Untitled - Hoshizaki America, Inc.

Untitled - Hoshizaki America, Inc.

Untitled - Hoshizaki America, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

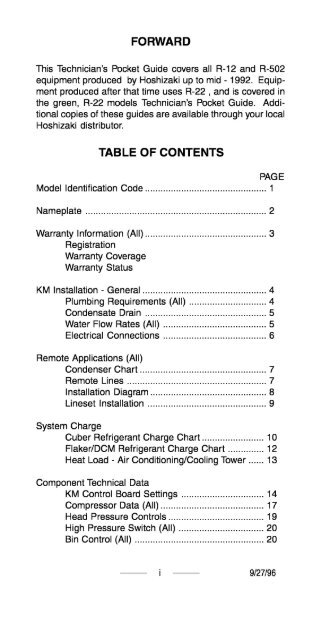

KM Sequence of Operation<br />

“A” & “B” Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21<br />

“C” & “Alpine” Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23<br />

KM Check Out Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24<br />

10 Minute Check Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25<br />

Reservior Flush System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26<br />

Componet Checks<br />

Float Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27<br />

Thermistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27<br />

Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28<br />

Bin Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28<br />

Cleaning/Sanitizing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30<br />

KM Production Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31<br />

Water and Refrigeration Circuit Reference Chart ......... 32<br />

KM Performance Data (R-502 Units)<br />

KM-250B-B ......................................................... 47<br />

KM-250B_C ......................................................... 48<br />

KM-250M-B ........................................................ 49<br />

KM-451 D ............................................................. 50<br />

KM-452D ............................................................. 51<br />

KM-450M-B ........................................................ 52<br />

KM-601 D ............................................................. 53<br />

KM-631 D ............................................................. 54<br />

KM-632D ............................................................. 55<br />

KM-630M-B ........................................................ 56<br />

KM-800M-B ........................................................ 57<br />

KM-l 201 D ........................................................... 58<br />

KM-l 200M-B ...................................................... 59<br />

KM-l 200S_B ....................................................... 60<br />

KM-l 600M-B ...................................................... 61<br />

KM-l 600M-B3 .................................................... 62<br />

KM-l 600S_B ....................................................... 63<br />

KM-l 600S_B3 ..................................................... 64<br />

KM-2000S_B3 ..................................................... 65<br />

NOTE: Performance Data Chart includes the following:<br />

A. Model<br />

B. Supply Voltage<br />

C. Total Amperage (Compressor RLA*)<br />

D. Ice production per cycle<br />

E. Water cooled condenser water consumption<br />

. Production 24 hours<br />

ii ~ g/27/96

G. Freeze cycle time<br />

H. Harvest cycle time<br />

I. High side pressure<br />

J. Suction pressure<br />

*Amperage taken 5 minutes into freeze with<br />

air temperature 104°F and water temperature 80°F.<br />

KM Wiring Diagram Reference Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . 66<br />

Remote Condenser Data ,............................................m 69<br />

Flake lr/DCM<br />

Installation - General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99<br />

Componant Technical Data .......................................... 99<br />

Gear Motor Safeties ............................................ 99<br />

Auger Bearings ................................................... 99<br />

Bearing Inspection .................................. .......... 100<br />

Auger Inspection / Bearing Replacement.. ....... 100<br />

Flaker Sequence of Operation<br />

Flaker Periodic Flush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102<br />

DCM Sequence of Operation ........................... .......... 103<br />

F/DCM Production Check ................................. .......... 103<br />

Water and Refrigeration Circuit<br />

Reference Chart . . ..,........................................... 104<br />

Flaker Performance Data<br />

F-251 B ............................................................... 115<br />

F-251 U, F-250B ................................................. 116<br />

F-441 U, F-440B ................................................. 117<br />

F-450B ............................................................... 118<br />

F-450B w/ Cubelet Kit ............................. .......... 119<br />

F-650M .............................................................. 120<br />

F-650M w/ Cubelet Kit ............................ .......... 121<br />

F-l OOOM ............................................................ 122<br />

F-l IOIA ............................................................. 123<br />

F-l 100 w/ Cubelet Kit ............................ .......... 124<br />

F-l 1 OOM ............................................................ 125<br />

F-2000M ............................................................ 126<br />

F-2000M3 .......................................................... 127<br />

. . .<br />

III ~ g/27/96

DCM Performance Data<br />

DCM-231 U, DCM241 U ...................................... 128<br />

DCM-240 BAA, BAB ......................................... 128<br />

DCM-451 U, DCM-450B ..................................... 129<br />

DCM-701 U, DCM-700B ..................................... 130<br />

DCM Wiring Diagram Reference Chart . . . . . . . . . . . . . . . . . . . . . . 131<br />

Flaker Wiring Diagram Referance Chart . . . . . . . . . . . . . . . . . . . . 132<br />

