<br />

Filters, Galvanized Panel Construction, Push Buttons (New 1999) SEE<br />

PHOTO<br />

(4) Wagner Model EPG-2007 Powder Coat System; S/N’s<br />

10295, 6336, Complete Cart Mounted w/ Powder Tank, Gun &<br />

Controls (New Late 90’s) SEE PHOTO<br />

7’ X 8’ Custom Built Tilting<br />

Portable Welding Fixture<br />

NEW<br />

LATE 90’s<br />

(4) Wagner Model EPG-<br />

2007 Powder Coat System

CROWN NORTH AMERICA – PLANO, TEXAS<br />

DRILLING & TAPPING MACHINES<br />

Ettco Model ATU-5 Multi-Spindle Leadscrew Tapping Machine;<br />

S/N 759-120-135-5000, 5” Stroke, Ettco Model 2111 Six-Spindle Tapping<br />

Attachment, 24” X 24” Table, Coolant, Automatic Push Button Controls<br />

SEE PHOTO<br />

Sotech Corp. Five-Station Drilling Machine; (2) Sotech Model DP-14<br />

Multi-Head End Drills Stations w/ Vertical & Horizontal Spindles, Middle<br />

Horizontal Drill Head, Mounted on 42” X 100” Table, PLC Controls<br />

Zagar Model 722-545 Forty-Five Spindle Drilling Machine; S/N<br />

178413, (45) Drive Spindles, (27) Holes in Housing, 23” X 38” Table Area,<br />

Push Buttons SEE PHOTO<br />

GRINDING BOOTHS<br />

10’W X 15’L X 7’H IWI Model ECB-4 Drive-Thru Cross Draft<br />

Grinding Booth; S/N S298-48T Rev-1, Full Modular Bolt Together<br />

Construction, (4) Torit EVB-1 Cross Draft Side Filter Wall Units; S/N<br />

IG492974-3, Sound Dampening Pads, Lights, Push Button Control w/ Digital<br />

Panel (New 1998) SEE PHOTO<br />

10’W X 11’L X 7’H Torit Drive-Thru Cross Draft Grinding Booth;<br />

S/N N/A, Full Modular Bolt Together Construction, (3) Torit ECB Series Cross<br />

Draft Filter Wall Units, Sound Dampening Pads, Lights, Push Button Controls<br />

