Ae = Ca, Sr and Ba - Department of Materials and Environmental ...

Ae = Ca, Sr and Ba - Department of Materials and Environmental ...

Ae = Ca, Sr and Ba - Department of Materials and Environmental ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

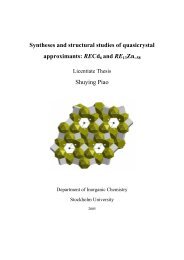

<strong>Ae</strong>AlSiH (<strong>Ae</strong> = <strong>Ca</strong>, <strong>Sr</strong> <strong>and</strong> <strong>Ba</strong>) Novel<br />

Semiconducting Zintl Phase Hydrides with<br />

Tuneable B<strong>and</strong> Gaps <strong>and</strong> Strong Metal-H<br />

Bonds<br />

Licentiate thesis<br />

Tomohiro Utsumi<br />

Division <strong>of</strong> Structural Chemistry<br />

<strong>Department</strong> <strong>of</strong> Physical, Inorganic <strong>and</strong> Structural Chemistry<br />

Stockholm University<br />

2008

Akademisk avh<strong>and</strong>ling som för avlägg<strong>and</strong>et av licentiatexamen i strukturkemi framlägges till<br />

<strong>of</strong>fentlig granskning i Rum 5Ö vid Arrhenius laboratoriet, Svante Arrhenius väg 12,<br />

måndagen den 5:e maj 2008, klockan 1000.<br />

Extern granskare Dr. Sabrina Sartori, Institute for Energy Technology, Norge<br />

Intern granskare Pr<strong>of</strong>. Osamu Terasaki, Stockholms universitet<br />

2

Abstract<br />

This thesis reports the synthesis <strong>and</strong> characterisation <strong>of</strong> two novel semiconductor Zintl<br />

phase hydrides <strong>Ca</strong>AlSiH <strong>and</strong> <strong>Ba</strong>AlSiH. <strong>Ca</strong>AlSiH was obtained by direct hydrogenation <strong>of</strong><br />

<strong>Ca</strong>AlSi for 50 minutes at 500 ˚C with 90 bars hydrogen pressure. <strong>Ba</strong>AlSiH was obtained by<br />

direct hydrogenation <strong>of</strong> <strong>Ba</strong>AlSi above 600 ˚C using 70 bars <strong>of</strong> hydrogen pressure for 2 days.<br />

Similarly deuterated <strong>Ae</strong>AlSiDs (<strong>Ae</strong> = <strong>Ca</strong> <strong>and</strong> <strong>Ba</strong>) were used to determine the full structure by<br />

neutron diffraction. Both compounds have the <strong>Sr</strong>AlSiD structure type in space group P3m1.<br />

The cell parameters were determined to a = 4.133(1) Å c =4.761(2) Å for <strong>Ca</strong>AlSiD <strong>and</strong> a =<br />

4.3087 (6) Å c = 5.203(1) Å for <strong>Ba</strong>AlSiD, respectively.<br />

<strong>Ca</strong>AlSiH <strong>and</strong> <strong>Ba</strong>AlSiH started to release hydrogen around 420 ˚C <strong>and</strong> 500 ˚C,<br />

respectively, when heated in vacuum. These high decomposition temperatures indicate that<br />

both <strong>Ca</strong>AlSiH <strong>and</strong> <strong>Ba</strong>AlSiH are fairly stable hydrides. This stability was attributed to a strong<br />

ionic interaction between <strong>Ae</strong> (<strong>Ca</strong> <strong>and</strong> <strong>Ba</strong>) <strong>and</strong> H in addition to the covalent Al-H bond. The<br />

hydrogenation/dehydrogenation reaction was found to be reversible according to 2<strong>Ae</strong>AlSi +<br />

H2 ↔ 2<strong>Ae</strong>AlSiH (<strong>Ae</strong> = <strong>Ca</strong> <strong>and</strong> <strong>Ba</strong>).<br />

For the barium compound, we could gradually substitute Si - with isoelectric (Al-H) -<br />

entities into <strong>Ba</strong>Al2-xSixH2-x (0 < x < 2), by direct hydrogenation <strong>of</strong> <strong>Ba</strong>Al2-xSix.<br />

The a-axis length is linearly decreasing with increasing x-value, as the smaller Si is<br />

substituted by Al. The c-axis is linearly increasing with x, as a larger [Si] - -lone pair is<br />

substitute by an [Al-H] - unity. DFT calculations show that the end compositions <strong>Ba</strong>Si2 (x = 2)<br />

<strong>and</strong> <strong>Ba</strong>Al2H2 (x = 0) are metal conductors whereas the intermediate <strong>Ba</strong>AlSiH (x = 1) is a<br />

semiconductor with a b<strong>and</strong> gap <strong>of</strong> 0.71 eV. This opens up for a possibility to have tuneable<br />

b<strong>and</strong> gap by changing the ratio <strong>of</strong> (Al-H) - to Si - .<br />

3

List <strong>of</strong> papers<br />

The thesis is based on the following papers:<br />

1. T. Utsumi, T. Björling, D. Moser, U. Häussermann, D. Noréus, “A series <strong>of</strong> Zintl phase<br />

hydrides; <strong>Ba</strong>Al2-xSixH2-x (0.4 < x < 1.6) with compositions <strong>and</strong> structures in between the<br />

electric conductors <strong>Ba</strong>Si2 <strong>and</strong> <strong>Ba</strong>Al2H2 ” To be published.<br />