iv ~ g/27/96

IDENTIFICATION CODE<br />

KM - 12<br />

UNITTYPE -r -<br />

KM - Crescent Cuber<br />

F- Flaker<br />

DCM - Dispenser Cubelet Maker<br />

DB - Dispenser Bin<br />

B- Bin<br />

DM - Countertop Dispenser<br />

PRODUCTION<br />

Approximate production/24 Hours<br />

70°F Air/SO”F Water<br />

UNIT STYLE<br />

M/D/A- Modular<br />

S- Stackable<br />

B- Self contained with bin<br />

CONDENSER STYLE<br />

AN- Air cooled<br />

W- Water cooled<br />

R/S - Remote air cooled<br />

GENERATION<br />

IO F<br />

- -<br />

Model designation<br />

U - US Model Designation (First Production)<br />

. - I<br />

The model number, serial number, electrical specifications<br />

and refrigerant data are found on the unit name plate. (See<br />

name plate)<br />

-I- g/27/96

See the Nameplate for electrical and refrigeration specifica-<br />

tions.This Nameplate is located on the upper right hand side<br />

of rear panel. Since this Nameplate is located on the rear<br />

panel of the icemaker, it cannot be read when the back of the<br />

icemaker is against a wall or against another piece of kitchen<br />

equipment. Therefore, the necessary electrical and refrig-<br />

eration information is also on the rating label included on<br />

later model units. This label can be easily seen by removing<br />

only the front panel of the icemaker. We reserve the right to<br />

make changes in specifications and design without prior no-<br />

tice. (Nameplate may vary slightly with older models)<br />

-2p g/27/96

REGISTRATION-<br />

Two warranty registration cards are supplied with the<br />

equipment. They must be completed and sent in to initiate<br />

warranty. The warranty begins on the date of installation if<br />

registration procedures are followed. If registration is not<br />

completed, the warranty date will be the date of sale or<br />

date of shipment from the factory, respectively.<br />

WARRANTY COVERAGE-<br />

The warranty will cover defects in material or workmanship<br />

under normal and proper use and maintenance service as<br />

specified by <strong>Hoshizaki</strong>. Coverage for parts and labor is<br />

limited to the repair or replacement of parts or assemblies<br />

that in <strong>Hoshizaki</strong>’s opinion are defective.<br />

WARRANTY STATUS-<br />

The warranty coverage for R-502 / R-l 2 equipment varies<br />

depending on the model and date of manufacture. Refer to<br />

the warranty statement shipped with the unit to establish<br />

the warranty coverage for that model.<br />

If you need warranty status for later model units, contact<br />

the Care Department with complete model and serial<br />

number. We will provide you with the installation date and<br />

warranty status , if available. You will find the model and<br />

serial number on the nameplate located on the rear of the<br />

unit. Early model units will have the serial number<br />

stamped in ink in the compressor compartment.<br />

See Warranty Statement supplied with the unit for details.<br />

Warranty valid in United States, Canada, Mexico, Puerto<br />

Rico, and U. S. Virgin Islands.<br />

Contact factory<br />

or possessions.<br />

for warranty in other countries, territories,<br />

-3- g/27/96

KM INSTALLATION<br />

GENERAL -<br />

The ice machine is not intended for outdoor use.<br />

OPERATING CONDITIONS - ALL MODELS<br />

ITEM<br />

Voltage Range<br />

MODEL RANGE<br />

115V units 104- 127V.<br />

208-230 V units 187-264V.<br />

Ambient Temperature All 45 - 100 Deg. F.<br />

Remote Condenser Early -20 - 110 Deg. F.<br />

Later -20 - 122 Deg F.<br />

Water SupplyTemperature All 45 - 90 Deg. F.<br />

Water Supply Pressure Early 7 -113 PSIG<br />

Later 10 - 113 PSIG<br />

Allow 6” clearance at rear, sides, and top for proper air<br />

circulation and ease of maintenance or service. 20” top<br />

clearance for F/DCM.<br />

PLUMBING REQUIREMENTS -<br />

Water Supply:<br />

On KM units the water supply line size is critical due to the<br />

water assisted harvest and the use of a ported inlet water<br />

valve solenoid.<br />

MODEL Line Size<br />

KM-250 - KM-800 318” OD<br />

KM-1200 - KM-2000 l/2” OD<br />

All F/DCM 318” OD<br />

*Water cooled condenser units require<br />

supplies sized as per list above.<br />

Fittinq Size<br />

l/2” FPT<br />

l/2” FPT<br />

l/2” FPT<br />

two separate<br />

Drain:<br />

MODEL Line Size Fittinq Size<br />

All Bins 3/4” OD 3/4” FPT<br />

Early KM’s 3/4” OD I” FPT<br />

Later KM’s 3/4” OD 3/4” FPT<br />

**FIakers 3/4” OD 3/4” FPT*<br />

**DCM 3/4” OD 3/4” FPT*<br />

*Some models have 2 drain outlets.<br />

** Some early models had insert type drain fitings<br />

-4- 9127196

<strong>Hoshizaki</strong> recommends that the ice machine drain and bin<br />

drain be piped separately to the drain connection point<br />

allowing ii4” per foot fall.<br />

CONDENSATE DRAIN -<br />

The condensate drain is generally connected to the ice<br />

machine drain for simplicity. It can be piped separately to<br />

the drain exit if desired.<br />

A 6” vent tee is recommended as per drawing:<br />

Reservoir /<br />

Drain<br />

FLOW RATES -<br />

Condensate<br />

Drain<br />

The minimum flow rate requirements for <strong>Hoshizaki</strong> ice<br />

maker units are as follows:<br />

KM-250/AI I Flakers 1.05 GPM<br />

KM-451 /452/450 1.58 GPM<br />

KM-601/631/630/800/Ail DCM’s 2.11 GPM<br />

KM-l 200/l 600 3.96 GPM<br />

KM-1201/2000 4.23 GPM<br />

Use this information when sizing a filter system for the ice<br />

machine application.<br />

NOTE: A good rule of thumb is to utilize a 3 GPM flow rate<br />

filter for KM-250 - 800 and a 5 GPM flow rate filter for KM-<br />

1200 or larger.<br />

-5- g/27/96

ELECTRICAL CONNECTIONS -<br />

115V.<br />

(2 wire<br />

w/gnd)<br />

115VOLT/l PHASE<br />

(Ground<br />

screw not<br />

used on early<br />

models)<br />

208=23OVOLT/l PHASE<br />

208-23OV/l Phase units require a dedicated neutral due to<br />

the use of 115V components.<br />

208-230V.<br />

3 phase<br />

(3 wire<br />

w/gnd)<br />

The dedicated<br />

neutral<br />

requires an<br />

insulated<br />

conductor<br />

which runs<br />

directly to the<br />

panel.<br />

If high leg is present connect to black wire<br />

-<br />

208-230 VOLT/3 PHASE<br />

REMOTE CONDENSER CONNECTIONS<br />

Fan<br />

Control<br />

Circut<br />

From<br />

Unit<br />

115V.<br />

Neutral<br />

GND+@<br />

(Remote<br />

wiring color<br />

varies on<br />

early<br />

models)<br />

9127196

REMOTE APPLICATIONS<br />

CONDENSER CHART<br />

CONDENSER MODEL MODEL NUMBERS<br />

S-0466 KM-601/631 DSU<br />

s-0454 KM-l 201 DSU<br />

S-0387 F-l IOIASU<br />

U RC-4A KM-452DSU, KM-450MRB<br />

U RC-GA/B KM-632DSU, KM-630MRB,<br />

F-l 000/l 1 OOMRB<br />

URC-12B/C KM-800/l 200MRB,<br />

KM1 200SRB<br />

U RC-20C KM-l 600/2000MRB,<br />

KM1 600/2OOOSRB<br />

F-2000MRB<br />

When installing a remote application the unit/condenser<br />

combination must match with the above chart. A non-OEM<br />

multi-pass condenser can be used with prior written factory<br />

approval.<br />

REMOTE LINES-<br />

<strong>Hoshizaki</strong> has 3 precharged line set lengths. 20 foot, 35<br />

foot, and 55 foot sets are available. The line sets are<br />

available in different line sizes for different models.<br />

LINE SET IDENTIFICATION CODE<br />

R502 - 35 6 10<br />

Refrigerant m<br />

Length In Feet<br />

Liquid Line Size in 16th’s<br />

Discharge Line Size in 16th’s<br />

LINE SET APPLICATIONS<br />

MODELS<br />

KM-452/450/631/<br />

LINE SET LL (SIZE] DL<br />

632/630 R502--46-2 l/4” OD 3/8” OD<br />

F-l 000/l 100 R502--46-2 l/4” OD 3/8” OD<br />

KM-l 201 R502--66-2 3/8” OD 3/8” OD<br />

KM-800/l 200 R502--68-2 3/8” OD l/2” OD<br />

KM-l 600/2000 R502--610 3/8” OD 5/8” OD<br />

-7- 9127196

Remote Condenser Installation on Roof<br />

For best<br />

performance<br />

allow 24”<br />

clearance for<br />

air circulation<br />

For best perfor-<br />

mance the Remote<br />

Condenser should<br />

not be more then<br />

33’ above the<br />

icemaker or more<br />

then 10’ below it.<br />

These distances<br />

are measured from<br />

or Connection<br />

..........................................<br />

.........................................<br />

-8- 9127196

LINE SET INSTALLATION<br />

A universal line set adapter kit, part number OS-QUICK, is<br />

available if you need to field engineer your line set. Both<br />

lines should be insulated separately the entire length of<br />

run.<br />

The refrigerant charge for a new unit is distributed between<br />

the unit head and the remote condenser. The line set has a<br />

minimal holding charge of 15 to 30 psig refrigerant vapor.<br />

If you need to field engineer your line set or shorten/<br />

lengthen a precharged line set you can do so by following<br />

these steps:<br />

1. Using the OS-QUICK kit, braze the line set connec-<br />

tions. (If you shorten or lengthen a precharged line<br />

set, recover the holding charge, cut or lengthen and<br />

braze the connections.)<br />

2. Pressurize the lines and leak check all braze joints.<br />

3. Evacuate the lines through the service<br />

