Demag DR rope hoist - Demag Cranes & Components

Demag DR rope hoist - Demag Cranes & Components

Demag DR rope hoist - Demag Cranes & Components

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

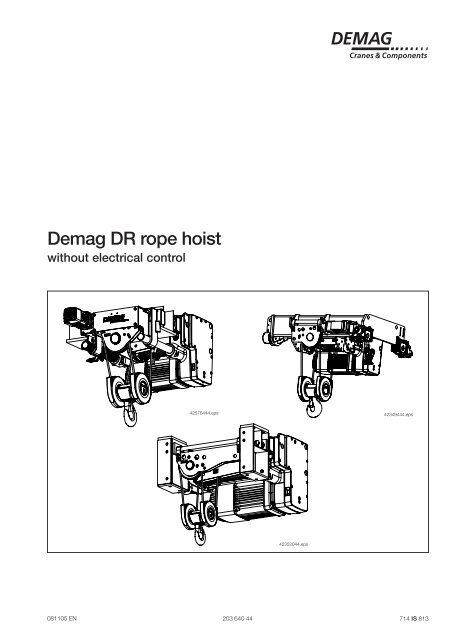

<strong>Demag</strong> <strong>DR</strong> <strong>rope</strong> <strong>hoist</strong><br />

without electrical control<br />

42576444.eps<br />

42352044.eps<br />

42349444.eps<br />

081105 EN 203 640 44 714 IS 813

Manufacturer <strong>Demag</strong> <strong>Cranes</strong> & <strong>Components</strong> GmbH<br />

P.O. Box 67, D-58286 Wetter<br />

Telephone (+49 2335) 92-0 · Telefax (+49 2335) 927676<br />

www.demagcranes.com<br />

Further<br />

documents<br />

Operating<br />

instructions<br />

Please fill in the following table before first putting the <strong>hoist</strong> into service.<br />

This provides you with a definitive documentation of your <strong>Demag</strong> <strong>rope</strong> <strong>hoist</strong><br />

and important information if you ever have to contact the manufacturer or his<br />

representative.<br />

Owner<br />

Where in use<br />

Range<br />

Serial number<br />

Main <strong>hoist</strong> motor number<br />

Operating voltage<br />

Control voltage<br />

Frequency<br />

Wiring diagram number<br />

<strong>Demag</strong> <strong>rope</strong><br />

<strong>hoist</strong><br />

F<strong>DR</strong><br />

3 - F<strong>DR</strong><br />

5-<br />

F<strong>DR</strong><br />

10<br />

( PRO)<br />

214 932<br />

44<br />

720 IS 813<br />

<strong>Demag</strong> <strong>rope</strong><br />

<strong>hoist</strong><br />

EK<strong>DR</strong><br />

3 - EK<strong>DR</strong><br />

5-<br />

EK<strong>DR</strong><br />

10<br />

( PRO)<br />

214 725<br />

44<br />

720 IS 813<br />

<strong>Demag</strong> <strong>rope</strong><br />

<strong>hoist</strong><br />

EZ<strong>DR</strong><br />

5-<br />

EZ<strong>DR</strong><br />

10<br />

( PRO)<br />

214 961<br />

44<br />

720 IS 813<br />

<strong>Demag</strong> <strong>rope</strong><br />

<strong>hoist</strong><br />

F<strong>DR</strong><br />

3 - F<strong>DR</strong><br />

5-<br />

F<strong>DR</strong><br />

10<br />

( COM)<br />

214 990<br />

44<br />

720 IS 813<br />

<strong>Demag</strong> <strong>rope</strong><br />

<strong>hoist</strong><br />

EK<strong>DR</strong><br />

3 - EK<strong>DR</strong><br />

5-<br />

EK<strong>DR</strong><br />

10<br />

( COM<br />

214 916<br />

44<br />

720 IS 813<br />

<strong>Demag</strong> <strong>rope</strong><br />

<strong>hoist</strong><br />

EZ<strong>DR</strong><br />

5-<br />

EZ<strong>DR</strong><br />

10<br />

( COM)<br />

214 965<br />

44<br />

720 IS 813<br />

Dedrive Compact<br />

DIC<br />

214 708<br />

44<br />

720 IS 922<br />

CD Dedrive<br />

Compact<br />

DIC<br />

213 137<br />

44<br />

716 IS 922<br />

External pulse<br />

generator<br />

214 372<br />

44<br />

720 IS 919<br />

Z motor<br />

range<br />

214 228<br />

44<br />

720 IS 919<br />

2 20364044.p65/081105

20364044.p65/081105<br />

Introduction<br />

This document contains information on <strong>rope</strong> <strong>hoist</strong>s without electrical control. It applies<br />

for <strong>DR</strong>-Pro, EK<strong>DR</strong>-Pro, EZ<strong>DR</strong>-Pro, F<strong>DR</strong>-Pro, EK<strong>DR</strong>-Com, EZ<strong>DR</strong>-Com, F<strong>DR</strong>-<br />

Com <strong>rope</strong> <strong>hoist</strong>s.<br />

Depending on the type, the standard scope of delivery includes:<br />

- 12/2-pole <strong>hoist</strong> motor with Microtherm and EG integrated pulse generator<br />

- GS and VE brake modules<br />

- 4-pole <strong>hoist</strong> motor with Microtherm and mechanical mounting device for AG 1 - 3<br />

external pulse generators<br />

- GS and VE brake modules<br />

- 4-pole cross travel motor with Microtherm<br />

- GE and VE brake modules<br />

- Base plate in the <strong>rope</strong> <strong>hoist</strong> electrical enclosure for connecting the <strong>hoist</strong> motor and<br />

sensors<br />

- SGG geared limit switch<br />

- SGS overload cut-out<br />

3

Design overview<br />

Example of EK<strong>DR</strong><br />

Fig. 1<br />

Thrust rocker<br />

Electrical equipment cover<br />

with terminal strip and<br />

geared limit switch<br />

4/1 bottom block<br />

Explanation of size designation / type assignment<br />

EK <strong>DR</strong> - Pro 3 - 3,2 4/1 - 6 Z - 6/1 - 400 - 00 - 50 - 30 300 45<br />

Travel motor<br />

EK<strong>DR</strong> low-headroom monorail <strong>hoist</strong><br />

Gearbox with <strong>hoist</strong> motor<br />

42577844.eps<br />

Rail head width in mm<br />

} Only for EZ<strong>DR</strong><br />

or track gauge in mm<br />

Flange width of the girder in mm<br />

or girder section and size (IPE240)<br />

Maximum cross-travel speed in m/min<br />

Frequency [Hz]<br />

Electrical equipment code 1)<br />

Operating voltage [ V ]<br />

Hoist speed in m/min<br />

Motor type: Z = Cylindrical rotor<br />

Hook path in m<br />

20364044.p65/081105<br />

E = Electric travel trolley<br />

1) Code 00 <strong>DR</strong> without electrical control<br />

Code 01 EK<strong>DR</strong> with internal electrics for application on a crane. Crane bridge enclosure, DSE-8R control pendant with control cable and cables for the<br />

mobile floor control must be ordered separately.<br />

Code 02 F<strong>DR</strong>/EK<strong>DR</strong>/EZ<strong>DR</strong> with internal electrics and solo electrics with crane switch and transformer fitted in an enclosure on the trolley, for application as a<br />

solo trolley. DSE-8R control pendant with control cable must be ordered separately.<br />

Code 03 Like code 01 but control via radio control system<br />

Code 04 Like code 02 but control via radio control system<br />

4 Code 05 EK<strong>DR</strong> with fitted parallel interface “in”<br />

Reeving<br />

SWL in t<br />

Range 3; 5; 10<br />

<strong>Demag</strong> <strong>rope</strong> <strong>hoist</strong><br />

K = Low-headroom monorail <strong>hoist</strong><br />

Z = Crab<br />

F = Stationary

20364044.p65/081105<br />

Selection criteria<br />

<strong>DR</strong>-Pro F-/EK<strong>DR</strong> 3 - F-/EK-/EZ<strong>DR</strong> 5, 10<br />