2. T. Björling, T. Utsumi, D. Moser, B. C. Hauback, U. Häussermann, D. Noréus,<br />

“Characterisation <strong>of</strong> two new Zintl phase hydrides <strong>Ba</strong>AlSiH <strong>and</strong> <strong>Ca</strong>AlSiH” To be published.<br />

4

Contents<br />

1 INTRODUCTION.............................................................................................................................................. 6<br />

2 EXPERIMENTAL SECTION ........................................................................................................................ 10<br />

2.1 SYNTHESIS .................................................................................................................................................. 10<br />

2.1.1 <strong>Ba</strong>Al2-xSix (0.4 < x < 1.6) <strong>and</strong> <strong>Ca</strong>AlSi alloys....................................................................................... 10<br />

2.1.2 <strong>Ba</strong>Al2-xSixH2-x (0.4 < x < 1.6), <strong>Ca</strong>AlSiH <strong>and</strong> <strong>Ba</strong>AlSiD........................................................................ 10<br />

2.2 CHARACTERIZATION ................................................................................................................................... 11<br />

2.2.1 X-ray powder diffraction .................................................................................................................... 11<br />

2.2.2 X-ray single crystal diffraction........................................................................................................... 11<br />

2.2.3 Neutron diffraction ............................................................................................................................. 12<br />

2.2.4 Thermal analysis................................................................................................................................. 13<br />

2.3. COMPUTATIONAL DETAILS ......................................................................................................................... 13<br />

2.3.1 Computational details......................................................................................................................... 13<br />

3. RESULTS AND DISCUSSION ..................................................................................................................... 14<br />

3.1 ALLOYS....................................................................................................................................................... 14<br />

3.1.1 <strong>Ba</strong>AlSi <strong>and</strong> <strong>Ca</strong>AlSi alloys ................................................................................................................... 14<br />

3.1.2 <strong>Ba</strong>Al2-xSix (0.4 < x < 1.6) alloys ........................................................................................................ 17<br />

3.2 HYDRIDES ................................................................................................................................................... 19<br />

3.2.1 <strong>Ba</strong>AlSiH <strong>and</strong> <strong>Ca</strong>AlSiH........................................................................................................................ 19<br />

3.2.2 <strong>Ba</strong>Al2-xSixH2-x (0 < x < 2)....................................................................................................................32<br />

3.3 COMPUTATIONAL RESULTS ......................................................................................................................... 38<br />

3.3.1 Computationally relaxed structural parameters................................................................................. 38<br />

3.3.2 DOS <strong>of</strong> <strong>Ae</strong>AlSiD ................................................................................................................................ 39<br />

3.3.3 DOS <strong>of</strong> <strong>Ba</strong>Al2-xSixH2-x......................................................................................................................... 40<br />

4. SUMMARY ..................................................................................................................................................... 42<br />

4.1 ALLOYS OF CAALSI AND BAAL2-XSI X.......................................................................................................... 42<br />

4.2 ZINTL PHASE HYDRIDES, CAALSIH AND BAALSIH..................................................................................... 42<br />

4.3 ZINTL PHASE HYDRIDE, BAAL2-XSI XH2-X (0.4 < X < 1.6) ............................................................................... 43<br />

7. REFERENCES................................................................................................................................................ 46<br />

5

1 Introduction<br />

Hydrogen storage in metal hydrides has a number <strong>of</strong> advantages over gaseous high<br />

pressure storage or liquid LH2 cryo storage. Gaseous storage even at the highest available<br />

pressures today, takes a lot <strong>of</strong> space. This is especially critical when a filling station, with a<br />

capacity comparable to a normal gas station has to be fitted into urban areas. Compressors are<br />

also costly <strong>and</strong> energy consuming. Liquid storage is even more costly as the energy needed to<br />

liquefy hydrogen at temperatures below -253 o C corresponds to 1/3 <strong>of</strong> the total energy content<br />

<strong>of</strong> the stored hydrogen. Boil <strong>of</strong>f losses adds further to this during practical use.<br />

Well functioning hydrogen storage is, however, important when trying to realize a<br />

future “hydrogen economy” where hydrogen produced from renewable energy sources is<br />

envisioned to become an environmental friendly fuel. This has promoted research <strong>and</strong><br />

development <strong>of</strong> new materials, <strong>and</strong> in certain niche markets hydrogen storage in metal<br />

hydrides has already led to commercial products. The largest is in rechargeable NiMH<br />

batteries where the metal hydride is both hydrogen storage as well as the hydrogen electrode.<br />

Interestingly are NiMH batteries the prime choice <strong>of</strong> batteries for Hybrid Electric Vehicles<br />

(HEV) such as Toyota Prius <strong>and</strong> Honda Insight. More models are presently being launched<br />

<strong>and</strong> this rapidly growing HEV market will help to reduce the fuel consumption in the<br />

transport sector. In a sense one can say that fundamental research on hydrogen storage<br />

hydrides is already helping to reduce green house gas emissions.<br />

Another coming <strong>and</strong> probably even more important use <strong>of</strong> metal hydrides will be in<br />

hydrogen storage systems for fuel cells. This is so far a niche market mainly developed for<br />

military submarines, but civilian application such as power back up systems for mobile phone<br />

base stations <strong>and</strong> auxiliary power units for airplanes <strong>and</strong> trucks based on fuel cells are soon<br />

expected to be commercial. Improved metal hydrides with higher storage capacities at lower<br />

cost <strong>and</strong> with better resistance against unintentional oxidising impurities will accelerate this<br />

development. The long term solution to both climate problems, as well as limited resources <strong>of</strong><br />

fossil fuel, will probably contain fuel cell propelled vehicles using hydrogen produced by<br />

renewable energy.<br />

6

The commercial metal hydride production is now several thous<strong>and</strong> <strong>of</strong> tons per year.<br />