Aeroquip quick connect fittings.<br />

ports on the<br />

4. Charge both lines with 15 to 30 psig R-22 vapor.<br />

To make Aeroquip connection to the unit head and<br />

condenser:<br />

1. Lubricate the th reads and O-ring with clean<br />

refrigerant oil.<br />

2. Tighten the female connector until it bottoms out.<br />

3. Then turn an additional l/4 turn to assure a good<br />

brass to brass seal. Leak check the joints with soap<br />

bubbles or an electronic leak detector.<br />

-9- g/27/96

SYSTEM CHARGE<br />

The ice machine head and remote condenser are shipped<br />

with enough refrigerant charge for up to 66 feet of line set<br />

length. The maximum line set length is 100 equivalent feet<br />

from the head to the condenser.<br />

For applications longer than 66 ft. up to the maximum 100<br />

ft. length, additional refrigerant must be added. For units<br />

utilizing l/4” L.L. and 3/8” D.L., the line size should be<br />

increased to 3/8”L.L. and U2”D.L. for the entire length of<br />

the run. Add 21 ounces plus l/2 oz. per foot over 66 feet.<br />

For units utilizing 3/8”L.L., add l/2 oz. per foot over 66 feet.<br />

NOTE:<br />

(1)<br />

(2)<br />

(3)<br />

(4)<br />

(5)<br />

Recommended line sizes are same as listed in the<br />

line set application chart. (Page 7)<br />

Always check the unit nameplate for the<br />

correct refrigerant type.<br />

If refrigerant is added due to extended line set<br />

length, mark the correct total charge on the unit<br />

nameplate for future reference.<br />

When routing and installing remote lines, always<br />

use standard refrigerant piping practices.<br />

<strong>Hoshizaki</strong> recommends eliminating any excess<br />

loops in a pre-charged line set application before<br />

making the unit connections. This will eliminate oil<br />

traps and possible crimps in the excess tubing.<br />

The total system charge is critical for proper operation<br />

according to <strong>Hoshizaki</strong> specification. Always weigh in the<br />

proper charge per the following charge chart. (Remote<br />

units show standard charge good for up to 66 feet.)<br />

~ IO ~ g/27/96

MODEL<br />

HOSHIZAKI CUBER<br />

REFRIGERANT CHARGE CHART<br />

KM-250 BAB<br />

BWB<br />

KM-250 BAC<br />

BWC<br />

KM-250 MAB<br />

MWB<br />

KM-451 DU<br />

DWU<br />

KM-452 DU<br />

DWU<br />

DSU<br />

KM-450 MAB<br />

MWB<br />

MRB<br />

KM-601 DU<br />

DWU<br />

KM-632 DU<br />

DWU<br />

DSU<br />

KM-630 MAB<br />

MWB<br />

MRB<br />

KM-800 MAB<br />

MWB<br />

MRB<br />

KM-1201 DU<br />

DWU<br />

DSU<br />

KM-l 200 MAB<br />

MWB<br />

MRB<br />

KM1200 SAB<br />

SWB<br />

SRB<br />

KM-l 600 M/SWB<br />

M/SRB<br />

KM-2000 M/SWB<br />

M/SRB<br />

TOTAL CHARGE REFRIGERANT<br />

1 lb. 5 oz. R-502<br />

13.5 oz. LL<br />

13.8 oz. LL<br />

13.4 oz. LL<br />

1 lb. 13.5 oz. LL<br />

1 lb. 12.5 oz. LL<br />

1 lb. 9 oz. LL<br />

1 lb. 3 oz. LL<br />

1 lb. 10 oz. LL<br />

1 lb. 3 oz. LL<br />

5 Ibs. 5 oz. LL<br />

1 lb. 10 oz. LL<br />

1 lb. 1 oz. LL<br />

5 Ibs. 5 oz. LL<br />

2 Ibs. 3 oz. LL<br />

1 lb. 5 oz. LL<br />

2 Ibs. 3 oz. LL<br />

1 lb. 7 oz. LL<br />

5 Ibs. 12 oz. LL<br />

2 Ibs. 3 oz. LL<br />

1 Ibs. 8 oz. LL<br />

5 Ibs. 12 oz. LL<br />

3 Ibs. 1 oz. LL<br />

2 Ibs. 3 oz. LL<br />

8 Ibs. 13 oz. LL<br />

4 Ibs. LL<br />

2 lb. 7 oz. LL<br />

11 Ibs. 1 oz. LL<br />

4 Ibs. 6 oz. LL<br />

2 Ibs. 1 oz. LL<br />

11 Ibs. 11 oz. LL<br />

4 Ibs. 6 oz. LL<br />

2 Ibs. LL<br />

12 Ibs. 2 oz. LL<br />

2 Ibs. 14 oz. LL<br />

17 Ibs. 10 oz. LL<br />

3 Ibs. 12 oz. LL<br />

17 Ibs. 10 oz. LL<br />

g/27/96

MODEL<br />

F-251 B<br />

F-251 U<br />

F-250 BAA<br />

F-441 U<br />

F-440 BAA<br />

F-450 BAB<br />

BWB<br />

F-650 MAB<br />

MWB<br />

MRB<br />

F-l 000 MAB<br />

MWB<br />

MRB<br />

F-1101 AU<br />

AWU<br />

ASU<br />

F-l 100 MAB<br />

MWB<br />

MRB<br />

F-2000 MWB<br />

MRB<br />

DCM-231 U<br />

DCM-241 U<br />

DCM-451 U<br />

HOSHIZAKI FLAKERWDCM’S<br />

REFRIGERANT CHARGE CHART<br />

TOTAL CHARGE<br />

6.3 oz.<br />

7.76 oz.<br />

7.76 oz.<br />

13.4 oz.<br />

13.4 oz.<br />

1 lb.<br />

12.70~.<br />

1 lb. 9 oz.<br />

12.7 oz.<br />

4 Ibs.<br />

1 Ibs.<br />

1 lb.<br />

6 Ibs.<br />

1 Ibs.<br />

1 Ibs.<br />

5 Ibs.<br />

1 lb.<br />

1 lb.<br />

5 Ibs.<br />

1 lb.<br />

15 Ibs.<br />

14 oz.<br />

10 oz.<br />

12 oz.<br />

2 oz.<br />

1 oz.<br />

8 oz.<br />

loz.<br />

8 oz.<br />

1 loz.<br />

10 oz.<br />

7.5 oz.<br />

8.8 oz.<br />

14.1 oz.<br />

REFRIGERANT<br />

R-12<br />

R-12<br />

R-12<br />

R-12<br />

R-12<br />

R-502<br />

R-502<br />

R-502<br />

R-502<br />

R-502<br />

R-502<br />

R-502<br />

R-502<br />

R-502<br />

R-502<br />

R-502<br />

R-502<br />

R-502<br />

R-502<br />

R-502<br />

R-502<br />

R-12<br />

R-12<br />

R-12<br />

DCM-450 BAAIBAB 14.1 oz. R-12<br />

DCM-450 BWA/BWB 10.6 oz. R-12<br />

DCM-701 U 1 lb. 12.2 oz. R-502<br />

DCM-701 WU 1 lb. 6.9 oz. R-502<br />

DCM-700 BAA/BAB 1 lb. 12.2 oz. R-502<br />

DCM-700 BWA/BWB 1 lb. 6.9 oz. R-502<br />

~ 12 ~ g/27/96

HEAT LOAD<br />

The heat of rejection information listed below by model<br />

number should be used for sizing air conditioning equip-<br />

ment or for sizing a water cooled cooling tower application.<br />

MODEL<br />

KM-250B<br />

KM-250M<br />

KM-451 D<br />

KM-452D<br />

KM-450M<br />

KM-601 / 631 D<br />

KM-632D<br />

KM-630M<br />

KM-800M<br />

KM-l 201 D<br />

KM-l 200M<br />

KM-l 200s<br />

KM-l 600M/S<br />

KM-2000M/S<br />

MODEL<br />

F-251 B<br />

F-251 U<br />

F-250 B-A<br />

F-441 U<br />

F-440 B-A<br />

F-450 B-B<br />

F-650 M-B<br />

F-l 000 M-B<br />

F-1101 A-<br />

F-l 100 M-A<br />

F-2000 M-B<br />

DCM-231/241 U<br />

DCM-240 B<br />

DCM-451 U<br />

DCM-450 B<br />

DCM-701 U<br />

DCM-700 B<br />

TOTAL HEAT REJECTION<br />

AIR WATER COOLED<br />

COOLED (CONDENSER ONLY]<br />

5443 BTU/h 5245 BTU/h<br />

5450 5250<br />

10319 8500<br />

9220 8047<br />

9250 6160<br />

11509 9520<br />

12713 11817<br />

12713 10985<br />

16960 12700<br />

20300 16500<br />

19500 17000<br />

20550 17370<br />

-------- 24393<br />

-------- 28120<br />

TOTAL HEAT REJECTION<br />

AIR WATER COOLED<br />

COOLED (CONDENSER ONLY]<br />

3170 BTU/h ------ BTU/h<br />

2614 ------<br />

3980 ------<br />

6030 ------<br />

6030 ------<br />

5000 2860<br />

6830 5546<br />

8480 6700<br />

10600 8990<br />

10800 9500<br />

--- 18100<br />

3040 ------<br />

3980 ------<br />

5680 5160<br />

5680 5160<br />

8440 6620<br />

8440 6690<br />

Figures shown are at 90” F air temp. 70” F water temp.<br />

Allow for a pressure drop of 7 psi across the water cooled<br />

condenser.<br />

~ 13 ~ g/27/96

KM-451/601/631/1201 First Generation<br />

(unit starts in harvest)<br />

The first generation of KM cubers used an “A” style control<br />

board. This board has a variable resistor in the upper right<br />

hand corner marked VRI. To adjust the defrost completion<br />

timer and extend the harvest period, turn VRI “CW”. The<br />

range extends from 1 to 4 minutes. Fully “CCW” provides<br />

1 minute on the completion timer. Extending the harvest<br />

will increase the flush for more cleaning. The factory<br />

setting is 1 minute (fully CCW).<br />

KM-451/ 631/1201 Second Generation<br />

(unit starts in harvest)<br />

The control board on the second generation of KM cubers<br />

was changed to a “B” style. This board uses two dip<br />

switches to adjust the defrost completion timer. A dip<br />

switch setting chart is printed on the board, beside the<br />

switches. Adjust the two switches to extend the harvest<br />

period from 1 to 4 minutes. This board also has a 60<br />

minute back-up freeze completion timer and a high<br />

temperature safety included. The factory setting is 1<br />

minute. The “B” style board is a direct replacement for the<br />

“A” board.<br />

KM-452/632/ early M & S units Third Generation<br />

(unit starts in 1 minute fill cycle and has every cycle pump-out)<br />

The third generation control board for the KM cubers is a<br />

“C” style board. This board has 4 dip switches. Number 1<br />

& 2 adjust the defrost completion timer from 1 to 3 minutes.<br />

Number 3 & 4 adjust the length of pump-out and should<br />

remain in the factory position. The pump-out will occur<br />

after every harvest cycle on these units. For the factory<br />

setting, see the dip switch setting chart for Alpine boards.<br />

The “C” board replacement is the Universal Alpine #<br />

2UO139-01. This is a direct replacement. Install the<br />

universal board and adjust the 8 dip switches by model per<br />

the dip switch setting chart. “C” board switches 1 through 4<br />

are the same as on the Alpine board.<br />

KM later model M & S units Forth Generation<br />

(unit starts in 1 minute fill cycle and has every cycle pump-out)<br />

All KM Units are now manufactured with the original Alpine<br />

control board part # 2UO127-01 (subs to # SAOOOI). This<br />

board has 8 dip switches and provides the ability to adjust<br />

~ 14 ~ g/27/96

for pump-out to occur every 1, 2, 5, or 10 cycles. The<br />

setting guide below explains the Original and Universal<br />

Alpine dip switches.<br />

Note: The Universal Alpine # 2UOO139-01 can be used to<br />

replace the Original Alpine # 2UO127-01 if a slight<br />

modification is made. Follow the instructions supplied<br />

with the replacement board which instruct you to cut the<br />

black jumped (R065) for this application.<br />

DIP SWITCH SE<br />

ADJUSTMENTS DIP<br />

DEFROST<br />

TIMER<br />

ADJUSTMENT<br />

PUMP OUT 3<br />

LENGTH 4<br />

PERIODIC<br />

PUMP OUT<br />

FREQUENCY<br />

0 1 0 1<br />

0 0 1 1<br />

seconds 10 10 10 20<br />

5 0 1 0 1<br />

6 0 0 1 1<br />

TEST 8 OFF FOR TEST<br />

Switch Code =ON O=Off<br />

glF II2 II5 l/IO 1<br />

I/VSTRUCTIO/VS:<br />

TO IMPROVE BUILT-IN CLEANING Adjust switches<br />

per this guide. Switches 1 & 2 provide for longer flush<br />

at the end of harvest. Switches 5 & 6 provide<br />

maximum cleaning at every cycle 1 / 1 setting. The 1 /<br />

10 setting will pump-out less to conserve water (less<br />

cleaning).<br />

DO NOT ADJUST SWITCHES 3,4,7, & 8 FROM<br />

THE FACTORY SETTINGS !<br />

DO NOT MAKE CONNECTIONTOTHE RED K-4<br />

TERMINAL !<br />

The replacement board should be adjusted to the<br />

factory settings unless local conditions require<br />

alternate settings to improve cleaning.<br />

~ 15 ~ g/27/96

g/27/96<br />

000000000<br />

ooooo----<br />

Orn<br />

3<br />

><br />

ooo-o---ooo-o----<br />

-I<br />

7<br />

-7-700000<br />

-7-700000<br />

0<br />

0<br />

000000000<br />

000000000

- 17<br />

I I g/27/96

9127196

WATER COOLED<br />

HEAD PRESSURE CONTROLS<br />

An adjustable (Pressure Modulated) water regulating valve<br />

is installed on the water cooled condenser outlet. Adjust<br />

the valve per this diagram to reflect the outlet temperature<br />

in the chart below.<br />

ADJUSTMENT SCREW Adjust:<br />

TOP VIEW<br />

CW - for higher<br />

pressure and outlet<br />

water temperature,<br />

lower water flow.<br />

CCW - for lower<br />

pressure and outlet<br />

water temperature,<br />

higher water flow.<br />

CONDENSER OUTLET WATER TEMPERATURE RANGE<br />

Model Ranqe (F”) Model Ranqe (F”)<br />

KM-250BWB / 100 - 104 KM-1201DWU 110 - 115<br />

BWC / MWC<br />

KM-451 DWU , 100 - 104 KM-1200 MWB 100 - 104<br />

KM-450 MWB<br />

KM-601/631/ 100 - 104 KM-1200 SWB 108 - 113<br />

632DWU<br />

KM-630 MWB 100 - 104 KM-1600 MWB 104 - 115<br />

KM-800 MWB 102 - 108 KM-1600 SWB 104 - 115<br />

KM-2000 SWB 104 - 115 All Flaker / DCM 100 - 104<br />

REMOTE<br />

All remote condenser units use a condenser pressure<br />

regulator ( CPR or Headmaster ) to maintain adequate<br />

head pressure in low ambient conditions. This valve is<br />

located in the remote condenser unit. The replacement<br />

valve is a Sporlan 190 psi LAC-4 valve <strong>Hoshizaki</strong> part<br />

number 440918-01. This valve can be used on any remote<br />

R-502 unit.<br />

The symptoms of a bad headmaster are similar to an<br />

undercharged unit. To diagnose a headmaster, add<br />

~ 19 ~ g/27/96

additional refrigerant in 2 lb. increments and watch the<br />

pressures. If the pressures begin to look normal, the unit<br />

was undercharged. If not, a bad headmaster is a possibil-<br />

ity. Check to see if the valve is stuck open or closed by<br />

conducting temperature test at the outlet of the headmas-<br />

ter.<br />

Always use safe refrigeration practices<br />

valve and protect from overheating.<br />

HIGH PRESSURE SAFETY SWITCH -<br />

when removing the<br />

An automatic reset high pressure safety switch is used on<br />

some Flakers and DCM’s, and on all KM series units. The<br />

pressure switch settings are as follows:<br />

MODELS PART NUMBER CUT OUT CUT IN<br />

(psig) (psig)<br />

F-441U , DCM-451U DCM-450B<br />

3110069-03 228 +I- 21.3 185 +I- 21.3<br />

KM-451 D ,<br />

KM-l 201 D<br />

-B/M/S<br />

KM-6OIU , KM-63<br />

3110069-01<br />

3110069-04<br />

AIR COOLED<br />

43344 I-05<br />

1 D , DCM-70<br />

356 +I- 21.3<br />

356 +I- 21.3<br />

& REMOTE<br />

384 +I- 21.3<br />

IU<br />

, DCM-700B<br />

256 +I- 21.3<br />

256 +I- 21.3<br />

284 +I- 21.3<br />

KM-B / M / S WATER COOLED, F-450B , F-650M ,<br />

FIOOOM , F-2000M<br />

433441-01 355.6 +I- 21.3 256 +I- 21.3<br />

F-IIOIA , F-l 1 OOM<br />

4256 79-01 356 +I- 21.3 296 +/- 21.3<br />

BIN CONTROL<br />

KM series units use a thermostatic bin control. The<br />

capillary bulb is mounted in the ice drop zone or on a drop<br />

down bracket which extends into the bin cavity. The drop<br />

down bracket should be secured to the unit base and plug<br />

connection must be made before the unit will operate.<br />

When replacing a thermostatic bin control, be sure to use<br />

the ABS mounting hardware supplied with the new control.<br />

~ 20 ~ g/27/96

Check the operation of the bin control by holding ice<br />

against the thermostatic bulb with the unit running. The<br />

unit should shut down within 6 to 10 seconds. Adjust the<br />

control “CCW ” for a faster shut down. If the bin control<br />

bulb is not contacting the ice pyramid, a bracket extention<br />

may be needed.<br />

Flaker / DCM units use mechanical bin controls. A paddle<br />

pivots on a hinge pin to operate either a microswitch or<br />

magnetic proximity switch. For proper operation, assure<br />

that the paddle swings freely.<br />

CAPACITORS<br />

See wiring diagram reference chart for capacitor ratings.<br />

HOSHIZAKI KM CUBER SEQUENCE<br />

OF OPERATION FOR “A” & “B”<br />

CONTROL BOARD UNITS<br />

1. Harvest Cycle<br />

The unit always starts in the ha ,rvest cycle. When the<br />

power switch is set to the “ICE” position and the bin<br />

control is closed (calling for ice) the harvest cycle<br />

begins. The compressor and remote fan motor starts,<br />

the hot gas valve opens, and the inlet water valve(s)<br />

opens. This is a hot gas defrost with water assist. The<br />

water flows through the center of the evaporator, picks<br />

up heat from the serpentine and transfers it to the<br />

stainless freezing surface. When the suction line<br />

temperature reaches 48°F (43°F on KM-120 1) the<br />

thermistor which is mounted to the suction line signals<br />

the board to start the defrost completion timer. This<br />

timer is factory set at 1 minute, however, it can be<br />

adjusted from 1 to 4 minutes.<br />

The total harvest time will be the time it takes for the<br />

evaporator to reach 48°F or 43°F plus the defrost<br />

completion timer setting. Total harvest time will be<br />

longer in the winter due to the colder incoming water<br />

temperature. The inlet water valve will be open a<br />

maximum time of 3 minutes on KM-451/601/631 water<br />

cooled models and 4 minutes on other “A” & “B” board<br />

models or the length of harvest, whichever is less.<br />

~ 21 ~ g/27/96

2.<br />

At the end of every harvest, water overflows the<br />

reservoir stand pipe to flush concentrated minerals<br />

out of the reservoir and down the drain. This<br />

flush can be extended by adjusting the defrost<br />

completion timer to a longer setting. Remember that<br />

this will lengthen the total harvest time.<br />

Freeze Cycle<br />

When the defrost completion timer times out, the<br />

freeze cycle begins. The compressor continues to<br />

operate, the hot gas and inlet water valves close, and<br />

the pump motor and self contained condenser fan<br />

motor starts. For the first five minutes of freeze, a<br />

short cycle protection timer on the board is in control.<br />

After 5 minutes, the control board re-checks the<br />

thermistor for 43°F (38°F for KM-1201). this assures<br />

that the hot gas valve has closed. The float switch now<br />

assumes control of the freeze cycle.<br />

You will notice that the total cycle time for KM units is<br />

up to three times that of other cubers in the market.<br />

This longer cycle is designed into the unit operation.<br />

See the unit performance data by model in this guide<br />

for actual cycle times.<br />

As the water cools and ice forms on the evaporator,<br />

the water level in the reservoir drops. When the level<br />

drops, the float in the float switch drops and finally<br />

opens the circuit. This starts the next harvest cycle<br />

(cycle returns to 1 above). The water level in the<br />

reservoir actually controls the float switch circuit. If the<br />

float is adjusted upwards, the unit will cycle quicker<br />

allowing for a smaller cube size. The unit is shipped<br />

from the factory with the float switch adjusted to the<br />

large cube size. This setting provides the best<br />

efficiency for the KM series units.<br />

FOR FACTORY SUPPORT<br />

co NTACT HOSHIZAKI CARE<br />

1 -800-233-I 940<br />

AT:<br />

~ 22 ~ g/27/96

HOSHIZAKI KM CUBER<br />

SEQUENCE OF OPERATION<br />

For ALL “C” or ALPINE control board units, KM452, 632,<br />

M & S Models<br />

THE STEPS IN THE SEQUENCE ARE AS FOLLOWS:<br />

1. 1 Minute Fill Cycle<br />

The unit always starts in the 1 minute fill cycle. When<br />

power is applied to the unit the water valve is energized<br />

and the fill period begins. After 1 minute the board<br />

checks for a closed float switch. If the float switch is<br />

closed the harvest cycle begins. If not, the unit will not<br />

start without adequate water in the sump. This serves<br />

as a low water safety shut off. The water valve will<br />

remain energized through additional 1 minute cycles<br />

until water enters the sump and the float switch closes.<br />

2. 1st Harvest Cycle<br />

The compressor starts, hot gas valve opens, water<br />

valve remains open and harvest begins. As the<br />

evaporator warms, the thermistor located on the<br />

suction line checks for a 48” F. temperature. When<br />

48” F. is reached, the harvest is turned over to the<br />

adjustable control board defrost timer which is factory<br />

set for normal conditions. This adjustment can vary the<br />

defrost timer from 1 to 3 minutes.<br />

3. Freeze Cycle<br />

After the timer terminates the harvest cycle, the<br />

hot gas and water valves close, and the freeze<br />

cycle starts. For the first 5 minutes the controller<br />

board will not accept a signal from the float switch to<br />

end the freeze cycle. This 5 minute minimum freeze<br />

acts as a short cycle protection. At the end of 5<br />

minutes the float switch assumes control. As ice builds<br />

on the evaporator the water level in the sump lowers.<br />

The freeze continues until the float switch opens and<br />

terminates ice production.<br />

4. Harvest Pump Out<br />

When the float switch opens and signals the<br />

completion of the freeze cycle, the harvest cycle<br />

begins. The hot gas valve opens and the compressor<br />

~ 23 ~ g/27/96

continues to run. The d rain<br />

IO/20 second pump ou t.<br />

starts counting the<br />

The water pump stops for 2 seconds and reverses,<br />

taking water from the bottom of the sump and forcing<br />

pressure against the check valve seat allowing water to<br />

go through the check valve and down the drain. At the<br />

same time water flows through the small tube to power<br />

flush the float switch. When the drain timer stops<br />

counting, the pump out is complete.<br />

Pump out always occurs on the 2nd harvest after<br />

startup. The Alpine control board allows for adjustment<br />

for pump out to occur every cycle, or every 2nd, 5th or<br />

10th cycle from this point.<br />

5. Normal Harvest Cycle<br />

The water valve opens to allow water to assist the<br />

harvest. As the evaporator warms, the thermistor<br />

reaches 48” F. The control board receives the<br />

thermistor signal and starts the defrost timer. The water<br />

valve is open during harvest (defrost) for a maximum of<br />

6 minutes or the length of harvest, whichever is shorter.<br />

When the defrost timer completes its count down, the<br />

defrost cycle is complete and the next freeze cycle<br />

starts.<br />

The unit continues through 3, 4 and 5 sequence until<br />

the bin control senses ice and shuts the unit down.<br />

KM CHECK OUT PROCEDURE<br />

The 10 minute check out procedure is basically a<br />

sequence check which can be used at unit start up or for<br />

system diagnosis. Using this check out procedure will allow<br />

you to diagnose electrical system and component failures<br />

in approximately 10 minutes under normal operating<br />

conditions of 70°F or warmer air and 50°F or warmer water<br />

temperatures. Before conducting a 10 minute check out,<br />

check for correct installation, proper voltage per unit name<br />

plate and adequate water supply. As you go through the<br />

procedure, check to assure the components energize and<br />

de-energize correctly. If not, those components and<br />

controls are suspect.<br />

~ 24 ~ 9127196

10 MINUTE CHECK OUT PROCEDURE<br />

ALPINE CONTROL BOARD<br />

I-Turn power off-Gain access to control board<br />

2-Turn power on-place control switch in ice position<br />

A) 1 minute fill period-WV energized<br />

After 1 minute control board checks FS. If FS is<br />

closed . . . unit cycles to Harvest. Continue to (B).<br />

If FS is open unit repeats 1 minute fill cycle until<br />

switch closes (low water safety protection during<br />

initial start up and at the end of each harvest.)<br />

B) Initial Harvest Cycle WV remains energized, C,<br />

HGV, (FM on RS model) energize. Evaporator<br />

warms-thermistor senses 48°F turns operation of<br />

harvest to control board defrost completion timer-<br />

timer completes-unit cycles to freeze continue to (C)<br />

* Harvest time varies with water and air temp.<br />

(Average 2-3 minutes). If unit fails to cycle into<br />

freeze, check thermistor and control board.<br />

C) Freeze cycle-C remains energized, PM (LV on RS<br />

model) and FM energized, WV, HGV de-energized.<br />

Unit is locked in freeze by 5 minute short cycle<br />

protection timer. After 5 minutes, freeze cycle<br />

operation is transferred to FS for freeze termina-<br />

tion. During first 5 minutes of freeze, confirm that<br />

evaporator temp. drops. After 7 minutes in freeze,<br />

remove black float switch lead from control board<br />

(K5) terminal . . . unit should immediately switch to<br />

normal Harvest Cycle-continue to (D).<br />

*If unit remains in Freeze after 7 minutes with<br />

FS lead removed, change control board.<br />

D) Normal Harvest Cycle (IO/20 second pump out) C<br />

remains energized, HGV energizes. PM stops for 2<br />

seconds and starts in reverse rotation for 1 O/20<br />

seconds. (This removes contaminants from water<br />

sump through check valve and down the drain and<br />

allows for power flush of FS.) Check clear tubing at<br />

check valve, or unit drain for water flow to affirm<br />

pumpout.<br />

~ 25 ~ g/27/96

E) Normal harvest continues -WV energized- return<br />

to (B).<br />

* Unit continues through sequence (B) . . (C) . .<br />

(D) until bin control is satisfied or power is<br />

turned off.<br />

* Unit starts at (A) any time bin control operates<br />

or power is interrupted.<br />

NOTE: A & B control board check out procedure<br />

requires additional time (approximately 18 minutes total).<br />

Same sequence as above excluding step (A) 1 minute fill<br />

and (D) 1 O/20 second pump out. In step (C) allow 10 to 12<br />

minutes in freeze before removing FS lead.<br />

Legend: C = Compressor LV = Line Valve<br />

CC = Contractor Coil PM = Pump Motor<br />

FM = Condenser Fan Motor RS = Remote System<br />

FS = Float Switch WV = Inlet Water Valve<br />

HGV = Hot Gas Valve<br />

RESERVOIR FLUSH SYSTEM<br />

A displacement device ( cap or assembly ) is positioned<br />

over the top of the overflow stand pipe. This device allows<br />

sediment to be pulled from the bottom of the reservoir and<br />

flush down the drain when overflow occurs. Water should<br />

always overflow the stand pipe for a short period towards<br />

the end of harvest to allow this flushing action. If overflow<br />

does not occur, you have restricted water flow into the unit.<br />

Check the inlet water valve screen , your incoming water<br />

line size or the external filtration system.<br />

Pump out models have a built-in power flush of the float<br />

switch. Models without a pump out will have a white,<br />

gravity flow, flush box mounted inside of the evaporator<br />

compartment. This box has an internal stand pipe with a<br />

siphon cap over it. A small fill tube fills the box with water<br />

from the inlet supply pipe during harvest. When this box<br />

fills completely, it empties due to the siphon effect and<br />

flushes the float tank. If the water valve is leaking by, the<br />

box will fill in freeze and empty into the float. This can<br />

cause premature harvest or a short cycling effect.<br />

~ 26 ~ g/27/96

COMPONENT CHECKS:<br />

1. Check out the float switch with an ohm meter. When the<br />

float is up, the switch is closed. When the float is fully<br />

down, the switch is open. The symptoms of a bad or<br />

sticking float switch are:<br />

Up / Closed: 60 minute freeze cycle (longer for<br />

“A” board units)<br />

Down / Open: “A” or “B” board units will cycle<br />

back to harvest after 5 to 7 minutes<br />

in freeze. “C” or Alpine board units<br />

will shut down on low water safety<br />

(water runs continuously with no<br />

unit operation).<br />

2. The thermistor must be mounted securely to the suction<br />

line using a heat sink compound. This assures good<br />

heat transfer and accurate sensing of the suction line<br />

temperature. Use <strong>Hoshizaki</strong> part number: 4A0683-01 or<br />

equivalent. (Radio Shack #276-1372 or GE Electronics<br />

#I O-81 08)<br />

Check out the thermistor mounting and check thermistor<br />

resistance versus temperature per this chart:<br />

THERMISTOR TEMPERATURE / RESISTANCE<br />

SENSOR TEMP(“F) RESISTANCE (K OHMS)<br />

0 14.4<br />

10<br />

10.6<br />

32<br />

6.0<br />

50 3.9<br />

70 2.5<br />

90 1.6<br />

The symptoms of a bad thermistor are:<br />

Open: Unit remains in harvest for 15 minutes on “C”<br />

board, 20 minutes on Alpine boards.<br />

Unit remains in harvest permanently on “A”<br />

or “B” boards.<br />

Shorted: Unit locks out on manual reset high tempera-<br />

ture safety.<br />

Note: On “B”, “C”, & Alpine boards, if the evaporator<br />

reaches 127°F the thermistor signal (500 ohms) shuts<br />

down the unit on this manual reset safety. This is the only<br />

~ 27 ~ 9127196

manual safety in the KM series units. To safety<br />

turn the unit power off and back on.<br />

3. For “C” or Alpine board units, check out the control<br />

board using a volt meter to check the 12 volt control<br />

voltage at connector K2. On all boards, check for 115<br />

to 120 VAC input and output voltage to each compo-<br />

nent at the Kl connector. High input voltage will shut<br />

down “C” or Alpine units on an automatic reset safety.<br />

Alpine units have a built in automatic reset low voltage<br />

safety also.<br />

4. The bin control used on all KM units is an adjustable,<br />

thermostatic control. The thermostatic bulb is mounted<br />

in the ice drop area. To adjust the bin control, hold ice<br />

against the bulb while the unit is operating. The unit<br />

should shut off within 6 to 10 seconds. If this does not<br />

occur adjust the thermostatic control by turning the<br />

screwdriver slot. Adjusting towards warmer will allow<br />

the unit to shut down quicker. This adjustment should<br />

be checked at installation, when diagnosing a bin<br />

control problem, or if a replacement bin control is<br />

installed.<br />

KM 451 / 631 / 1201 units have a bin control bracket<br />

that mounts under the unit. KM-250M, and all KM-<br />

1200M / S and larger units have a drop down bracket<br />

that must be dropped down, secured, and plugged in<br />

at installation. The ice must contact the bulb to<br />

operate the bin control. Some bin applications<br />

require an extention bracket or relocation of the bulb<br />

mounting to allow for proper shut down. Check this<br />

positioning if the control is adjusted properly and ice<br />

continues to back up into the evaporator section.<br />

The symptom of a bad bin control are:<br />

Stuck closed : The unit continues to operate when<br />

the bin is full. This allows ice to back up in the<br />

evaporator section and generally causes a freeze up<br />

condition. This will also occur if the bin control is<br />

adjusted to cold or fully “CW”. Check the adjustment<br />

and bulb location before you diagnose a stuck bin<br />

control.<br />

~ 28 ~ g/27/96

Stuck open : The unit will not start in the ice position.<br />

An easy method to check for an open bin control on M<br />

& S units is to flip the control switch to wash, if the<br />

pump starts, the bin control is closed. The same check<br />

can be used on KM-451 / 631 / 1201 units however,<br />

they have a 2 minute time delay before the pump starts<br />

if the unit is shut off.<br />

DCM Bin controls may be a mechanical flapper with a<br />

magnetic proximity switch or a micro-switch assembly.<br />

Since these controls have moving parts, make sure<br />

that all parts move freely. Sticking can occur if scale<br />

builds at the pivot points.<br />

Flakers may have either a mechanical or thermostatic<br />

control. In some cases, depending on the model, both<br />

types are combined to provide increased safety. Some<br />

flakers have an additional spout safety control which<br />

will be a thermostatic or mechanical type. This control<br />

may have an audible alarm and has a manual reset.<br />

The spout control backs up the bin control, shuting<br />

down on this manual reset safety. If this occurs, always<br />

check the bin control operation.<br />

5. Check other<br />

multimeter.<br />

components using a good quality<br />

~ 29 ~ g/27/96

A label which details the step by step cleaning/sanitizing<br />

procedure is located on the inside front panel of the ice<br />

machine. These instructions are also provided in the<br />

Instruction Manual shipped with each unit. Follow these<br />

instructions to conduct a thorough cleaning and sanitizing<br />

of the water system.<br />

Annual cleanings are recommended. More frequent<br />

cleanings may be required in bad water areas.<br />

CLEANERS-<br />

<strong>Hoshizaki</strong> recommends “<strong>Hoshizaki</strong> Scale Away’ or “Lime-<br />

A-Way” (by Economics Laboratory, <strong>Inc</strong>.) however any FDA<br />

approved ice machine cleaner is acceptable. If you carry a<br />

nickel safe cleaner, the acidic solution is weaker than<br />

normal cleaners to protect plated surfaces.You may need<br />

to use a heavier mixture of nickel safe to cut heavier scale<br />

deposits.<br />

RECOMMENDED CLEANING SOLUTION MIXTURE<br />

MODEL CLEANER WATER<br />

KM-250 7 FI. Oz.<br />

KM-500/630/800 16 FI. Oz.<br />

KM-l 200/l 600 27 FI. Oz.<br />

KM-2000/2400 38 FI. Oz.<br />

All Flakers / DCM 9.6 FI. Oz.<br />

1.3 Gal.<br />

3.0 Gal.<br />

5.0 Gal.<br />

7.0 Gal.<br />

1.6 Gal.<br />

The system should be sanitized using a solution of water<br />

and 5.25% sodium hypochlorite. Any commercial sanitizer<br />

recommended for ice machine application is acceptable.<br />

RECOMMENDED SANITIZING SOLUTION MIXTURE<br />

MODEL SANITIZER WATER<br />

KM-250<br />

KM-500/630/800<br />

KM-l 200/l 600<br />

KM-2000/2400<br />

All Flakers / DCM<br />

.65 FI. Oz. 1.3 Gal.<br />

1.5 FI. Oz. 3.0 Gal.<br />

2.5 FI. Oz. 5.0 Gal.<br />

3.7 FI. Oz. 7.0 Gal.<br />

2.5 FI. Oz. 5.0 Gal.<br />

~ 30 ~ g/27/96

The steps for a cuber production check are as follows:<br />

1. Time a complete cycle from the beginning of one<br />

freeze cycle to the beginning of the next freeze<br />

cycle.<br />

2. Catch al of the<br />

the total batch.<br />

ice from this freeze cycle and weigh<br />

3. Divide the total minutes in a 24 hour day (1440<br />

minutes) by the complete cycle time in minutes to<br />

obtain the number of cycles per day.<br />

4. Multiply the number of cycles per day by the cycle<br />

batch weigh t for the cuber production per 24 hours.<br />

(1440. Total Cycle Time)<br />

24 Hou r Production<br />

x Ice Weight=<br />

Once you calculate the production, check the incoming<br />

water temperature, and ambient condensing temperature<br />

at the cuber and cross reference to performance data<br />

included in this manual to see if the calculation falls within<br />

10% of the specification.<br />

For the most accurate production check, a normal freeze<br />

cycle should be checked. If the evaporator compartment<br />

has been opened for service or if the unit has been cut off<br />

for a long period of time, the first freeze cycle will be longer<br />

than normal. Timing this cycle can result in an inaccurate<br />

production check. To avoid this, start the unit and allow it to<br />

operate for 10 minutes in the freeze cycle, unplug the float<br />

switch lead and cause the unit to cycle into harvest mode.<br />

Replug the float switch and start timing as soon as the next<br />

freeze begins. Also remember that the evaporator<br />

compartment must be closed during the production check.<br />

Removing the front cover to check the ice buildup during a<br />

production check will allow heat into the evaporator and will<br />

affect the total cycle time and actual production.<br />

~ 31 ~ g/27/96

WATER AND REFRIGERATION CIRCUIT<br />

DRAWING REFERENCE CHART<br />

MODEL PAGE<br />

KM-250B .................................................................... 33<br />

KM-250M ................................................................... 34<br />

KM-451 DU ................................................................. 35<br />

KM-451 DWU .............................................................. 36<br />

KM-452DU, DWU ....................................................... 40<br />

KM-450MAB, MWB ................................................... 40<br />

KM-450MRB .............................................................. 41<br />

KM-601 D .................................................................... 36<br />

KM-631 DU, DWU ....................................................... 36<br />

KM-631 DSU ............................................................... 37<br />

KM-632DU, DWU ....................................................... 40<br />

KM-632DSU ............................................................... 41<br />

KM-630MAB, MWB ................................................... 40<br />

KM-630MRB .............................................................. 41<br />

KM-800MAB, MWB ................................................... 40<br />

KM-800MRB .............................................................. 41<br />

KM-l 201 DWU ............................................................ 38<br />

KM-l 201 DU, DSU ..................................................... 39<br />

KM-l 200MAB, MWB ................................................. 42<br />

KM-1200MRB ............................................................ 43<br />

KM-1200SAB, SWB ................................................... 44<br />

KM1 200SRB .............................................................. 45<br />

KM-l GOOMRB ............................................................ 43<br />

KM1 600SWB ............................................................. 44<br />

KM1 GOOSRB .............................................................. 45<br />

KM2000SWB, SRB .................................................... 46<br />

NOTE: Some drawings have been combined to represent<br />

more than one model.<br />

g/27/96

KM=250BAB, KM-250BWB<br />

KM=250BAC, KM-250BWC<br />

~ 33 ~ g/27/96

KM=250MAB, KM-250MWB<br />

Water<br />

/==<br />

g/27/96

**stw<br />

%PFl,<br />

-<br />

KM-451 DU<br />

~ 35 ~ 9127196

KM-451 DWU<br />

KM-601 DU, KM-601 DWU<br />

KM-631 DU, KM-631 DWU<br />

g/27/96

KM-631 DSU<br />

\.-.<br />

~ 37 ~ 9127196

KM-1201 DWU<br />

g/27/96

KM-1201 DU<br />

KM-1201 DSU<br />

g/27/96

KM-452 DU KM-452 DWU<br />

KM-450 MA6 KM-450 MWB<br />

KM-632 DU KM-632 DWU<br />

KM-630 MAB KM-630 MWB<br />

KM-800MAB KM-800 MWB<br />

* A HIGH Side access valve is included on later “M”<br />

models<br />

~ 40 ~ g/27/96

KM-450 MRB<br />

KM-632 DSU<br />

KM-630 MRB<br />

KM-800 MRB<br />

g/27/96

KM-1200 MAB<br />

KM-1200 MWB<br />

Spray Tube<br />

c Relriperant Circuit<br />

- Water Circuit<br />

/WI --- ---P - - - 1<br />

Drier<br />

-A<br />

Expankn Valv@<br />

Water Regulating Value<br />

~ 42 ~ 9127196<br />

Line Valu

m Water Circuit<br />

KM-1200 MRB<br />

KM-1600 MRB<br />

COndcrrsirlp Pr~urt Rqulatnr<br />

f<br />

9127196

~ 44 ~ 9127196<br />

KM-1 200 SAB<br />

KM-1200 SWB<br />

KM-1600 SWB

___ 45 ~ 9127196<br />

KM-1200 SRB<br />

KM-1600 SRB

g/27/96<br />

KM-2000 SW6<br />

KM-2000 SRB

~ 47 ~ 9127196

~ 48 ~ 9127196

-<br />

-<br />

g/27/96<br />

,<br />

,<br />

,<br />

,<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I

~ 50 ~ g/27/96

-<br />

:<br />

C<br />

.<br />

C<br />

.<br />

C<br />

.<br />

.<br />

.<br />

C<br />

.<br />

.<br />

.<br />

C<br />

.<br />

C<br />

.<br />

C<br />

.<br />

r<br />

.<br />

C<br />

.<br />

r<br />

.

g/27/96<br />

i<br />

:<br />

c

~ 53<br />

~<br />

g/27/96<br />

I I 1

g/27/96

-<br />

c<br />

1<br />

c<br />

.<br />

c<br />

.<br />

C<br />

.<br />

‘1<br />

.<br />

c<br />

.<br />

.<br />

C<br />

.<br />

c<br />

.<br />

c<br />

.<br />

.<br />

c<br />

.<br />

c<br />

.

g/27/96

-<br />

I<br />

I<br />

1<br />

1<br />

1<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I

58 ~<br />

g/27/96<br />

I<br />

- I<br />

I<br />

I I I I

-<br />

C<br />

1<br />

c<br />

.<br />

1<br />

.<br />

C<br />

.<br />

1<br />

.<br />

1<br />

.<br />

I<br />

.<br />

c<br />

.<br />

I<br />

.<br />

c<br />

.<br />

c<br />

1<br />

I<br />

.<br />

‘1<br />

1

62 ___ g/27/96<br />

-<br />

I<br />

, -

63 ~ g/27/96<br />

9

g/27/96<br />

-<br />

-<br />

I<br />

, -

g/27/96

m a<br />

L-<br />

I<br />

I

g/27/96<br />

X<br />

CD<br />

XL0<br />

N<br />

CD<br />

XL0<br />

N

g/27/96

~ 69 ~ g/27/96<br />

a<br />

k<br />

P

__ 70 ___ g/27/96<br />

KM-250BWB All - K, A<br />

up to A 10705<br />

“C” Board for other serial numbers unit see diagram B<br />

MODEL<br />

KM-250BAB<br />

A<br />

SERIAL NUMBER<br />

All - K, A<br />

up to A 22955

~ 71 ~ g/27/96<br />

$!L-. .-.-. 3;-.cp -.-.,<br />

Si c41<br />

g;- % - i<br />

------- -_ i<br />

Ui<br />

i<br />

fii -<br />

3L.Z. ._. -.-. z - -.-, * .-.I i<br />

’ F !F<br />

I<br />

-~-'-.-'---'-.-'-'---.-., r'-'-'~ . N<br />

P gj i A<br />

i<br />

rcI<br />

0<br />

NOTE: Later B-B and ALL B-C units have an additional<br />

“Flush” water valve on terminal 3 of the Control<br />

Switch and No Interlock Switch<br />

6<br />

MODEL SERIAL NUMBER<br />

KM-250 BAB ALL after A 22956, All B,C<br />

KM-250 BWB ALL after a 10706, All B,C<br />

KM-250 BAC / MAB All<br />

KM-250 BWC / MWB All<br />

Alipne Board

g/27/96<br />

C<br />

KM-451 DU, DWU<br />

No serial number break available.<br />

If 9 pin connector has DBU jumper use this diagram.<br />

“A” Board

~ 73 ~ 9127196<br />

IE<br />

3 w w<br />

7 -I<br />

D<br />

KM-451 DU, DWU<br />

No serial number break available.<br />

If 9 pin connector has no DBU jumper use this diagram.<br />

“B” Board

g/27/96<br />

E<br />

MODEL SERIAL NUMBER<br />

KM-452 DU, DWU ALL units produced<br />

“C” Board

g/27/96<br />

MODEL<br />

KM-452 DSU<br />

F<br />

SERIAL NUMBER<br />

ALL Units produced<br />

“C” Board

~ 76 ~ g/27/96<br />

00<br />

.._ ~._. C..<br />

-.-. .-<br />

I<br />

i<br />

. e<br />

._____-_~_~~~-~.f_f.~-l..<br />

I<br />

3<br />

i<br />

____ __-_-_- *-.m+ _.l._ q<br />

i<br />

*meC-OOCn-.<br />

_.- - - _ -.-_-_-__ _ __ --.-_-,-.-.- -.- _ ____ -.-.-<br />

MODEL<br />

KM-450 MAB<br />

KM-450 MWB<br />

G<br />

SERIAL NUMBER<br />

ALL J, K, A up to A26245<br />

ALL J, K, A up to A22106<br />

“C” Board

g/27/96<br />

lb<br />

_-_---------------<br />

c<br />

%<br />

C<br />

EE<br />

SS<br />

L<br />

_ _-_-.-_- - -1<br />

0<br />

00<br />

. . - .--.-.-_ .-.<br />

!<br />

MODEL<br />

KM-450 MRB<br />

H<br />

SERIAL NUMBER<br />

ALL J, K, A up to A10181<br />

“C” Board

~ 78 ~ 9127196<br />

r.~ ____. ~ -_-.-_-.-. *<br />

8<br />

II -<br />

i i<br />

-i-<br />

8 i ------- -- i<br />

Xi<br />

i<br />

i= YI i<br />

* n<br />

L.,. .-.-.-*-.-.-- .,.I<br />

Ip ’ j7<br />

5<br />

I p<br />

-.-.-.-*-.-.-*_*-.-*-.-.<br />

i Q Q<br />

i ia i-y----- F-*-y ilNICI(<br />

i 0’ i 0’<br />

i.,.,., 1 &,,,Z -2<br />

MODEL<br />

KM-450 MAB<br />

KM-450 MWB<br />

I<br />

SERIAL NUMBER<br />

All after A26246, B, C, D<br />

All after A221 07, B, C, D<br />

Alpine Board

~ 79 ~ 9127196<br />

I I<br />

..-. .-<br />

..-_ .-<br />

*mcmur~~~-; ;-mm: i<br />

0<br />

4<br />

2 Q i<br />

-.- -_- -.-.- -.-.-.-.-‘, I-‘-‘-.-,<br />

MODEL<br />

KM-450 MRB<br />

J<br />

SERIAL NUMBER<br />

All after A10182, B, C, D<br />

Alpine Board

~ 80 ~ g/27/96<br />

,---------<br />

I<br />

i= E<br />

K<br />

KM-631 DU, DWU<br />

No serial number break available.<br />

If 9 pin connector has DBU jumper use this diagram. If not,<br />

use diagram M.<br />

“A” Board

~ 81 ~ g/27/96<br />

L<br />

KM-631 DSU<br />

No serial number break available.<br />

If 9 pin connector has DBU jumper use this diagram. If not,<br />

use diagram N.<br />

“A” Board

~ 82 ~ g/27/96<br />

M<br />

KM-631 DU, DWU<br />

No serial number break available.<br />

If 9 pin connector has no DBU jumper use this diagram. If it<br />

does, use diagram K.<br />

“B” Board

~ 83 ~ g/27/96<br />

N<br />

KM-631 DSU<br />

No serial number break available.<br />

If 9 pin connector has no DBU jumper use this diagram. If it<br />

does, use diagram L.<br />

“B” Board

~ 84 ~ 9127196<br />

NOTE: KM-632D does not have protect relay. Hi-Pressure<br />

switch and control switch are located at “X”.<br />

KM-800 MWB has compressor cooling fan<br />

0<br />

MODEL SERIAL NUMBER<br />

KM-632 DU, DWU All units produced<br />

KM-630 MAB All J, K, A up to A23851<br />

KM-630 MWB All J, K, A up to Al 1501<br />

KM-800 MAB All J, K, A up to A21 181<br />

KM-800 MWB All J, K, A up to A20731<br />

“C” Board

~ 85 ~ g/27/96<br />

NOTE: KM-632 DSU does not have protect relay<br />

MODEL<br />

KM-632 DSU<br />

KM-630 MRB<br />

KM-800 MRB<br />

P<br />

SERIAL NUMBER<br />

ALL<br />

ALL J,K, A up to A12201<br />

All J, K, A up to A20806<br />

“C” Board

~ 86 ~ g/27/96<br />

i<br />

i<br />

,--.,<br />

E .<br />

i<br />

i I<br />

E<br />

&di<br />

13 52 e<br />

i i4N”i m-------3 p.---.-, ,<br />

i35yr)i i<br />

P<br />

i<br />

i Oi L,,P,ii<br />

i .-.-1-.-. t :, -.-. . ._._.<br />

NOTE: KM-800 has compressor cooling fan<br />

MODEL<br />

KM-630 MAB<br />

KM-630 MWB<br />

KM-800 MWB<br />

KM-800 MWB<br />

Q<br />

SERIAL NUMBER<br />

ALL after A 23852, ALL B, C, D<br />

ALL after A 11502, ALL B, C, D<br />

ALL after A 21182, ALL B, C, D<br />

ALL after A 20732, ALL B, C, D<br />

Alpine Board

~ 87 ~ 9127196<br />

i<br />

52 i<br />

-.-.- .-.-‘, r’-‘-‘-, i<br />

* m e-l ;<br />

i<br />

.<br />

NOTE: KM-800 MRB does not have compressor cooling<br />

fan<br />

MODEL<br />

KM-630 MRB<br />

KM-800 MRB<br />

R<br />

SERIAL NUMBER<br />

ALL after A12202, ALL B, C, D<br />

ALL after A 20807, ALL B, C, D<br />

Alpine Board

g/27/96<br />

a<br />

3<br />

S<br />

KM-1201 DU, DSU<br />

No serial number break available.<br />

If 9 pin connector has DBU jumper use this diagram.<br />

If not use diagram U.<br />

“A” Board

g/27/96<br />

KM-l 201 DSU<br />

No serial number break available.<br />

If 9 pin connector has DBU jumper use this diagram.<br />

If not use diagram V.<br />

“A” Board

9127196<br />

W<br />

U<br />

KM-1201 DU, DWU<br />

No serial number break available.<br />

If 9 pin connector does not have DBU jumper use this<br />

diagram.<br />

If it does use diagram S.<br />

“B” Board

g/27/96<br />

V<br />

KM-l 201 DSU<br />

No serial number break available.<br />

If 9 pin connector does not have DBU jumper use this<br />

diagram.<br />

If it does use diagram T.<br />

“B” Board

5<br />

i<br />

NOTE: Early MAB, MWB had 3rd hot gas valve operated<br />

by a Hi-Pressure switch and no line valve.<br />

SAB, SWB has 1 hot gas valve and 1 fan motor<br />

W<br />

MODEL SERIAL NUMBER<br />

KM-l 200MAB ALL J, K, A up to A 20981<br />

KM-1200 MWB All J, K, A up to A 10679<br />

KM-l 200 SAB ALL K, A, up to A 20431<br />

KM-l 200 SWB ALL, K, A up to 10381<br />

“C” Board

~ 93 ~ 9127196<br />

iz<br />

32 !2<br />

,-.-.-.y r--.-.-,<br />

; g!/ ;-cum; ;-NC-J;<br />

0,<br />

O*<br />

i--<br />

i<br />

i.-.-.-.-. .l..'-.-. : ::7'_<br />

0<br />

.-. --<br />

.-. .- 4<br />

z<br />

m<br />

i2 i A<br />

QD<br />

I<br />

-.- - ----,#-.-.-.-, 0<br />

-ernN ~;i-^1c3 i !<br />

~.~.~_~_~_~___-___~_~.~.~.~.<br />

I<br />

i -<br />

-.-.-.-.- -.- -._._. 4<br />

I<br />

i<br />

S<br />

NOTE: SAB, SWB has 1 hot gas valve and 1 fan motor.<br />

MWB has no fan motor.<br />

X<br />

MODEL SERIAL NUMBER<br />

KM-l 200MAB ALL after A 20982, ALL B, C, D<br />

KM-1200 MWB ALL after A 10680, ALL B, C, D<br />

KM-l 200 SAB ALL after A 20432, ALL B, C, D<br />

KM-1200 SWB ALL after A 10382, ALL B, C, D<br />

Alpine Board

~ 94 ~ 9127196<br />

r-7<br />

1 J<br />

I<br />

---<br />

4:<br />

F<br />

Ei<br />

7<br />

!i<br />

NOTE: Early Early MRB had 3rd 3rd hot gas valve operated by a Hi-<br />

Pressure switch and no line line valve.<br />

SRB SRB has has 1 hot gas gas valve valve and 1 fan motor<br />

MODEL<br />

KM-1200MRB<br />

KM-l 200 SRB<br />

Y<br />

SERIAL NUMBER<br />

ALLJ,K,AuptoA12196<br />

ALL K, A, up to A 11381<br />

“C” Board

~ 95 ~ g/27/96<br />

i - -3 i - -P_i i<br />

.-.-. .-.-.-. ._,-.<br />

I- -.-.-I r.- _.-, ,<br />

i~“Wi ;-c-4-i i<br />

8 M<br />

I<br />

x” 5-4 i<br />

_ f f -‘-‘-‘-‘-.-.-.-.-.,r .-.- -,<br />

5<br />

0<br />

I<br />

00<br />

0<br />

Qo<br />

N<br />

P-J<br />

MODEL<br />

KM-1200MRB<br />

KM-l 200 SRB<br />

z<br />

SERIAL NUMBER<br />

ALL after A 12197, ALL B, C, D<br />

ALL after A 11382, ALL B, C, D<br />

Alpine Board

~ 96 ~ 9127196<br />

KM-<br />

KM-<br />

MODEL<br />

1600 MWB, MRB<br />

1600 SWB, SRB<br />

AA<br />

SERIAL NUMBER<br />

All units produced<br />

All Units produced<br />

Alpine Board

~ 97 ~ 9127196<br />

BB<br />

MODEL SERIAL NUMBER<br />

KM-1600 MWB3, MRB3 All units produced<br />

KM-1600 SWB3, SRB3 All Units produced<br />

Alpine Board

~ 98 ~ 9127196<br />

r”.~“-.‘.“-‘-‘-.-.~~-.-.-.-.-.-.-.-.-.-.~~-.-.-.-.~.-.-.-.~-. --------‘7<br />

I<br />

I<br />

cc<br />

MODEL SERIAL NUMBER<br />

KM-2000 SWB3, SRB3 All Units produced<br />

Alpine Board

FLAKEFUDCM<br />

INSTALLATION - GENERAL<br />

Three things are critical for a proper F/DCM installation:<br />

1. The water temperature<br />

to 90” F range.<br />

should fall within the 45” F<br />

Colder water can cause excess stress on the auger<br />

gear motor which may activate the gear motor<br />

overload.<br />

2. A filter system is very important in poor water<br />

quality areas as high mineral content can cause<br />

premature bearing wear.<br />

3. The unit should be level, front to back, side to side<br />

to assure proper evaporator water level and<br />

maximum production.<br />

COMPONENTTECHNICAL DATA<br />

GEAR MOTOR SAFETIES<br />

The auger gear motor circuit includes two overload<br />

safeties. The primary safety is a manual reset, current type<br />

protector located in the control box. This is a time delay<br />

protector which operates at .9 amp over the normal gear<br />

motor amp draw. The secondary safety is a thermal<br />

protector which is incorporated into the gear motor<br />

windings.<br />

AUGER BEARINGS -<br />

Bearing Type: Sleeve/Alignment<br />

Bearing Material: Poly/Carbon<br />

The bearings are pressed into the (top) extruding head and<br />

(lower) brass housing. A repress program is available<br />

through the local <strong>Hoshizaki</strong> Distributor.<br />

~ 99 ~ g/27/96

BEARING INSPECTIONS<br />

Annual bearing inspections are recommended. More<br />

frequent inspections may be necessary in poor water<br />

quality areas.<br />

The steps for bearing inspections are as follows:<br />

(1 1 G ain access to the ice chute head by removing<br />

panel and spout connectors as necessary.<br />

the top<br />

(2) Remove the thumbnuts which hold the ice chute head<br />

in place and lift it up and off of the evaporator (take care to<br />

place the O-ring in a safe location until you replace the<br />

head.)<br />

(3) Remove the stainless steel bolt holding the cutter or<br />

breaker in place and lift off to access the extruding head<br />

and auger shaft.<br />

(4) Replace the bolt into the auger shaft and use it to push<br />

the auger back and forth from left to right to check for<br />

excessive movement.<br />

(5) Pull the auger towards you and try to insert a .02” round<br />

stock or pin gauge in between the back side of the auger<br />

shaft and bearing surface. Check several locations around<br />

the auger shaft. If the gauge will go in between the shaft<br />

and bearing, it is time to install new bearings. Both top and<br />

bottom bearings should be replaced if the top bearing is<br />

worn. If there is no excessive movement in the auger shaft<br />

and the gauge does not fit, the bearings are okay. Replace<br />

the cutter, O-ring, ice chute head and connectors.<br />

AUGER INSPECTION / BEARING<br />

REPLACEMENT<br />

A visual inspection of the auger bearing shaft surface is<br />

also recommended annually in poor water areas. The steps<br />

for this inspection is as follows:<br />

(1) Follow steps 1<br />

procedure above.<br />

(2) Remove the (metric) Allen<br />

the extruding head in place.<br />

through 5 of the bearing inspection<br />

head cap screws that secure<br />

~ 100 ~ g/27/96

(3) Thoroughly drain the water supply system.<br />