(New 1990’s)<br />

10’W X 8’D X 7’H Torit Model ECB-3 Drive-In Back Draft<br />

Grinding Booth; S/N 1G30099, All Modular Bolt Together Construction,<br />

Three-Section Back Draft Filter System, Overhead Lights, Push Button<br />

Controls (New 1999)<br />

MISCELLANEOUS MACHINERY<br />

50 Ton (Est.) Walsh No.55 Back Geared Type OBI <strong>Press</strong>; S/N<br />

6705, 19” X 32” Bolster, Air Actuated Mechanical Clutch<br />

14”/23” X <strong>40</strong>” Summit Model 14 Geared Head Gap Bed Engine<br />

Lathe; S/N 0756, 16-Spindle Speeds: 19-1,800 RPM, Inch & Metric<br />

Threading, 8” 3-Jaw Chuck<br />

1 HP Millport Model 3V 8-Speed Vertical Mill; S/N 85073S, 9” X 42”<br />

Table, Power Infeed, 6” Swivel Vise<br />

9” X 16” W.F. Wells Model W-9 Horizontal Metal Cutting Band<br />

Saw; S/N 772513, Coolant System<br />

5,000 LB Breechbuler Model BSI-6060-05 Digital Platform Scale;<br />

60” X 60” Platform, Digital Readout<br />

Schriber Trueton Model 100AC Portable Chiller System; S/N 4441<br />

PMC Work-A-Matic Vertical Band Saw<br />

10” Kalamazoo Model K10 Mitre Base Saw<br />

16” Walker Production Table Drill; 24” X 72” Table<br />

Milwaukee Model 4262-1 Magnetic Base Drill<br />

(2) 16” Jet & Walker Floor Drills w/ Tapping Heads<br />

(3) 6”/10” Palmegren & Jet Combination Sanders<br />

Double End Pedestal Grinder<br />

24” X 30” Cyclone Model 3024 Abrasive Blast Cabinet<br />

COORDINATE MEASURING MACHINE &<br />

INSPECTION<br />

1999 Faro “Silver Series” Model S12-02 Portable Flex-Arm<br />

Coordinate Measuring Machine; S/N S12029901396, Rev-25 Power<br />

Supply & Data Unit, Floor Standing Base, Protective Case & Accessories<br />

SEE PHOTO<br />

70”W X 10’L X 4” Thick Cast Iron Slotted Precision Layout<br />

Table; Structural Frame Base, Slots on 10” Centers<br />

Harshaw Model 22 Filtrol Humidity Test Chamber; S/N 22D-088,<br />

48” X 34” X 30” Deep, Filter System, Reclaim Tank<br />

Macbeth Model SPL-75B Color Inspection Booth; S/N 70045<br />

Inspection Tools Consisting of; 18” Mitutoyo Model 192-606 Digital<br />

Height Gauge, 12” Mitutoyo Dial Height Gauge, BYK Gardner Digital Color<br />

Guide, Misc. Calipers, Gauge Blocks, Angle Plates, Torque Wrenches, &<br />

Other Related Items<br />

CANTILEVER RACKS<br />

(8) Sections 78”W X 12’H X 4’ Arm Heavy-Duty Fabricated Steel<br />

Single Side Cantilever Racks; Most w/ 8-Levels<br />

(3) Sections 66”W X 14’H X 4’ Arm Two-Sided Adjustable Arm<br />

Cantilever Racks; Most w/ 6-Levels, 2-Uprights SEE PHOTO<br />

Approx. (50) 8’ Wide Teardrop Style Cross Beams<br />

NEW<br />

LATE 90’s<br />

4,000 LB (Est.) Caterpillar Sit-<br />

Down Electric Lift Truck<br />

8’W X 12’L X 8’H Lewco Heat-Pro<br />

Model WI5GTD-9614496 Natural<br />

Gas Fired Drive-Thru Cure Oven<br />

NEW<br />

1999<br />

8’W X 16’L X 8’H Steelman Model 8816 GPC-DR-R2<br />

Natural Gas Fired Drive-Thru Cure Oven<br />

PRESSURE WASHERS<br />

(2) Landa Model VNG4-20021C/R Natural Gas Fired Steam<br />

Cleaners; S/N’s P0<strong>40</strong>9-16025 & P029-9099, 275 Degree F Max.<br />