The main advantage is the very high volumetric density <strong>of</strong> hydrogen in the metal hydride.<br />

This is close to twice <strong>of</strong> that in liquefied hydrogen <strong>and</strong> it is also the reason for the doubling <strong>of</strong><br />

the capacity <strong>of</strong> NiMH batteries compared to the corresponding sizes <strong>of</strong> NiCd batteries.<br />

When hydrogen is absorbed in a metal hydride, the bond between the atoms in the H2<br />

molecule is broken as electrons from the metal lattice is filled into the anti bonding orbitals <strong>of</strong><br />

the H2 molecule <strong>and</strong> the H atoms are intercalated into the interstitial sites between the metal<br />

atoms. The bond between the hydrogen <strong>and</strong> the metal atoms should neither be too strong nor<br />

too weak, to make it possible for hydrogen to be stored <strong>and</strong> released at temperatures <strong>and</strong><br />

pressures close to ambient. This is accomplished by alloying electropositive metals from the<br />

left in the periodic table, which form stable hydrides, with less electropositive metals from the<br />

right, which usually form unstable or no hydrides. Typical hydrogen storage hydrides are<br />

FeTiH2, TiMn2H3, LaNi5H6 etc. An H/M ratio around 1 <strong>and</strong> an average metal atom weight<br />

around 50 grams per mole leads to a weight storage <strong>of</strong> around 2 wt%. To make hydrogen<br />

propelled cars with somewhat comparable performance to conventional cars, car industries<br />

have globally targeted storage capacities in excess <strong>of</strong> 6 wt% <strong>and</strong> assume metals that are more<br />

available <strong>and</strong> less costly than those presently used in commercial metal hydrides. This has<br />

focussed the research on metal hydride for hydrogen storage down to a few possible metals<br />

such as Li, Na, Mg <strong>and</strong> Al, which for weight reasons have to make up for most <strong>of</strong> the content<br />

in the metal hydride.<br />

Aluminium based alanates i.e. NaAlH4 <strong>and</strong> Na3AlH6 have attracted considerable<br />

interest as possible reversible hydrogen storage systems, since Bogdanović et al. discovered<br />

that a titanium containing catalyst could significantly improve the usually sluggish<br />

hydrogen/dehydrogenation reactions [1]. Typically, Al-hydrides (alanates) consists <strong>of</strong> isolated<br />

tetrahedral [AlH4] - or octahedral [AlH6] 3- entities [2][3]. The Al-H bond is, however, rather<br />

weak <strong>and</strong> the equilibrium pressure is high <strong>and</strong> not affected by the added Ti-catalyst, the role<br />

<strong>of</strong> which also still is a matter <strong>of</strong> controversy [4]. The high equilibrium pressure necessitates<br />

impractical high hydrogen absorption pressures, when hydrogen should be stored in the<br />

system. This limits their practical applicability for regenerative hydrogen storage. To work as<br />

practical hydrogen storage, alanate needs to reach faster kinetics as well as to strengthen the<br />

hydrogen bond to the metal atom framework.<br />

7

In the search for other Al containing hydrides Gingl et al. discovered the Zintl<br />

phase hydride <strong>Sr</strong>Al2H2 [5]. A Zintl phase is a material class between intermetallic <strong>and</strong> ionic<br />

compounds. <strong>Sr</strong>Al2H2 is called a Zintl phase hydride because hydrogen atoms are part <strong>of</strong> the<br />

Zintl anion [Al2H2] 2- . The compound has a very interesting structure, because <strong>Sr</strong>Al2H2<br />

contains both Al-Al <strong>and</strong> Al-H bonds. In <strong>Sr</strong>Al2H2, Al atoms are formally reduced by<br />

electropositive <strong>Sr</strong>. These Al atoms form with hydrogen a polyanionic Zintl anion [Al2H2] 2- .<br />

Each Al atom is surrounded by four neighbours, one H atom <strong>and</strong> three Al atoms, in a<br />

tetrahedral fashion (cf. Figure 10 where structures are further discussed). This coordination<br />

has not been observed before <strong>and</strong> is totally different from typical alanates. Moreover, the<br />

existences <strong>of</strong> the Zintl phase are also interesting in perspective <strong>of</strong> alanate synthesis. If the<br />

<strong>Sr</strong>Al2H2 is continued to be hydrogenated, an alanate phase <strong>Sr</strong>2AlH7 [6] will appear. Still, the<br />

Al-H bonds in <strong>Sr</strong>Al2H2 are fairly weak but more moderate hydrogen pressures are sufficient<br />

during the synthesis.<br />

A second Zintl phase hydride was discovered, by substituting an [AlH] - unit with an<br />

isoelectric Si - . Björling et al recently reported on a new semiconducting Zintl phase hydride<br />

<strong>Sr</strong>AlSiH [7]. This material is structurally closely related with previously discussed <strong>Sr</strong>Al2H2.<br />

To obtain <strong>Sr</strong>AlSiH, half <strong>of</strong> the [Al-H] - entities in <strong>Sr</strong>Al2H2 are substituted by isoelectric Si - .<br />