The size of the <strong>hoist</strong> is determined by the load<br />

spectrum, average operating time per working day,<br />

SWL and reeving.<br />

The load spectrum<br />

(in most cases estimated) can be evaluated in<br />

accordance with the following definitions:<br />

1 Light<br />

Hoist units which are usually subject to very small<br />

loads and in exceptional cases only to maximum<br />

loads.<br />

SWL<br />

Operating time<br />

2 Medium<br />

Hoist units which are usually subject to small loads<br />

but rather often to maximum loads.<br />

SWL<br />

SWL<br />

SWL<br />

Operating time<br />

Operating time<br />

Operating time<br />

Small partial load<br />

Small dead load<br />

Heavy partial load<br />

Medium partial load<br />

Medium dead load<br />

3 Heavy<br />

Hoist units which are usually subject to medium<br />

loads but frequently to maximum loads.<br />

Heavy dead load<br />

4 Very heavy<br />

Hoist units which are usually subject to maximum or<br />

almost maximum loads.<br />

Selection table<br />

Very heavy dead load<br />

Range Group<br />

of<br />

mechanisms<br />

to<br />

FEM/<br />

ISO<br />

F-/<br />

EK-<br />

<strong>DR</strong><br />

3<br />

F-/<br />

EK-/<br />

EZ-<br />

<strong>DR</strong><br />

5<br />

F-/<br />

EK-/<br />

EZ-<br />

<strong>DR</strong><br />

10<br />

1. What are the operating conditions?<br />

2. What is the specified safe working load?<br />

3. To what height must the load be lifted?<br />

4. What is the required lifting speed?<br />

The<br />

g<br />

roup<br />

is<br />

Group<br />

of<br />

mechanisms<br />

F EM/<br />

ISO<br />

1)<br />

determined<br />

from<br />

the<br />

operating<br />

time<br />

and<br />

load<br />

spectrum<br />

Rope reeving<br />

2 / 1,<br />

4/<br />

2<br />

5. Do the loads need to be lifted and lowered with<br />

high precision?<br />

6. Is horizontal load travel necessary?<br />

7. How is the <strong>hoist</strong> to be controlled?<br />

Load spectrum<br />

Average<br />

operating<br />

time<br />

per<br />

day<br />

in<br />

hours<br />

1 Light 4-8 8-16 over<br />

16<br />

2 Medium 2-4 4-8 8-16<br />

3 Heavy 1-2 2-4 4-8<br />

4 Very heavy<br />

0, 5-1<br />

1-2 2-4<br />

Group<br />

of<br />

mechanisms<br />

to<br />

FEM 2 m<br />

3 m<br />

4 m<br />

ISO M 5<br />

M 6<br />

M 7<br />

2m/ M 5 3m/ M 6 4m/ M 7 2m/ M 5 3m/ M 6 4m/ M 7 2m/ M 5 3m/ M7<br />

4 m/<br />

M 7<br />

2 )<br />

/ 1<br />

4 6 / 1<br />

Range SWL in<br />

t<br />

<strong>DR</strong> 5<br />

2, 5 2 1, 6 5 4 3, 2 - - -<br />

<strong>DR</strong> 10<br />

5 4 3, 2 10 8 6, 3 16 12, 5 -<br />

Example<br />

SWL 5 t<br />

Load spectrum “medium” from table<br />

Hoist speed 6 m/min<br />

Creep <strong>hoist</strong> speed 1 m/min<br />

Reeving 4/1<br />

Average hook path 3 m<br />

No. of cycles/hour 20<br />

Working time/day 8 hours<br />

The average operating time per working day is estimated or calculated as follows:<br />

2 x average hook path x no.<br />

of<br />

cycles/h x working<br />

time/day<br />

Operating time/day =<br />

60 x lifting speed<br />

Operating time/day<br />

2 x 3 x 20 x 8<br />

=<br />

= 2,66<br />

60 x 6<br />

For the “medium” load spectrum and an average daily operating time of 2,66 hours,<br />

the table shows group 2 m. For a load capacity of 5 t and 4/1 <strong>rope</strong> reeving, the table<br />

indicates <strong>hoist</strong> size <strong>DR</strong> 5 - 5.<br />

SWL Hook path<br />

Lifting speed<br />

m/ min<br />

SWL Hook path<br />

Lifting speed<br />

m/<br />

min<br />

t m V1 V2 V3 t m V1 V2 V3<br />

2/ 1<br />

4/<br />

1<br />

2 m/<br />

M 5 1,<br />

6<br />

3,<br />

2<br />

3 m/<br />

M 6 1, 25<br />

12; 20<br />

12/ 2 1 8/<br />

3 2-25<br />

3)<br />

2,<br />

5<br />

4 m/<br />

M 7<br />

1 2<br />

1) Gearbox service life 20 % above the FEM value<br />

2) 4/2 and 6/1 <strong>rope</strong> reeving only for <strong>DR</strong> 10<br />

hours<br />

2 )<br />

6; 10<br />

6/ 1 9 / 1,<br />

5 1-12,<br />

5 3)<br />

2 m/<br />

M 5 2,<br />

5<br />

5<br />

3 m/<br />

M 6 2 12; 20<br />

12/ 2 1 8/<br />

3 2-25<br />

3)<br />

4 6; 10<br />

6/ 1 9 / 1,<br />

5 1-12,<br />

5 3)<br />

4 m/<br />

M 7 1, 6<br />

3,<br />

2<br />

2 m/<br />

M 5 5<br />

10<br />

3 m/<br />

M 6 4 12; 20<br />

1 0/<br />

1,<br />

7 2 -18<br />

3)<br />

2-25<br />

3)<br />

8 6; 10<br />

5 / 0,<br />

8 1 -9<br />

3)<br />

1-12,<br />

5 3)<br />

4 m/<br />

M 7 3, 2<br />

6,<br />

3<br />

4 / 2<br />

6/<br />

1 4)<br />

2 m/<br />

M 5 5<br />

16<br />

3 m/<br />

M 6 4<br />

5,<br />

8;<br />

11,<br />

35;<br />

15,<br />

2<br />

1 0/<br />

1,<br />

7 2 -18<br />

3)<br />

2-25<br />

3)<br />

12,<br />

5 6, 7;<br />

13,<br />

3 2, 7/<br />

0,<br />

4 0, 7-6<br />

-<br />

4 m/<br />

M 7 3, 2<br />

10<br />

3) for 87 Hz delta operation<br />

4) 6/1 <strong>rope</strong> reeving only for EZ<strong>DR</strong> 10<br />

5

<strong>DR</strong>-Com F-/EK<strong>DR</strong> 3 - F-/EK-/EZ<strong>DR</strong> 5, 10<br />

The size of the <strong>hoist</strong> is determined by the load<br />

spectrum, average operating time per working day,<br />

SWL and reeving.<br />

The load spectrum<br />

(in most cases estimated) can be evaluated in<br />

accordance with the following definitions:<br />

1 Light<br />

Hoist units which are usually subject to very small<br />

loads and in exceptional cases only to maximum<br />

loads.<br />

SWL<br />

Operating time<br />

2 Medium<br />

Hoist units which are usually subject to small loads<br />

but rather often to maximum loads.<br />

SWL<br />

SWL<br />

SWL<br />

Operating time<br />

Operating time<br />

Operating time<br />

Small partial load<br />

Small dead load<br />

Heavy partial load<br />

Medium partial load<br />

Medium dead load<br />

3 Heavy<br />

Hoist units which are usually subject to medium<br />

loads but frequently to maximum loads.<br />

Heavy dead load<br />

4 Very heavy<br />

Hoist units which are usually subject to maximum or<br />

almost maximum loads.<br />

Selection table<br />

Very heavy dead load<br />

1. What are the operating conditions?<br />

2. What is the specified safe working load?<br />

3. To what height must the load be lifted?<br />

4. What is the required lifting speed?<br />

The<br />

Load<br />

g<br />

roup<br />

is<br />

spectrum<br />

determined<br />

from<br />

the<br />

operating<br />

time<br />

and<br />

load<br />

spectrum<br />

5. Do the loads need to be lifted and lowered with<br />

high precision?<br />

6. Is horizontal load travel necessary?<br />

7. How is the <strong>hoist</strong> to be controlled?<br />

G roup<br />

of<br />

mechanisms<br />

to<br />

FEM/<br />

ISO<br />

1) 1 Am/<br />

M 4<br />

Rope reeving<br />

arrangement<br />

4/<br />

1<br />

Range SWL<br />

in<br />

t<br />

<strong>DR</strong> 3<br />

3,<br />

2<br />

<strong>DR</strong> 5<br />

5<br />

<strong>DR</strong> 10<br />

10<br />

Average<br />

operating<br />

time<br />

per<br />

day<br />

in<br />

hours<br />

1 Light 2-4<br />

2 Medium 1-2<br />

3 Heavy 0,<br />

5-1<br />

4 Very heavy<br />

up<br />

to<br />

0,<br />

5<br />

Group<br />

of<br />

mechanisms<br />

to<br />

FEM 1 Am<br />

ISO M 4<br />

Example<br />

SWL 5 t<br />

Load spectrum “medium” from table<br />

Hoist speed 4.5 m/min<br />

Creep <strong>hoist</strong> speed 0,8 m/min<br />

Reeving 4/1<br />

Average hook path 3 m<br />

No. of cycles/hour 10<br />

Working time/day 8 hours<br />

The average operating time per working day is estimated or calculated as follows:<br />

Operating time/day<br />

Operating time/day<br />

For the “medium” load spectrum and an average daily operating time of 1,7 hours,<br />

the table shows group 1 Am . For a load capacity of 5 t and 4/1 <strong>rope</strong> reeving, the<br />

table indicates <strong>hoist</strong> size <strong>DR</strong> 5 - 5.<br />

Range Group<br />

of<br />

mechanisms<br />

to<br />

FEM/<br />

ISO<br />

F-/<br />

EK<strong>DR</strong><br />

3<br />

F-/<br />

EK-/<br />

EZ<strong>DR</strong><br />

5<br />

=<br />

2 x average hook path x no.<br />

of<br />

cycles/h x working<br />

time/day<br />

60 x lifting speed<br />

2 x 3 x 10 x 8<br />

=<br />

=<br />

60 x 4,5<br />

SWL Hook path<br />

Lifting<br />

speed<br />

m/<br />

min<br />

t m<br />

4/<br />

1<br />

V1<br />

6,<br />

3<br />

F-/<br />

EK-/<br />

EZ<strong>DR</strong><br />

10<br />

8<br />

6; 10<br />

4/<br />

0,<br />

7<br />

10<br />

6 1) Gearbox service life 20 % above the FEM value<br />

20364044.p65/081105<br />

1 Am/<br />

M<br />

4<br />

1,<br />

7<br />

hours<br />

2<br />

2,<br />

5<br />

3,<br />

2<br />

4<br />

5<br />

6; 10<br />

4,<br />

5/<br />

0,<br />

8<br />

6; 10<br />

4,<br />

5/<br />

0,<br />

8

20364044.p65/081105<br />

7

Key data pole-changing <strong>hoist</strong> drives <strong>DR</strong> 3 – <strong>DR</strong> 5 – <strong>DR</strong> 10<br />

Design is in accordance with the VDE regulations and the design rules of the FEM, to meet the high demands made on<br />

electric <strong>hoist</strong>s.<br />

Main/creep lifting F6<br />

Range <strong>DR</strong><br />

3 No.<br />

of<br />

poles<br />

Required supply cable conductor cross sections and fuse links<br />

Code P % CDF<br />

n Starts/ h Rated current<br />

INand<br />

starting<br />

current<br />

IA<br />

for<br />

50<br />

Hz<br />

cos cos<br />

400 V<br />

ϕN ϕA Motor size<br />

kWrpm IN ( A)<br />

IA ( A)<br />

ZBR<br />

100<br />

C 12/<br />

2 - B050<br />

ZBR<br />

100<br />

D 12/<br />

2 - B050<br />

12<br />

0, 55<br />

20 430 240 4, 6<br />

7 0, 53<br />

0,<br />

72<br />

V1<br />

2 3, 4 40 2800 120 8, 5<br />

40 0, 78<br />

0,<br />

88<br />

12<br />

0, 8 20 410 240 5, 7<br />

9 0, 55<br />

0,<br />

75<br />

V2<br />

2 5, 3 40 2780 120 11 55 0, 88<br />

0,<br />

85<br />

Range<br />

<strong>DR</strong><br />

3<br />

Mains connection<br />

delay<br />

fuse<br />

for<br />

50<br />

Hz<br />

1)<br />

Supply lines<br />

for<br />

5%<br />

voltage<br />

drop<br />

∆U and<br />

starting<br />

current<br />

IA<br />

for<br />

50<br />

Hz<br />

2)<br />

4 00<br />

V<br />

400 V ( ∆ U 20<br />

V)<br />

Motor size<br />

A mm² m<br />

ZBR 100<br />

C 12/<br />

2<br />

201, 5<br />

25<br />

ZBR 100<br />

D 12/<br />

2<br />

251, 5<br />

19<br />

Range <strong>DR</strong><br />

5 No.<br />

of<br />

poles<br />

Code P % CDF<br />

n Starts/ h Rated current<br />

INand<br />

starting<br />

current<br />

IA<br />

for<br />

50<br />

Hz<br />

cos cos<br />

400 V<br />

ϕN ϕA Motor size<br />

kWrpm IN ( A)<br />

IA ( A)<br />

ZBR<br />

100<br />

D 12/<br />

2 - B050<br />

ZBR<br />

132<br />

D 12/<br />

2 - B140<br />

12<br />

0, 8 20 410 240 5, 7<br />

9 0, 55<br />

0,<br />

75<br />

V1<br />

2 5, 3 40 2780 120 11 55 0, 88<br />

0,<br />

85<br />

12<br />

1, 4 20 400 240 9, 6<br />

15 0, 54<br />

0,<br />

68<br />

V2<br />

2 8, 9 40 2870 120 18 120 0, 89<br />

0,<br />

85<br />

Range<br />

<strong>DR</strong><br />

5<br />

Mains connection<br />

delay<br />

fuse<br />

for<br />

50<br />

Hz<br />

1)<br />

Supply lines<br />

for<br />

5%<br />

voltage<br />

drop<br />

∆U and<br />

starting<br />

current<br />

IA<br />

for<br />

50<br />

Hz<br />

2)<br />

4 00<br />

V<br />

400 V ( ∆ U 20<br />

V)<br />

Motor size<br />

A mm² m<br />

ZBR 100<br />

D 12/<br />

2<br />

251, 5<br />

19<br />

ZBR 132<br />

D 12/<br />

2<br />

502, 5<br />

15<br />

Range <strong>DR</strong><br />

10<br />

No.<br />

of<br />

poles<br />

Code P % CDF<br />

n Starts/ h Rated current<br />

INand<br />

starting<br />

current<br />

IA<br />

for<br />

50<br />

Hz<br />

cos cos<br />

400 V<br />

ϕN ϕA Motor size<br />

kWrpm IN ( A)<br />

IA ( A)<br />

ZBR<br />

132<br />

D 12/<br />

2 - B140<br />

12<br />

1, 4 20 400 240 9, 6<br />

15 0, 54<br />

0,<br />

68<br />

V1<br />

2 8, 9 40 2870 120 18 120 0, 89<br />

0,<br />

85<br />

Range<br />

<strong>DR</strong><br />

10<br />

Mains connection<br />

delay<br />

fuse<br />

for<br />

50<br />

Hz<br />

1)<br />

Supply lines<br />

for<br />

5%<br />

voltage<br />

drop<br />

∆U and<br />

starting<br />

current<br />

IA<br />

for<br />

50<br />

Hz<br />

2)<br />

4 00<br />

V<br />

400 V ( ∆ U 20<br />

V)<br />

Motor size<br />

A mm² m<br />

ZBR 132<br />

D 12/<br />

2<br />

502, 5<br />

15<br />

1) Fuse links also apply in conjunction with a cross travel motor.<br />

8 2) The lengths of the supply lines are calculated on the basis of an earth-loop impedance of 200 mΩ.<br />

20364044.p65/081105

20364044.p65/081105<br />

Key data cross travel drives <strong>DR</strong> 3 – <strong>DR</strong> 5 – <strong>DR</strong> 10<br />

The cross travel drives of the <strong>DR</strong> without electrical control are designed for operation with a <strong>Demag</strong> frequency inverter in the<br />

120 Hz range. We recommend that <strong>Demag</strong> DIC Dedrive Compact frequency inverters be used. Owing to the large input voltage<br />

range of the Dedrive Compact, the <strong>DR</strong> without electrical control can be operated with mains voltages of 380...480 V with<br />

50...60 Hz. At 380 V, the max. frequency must be reduced by 5 Hz.<br />

Key data of inverter-controlled cross travel drive <strong>DR</strong> 3, <strong>DR</strong> 5, <strong>DR</strong> 10 - 2/1 - 4/1 - 4/2<br />

Range <strong>DR</strong><br />

3-10<br />

No. of<br />

poles<br />

% CDF<br />

Output<br />

Current<br />

cos ϕ n<br />

Recommended<br />

P<br />

at<br />

220<br />

V<br />

for<br />

50<br />

Hz<br />

inverter<br />

type<br />

Motor size<br />

k W<br />

I ( A)<br />

rpm Dedrive<br />

Compact<br />

ZBA 71<br />

B4<br />

- B003<br />

4 60 0, 37<br />

2, 6<br />

0, 54<br />

1375 DIC-4-004-E<br />

Key data of inverter-controlled cross travel drive EZ<strong>DR</strong> 10 -Pro 6/1<br />

Range <strong>DR</strong><br />

10<br />

No. of<br />

poles<br />

% CDF<br />

Output<br />

Current<br />

cos ϕ n<br />

Recommended<br />

P<br />

at<br />

220<br />

V<br />

for<br />

50<br />

Hz<br />

inverter<br />

type<br />

Motor size<br />

k W<br />

I ( A)<br />

rpm Dedrive<br />

Compact<br />

ZBA 90<br />

A4<br />

- B007<br />

4 60 1, 1<br />

5, 1<br />

0, 74<br />

1400 DIC-4-007-E<br />

Example for calculating the cross sections<br />

of the conductors of cables exceeding<br />

the length indicated in the table:<br />

ZBR 100 C 2/12, 400 V required length 25 m<br />

Known cross section x requiredlength<br />

2,5 x 25<br />

=<br />

= 4<br />

Known cable length<br />

16<br />

2<br />

mm<br />

9

Key data of inverter-operated <strong>hoist</strong> drives <strong>DR</strong> 3, <strong>DR</strong> 5, <strong>DR</strong> 10<br />

Design is in accordance with the VDE regulations and the design rules of the FEM, to meet the high demands made on<br />

electric <strong>hoist</strong>s.<br />

The <strong>hoist</strong> drives of the <strong>DR</strong> without electrical control are designed for operation with a <strong>Demag</strong> frequency inverter in the 87 Hz<br />

range. We recommend that <strong>Demag</strong> DIC Dedrive Compact frequency inverters be used. Owing to the large input voltage range of<br />

the Dedrive Compact, the <strong>DR</strong> without electrical control can be operated with mains voltages of 380...480 V with 50...60 Hz. At<br />

380 V, the max. frequency must be reduced by 5 Hz.<br />

Range <strong>DR</strong><br />

3<br />

No. of<br />

poles<br />

Code FEM classification<br />

% CDF<br />

Output<br />

P<br />

Current<br />

at<br />

220<br />

V<br />

cos ϕ n<br />

for<br />

50<br />

Hz<br />

Recommended<br />

inverter<br />

type<br />

Motor size<br />

k W I ( A)<br />

rpm Dedrive<br />

Compact<br />

ZBR<br />

100<br />

B 4 - B050<br />

2m<br />

DIC-4-017<br />

ZBR 100<br />

B 4 - B050<br />

4 V3<br />

3m 604, 2 16, 9 0, 85<br />

1350<br />

DIC-4-014<br />

ZBR 100<br />

B 4 - B050<br />

4m DIC-4-014<br />

Range D R 3<br />

Mains connection<br />

delay<br />

fuse<br />

for<br />

50<br />

Hz<br />

1)<br />

Supply lines<br />

for<br />

5%<br />

voltage<br />

drop<br />

∆U ) 2<br />

4 00<br />

V<br />

400 V ( ∆ U 20<br />

V)<br />

Inverter type<br />

A mm² m<br />

DIC-4-017 161, 5<br />

58<br />

DIC-4-014 161, 5<br />

70<br />

Range <strong>DR</strong><br />

5<br />

No. of<br />

poles<br />

Code FEM classification<br />

% CDF<br />

Output<br />

P<br />

Current<br />

at<br />

220<br />

V<br />

cos ϕ n<br />

for<br />

50<br />

Hz<br />

Range D R 10<br />

Mains connection<br />

delay<br />

fuse<br />

for<br />

50<br />

Hz<br />

1)<br />

Supply lines<br />

for<br />

5%<br />

voltage<br />

drop<br />

∆U ) 2<br />

4 00<br />

V<br />

400 V ( ∆ U 20<br />

V)<br />

Inverter type<br />

A mm² m<br />

Recommended<br />

inverter<br />

type<br />

Motor size<br />

k W I ( A)<br />

rpm Dedrive<br />

Compact<br />

ZBR<br />

132<br />

B 4 - B140<br />

2m<br />

8, 3 29, 0 0, 87<br />

1420 DIC-4-025<br />

ZBR 112<br />

A 4 - B140<br />

4 V3<br />

3m<br />

60<br />

DIC-4-025<br />

5, 3 18, 7 0, 84<br />

1430<br />

ZBR 112<br />

A 4 - B140<br />

4m DIC-4-017<br />

Range D R 5<br />

Mains connection<br />

delay<br />

fuse<br />

for<br />

50<br />

Hz<br />

1)<br />

Supply lines<br />

for<br />

5%<br />

voltage<br />

drop<br />

∆U ) 2<br />

4 00<br />

V<br />

400 V ( ∆ U 20<br />

V)<br />

Inverter type<br />

A mm² m<br />

DIC-4-025 352, 5<br />

65<br />

DIC-4-017 161, 5<br />

58<br />

Range <strong>DR</strong><br />

10<br />

No. of<br />

poles<br />

Code FEM classification<br />

% CDF<br />

Output<br />

P<br />

Current<br />

at<br />

220<br />

V<br />

cos ϕ n<br />

for<br />

50<br />

Hz<br />

Recommended<br />

inverter<br />

type<br />

Motor size<br />

k W I ( A)<br />

rpm Dedrive<br />

Compact<br />

ZBR<br />

132<br />

C 4 - B140<br />

2m<br />

10, 2 38, 0 0, 84<br />

1425 DIC-4-040<br />

ZBR 132<br />

B 4 - B140<br />

V2<br />

3m<br />

60<br />

DIC-4-032<br />

8, 3 29, 0 0, 87<br />

1420<br />

ZBR 132<br />

B 4 - B140<br />

4m DIC-4-025<br />

4<br />

ZBR<br />

132<br />

C 4 - B140<br />

2m50 13, 1 46, 5 0, 83<br />

1410 DIC-4-040<br />

ZBR 132<br />

C 4 - B140<br />

V3<br />

3m<br />

DIC-4-040<br />

6010, 2 38, 0 0, 84<br />

1425<br />

ZBR 132<br />

C 4 - B140<br />

4m DIC-4-032<br />

20364044.p65/081105<br />

DIC-4-040 506, 0<br />

97<br />

DIC-4-032 354, 0<br />

80<br />

DIC-4-025 352, 5<br />

65<br />

1) Fuse links also apply in conjunction with a cross travel motor.<br />

10 2) The lengths of the supply lines are calculated on the basis of an earth-loop impedance of 200 mΩ.

20364044.p65/081105<br />

Parameter settings for recommended <strong>Demag</strong> DIC Dedrive Compact frequency inverter<br />

Please refer to the table below for the required parameter settings.<br />

For the <strong>hoist</strong> drives, rotary encoder feedback on the motor is required. We recommend that the <strong>Demag</strong> AG 2 external pulse generator<br />

be used together with the EM-ENC-02 extension module for the <strong>Demag</strong> Dedrive Compact frequency inverter.<br />

After entry of the rated motor values, it is absolutely necessary to perform parameter identification.<br />

No. Name Unit ZBA ZBR<br />

71B4 90A4 100 B4<br />

112 A4<br />

132 B4<br />

132<br />

C4<br />

6 0%<br />

5 0%<br />

60%<br />

030 Configuration - 410 210<br />

370 Rated voltage<br />

V 220<br />

371 Rated current<br />

A 2, 6<br />

5, 1 16, 9 18, 7 29, 0 46, 5 38,<br />

0<br />

372 Rated speed<br />

rpm 1375 1400 1350 1430 1420 1410 1425<br />

373 No. of<br />

pole<br />

pairs<br />

- 2<br />

374 Rated cosine<br />

phi<br />

- 0, 54<br />

0, 74<br />

0, 85<br />

0, 84<br />

0, 87<br />

0, 83<br />

0,<br />

84<br />

375 Rated frequency<br />

Hz 50<br />

376 Mech. rated<br />

output<br />

kW 0, 4<br />

1, 1 4, 2<br />

5, 3<br />

8, 3 13, 1 10,<br />

2<br />

417 Frequency switch-off<br />

limit<br />

Hz 250 100<br />

418 Min. frequency<br />

Hz 5 8<br />

419 M ax.<br />

frequency<br />

1) Hz120 84 85 86<br />

420 Acceleration Hz/ s<br />

25 42 42, 5<br />

43<br />

421 Deceleration Hz/ s<br />

50 42 42, 5<br />

43<br />

490 Operating mode<br />

encoder<br />

1<br />

- 0 4<br />

491<br />

Pulse<br />

number<br />

per<br />

revolution<br />

of<br />

encoder<br />

1<br />

- - Depending<br />

on<br />

rotary<br />

encoder<br />

used<br />

721 Amplification speed<br />

controller<br />

- 3 10<br />

722<br />

Integral<br />

action<br />

controller<br />

time<br />

speed<br />

ms200 100<br />

For further details regarding commissioning, the many control possibilities, the various <strong>hoist</strong> functions and the selection of further<br />

additional components of the DIC Dedrive Compact, refer to the operating instructions 214 708 44 and 214 716 44. The permissible<br />

ambient conditions must be complied with.<br />

1) At 380 V, the max. frequency must be reduced by 5 Hz.<br />

11

Connection plate with terminal strip for <strong>DR</strong> with 2-/12-pole <strong>hoist</strong><br />

Fig. 2<br />

1<br />

Top-hat rail, 200 mm long<br />

5<br />

PE<br />

J<br />

EG<br />

PE<br />

123456<br />

3 4<br />

42354944.eps<br />

12 20364044.p65/081105<br />

2-pole 2 pol. <strong>hoist</strong> HUB<br />

2<br />

PE PE<br />

PE<br />

12VE A 1A B 1B GDNE<br />

12-pole 12 pol. HUB <strong>hoist</strong><br />

K<br />

9<br />

6 7 8<br />

11 12<br />

10<br />

X52<br />

L<br />

Cross1<br />

Kreuz1 Cross2 Kreuz2<br />

2 3 PE 1 2 3 PE<br />

SGS SGG<br />

U V W<br />

U V W<br />

1<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

PE<br />

2<br />

1<br />

ThH ThH Brg Brg BrH BrH SGS SGS PE SGG1SGG2 SGG3SGG4<br />

SGG5SGG6SGG7SGG8<br />

X161 X162 X163 PE X418 X482 X483 PE<br />

X11<br />

X48<br />

X16<br />

X5<br />

X53<br />

A<br />

PE<br />

PE<br />

X9<br />

B C D E F G H I

20364044.p65/081105<br />

Customer connections<br />

1 Top-hat rail<br />

2 12-pole <strong>hoist</strong> motor connection<br />

3 2-pole <strong>hoist</strong> motor connection<br />

4 EG integrated pulse generator<br />

5 Protective earth conductor PE<br />

6 Thermo-switch <strong>hoist</strong> motor<br />

7 Brake release contact <strong>hoist</strong> motor<br />

8 Brake <strong>hoist</strong> motor<br />

9 SGS overload protective device, electro-mechanical<br />

10 SGG geared limit switch<br />

11 Cross travel cut-out system, general<br />

12 Cross travel cut-out system, preliminary (v2 → v1)<br />

All terminals must be connected with up to 4 mm² Cu cross section, except<br />

2-pole <strong>hoist</strong> and PE which must be connected with up to 16 mm² Cu cross<br />

section.<br />

Factory connections<br />

A Terminal X11 (12-pole <strong>hoist</strong> motor)<br />

B Terminal X9 (2-pole <strong>hoist</strong> motor)<br />

C Terminal X10 (signals <strong>hoist</strong> motor)<br />

D Terminal X53 (SGS)<br />

E Protective earth conductor PE<br />

F Terminal X5 (SGG)<br />

G Terminal X16 (cut-out)<br />

H Terminal X48 (prel.)<br />

I Protective earth conductor PE<br />

J Protective earth conductor PE<br />

K Protective earth conductor PE<br />

L Connection X52 (integrated pulse generator <strong>hoist</strong> motor)<br />

13

Connection plate with terminal strip for <strong>DR</strong> with 4-pole <strong>hoist</strong> motor<br />

Fig. 3<br />

1<br />

Top-hat rail, 200 mm long<br />

5<br />

PE<br />

J<br />

EG<br />

PE<br />

123456<br />

3 4<br />

42356144.eps<br />

14 20364044.p65/081105<br />

2-pole 2 pol. HUB <strong>hoist</strong><br />

2<br />

PE PE<br />

PE<br />

12VE A 1A B 1B GDNE<br />

12-pole 12 pol. HUB <strong>hoist</strong><br />

K<br />

9<br />

6 7 8<br />

11 12<br />

10<br />

X52<br />

L<br />

Kreuz1 Cross1<br />

Cross2<br />

Kreuz2<br />

SGS SGG<br />

U V W<br />

U V W<br />

PE<br />

3<br />

2<br />

1<br />

PE<br />

3<br />

2<br />

1<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

PE<br />

2<br />

1<br />

ThH ThH Brg Brg BrH BrH SGS SGS PE SGG1SGG2 SGG3SGG4<br />

SGG5SGG6SGG7SGG8<br />

X161 X162 X163 PE X418 X482 X483 PE<br />

X11<br />

X48<br />

X16<br />

X5<br />

X53<br />

A<br />

PE<br />

PE<br />

X9<br />

B C D E F G H I

20364044.p65/081105<br />

Customer connections<br />

For the <strong>DR</strong> with 4-pole <strong>hoist</strong> motor, the connection is made directly in the motor<br />

terminal box<br />

1 Top-hat rail<br />

2 -<br />

3 -<br />

4 -<br />

5 Protective earth conductor PE<br />

6 -<br />

7 -<br />

8 -<br />

9 SGS overload protective device, electro-mechanical<br />

10 SGG geared limit switch<br />

11 Cross travel cut-out system, general<br />

12 Cross travel cut-out system, preliminary (v2 → v1)<br />

All terminals must be connected with up to 4 mm² Cu cross section, except<br />

2-pole <strong>hoist</strong> and PE which must be connected with up to 16 mm² Cu cross<br />

section.<br />

Factory connections<br />

A Terminal X11 (12-pole <strong>hoist</strong> motor)<br />

B Terminal X9 (2-pole <strong>hoist</strong> motor)<br />

C Terminal X10 (signals <strong>hoist</strong> motor)<br />

D Terminal X53 (SGS)<br />

E Protective earth conductor PE<br />

F Terminal X5 (SGG)<br />

G Terminal X16 (cut-out)<br />

H Terminal X48 (prel.)<br />

I Protective earth conductor PE<br />

J Protective earth conductor PE<br />

K Protective earth conductor PE<br />

L Connection X52 (integrated pulse generator <strong>hoist</strong> motor)<br />

15

Cable unions<br />

1<br />

1<br />

Fig. 4<br />

<strong>DR</strong> 3 cable unions <strong>DR</strong> 5 cable unions<br />

2<br />

<strong>DR</strong> 10 cable unions<br />

3<br />

3<br />

2<br />

42355044.eps<br />

42355244.eps<br />

1 Round cable union M25 1)<br />

2 Round cable union M20 1)<br />

1) Screw-type unions must have long threads (approx. 15 mm)<br />

e.g. cable union Schlemmer-Tec, manufacturer no. 5307620 (M20 x 1,5)<br />

16 cable union Schlemmer-Tec, manufacturer no. 5307125 (M25 x 1,5)<br />

20364044.p65/081105<br />

1<br />

Cable unions, <strong>DR</strong> 3, <strong>DR</strong> 5, <strong>DR</strong> 10 cover<br />

3 Twist-type cable entry gland for cable glands up to max. 12,5 mm<br />

4 Round cable union M25<br />

3<br />

2<br />

42355144.eps<br />

4<br />

42355344.eps

20364044.p65/081105<br />

Connection diagrams<br />

Hoist motor connection diagrams<br />

Pole-changing <strong>hoist</strong> drive<br />

low<br />

speed<br />

PE<br />

Fig. 5<br />

1L1 1L2 1L3<br />

1U<br />

2U<br />

PE<br />

U U U<br />

1V<br />

1W<br />

M<br />

3~<br />

U U<br />

2V 2W<br />

U<br />

CW<br />

1L1 1L2 1L3<br />

~ ~<br />

U V W<br />

high<br />

speed<br />

U1 V1W1<br />

M 3~<br />

U2<br />

V2<br />

W2<br />

CCW<br />

Switchgear<br />

cabinet<br />

Motor<br />

TB1<br />

TB2<br />

1S2<br />

1S1<br />

VE<br />

RD BU WH<br />

RD<br />

BD2 BD1<br />

Hoist drive with frequency inverter<br />

VE<br />

RD BU WH<br />

RD<br />

X1<br />

X1<br />

U<br />

Frequency<br />

inverter <strong>hoist</strong><br />

Thermo-switch<br />

Brake monitoring<br />

Switchgear<br />

cabinet<br />

2L1 2L2 2L3<br />

BD2 BD1<br />

Motor<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1 + -<br />

GS<br />

~<br />

~<br />

~<br />

2L1 2L2 2L3<br />

Re-start block min.<br />

250 ms!<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

7<br />

GS<br />

TB1<br />

TB2<br />

1S2<br />

1S1<br />

42356044.eps<br />

~<br />

~<br />

~<br />

+ -<br />

Brake monitoring<br />

Thermo-switch PCB in <strong>DR</strong><br />

Re-start block min.<br />

250 ms!<br />

Motor<br />

terminal box<br />

42355944.eps<br />

Y/Y<br />

Y/D<br />

ZBR 100 motor terminal block<br />

1U<br />

T1<br />

1V<br />

T2<br />

U U U<br />

1SP1 1SP2 1SP3 2SP1 2SP2 2SP3<br />

U2<br />

U1<br />

1U<br />

T1<br />

1SP1<br />

1W<br />

T3<br />

1V<br />

T2<br />

1SP2<br />

2U<br />

T11<br />

1W<br />

T3<br />

1SP3<br />

2V 2W<br />

T12 T13<br />

U U U<br />

2U<br />

T11<br />

2SP1<br />

2V<br />

T12<br />

2SP2<br />

BD1 BD2<br />

2W<br />

T13<br />

2SP3<br />

BD1<br />

SP1<br />

1L1 1L2 1L3 1L1* 1L2* 1L3* L+ 1L-<br />

1U<br />

Motor terminal board<br />

V2<br />

V1<br />

W2<br />

W1<br />

W2 U2 V2<br />

U1 V1 W1<br />

1L1 1L2 1L3<br />

X1<br />

RD<br />

VE+ GS1 BD1<br />

VE<br />

- +<br />

WH BU RD<br />

4 3 X1<br />

GS<br />

BD1 BD2<br />

U<br />

SP1 SP2 TB1 TB2<br />

BD2<br />

SP2<br />

ZBR 132 motor terminal block<br />

1U<br />

T1<br />

1V<br />

T2<br />

U U U<br />

U U U<br />

1SP1 1SP2 1SP3 2SP1 2SP2 2SP3<br />

T1<br />

1SP1<br />

1L1 1L2 1L3 1L1* 1L2* 1L3* L+ 1L-<br />

TB1 TB2<br />

4 2 1<br />

wh gn bn<br />

1S3 1S2 1S1<br />

TB1 TB2 1S3 1S2 1S1<br />

SP1 SP2 TB1 TB2<br />

1W<br />

T3<br />

2U<br />

T11<br />

2W<br />

T13<br />

BD1 BD2<br />

1V<br />

T2<br />

1SP2<br />

1W<br />

T3<br />

1SP3<br />

2V<br />

T12<br />

2U<br />

T11<br />

2SP1<br />

2V<br />

T12<br />

2SP2<br />

2W<br />

T13<br />

2SP3<br />

BD1<br />

SP1<br />

U<br />

BD2<br />

SP2<br />

GS<br />

- +<br />

7 6 5 4 3 2 1<br />

WH BU<br />

2L3 2L2 2L1 BD2 X1<br />

VE<br />

4 2 1<br />

wh gn bn<br />

1S3 1S2 1S1<br />

TB1 TB2 1S3 1S2 1S1<br />

4 2 1<br />

wh gn bn<br />

1S3 1S2 1S1<br />

41003284.eps<br />

41004384.eps<br />

03800784.eps<br />

17

Cross travel motor connection diagram<br />

Cross-travel drive with frequency inverter<br />

Fig. 6<br />

PE<br />

1L1 1L2 1L3<br />

U1<br />

~ ~<br />

M 3~<br />

V1 W1<br />

TB1<br />

TB2<br />

EG integrated pulse<br />

generator<br />

Brake release contact<br />

Temperature sensor, <strong>hoist</strong><br />

and cross travel motor<br />

Thermo-switch<br />

Switchgear<br />

cabinet<br />

VE<br />

RD BU WH<br />

RD<br />

Motor<br />

X1<br />

BD2 BD1<br />

Brake<br />

2L1 2L2 2L3<br />

U<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

7<br />

GE<br />

~<br />

~<br />

+ -<br />

Motor terminal<br />

block<br />

Motor terminal block<br />

18 20364044.p65/081105<br />

U1<br />

T1<br />

V1<br />

T2<br />

U1<br />

T1<br />

W1<br />

T3<br />

V1<br />

T2<br />

L1 L2 L3<br />

W1<br />

T3<br />

U<br />

SP1 SP2 TB1 TB2<br />

BD1<br />

SP1<br />

L+ L-<br />

BD1 BD2<br />

42355844.eps 41003384.eps<br />

BD2<br />

SP2<br />

TB1 TB2<br />

See operating instructions for Motors, type Z, ident. no. 214 228 44<br />

See operating instructions for Motors, type Z, ident. no. 214 228 44<br />

See operating instructions for Motors, type Z, ident. no. 214 228 44

20364044.p65/081105<br />

Brake control<br />

Various control modules are available for controlling <strong>Demag</strong> B003 to B680 disk<br />

brakes with DC magnets.<br />

All modules can also be fitted inside the switchgear cabinet.<br />

In this case, the brake coil must be protected against switching voltage peaks by<br />

means of a varistor, part no. 260 898 84, in the motor terminal box.<br />

All rectifiers feature varistor protection against overvoltage at the AC input and on the<br />

switching contact terminal as standard.<br />

The braking rectifiers are approved for a max. AC voltage of 500 V AC.<br />

Brake cut-out in the AC or DC circuit is possible with GE rectifiers (cross travel) and<br />

GS rectifiers (<strong>hoist</strong>) depending on the connection.<br />

Brake application times are highly dependent on the way in which the brake is<br />

switched off.<br />

For the <strong>DR</strong> without electrical control system, cut-out in the DC circuit by using the<br />

VE module is necessary.<br />

Operation with frequency inverters<br />

If ZB cylindrical rotor brake motors are operated together with inverters, the<br />

brake must be provided with a separate power supply and control.<br />

Brake control modules<br />

GE brake rectifiers (normal excitation)<br />

GE brake rectifiers are used for the cross travel drive of the <strong>DR</strong> as standard.<br />

They mainly consist of a half-wave rectifier with integrated free-wheeling circuit.<br />

GS brake rectifiers (high-speed excitation)<br />

GS brake rectifiers are used for the ZBR motors of the <strong>DR</strong> <strong>hoist</strong> drives as<br />

standard.<br />

The GS module includes a reversible rectifier which overexcites the brake for approx.<br />

0,3 seconds to release it and supplies it with the appropriate holding voltage<br />

from a half-wave rectifier (overexcitation factor of 2,5 with 3-phase connection).<br />

Important: When used with a pole-changing motor, GS modules must always<br />

be provided with a separate power supply.<br />

To ensure perfect functioning for cut-out of the GS and VE modules, i.e. switching<br />

with overexcitation, min. 250 ms must expire between cut-out and switching on<br />

again.<br />

VE voltage relays (voltage-dependent high-speed trip relay)<br />

VE voltage relays can be combined with GE, GS and GP brake rectifiers. VE<br />

voltage relays must only be used for brakes with a separate power supply.<br />

These modules are preferably used for inverter-fed motors. They are used for<br />

high-speed demagnetization of the brake to achieve fast brake application times<br />

without the need for additional wiring for brake cut-out in the DC circuit. VE<br />

voltage relays are connected to the brake power supply. The contact in the DC<br />

circuit is opened when the brake is switched off.<br />

19

SGG geared limit switch<br />

Fig. 7<br />

Adjusting instructions for SGG<br />

Operating principle<br />

Adjust<br />

Setting the contacts for individual<br />

adjustment:<br />

Setting the contacts for adjustment in<br />

blocks:<br />

Adjusting screw, black Adjusting screw, white<br />

For adjusting the geared limit switch, a hexagon socket key, 4 mm, is required.<br />

42589444.eps<br />

SGG/terminal strip connection<br />

SGG Switch contacts<br />

20 20364044.p65/081105<br />

1<br />

2<br />

3<br />

4<br />

1 1<br />

2 2<br />

3 3<br />

4 4<br />

5 5<br />

6 6<br />

7 7<br />

8 8<br />

Before setting the switching points, make sure that live contacts are provided with a<br />

touch guard in order to protect them against accidental contact.<br />

Allow for run-on!<br />

Each contact is allocated to a cam disk which is infinitely adjustable.<br />

The cam disks can be adjusted independently by means of the white adjusting<br />

screws.<br />

When turning the white adjusting screw clockwise, the cam disk is also turned clockwise.<br />

The switching point is shifted upwards in accordance with the hook path.<br />

When turning the screw anti-clockwise, the switching point is shifted downwards.<br />

Standard cam disks are designed in such a way that a max. useful path and a run-on<br />

path are available.<br />

The geared limit switch is already permanently connected with the control system via<br />

the system connector cable. For setting the contacts, turn the white adjusting screw<br />

until the contact maker opens the contact.<br />

If the run-on path is exceeded, the contact either opens or closes.<br />

The contacts are adjusted in blocks by means of the black adjusting screw. All cam<br />

disks are adjusted together, while the relative adjustment of the individual contacts<br />

remains unchanged. When turning the black adjusting screw clockwise, the cam<br />

disks are also turned clockwise.<br />

Approach cut-out points several times to check the limit switch functions are<br />

operating correctly!

20364044.p65/081105<br />

Technical data<br />

Transmission ratio:<br />

Switch contacts:<br />

Contact type:<br />

Cam disc:<br />

Switching point repeat accuracy:<br />

Electrical connection:<br />

Technical features:<br />

Compliance with standards<br />

Ambient temperature<br />

Type of enclosure<br />

Insulation class<br />

Approvals<br />

Technical features of<br />

switching elements:<br />

Positive opening to rated operating voltage<br />

Ui Thermal continuous current Ith Category acc. to VDE 0660:<br />

Mechanical service lives in switching<br />

cycles<br />

Terminal identification<br />

Approvals<br />

Current load to plug connector<br />

Outer dimensions:<br />

Length up to pinion cover<br />

Enclosure dimensions<br />

Overall height<br />

i = 205 with block setting of all cam disks designed for min. >1x10 6 switching<br />

operations<br />

4<br />

Change-over contact, snap-action contact, NC with automatic disconnection,<br />

contact material: silver/silver<br />

with 15° leading cams<br />

approx. +/-15 mm on hook, least favourable case for 2/1 reeving and hook path<br />

12 m. In this case, the 47 revolutions on the drive shaft result in an adjusting angle<br />

of 79,71° on the cam shaft for i = 205.<br />

Terminal strip direct connection on PCB.<br />

EN 60204-1 IEC 947-5-1 EN 60947-T5-1<br />

EN 60529 EN 50013 IEC 536<br />

Continuous operation -40 °C to +80 °C<br />

IP 54<br />

Class II<br />

CE and CSA<br />

VDE 0660 part 200 from 7/92<br />

250 V AC and 24/80 V DC<br />

6 A<br />

AC-15, 230 V AC/1,5 A<br />

DC-13, 60 V DC/0,5 A<br />

10 x 106 switching operations<br />

Acc. to EN 50013<br />

CE-UL/CSA<br />

6 A / 85 °C 250 V AC<br />

approx. 165 mm<br />

approx. 91 x 72 mm<br />

approx. 95 mm<br />

21

Load detector<br />

SGS overload cut-out,<br />

electro-mechanical<br />

Fig. 8<br />

Position switch<br />

Receptacle with tab, 6,3-2.1<br />

Socket connector, 2-pole<br />

42355444.eps<br />

Depending on the design, the SGS overload switch is set to the rated load of the <strong>DR</strong><br />

and integrated in the <strong>DR</strong> <strong>hoist</strong>. The SGS contact must be evaluated in addition to<br />

avoid any vibration in the system caused by switching off and on again.<br />

We recommend the use of MKA-2 contact evaluators for standard applications.<br />

This unit prevents premature enabling of the lifting motion and the resulting vibration<br />

processes by means of signal filtering. The unit is available for three control voltage<br />

ranges, it is included in the supply depending on the order.<br />

In combination with the SGS, only the ‘overload cut-out’ function can be used.<br />

SGS Load link<br />

Input voltage: 24 V, 9600 Hz<br />

Output signal: Load limit contact NC -X53<br />

V switching capacity: 4 A/230 V AC; 1 A/24 V DC<br />

Ambient temperature: -30° C to +80° C<br />

Type of enclosure: IP 67<br />

Mounting position: Any<br />

22 20364044.p65/081105

20364044.p65/081105<br />

MKA-2 front plate/connection<br />

diagram/dimensions<br />

Fig. 9<br />

A1 13 14 23 24<br />

O.K CLK<br />

MGS<br />

Dematik<br />

46953144<br />

gn br/ws ge<br />

1 2 3 4 A2<br />

Jumper positions<br />

1)<br />

®<br />

MKA-2<br />

Overload protection<br />

Position 1 (not<br />

SGS)<br />

Position 2<br />

Overload cut-out<br />

41873344.eps<br />

1) Jumpers for crane acceptance test.<br />

Remove jumpers after acceptance test.<br />

MKA-2 dimensions<br />

MKA-2 front plate<br />

45,0 113,0<br />

Dematik ® MKA-2 contact evaluator<br />

Part no.: For control voltage 220...240 V, 50/60 Hz 469 531 44<br />

110...120 V, 50/60 Hz 469 532 44<br />

42...48 V, 50/60 Hz 469 533 44<br />

24 V, 50/60 Hz 469 534 44<br />

Other voltages in special designs:<br />

Possible contacts: 2 NO contacts<br />

Rated cut-out capacity: 230 V; 5 A AC11, 4 A conditional nominal short-circuit current<br />

Operating voltage range: 90 to 100 % of the nominal value<br />

Nom. consumption: max. 4 VA<br />

Ambient temperature range: -20° C to +70° C<br />

Mode: Suitable for continuous operation<br />

Type of enclosure: IP 40 to DIN 40050<br />

Conductor connection: max. 2 x 2,5 mm² with self-releasing washers<br />

Mounting position: Any<br />

Mounting: Quick mounting for carrier rail 35 mm<br />

Weight: 390 g<br />

71<br />

40995644.eps<br />

23

Block wiring diagram<br />

Dematik ® SGS/MKA-2 as overload cut-out<br />

Fig. 10<br />

L4<br />

L5<br />

L1,L2,L3 PE<br />

S2 S1<br />

S1 S2<br />

U1<br />

23<br />

24<br />

S3 S3<br />

K4 K3<br />

K3 K4<br />

Lifting Lowering<br />

Function: SGS / MKA-2 as overload<br />

cut-out<br />

F2<br />

K3 K4<br />

U1<br />

M<br />

3<br />

M2<br />

A1<br />

Dematik MKA-2<br />

A2 2 3<br />

SGS1 SGS2<br />

Brown<br />

Yellow<br />

SGS<br />

21 22<br />

Jumper in position 2<br />

= Overload cut-out<br />

(see page 23, fig 9)<br />

42356644.eps<br />

Equipment designation<br />

B1 = SGS limit switch<br />

F2 = Fuse ‘main <strong>hoist</strong> motor’<br />

K3 = Contactor ‘Main lifting’<br />

K4 = Contactor ‘Main lowering’<br />

M2 = Main <strong>hoist</strong> motor<br />

S1/S2 = Pushbutton lifting/lowering<br />

S3 = Emergency limit switch lifting/lowering<br />

U1 = MKA-2 contact evaluator<br />

The SGS load link is plugged into position SGS on the PCB (SGS 1, SGS 2, PE).<br />

The outgoing terminal connections are connected to the MKA-2 contact evaluator.<br />

<strong>DR</strong> terminal SGS 1 on MKA terminal 2 and <strong>DR</strong> terminal SGS 2 on MKA terminal 3.<br />

Plug the jumper behind the front plate of the MKA-2 into position 2, i.e. between the<br />

pins in the middle and at the bottom.<br />

(see also description of MGS/MKA-2 load detectors (206 689 44))<br />

When SGS and MKA are used in combination, only the ‘overload cut-out’ function<br />

can be used.<br />

Only use contacts 23 - 24 of the MKA.<br />

24 20364044.p65/081105

20364044.p65/081105<br />

ZMS, FGB-2, FWL overload protection<br />

Fig. 11<br />

ZMS<br />

Calculating and setting the<br />

overload switching point<br />

Calculation example for FWL overload<br />

cut-out<br />

Example:<br />

<strong>DR</strong> 10-Pro, 8 t in 4/1<br />

ZMS = 1,25 t<br />

A/B = 0,5<br />

Rope <strong>hoist</strong><br />

A/<br />

B<br />

<strong>DR</strong>3and 10<br />

0,<br />

5<br />

<strong>DR</strong>50, 64<br />

FGB-2 with PVC module<br />

For a detailed description: see document 206 880 44<br />

Screening over outer sheath<br />

42355544.eps<br />

Rope<br />

F EM<br />

Nominal load<br />

[ t]<br />

Lever ZMS 2/ 1<br />

4/ 1<br />

6/ 1<br />

4/ 2<br />

LF<br />

[ x10-<br />

3]<br />

<strong>hoist</strong><br />

2/ 1 4/ 1 6/ 1 4/ 2 A/ B Nom.<br />

load<br />

[ t]<br />

Value S1to S7<br />

Value S1to S7<br />

Value S1to S7<br />

Value S1to S7<br />

2/ 1 4/ 1 6/ 1 4/<br />

2<br />

2m1, 6 3,<br />

2<br />

751101001 75 1101001<br />

1,<br />

0596<br />

<strong>DR</strong><br />

3 3m1, 25<br />

2, 5<br />

0, 5 0,<br />

625<br />

60 0011110 60 0011110 - - - - 2,<br />

2222<br />

- -<br />

4m1 2 49 1000110 49 1000110 4,<br />

3403<br />

2m2, 5 5<br />

751101001 75 1101001<br />

1,<br />

0596<br />

<strong>DR</strong><br />

5 3m2 4 0, 64<br />

1,<br />

25<br />

61 1011110 61 1011110 - - - - 2,<br />

0696<br />

- -<br />

4m1, 6 3, 2<br />

50 0100110 50 0100110 4,<br />

0422<br />

2m5 10 16 5<br />

110 1100111 115 1100111 122 0101111 115 1100111 0, 2778<br />

0, 2289<br />

0,<br />

2778<br />

<strong>DR</strong><br />

10<br />

3m4 8 12, 5 4 0, 5 1,<br />

25<br />

93 1011101 93 1011101 115 1100111 93 1011101 0, 5425<br />

0, 4800<br />

0,<br />

5425<br />

4m3, 2 6, 3 10 3, 2<br />

75 1101001 74 0101001 78 0111001 75 1101001 1, 0596<br />

1, 1109<br />

0, 9375<br />

1,<br />

0596<br />

Nominalload<br />

x A/B x 110 8 t x 0,5 x 110<br />

FWL switch value =<br />

+ 5 =<br />

+ 5 = 93<br />

No. of <strong>rope</strong>s x nominalload<br />

ZMS 4 x 1,25 t<br />

25

FWL load spectrum recorder<br />

Application<br />

Mode of operation<br />

The service life of <strong>hoist</strong> units mainly depends on the selection of the appropriate<br />

group of mechanisms, i.e. the correct estimation of operating time and load spectrum.<br />

Over long periods of utilization, however, operating conditions may change at<br />

a later date which may result in a longer or shorter service life. The conversion from<br />

single to double-shift operation for a production crane, for example, results in doubling<br />

daily utilization and, therefore, results in correspondingly faster wear of the drive<br />

mechanisms.<br />

Since <strong>hoist</strong> units are designed for specific periods of operation based on the rules of<br />

fatigue strength, failures must be expected after the end of the theoretical service life<br />

has been reached.<br />

FWL units record all loads on the <strong>hoist</strong> unit during operation, in a power-failure safe<br />

and long-term memory. The load spectrum recorder indicates experienced utilization.<br />

It therefore continuously provides information on the operating conditions and the<br />

calculated remaining service life of the <strong>hoist</strong> unit.<br />

The load spectrum recorder measures the lifted load and the <strong>hoist</strong> motor operating<br />

period.<br />

The measured load is compared with the SWL and a relative load is calculated. Since<br />

wear on the moving parts of the <strong>hoist</strong> unit increases disproportionately with rising<br />

load, the value for relative loading is evaluated accordingly. Owing to this evaluation,<br />

operation of the <strong>hoist</strong> unit with half the rated load only creates (1/2) 3 = 1/8 of the load<br />

spectrum value (LK value) which is reached by operation with rated load.<br />

For ¼ rated load, therefore, the LK value is (1/4) 3 = 1/64, etc.<br />

The operating time of the <strong>hoist</strong> unit is measured as the duty time of the lifting and<br />

lowering motions. Since wear can be assumed proportionally to the operating time,<br />

the measured value is integrated as a proportion of time in the displayed LK value.<br />

Double the operating time with identical load as a consequence corresponds to a<br />

doubled LK value.<br />

The load spectrum recorder collects the measured loading of the <strong>hoist</strong> unit, continuously<br />

for any load and duty intervals. The LK value therefore corresponds to the sum<br />

total of loads experienced so far. In contrast to the elapsed operating time counter, it<br />

is not the pure duration of operation of the <strong>hoist</strong> unit that is displayed but the load on<br />

the <strong>hoist</strong> unit is recorded, which is of far greater importance for wear, and evaluated<br />

according to its influence.<br />

The counter in the load spectrum recorder is calibrated so that when the strain gauge<br />

carrier link is loaded with the SWL in group of mechanisms 1 Bm, the LK value<br />

counts +1 per second.<br />

This makes the load spectrum recorder an effective instrument for monitoring <strong>hoist</strong><br />

units.<br />

Based on continuous recording of the displayed LK value, in particular in conjunction<br />

with maintenance work, the owner of the <strong>hoist</strong> unit can easily obtain important information<br />

for cost-effective planning of maintenance and preventive maintenance work.<br />

It is possible to analyse utilization of <strong>hoist</strong> units on the basis of the recorded LK values<br />

to appropriately plan any extension or modernisation measures.<br />

The loading and operating time class to FEM can be verified at any time in conjunction<br />

with the elapsed operating time counter.<br />

26 20364044.p65/081105

20364044.p65/081105<br />

Calculation of the elapsed<br />

safe working period (SWP)<br />

Example: <strong>DR</strong> 3 3m<br />

Counter LK = 10014<br />

LF = 0,5425 x 106 L1, L2, L3, PE<br />

L4<br />

U3<br />

L5<br />

S1<br />

S3<br />

K1<br />

K1<br />

S2 S1<br />

U1<br />

K2<br />

13<br />

14<br />

S3<br />

K3<br />

F1<br />

M<br />

3<br />

M1<br />

A1 1 2 3<br />

A2 4 5 6 7<br />

U1<br />

S3<br />

S4<br />

K3<br />

23<br />

24<br />

S3<br />

K2 K3<br />

K2<br />

K2<br />

The FWL load spectrum recorder makes is possible to determine the past duration<br />

of service and, as a consequence, also the remaining duration of service.<br />

For measuring, the nominal load of the ZMS is used as the reference nominal load.<br />

This means that the FWL counts the full load seconds of the ZMS. If the ZMS is not<br />

to be loaded with its own nominal load (for <strong>hoist</strong> unit nominal load), the displayed<br />

value needs to be corrected by a specific factor. This correction factor must be entered<br />

into the crane test and inspection booklet when the unit is put into operation.<br />

The duration of service S in hours (to FEM 9.755) is calculated by means of the<br />

following formula:<br />

S = LK × LF<br />

S = Duration of service in full load hours<br />

Full load hours S = 10014 x 0,0005425 = 5,43 hours<br />

U1<br />

K3<br />

A1<br />

A2 1 2 3<br />

U2<br />

B1<br />

ZMS<br />

FGB-2<br />

FWL<br />

K2 K3<br />

16<br />

10<br />

P1<br />

LK = FWL counter reading<br />

LF = Load spectrum factor<br />

FGB-2/FWL as overload protection and load spectrum recorder for <strong>hoist</strong> units with pole-changing motors<br />

Switch 8 ON = overload protection<br />

Fig. 12<br />

Creep Main<br />

Lifting Lowering Lifting Lowering<br />

Green<br />

Brown<br />

White<br />

Screen<br />

Screen<br />

Green<br />

Brown<br />

White<br />

Yellow<br />

Equipment designation<br />

B1 = Strain gauge<br />

F1 = Fuse ‘Hoist motor’<br />

K1 = Contactor ‘Creep lifting/creep lowering’<br />

K2 = Contactor ‘Main lifting’<br />

K3 = Contactor ‘Main lowering’<br />

M1 = Creep – main <strong>hoist</strong> motor<br />

P1 = Elapsed operating time counter<br />

S1/S2 = Pushbutton lifting/lowering<br />

S3 = Emergency limit switch lifting/lowering<br />

S4 = Preliminary limit switch ‘Main lifting’<br />

U1 = Frequency evaluator/load spectrum<br />

recorder, overload<br />

U2 = FGB-2 frequency generator<br />

U3 = Hoist unit control (e.g. 250 ms re-start<br />

block)<br />

42356544.eps<br />

27

Cross travel limit switch<br />

Position switch XCK-MR<br />

Fig. 13<br />

Position switch<br />

2 x switching in steps with rotating stop<br />

Switching crossbar positions with<br />

contact arrangement<br />

Contact block<br />

‘A’<br />

Connection of cable on<br />

switch:<br />

Type XCK-MR54D1<br />

With rotating stop<br />

Key data:<br />

Housing: Zinc die-cast<br />

Type of enclosure: IP66<br />

Mechanical service life: 2 million switching cycles<br />

Actuating speed: max. 90 m/min<br />

Min. moment for actuation: 0,5 Nm<br />

Positive opening: 0,75 Nm<br />

Cable unions: 3 x M20<br />

Contact block<br />

‘B’<br />

Screw-type union M20 with long<br />

thread (approx. 15 mm)<br />

+180° +90° 0° -90° -180°<br />

Rated operating data: AC-15: 240 V; 3 A<br />

DC-13: 125 V; 0,55 A<br />

Connection/cross section: Flat terminal with washer M3,5/max. 2 x 1,5 mm²<br />

Earth lead connection/cross section: Flat terminal with washer M3/max. 1,5 mm²<br />

Short-circuit protection: Fusible link 10 A, gG (gL)<br />

A11 A12<br />

B21 B22<br />

B11 B12<br />

Positive lock connector 6,3 mm with lock<br />

Connector, 3-pole<br />

Connector -X16<br />

Connector, 3-pole<br />

Core 1 on pin 1<br />

Core 2 on pin 2<br />

Core 3 on pin 3<br />

Core 4 on pin 1<br />

Core 5 on pin 2<br />

Core 6 on pin 3<br />

5 mm offset without<br />

connector -X48<br />

42355444.eps<br />

Contact type: No snap function, positive opening of NC contact 21-22<br />

28 20364044.p65/081105

20364044.p65/081105<br />

Option packages<br />

Cross travel inverter<br />

<strong>DR</strong> PRO and <strong>DR</strong> COM<br />

Package 1<br />

Cross travel limit switch<br />

<strong>DR</strong> PRO and <strong>DR</strong> COM<br />

Package 2<br />

Selection via logic<br />

Fitted in the factory<br />

Overload cut-out, F series<br />

Only for <strong>DR</strong> PRO<br />

Package 3<br />

Selection via logic<br />

Fitted in the factory<br />

Accessories for parameter<br />

programming<br />

Package 1. 1<br />

1.<br />

2<br />

Inverter DIC-4-004 DIC-4-007<br />

537 713<br />

84<br />

537<br />

715<br />

84<br />

Braking<br />

resistor<br />

120<br />

Ohm<br />

0,<br />

4 KW<br />

- 537<br />

732<br />

84<br />

Braking<br />

resistor<br />

220<br />

Ohm<br />

0,<br />

2 KW<br />

537 730<br />

84<br />

-<br />

Order cable between trolley motor and FI separately, e.g. 4 x 1,5 + 2 x (2x0,5),<br />

part no.: 719 096 45<br />

EK<strong>DR</strong> 3 - 10<br />

With mech.<br />

fittings<br />

Cross<br />

travel<br />

limit<br />

switch<br />

719<br />

074<br />

45<br />

EZ<strong>DR</strong> 5 - 10<br />

With mech.<br />

fittings<br />

719<br />

174<br />

45<br />

Package 3. 1<br />

3. 2<br />

3. 3<br />

3. 4<br />

3. 5<br />

3.<br />

6<br />

Rope <strong>hoist</strong><br />

<strong>DR</strong>3 <strong>DR</strong>5, 10<br />

<strong>DR</strong>3 <strong>DR</strong>5, 10<br />

<strong>DR</strong>3 <strong>DR</strong><br />

5,<br />

10<br />

ZMS<br />

0, 625<br />

t<br />

491 390<br />

44<br />

1, 25<br />

t<br />

491 391<br />

44<br />

0, 625<br />

t<br />

491 390<br />

44<br />

1, 25<br />

t<br />

491 391<br />

44<br />

0, 625<br />

t<br />

491 390<br />

44<br />

1,<br />

25<br />

t<br />

491<br />

391<br />

44<br />

FGB-2 ( terminals)<br />

469<br />

674<br />

44<br />

FWL<br />

469 669<br />

44<br />

469 668<br />

44<br />

469<br />

667<br />

44<br />

42-48 V<br />

110-120 V<br />

220-240<br />

V<br />

Order cable LIYCY 3 X 0,5 mm² between FGB-2 and FWL separately,<br />

part no. 464 495 44<br />

For programming the parameters, order an operating unit (key-pad, see table 1) or an<br />

interface module and the ‘Parcom Compact’ parameter programming software (see<br />

table 2).<br />

Table 1<br />

KP500 operating<br />

unit<br />

537<br />

722<br />

84<br />

Table 2<br />

KP232 interface<br />

module<br />

537<br />

769<br />

84<br />

RS232 module<br />

CM<br />

- 232<br />

537<br />

723<br />

84<br />

Data line<br />

PC<br />

1,<br />

8 m<br />

537<br />

237<br />

84<br />

Parcom<br />

Compact<br />

parameter<br />

programming<br />

software<br />

537<br />

752<br />

84<br />

29

Notes<br />

30 20364044.p65/081105

20364044.p65/081105<br />

Notes<br />

31

<strong>Demag</strong> <strong>Cranes</strong> & <strong>Components</strong> GmbH<br />

P.O. Box 67, D-58286 Wetter<br />

Telephone (+49 2335) 92-0 · Telefax (+49 2335) 927676<br />

www.demagcranes.com<br />

Reproduction in whole or in part only with prior consent of <strong>Demag</strong> <strong>Cranes</strong> & <strong>Components</strong> GmbH, D-58286 Wetter Subject to change. Not liable for errors or omissions.<br />

Printed in Germany Basse/081105/5H