Temperature, 3.9 GPM, Fabricated Stand w/ Spill Skid<br />

MI-T-M Model 2004 Natural Gas Fired Steam Cleaner; Spray<br />

Wand, Fabricated Steel Stand w/ Spill Skid<br />

FORK LIFT & SHOP CRANE<br />

4,000 LB (Est.) Caterpillar Sit-Down Electric Lift Truck; S/N N/A,<br />

Four-Stage Mast, Fork Spreader & Side Shift Attachment, 48-Volt Battery<br />

Complete w/ Charger (New Late 90’s) SEE PHOTO<br />

2,000 LB Air Technical Industries Model RBC-2000SPB Walk-<br />

Behind Electric Shop Crane; S/N61004, 2,000 LB Capacity at 5’<br />

Retracted Boom, 48-Volt Battery Complete w/ Charger (New Late 90’s)<br />

2 Ton X 16’ Span Sachett Systems Self-Traveling Portable A-<br />

Frame Gantry Crane; 10’ Under Bridge, Harrington 2 Ton Electric Hoist,<br />

Power Trolley, 8’ Under Hook, Power Travel, (New Late 90’s) SEE PHOTO<br />

1,000 LB Anver Model LE100M4-86-2/44 Vacuum Sheet Lifter;<br />

S/N 961287, 6’ Max. Width, 12’ Max. Length (New <strong>1996</strong>)<br />

2,000 LB American Lifts Model P36-020 Electric Scissor Lift<br />

Table; Foot Pedals<br />

AIR COMPRESSOR & RELATED<br />

10 HP Worthington Model ED Horizontal Tank Mount Air<br />

Compressor<br />

250 Gallon Vertical Air Receiving Tank<br />

LATE MODEL SHOP EQUIPMENT<br />

Late Model Shop Equipment & Hand Tools Consisting of; Knack<br />

Portable Job Box, Pneumatic Rivet Guns, Pneumatic Staple & Nail Guns, Pop<br />

Rivet Guns, Pneumatic & Electric Drills & Grinders, Welding Clamps, 12”<br />

Heat Sealers, (10) Hydraulic Pallet Trucks, Two-Wheel Hand Trucks, Steel &<br />

Plastic Banding Outfits, (5) Banding Tools, Fireproof Storage Cabinets, Locker<br />