Interestingly, this substitution result in striking different properties. In contrast to thermally<br />

labile <strong>Sr</strong>Al2H2, <strong>Sr</strong>AlSiH is more stable, air <strong>and</strong> moisture insensitive. The thermal<br />

decomposition temperature <strong>of</strong> <strong>Sr</strong>AlSiH is 600 ℃ compared to 300 ℃ for <strong>Sr</strong>Al2H2, when the<br />

hydrides are heated in a DSC. In other words, substitution <strong>of</strong> [Al-H] - with Si - makes the<br />

metal-H bond stronger. If this can transferred to alanates, it would be possible to improve<br />

their properties. Another difference between <strong>Sr</strong>Al2H2 <strong>and</strong> <strong>Sr</strong>AlSiH is the electric conductivity.<br />

<strong>Sr</strong>Al2H2 is a conductor, but, <strong>Sr</strong>AlSiH is a semiconductor with a narrow indirect b<strong>and</strong> gap.<br />

Semiconductors with narrow b<strong>and</strong> gap are unusual <strong>and</strong> notable for metal hydrides.<br />

Additionally, <strong>Sr</strong>AlSiH has further interesting characteristics. In <strong>Sr</strong>AlSiH, it is possible to<br />

change the stoichiometric ratio without breaking the basic structure. The formula can be<br />

expressed as <strong>Sr</strong>Al2-xSixH2-x. This may allow a control <strong>of</strong> the conductivity by changing the<br />

composition. I.e. a tuneable b<strong>and</strong> gap can be achieved by substituting the (Si) - lone pair with<br />

an (Al-H) - unity. <strong>Sr</strong>AlSi which is the precursor material <strong>of</strong> <strong>Sr</strong>AlSiH is further a super<br />

conductor with a Tc = 5.1 K [8]. <strong>Ca</strong>AlSi is also a superconductor with a Tc = 7.7 K [8]. Both<br />

structures are closely related to that <strong>of</strong> MgB2 with a Tc = 39 K [9]. It would be interesting to<br />

investigate the superconducting as well as the normal conductive properties <strong>of</strong> (<strong>Ca</strong>, <strong>Sr</strong>, <strong>and</strong><br />

8

<strong>Ba</strong>)Al2-xSixH2-x <strong>and</strong> how they depend on the both metal atom composition <strong>and</strong> hydrogen<br />

content.<br />

In this thesis, I want to report on <strong>Ca</strong>AlSiH <strong>and</strong> <strong>Ba</strong>AlSiH which are homologous<br />

compounds to <strong>Sr</strong>AlSiH. Both <strong>Ca</strong>AlSi <strong>and</strong> <strong>Ba</strong>AlSi were synthesized by arcmelting, <strong>and</strong> the<br />

corresponding hydrides <strong>and</strong> deutrides were synthesized <strong>and</strong> characterized. The refined<br />

structures were compared with computationally calculated values, including also DOS<br />

calculations.<br />

In the barium compound we also varied the Al to Si ratio according to <strong>Ba</strong>Al2-xSix (0.4<br />

< x < 1.6) <strong>and</strong> made the corresponding hydrides in order to study how stoichiometry<br />

influences the properties. By studying these zintl phase hydride system, we hope to<br />

underst<strong>and</strong> how hydrogen binds to aluminium in the presence <strong>of</strong> other atoms. This can help us<br />

to develop better hydrogen storing system based on Al e.g. different alanates, but these new<br />

Zintl phase hydrides have also interesting electric properties such as possible tunable<br />

semiconductivity as well as superconductivity.<br />

9

2 Experimental section<br />

2.1 Synthesis<br />

2.1.1 <strong>Ba</strong>Al2-xSix (0.4 < x < 1.6) <strong>and</strong> <strong>Ca</strong>AlSi alloys<br />

Commercially pure Si powder, Al powder, <strong>Ba</strong> <strong>and</strong> <strong>Ca</strong> ingots were delivered from<br />

MERCK, Alfa <strong>Ae</strong>sar, Aldrich <strong>and</strong> ABCR respectively. The alloys, <strong>Ba</strong>Al2-xSix (0.4 < x < 1.6)<br />

<strong>and</strong> <strong>Ca</strong>AlSi were synthesized by arcmelting stoichiometric ratios <strong>of</strong> the elements in a MAM-1<br />

(Edmund Buhler) arcmelting furnace. The heating current was 15 A <strong>and</strong> the ingot cup was<br />

cooled by water. The melting was done under argon atmosphere. All <strong>of</strong> the samples were<br />

analyzed by powder x-ray diffraction. Some samples exhibited diffraction patterns with rather<br />

broad peaks. The broad peaks were attributed to poor crystallinity. They were especially<br />

frequent for the more aluminium rich samples. Such samples were subjected to a heat<br />

treatment at 500 ℃ for 2 days, whereby the shapes <strong>of</strong> the diffraction peaks improved. All<br />

samples were h<strong>and</strong>led under argon atmosphere in a glove box with less than 1 ppm <strong>of</strong> O2 <strong>and</strong><br />

H2O.<br />

2.1.2 <strong>Ba</strong>Al2-xSixH2-x (0.4 < x < 1.6), <strong>Ca</strong>AlSiH <strong>and</strong> <strong>Ba</strong>AlSiD<br />

To hydrogenate the prepared <strong>Ba</strong>Al2-xSix (0.4 < x < 1.6) <strong>and</strong> <strong>Ca</strong>AlSi alloys, the samples<br />

were divided into smaller pieces to fit into a corundum tube <strong>and</strong> reacted with hydrogen in a<br />

stainless steel autoclave. A stainless steel sealed thermo couple was inserted into the sample<br />

to record the reaction temperature. The reaction conditions are complied in section 3-2.<br />

10

2.2 Characterization<br />

2.2.1 X-ray powder diffraction<br />

All reactants <strong>and</strong> products obtained were investigated by powder x-ray diffraction,<br />

using a Guinier-Hägg focusing camera <strong>of</strong> diameter 40 mm, with monochromated CuKα1<br />

radiation (λ = 1.5405980 Å). These samples were mixed with an internal st<strong>and</strong>ard <strong>of</strong> silicon<br />

before recording the patterns. The films obtained were measured in an LS 18 film scanner<br />

[10]. The program SCANPI [11] was used to determine d-values <strong>and</strong> intensities recorded in<br />

the photographs. The programs TREOR [12] <strong>and</strong> PIRUM [13] were used to index the patterns<br />

<strong>and</strong> refine unit cell parameters.<br />

2.2.2 X-ray single crystal diffraction<br />

A single crystal <strong>of</strong> <strong>Ba</strong>SiAl was used for single crystal X-ray structure determination<br />

(cf. Table 1). Intensity data were collected by a STOE IPDS image-plate rotating anode<br />

diffractometer, operated at 50 kV <strong>and</strong> 90 mA at 291 K using graphite-monochromatized Mo<br />

Kα radiation (λ = 0.71073 Å). The distance from detector to crystal was 60 mm, <strong>and</strong> 2 theta<br />

range was 0 to 200º. The intensities <strong>of</strong> the reflections were integrated using the STOE<br />

s<strong>of</strong>tware supplied by the manufactures <strong>of</strong> the diffractometer. Numerical absorption correction<br />

was performed with the programs X-red [14] <strong>and</strong> X-shape [15]. The structure was solved by<br />

direct methods SHELXS97 [16] <strong>and</strong> refined by full matrix least squares on F2 using program<br />

SHELXL97 [17]. Molecular graphics were prepared with the program DIAMOND [18].<br />

11

Table 1: Crystal data for <strong>Ba</strong>AlSi<br />

Compound <strong>Ba</strong>AlSi<br />

Formula weight (g/mol) 192.41<br />

Temperature (K) 291(2)<br />

Wavelength (Å) 0.71073<br />

Crystal system Hexagonal<br />

Space group P6/mmm (191)<br />

Unit cell dimensions (Å) a =4.311(1)<br />

b =4.311(1)<br />

c = 5.155(2)<br />

Volume (Å 3 ) 82.98<br />

Formula unit/cell, Z 1<br />

Density (calculated) (g⋅cm -3 ) 3.850<br />

Absorption coefficient (mm -1 ) 12.28<br />

Absorption correction Numerical<br />

F(000) 83<br />

Crystal colour Metallic<br />

Crystal size (mm 3 ) 0.004188<br />

θ range for data collection (º) 7.9-56.1<br />

Index ranges -5 ≤ h ≤ 5<br />

-5≤ k ≤ 5<br />

-6≤ l ≤ 6<br />

Reflections collected 807<br />

Independent reflections 61[R(int) = 0.0185]<br />

Refinement method Full-matrix least squares on F 2<br />

Data/restraints/parameters 807/0/5<br />

Goodness-<strong>of</strong>-fit on F 2 0.994<br />

Final R indices [I > 2θ(I)] R1 = 0.0185<br />

wR2 = 0.0469<br />

R indices (all data) R1 = 0.0185<br />

wR2 = 0.0469<br />

Largest diff. hole <strong>and</strong> peak (e⋅Å -3 ) -1.39 <strong>and</strong> 0.52<br />

2.2.3 Neutron diffraction<br />

All atomic positions <strong>of</strong> <strong>Ca</strong>AlSiD <strong>and</strong> <strong>Ba</strong>AlSiD were determined from Rietveld pr<strong>of</strong>ile<br />

refinements <strong>of</strong> neutron powder diffraction data from deuterided samples measured at room<br />

temperature at Kjeller, Institute for Energy technology (IFE), Norway (λ =1.5554 Å for<br />

<strong>Ca</strong>AlSiD, <strong>and</strong> 1.54675 Å for <strong>Ba</strong>AlSiD). The program FULLPROF [19] was used for the<br />

refinement <strong>of</strong> structural parameters <strong>of</strong> <strong>Ca</strong>AlSiD <strong>and</strong> <strong>Ba</strong>AlSiD. Neutron diffraction spectra <strong>of</strong><br />

<strong>Ca</strong>AlSiD <strong>and</strong> <strong>Ba</strong>AlSiD are shown in Figure 5 <strong>and</strong> Figure 8.<br />

12

2.2.4 Thermal analysis<br />

The thermal behaviour <strong>of</strong> the obtained hydrides was investigated by degassing the<br />

samples into a tank with known volume while recording temperature <strong>and</strong> pressure. The<br />

samples were mounted in a heat resistant corundum tube in a stainless steel autoclave<br />

connected to the tank, which could be evacuated by a vacuum pump. A pressure gauge <strong>and</strong><br />

thermocouples recorded pressure <strong>and</strong> temperature to register when the dehydrogenation<br />

started.<br />

2.3. Computational details<br />

2.3.1 Computational details<br />

Total-energy calculations for <strong>Ba</strong>AlSiH <strong>and</strong> <strong>Ca</strong>SiAlH were performed in the<br />

framework <strong>of</strong> the frozen core all-electron Projected Augmented Wave (PAW) Method [20], as<br />

implemented in the program VASP [21]. The energy cut-<strong>of</strong>f was set to 500 eV. Exchange <strong>and</strong><br />

correlation effects were treated by the generalised gradient approximation (GGA), usually<br />

referred to as PW91 [22]. The integration over the Brillouin zone was done on special k-point<br />

determined according to the Monkhorst-Pack scheme [23]. Total energies were converted to<br />

at least 1meV/atom. Structural parameters were relaxed until forces had converged to less<br />

than 0.01 eV/Å.<br />

13

3. Results <strong>and</strong> discussion<br />

3.1 Alloys<br />

3.1.1 <strong>Ba</strong>AlSi <strong>and</strong> <strong>Ca</strong>AlSi alloys<br />

The single X-ray refinement revealed that the <strong>Ba</strong>AlSi alloy crystallize with hexagonal<br />

symmetry in space group P6/mmm (191) with cell parameters a = 4.311(1) Å <strong>and</strong> c = 5.155(2)<br />

Å. The <strong>Ba</strong>AlSi structure is related to that <strong>of</strong> the superconductor MgB2 with a presumed<br />

disordered arrangement <strong>of</strong> Al <strong>and</strong> Si on the B position. This structure (cf. Figure 1) consists <strong>of</strong><br />

[SiAl] 2- flat hexagonal layers, which are stacked on top <strong>of</strong> each other. In these layers, Si <strong>and</strong><br />

Al atoms are covalently bonded to each other, forming a hexagonal network. It is assumed<br />

that Si <strong>and</strong> Al atoms are more or less r<strong>and</strong>omly distributed over the 2d site. The <strong>Ba</strong> atoms are<br />

s<strong>and</strong>wiched between these layers. The final refinement gave atomic parameters according to<br />

Table 2 <strong>and</strong> an R1 value <strong>of</strong> 1.85 %. Selected interatomic distances in <strong>Ba</strong>AlSi are shown in<br />

Table 3. It is also possible that <strong>Ba</strong>SiAl crystallizes in space group as P-6/m2 (187), where Si<br />

<strong>and</strong> Al atoms are ordered by occupying alternately in the hexagonal network (Figure 2).<br />

Recently, based on single crystal synchrotron X-ray <strong>and</strong> powder neutron diffraction, Kuroiwa<br />

et al. reported that the Si <strong>and</strong> Al atoms are ordered in this way in the related <strong>Ca</strong>AlSi system<br />

[24]. However, for <strong>Ba</strong>AlSi, this ordering is difficult to detect with ordinary X-ray diffraction<br />

experiment as Al <strong>and</strong> Si are neighbours in the periodic table.<br />

Fig. 1: Structure <strong>of</strong> <strong>Ba</strong>AlSi (Space group 191) Fig. 2: Structure <strong>of</strong> <strong>Ba</strong>AlSi (Space group 187)<br />

14

Table 2: Atomic positions <strong>of</strong> <strong>Ba</strong>AlSi<br />

Atom Site x y z Occupancy U11 U22 U33 U12<br />

<strong>Ba</strong> a 0 0 0 1 0.01329 0.01329 0.01136 0.00664<br />

Al 2d 1/3 2/3 1/2 1/2 0.01027 0.01027 0.02285 0.00513<br />

Si 2d 1/3 2/3 1/2 1/2 0.01027 0.01027 0.02285 0.00513<br />

Table 3: Selected interatomic distances (Å) in <strong>Ba</strong>AlSi<br />

<strong>Ba</strong>-6 <strong>Ba</strong> 4.311(1)<br />

-2 <strong>Ba</strong> 5.156(2)<br />

-12 Al/Si 3.583(1)<br />

Al/Si-3 Al/Si 2.489(1)<br />

-6 <strong>Ba</strong> 3.583(1)<br />

-2 Al/Si 5.156(2)<br />

15

Powder x-ray diffraction patterns <strong>of</strong> <strong>Ba</strong>AlSi <strong>and</strong> <strong>Ca</strong>AlSi were also recorded. On the<br />

<strong>Ba</strong>AlSi film no impurity phase was observed. However, on the <strong>Ca</strong>AlSi film, small peaks <strong>of</strong><br />

<strong>Ca</strong>Al2Si2 [25] were observed as well as some peaks from some so far unidentified impurities.<br />

Both <strong>Ba</strong>AlSi <strong>and</strong> <strong>Ca</strong>AlSi could be indexed by a hexagonal unit cell with cell parameter, a =<br />

4.2989(6) Å c = 5.1438(7) Å <strong>and</strong> a = 4.1838(7) Å c = 4.396(1) Å, respectively. Obtained cell<br />

parameters for <strong>Ca</strong>AlSi, <strong>Sr</strong>AlSi <strong>and</strong> <strong>Ba</strong>AlSi are shown in Table 4. These cell parameter values<br />

are in line with previously reported <strong>Ba</strong>AlSi, a = 4.290 Å <strong>and</strong> c = 5.140 Å, <strong>and</strong> <strong>Ca</strong>AlSi, a =<br />

4.189 Å <strong>and</strong> c = 4.400Å, from Lorenz et al [8]. The unit cell exp<strong>and</strong>s when going from<br />

<strong>Ca</strong>AlSi to <strong>Ba</strong>AlSi following the increase in alkaline earth metal radius.<br />

Table 4: Cell parameters <strong>of</strong> <strong>Ae</strong>AlSi (<strong>Ae</strong> = <strong>Ca</strong>, <strong>Sr</strong> <strong>and</strong> <strong>Ba</strong>)<br />

Compound a(Å) c(Å) V(Å 3 )<br />

<strong>Ca</strong>AlSi 4.1838(7) 4.396(1) 66.64(2)<br />

<strong>Sr</strong>AlSi [7] 4.2767(7) 4.7442(9) 73.75(2)<br />

<strong>Ba</strong>AlSi 4.2989(6) 5.1438(7) 82.32(2)<br />

16

3.1.2 <strong>Ba</strong>Al2-xSix (0.4 < x < 1.6) alloys<br />

A wide stability range was reported for <strong>Ca</strong>Al2-xSix (0.6 < x < 1.2) <strong>and</strong> <strong>Sr</strong>Al2-xSix (0.6 <<br />

x < 1.2) [8]. Also, recently, Yamanaka et al. revealed that the Al/Si ratio in <strong>Ba</strong>AlSi is also<br />

changeable according to <strong>Ba</strong>Al2-xSix (1 < x < 1.5) [26]. Additionally, they reported <strong>Ba</strong>AlSi to<br />

be a superconductor with Tc = 2.8 K. Previous investigation had not observed any<br />

superconductivity above 2 K. In their report, however, the superconductivity was only found<br />

for x > 1.<br />

We also synthesized <strong>Ba</strong>Al2-xSix (0.4 < x < 1.6) alloys as precursors to <strong>Ba</strong>Al2-xSixH2-x.<br />

The samples with varying stoichometric ratio were investigated by powder XRD. For <strong>Ba</strong>AlSi<br />

(x = 1), a single phased sample was obtained. However, the <strong>Ba</strong>Al2-xSix (0.4 < x < 1.6) samples<br />

deviating from x = 1 exhibited secondary phases in the diffraction patterns, that were not<br />

eliminated by the heat treatment. For x-value above 1, small peaks <strong>of</strong> <strong>Ba</strong>Al2Si2O8 [27], <strong>Ba</strong>Si2<br />

(the orthorhombic phase) [28] were observed in addition to peaks from so far unidentified<br />

phases. For x-values below 1, also some so far unidentified peaks were observed. The amount<br />

was, however, not enough to allow for an identification <strong>of</strong> the impurity phases. As x<br />

increasingly deviates from 1, the intensity <strong>of</strong> the impurity peaks increased. We expect this<br />

introduced small systematic error in the targeted <strong>Ba</strong>Al2-xSix compositions, especially at larger<br />

deviation from x = 1. This indicates that the <strong>Ba</strong>AlSi where x = 1 is a preferred phase, <strong>and</strong> it<br />

suggests that Si <strong>and</strong> Al atoms are distributed in ordered way in <strong>Ba</strong>AlSi. Figure 3 shows the<br />

cell parameter change <strong>of</strong> <strong>Ba</strong>Al2-xSix as function <strong>of</strong> x. It could be confirmed that a solid<br />

solution is formed between 0.4 < x < 1.6. The a-axis is linearly decreasing with increasing x.<br />

This is reasonable as bigger Al atoms are replaced by smaller Si atoms. The c-axis is rather<br />

independent on x. The cell parameters <strong>and</strong> volumes for each composition are shown in Table<br />

5.<br />

17

Figure 3: Cell parameters <strong>of</strong> <strong>Ba</strong>Al2-xSix as a function <strong>of</strong> x<br />

Table 5: Cell parameters <strong>of</strong> <strong>Ba</strong>Al2-xSix at each x-value<br />

Composition a-axis[Å] c-axis[Å] V[Å 3 ]<br />

<strong>Ba</strong>Al1.6Si0.4 4.416(2) 5.142(2) 86.82(7)<br />

<strong>Ba</strong>Al1.4Si0.6 4.3884(9) 5.137(2) 85.67(4)<br />

<strong>Ba</strong>Al1.3Si0.7 4.3757(8) 5.141(1) 85.25(3)<br />

<strong>Ba</strong>Al1.2Si0.8 4.315(2) 5.146(2) 82.98(6)<br />

<strong>Ba</strong>AlSi 4.2989(6) 5.1438(7) 82.32(2)<br />

<strong>Ba</strong>Al0.8Si1.2 4.2611(3) 5.1403(4) 80.82(1)<br />

<strong>Ba</strong>Al0.7Si1.3 4.2414(5) 5.1381(8) 80.08(2)<br />

<strong>Ba</strong>Al0.6Si1.4 4.2342(4) 5.1345(6) 79.72(1)<br />

<strong>Ba</strong>Al0.4Si1.6 4.1948(3) 5.1230(6) 78.07(1)<br />

18

3.2 Hydrides<br />

3.2.1 <strong>Ba</strong>AlSiH <strong>and</strong> <strong>Ca</strong>AlSiH<br />

<strong>Ba</strong>AlSiH was obtained by hydrogenation <strong>of</strong> <strong>Ba</strong>AlSi at temperatures above 600 ℃, as<br />

described in Table 6. <strong>Ba</strong>AlSiH was found to have the same structure type as the polyanionic<br />

semiconductor <strong>Sr</strong>AlSiH, <strong>and</strong> similar to the hydrogenation <strong>of</strong> <strong>Sr</strong>AlSi. The <strong>Ba</strong>AlSi ingot retains<br />

the alloy ingot shape after hydrogenation. This is unusual. A typical solid state hydrogenation<br />

reaction usually yields a finely powdered product, due to the strains induced into the lattice<br />

when hydrogen enters it. During hydrogenation the color changed from metallic silver to dark<br />

gray. The cell parameters <strong>of</strong> the hydride were compared with that <strong>of</strong> the starting <strong>Ba</strong>AlSi alloy.<br />

Significant cell parameter change was observed during hydrogenation above 600 o C,<br />

indicating that the hydride formed above this temperature (cf. Table 6).<br />

Table 6: <strong>Ba</strong>AlSi + H2 (H2 pressure 70 bar)<br />

Temperature[ o C] Time[hours] XRD phase analysis.<br />

200 48 No hydride was present (Only <strong>Ba</strong>AlSi was observed).<br />

500 48 No hydride was present (Only <strong>Ba</strong>AlSi was observed).<br />

600 48 Formation <strong>of</strong> <strong>Ba</strong>AlSiH. Small peaks <strong>of</strong> an unknown phase<br />

were observed.<br />

700 48 Formation <strong>of</strong> <strong>Ba</strong>AlSiH.<br />

Figure 4 shows the powder x-ray diffraction pattern <strong>of</strong> a <strong>Ba</strong>AlSiH sample obtained by<br />

direct hydrogenation <strong>of</strong> a <strong>Ba</strong>AlSi at a hydrogen pressure <strong>of</strong> 70 bar at 700 o C. Using<br />

TREOR97 <strong>and</strong> PIRUM, an assumed hexagonal unit cell could be refined with (a = 4.3146(5)<br />

Å c = 5.2050(7) Å).<br />

19

Intensity (a.u.)<br />

♦<br />

♦<br />

Si<br />

♦<br />

♦<br />

15 30 45 60<br />

20<br />

♦<br />

♦<br />

2 theta (degree)<br />

♦<br />

♦: <strong>Ba</strong>AlSiH<br />

Si: Internal st<strong>and</strong>ard<br />

Figure 4: XRD patten <strong>of</strong> <strong>Ba</strong>AlSiH<br />

The neutron diffraction data from a similarly synthesized deutride <strong>Ba</strong>AlSiD (cf. Table<br />

7) was refined with FULLPROF. Starting parameters were taken from the corresponding<br />

<strong>Sr</strong>AlSiD [7]. The refinement confirmed that <strong>Ba</strong>AlSiD crystallizes in the same trigonal<br />

structure type in P3m1 (RB = 5.33 % <strong>and</strong> RF = 4.44 %) as <strong>Sr</strong>AlSiD. Experimental <strong>and</strong><br />

calculated neutron diffraction pattern from the <strong>Ba</strong>AlSiD is shown in Figure 5, <strong>and</strong> the<br />

structure <strong>of</strong> <strong>Ba</strong>AlSiD is shown in Figure 6. The atomic coordinates are given in Table 8. The<br />

<strong>Ba</strong>SiAlD is formed by slightly puckered trigonal zintl anion layers [AlSiD] 2- , where Al <strong>and</strong> Si<br />

atoms are distributed alternating in ordered way. S<strong>and</strong>wiched between these layers are the<br />

alkaline earth metal atoms <strong>of</strong> <strong>Ba</strong>. One D atom is bonded to each Al atoms parallel to the caxis.<br />

This intercalation <strong>of</strong> D atom between anionic layers elongates the c-axis.<br />

Table 7: <strong>Ba</strong>AlSi + D2 (D2 pressure 70 bar)<br />

Temperature[ o C] Time[hours] XRD phase analysis.<br />

700 96 Formation <strong>of</strong> <strong>Ba</strong>AlSiD. Small peaks <strong>of</strong> an unknown phase<br />

were also observed.<br />

Si<br />

♦<br />

♦<br />

Si<br />

♦<br />

♦

Bragg R-factor: 5.43 RF-factor: 4.70<br />

Some impurity lines are observed in the graph.<br />

Figure 5: The Rietveld refinement with neutron diffraction data <strong>of</strong> <strong>Ba</strong>AlSiD<br />

Figure 6: Structure <strong>of</strong> <strong>Ba</strong>AlSiD<br />

21

Table 8: Atomic parameters <strong>of</strong> <strong>Ba</strong>AlSiD<br />

Atom Site x y z Biso Occupancy<br />

<strong>Ba</strong> a 0 0 0 0.6(1) 1<br />

Al c 2/3 1/3 0.535(2) 1.1(2) 1<br />

Si b 1/3 2/3 0.450(2) 0.7(2) 1<br />

D c 2/3 1/3 0.868(2) 1.4(1) 1<br />

The cell parameters for <strong>Ba</strong>AlSi <strong>and</strong> <strong>Ba</strong>AlSiD were determined to a = 4.2989(6) Å c =<br />

5.1438(7) Å <strong>and</strong> a = 4.3087(6) Å c = 5.203(1) Å, respectively. The structural difference<br />

between <strong>Ba</strong>AlSi alloy <strong>and</strong> <strong>Ba</strong>AlSiD is small. This helps <strong>Ba</strong>AlSiH to retain the ingot shape<br />

after hydrogenation, instead <strong>of</strong> being shattered into a powder.<br />

22

To synthesize <strong>Ca</strong>AlSiH was very difficult. In 2001, H. