Nutech Nu-Strip Data Sheet

Nutech Nu-Strip Data Sheet

Nutech Nu-Strip Data Sheet

- TAGS

- nutech

- sheet

- westflex.com.au

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

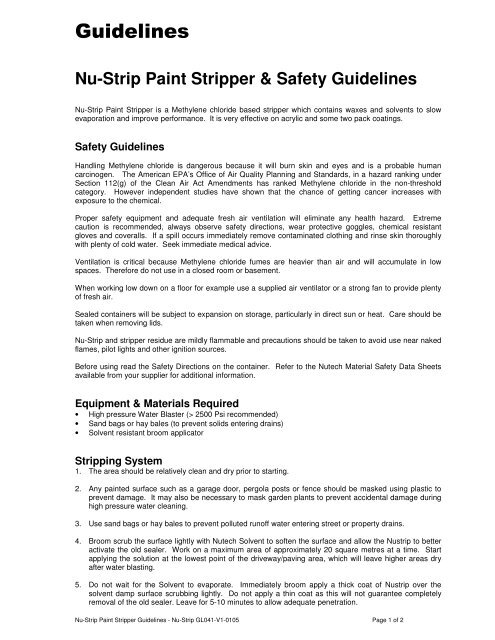

<strong>Nu</strong>-<strong>Strip</strong> Paint <strong>Strip</strong>per & Safety Guidelines<br />

<strong>Nu</strong>-<strong>Strip</strong> Paint <strong>Strip</strong>per is a Methylene chloride based stripper which contains waxes and solvents to slow<br />

evaporation and improve performance. It is very effective on acrylic and some two pack coatings.<br />

Safety Guidelines<br />

Handling Methylene chloride is dangerous because it will burn skin and eyes and is a probable human<br />

carcinogen. The American EPA’s Office of Air Quality Planning and Standards, in a hazard ranking under<br />

Section 112(g) of the Clean Air Act Amendments has ranked Methylene chloride in the non-threshold<br />

category. However independent studies have shown that the chance of getting cancer increases with<br />

exposure to the chemical.<br />

Proper safety equipment and adequate fresh air ventilation will eliminate any health hazard. Extreme<br />

caution is recommended, always observe safety directions, wear protective goggles, chemical resistant<br />

gloves and coveralls. If a spill occurs immediately remove contaminated clothing and rinse skin thoroughly<br />

with plenty of cold water. Seek immediate medical advice.<br />

Ventilation is critical because Methylene chloride fumes are heavier than air and will accumulate in low<br />

spaces. Therefore do not use in a closed room or basement.<br />

When working low down on a floor for example use a supplied air ventilator or a strong fan to provide plenty<br />

of fresh air.<br />

Sealed containers will be subject to expansion on storage, particularly in direct sun or heat. Care should be<br />

taken when removing lids.<br />

<strong>Nu</strong>-<strong>Strip</strong> and stripper residue are mildly flammable and precautions should be taken to avoid use near naked<br />

flames, pilot lights and other ignition sources.<br />

Before using read the Safety Directions on the container. Refer to the <strong><strong>Nu</strong>tech</strong> Material Safety <strong>Data</strong> <strong>Sheet</strong>s<br />

available from your supplier for additional information.<br />

Equipment & Materials Required<br />

• High pressure Water Blaster (> 2500 Psi recommended)<br />

• Sand bags or hay bales (to prevent solids entering drains)<br />

• Solvent resistant broom applicator<br />

<strong>Strip</strong>ping System<br />

1. The area should be relatively clean and dry prior to starting.<br />

2. Any painted surface such as a garage door, pergola posts or fence should be masked using plastic to<br />

prevent damage. It may also be necessary to mask garden plants to prevent accidental damage during<br />

high pressure water cleaning.<br />

3. Use sand bags or hay bales to prevent polluted runoff water entering street or property drains.<br />

4. Broom scrub the surface lightly with <strong><strong>Nu</strong>tech</strong> Solvent to soften the surface and allow the <strong>Nu</strong>strip to better<br />

activate the old sealer. Work on a maximum area of approximately 20 square metres at a time. Start<br />

applying the solution at the lowest point of the driveway/paving area, which will leave higher areas dry<br />

after water blasting.<br />

5. Do not wait for the Solvent to evaporate. Immediately broom apply a thick coat of <strong>Nu</strong>strip over the<br />

solvent damp surface scrubbing lightly. Do not apply a thin coat as this will not guarantee completely<br />

removal of the old sealer. Leave for 5-10 minutes to allow adequate penetration.<br />

<strong>Nu</strong>-<strong>Strip</strong> Paint <strong>Strip</strong>per Guidelines - <strong>Nu</strong>-<strong>Strip</strong> GL041-V1-0105 Page 1 of 2

6. Broom scrub the surface with Grease Magic to emulsify the sealer. Do not allow the surface to dry<br />

before water blasting.<br />

7. Immediately water blast the surface very thoroughly. After finishing inspect the surface. It may be<br />

necessary to quickly water blast a second time. If any thick white/coloured sealer residue remains scrub<br />

with stripper before the second water blast. Old slate impression surfaces may appear very grey/white<br />

when they dry after stripping. This does not indicate any damage and colours will return after re-sealing.<br />

8. After completely removing all old sealer and <strong>Nu</strong>strip acid etch the surface and lightly water blast flush. It<br />

is not necessary to wait until the surface. An acid solution between 1:15 to 1:30 is recommended subject<br />

to the surface finish and condition.<br />

9. Do not re-seal until the old sealer has been completely removed. Re apply new sealer in accordance<br />

with <strong><strong>Nu</strong>tech</strong> standard recommendation.<br />

The products recommended above are more efficient in cooler weather and are less efficient in direct sun,<br />

particularly in hot weather. Apply to a dry surface because the products are less effective once the surface<br />

is wet with water.<br />

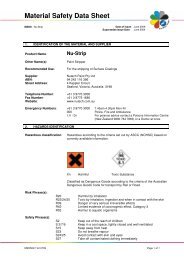

Health & Safety<br />

Warning:<br />

Paint strippers may be easy and convenient to use but they can cause health problems.<br />

Do not breathe in vapours. Do not use <strong>Nu</strong>-<strong>Strip</strong> in confined areas and always make sure that there is<br />

adequate ventilation in working areas.<br />

<strong>Nu</strong>-<strong>Strip</strong> is corrosive. Avoid contact with skin and eyes. Wear adequate protective clothing, gloves and eye<br />

goggles to protect skin contact.<br />

First Aid:<br />

Accidental splashes must be washed off immediately with soapy water or alcohol (methylated spirits).<br />

For eye contact rinse immediately with a large amount of water and seek medical attention.<br />

If swallowed induce vomiting with Ipecac Syrup (AFP) if available and contact a Doctor or Poisons<br />

Information Centre.<br />

Read the product label and Material Safety <strong>Data</strong> <strong>Sheet</strong> for additional safety and application details.