Units, Steel & Wood Top Workbenches, Warehouse & Dock Carts, 48” Dia.<br />

Shop Fans, Pedestal Shop Fans, Rolling Step Sets, Rubber Fatigue Mats,<br />

Plastic Tote Bins, Steel Storage Cabinets, Steel Shelving, Misc. Hardware,<br />

Building & Machine Maintenance Items, Shipping Supplies, Trash Cans,<br />

Desks, File Cabinets, & Many Other Related Items<br />

INDUSTRIAL REAL ESTATE FOR SUBLEASE<br />

3101 Summit Ave. Suite 300 – Plano, Texas –<br />

70,134 Sq. Ft. Total Space, 4,000 Sq. Ft. Office<br />

Area, 28’ Clear Height, 8-Dock & 1-Ground<br />

Doors, Heavy Power<br />

For More Information Contact<br />

CB Richard Ellis – Mark W. Becker<br />

972-458-4878 Telephone<br />

mark.becker@cbre.com<br />

NEW<br />

1990’s<br />

Zagar Model 722-545<br />

Forty-Five Spindle Drilling<br />

Machine<br />

NEW<br />

LATE 90’s<br />

NEW<br />

1999<br />

Ettco Model ATU-5 Multi-<br />

Spindle Leadscrew<br />

Tapping Machine<br />

(4) 8’W X 12’L X 8’H Steelman Model 8812 GPC-<br />

DE-R2 Natural Gas Fired Drive-Thru Cure Ovens<br />

NEW<br />

1999<br />

(4) 8’W X 12’L X 8’H Steelman Model 8812 GPC-<br />

DE-R2 Natural Gas Fired Drive-Thru Cure Ovens<br />

NEW<br />

1998<br />

10’W X 15’L X 7’H IWI Model ECB-4 Drive-Thru<br />

Cross Draft Grinding Booth<br />

NEW<br />

LATE 90’s<br />

2 Ton X 16’ Span Sachett Systems Self-<br />

Traveling Portable A-Frame Gantry Crane<br />

(3) Sections 66”W X 14’H X 4’<br />

Arm Two-Sided Adjustable Arm<br />

Cantilever Racks

LATE MODEL PRECISION FABRICATING & POWDER<br />

COATING EQUIPMENT<br />

PLANT CLOSED – FORMER ASSETS OF<br />

CROWN NORTH<br />

AMERICA<br />

3101 Summit Avenue – Plano, Texas 75074<br />

(25 Miles North of Dallas, TX))<br />

SALE DATE:<br />

Tuesday, December 19th<br />

STARTING: 9:00AM<br />

INSPECTION:<br />

Monday, December 18th<br />

10:00 AM to 4:00 PM<br />

<strong>Cincinnati</strong> Industrial<br />

Auctioneers Inc.<br />

2020 DUNLAP ST., CINCINNATI, OHIO 45214<br />

PHONE (513) 241-9701 / FAX (513) 241-6760<br />

INTERNET: cia-auction.com<br />

PLANT CLOSED – FORMER ASSETS OF<br />

CROWN NORTH AMERICA<br />

3101 Summit Avenue<br />

Plano, Texas 75074<br />

(25 Miles North of Dallas, TX)<br />

IMPORTANT NOTICE:<br />

Although information has been obtained from<br />

sources deemed reliable, the auctioneer makes no<br />

warranty or guarantee, expressed or implied, as to<br />

the accuracy of the information herein contained. It<br />

is for this reason that buyers should avail themselves<br />

of the opportunity to make inspection prior<br />

to the sale. This brochure is intended to provide general<br />

information of the equipment being offered and is<br />

subject to errors, omissions, additions or deletions.<br />

Please check with the Auctioneer’s Office for a final<br />

listing. Items offered may or may not necessarily be<br />

sold as described and/or photographed in this<br />

brochure.<br />

MAIL BIDS ACCEPTED WITH A 25% DEPOSIT<br />

FIRST CLASS MAIL!<br />

☞<br />

DIRECTIONS<br />

NEW<br />

<strong>1996</strong><br />

From I-635 North of Dallas Exit at No.19 US-75 North,<br />

Proceed 7 Miles North on US-75 to President George Bush<br />

Turnpike East Exit at No. 28B, Proceed to First Exit at<br />

Jupiter Rd. Follow Service Road to Light at Jupiter Rd. and<br />

Turn Left (North) On Jupiter Rd. and Proceed 1/2 Mile to<br />

Summit Ave. Turn Right (East) on Summit & Proceed 1/2<br />

Mile to Sale Site on Left. Watch for Auction Parking, Sale<br />

Entrance Signs & Arrows.<br />

AUCTIONEERS<br />

Jeffrey L. Luggen<br />

Texas License No. AUCTNR00011379<br />

Jerome A. Luggen<br />

Texas License No. AUCTNR00011380<br />

187 Ton X 168” <strong>Amada</strong> Promecam Model <strong>HFBO</strong>-<strong>170</strong>-<strong>40</strong><br />

Multi-Axis <strong>CNC</strong> Downacting Hydraulic <strong>Press</strong> Brake<br />

Important Mail<br />

TO BE DIRECTED TO THE ATTENTION<br />

OF EXECUTIVE PERSONNEL<br />

TUESDAY, DECEMBER 19TH<br />

SALE UNDER THE MANAGEMENT OF<br />

<strong>Cincinnati</strong> Industrial Auctioneers Inc.<br />

<strong>Cincinnati</strong> Industrial Auctioneers Inc.<br />

TERMS OF SALE<br />

All equipment described herein will be sold<br />

“as is”, “where is” to the highest bidder or<br />

bidders for cash in accordance with our regular<br />

terms and conditions of sale. Unless other<br />

satisfactory arrangements are made, a 25%<br />

deposit in cash, certified or cashier’s check<br />

payable to <strong>Cincinnati</strong> Industrial Auctioneers,<br />

Inc., is required on all purchases. Firm and<br />

personal checks accepted only if accompanied<br />

by a letter from your bank guaranteeing your<br />

funds. All sales are subject to state and/or<br />

local taxes unless a signed exemption form is<br />

presented at the time of purchase. All balances<br />

are due at the conclusion of the sale.<br />

No merchandise may be removed while the<br />

sale is in progress. All bidders must comply<br />

with our Standard Terms of Sale, copies of<br />

which will be available at the sale site or can<br />

be obtained from our website.<br />

A 12% BUYER’S PREMIUM<br />

IN EFFECT FOR THIS SALE.<br />

2020 DUNLAP ST., CINCINNATI, OHIO 45214 PHONE (513) 241-9701 / FAX (513) 241-6760<br />

INTERNET: cia-auction.com for printable brochures, catalog, terms and pre-bidding<br />

PRE-SORT<br />

FIRST CLASS<br />

U.S. POSTAGE<br />

PAID<br />

CINCINNATI, OHIO<br />

PERMIT NO. 3593<br />

SALE DATE<br />

Tuesday,<br />

December 19th<br />

9:00 AM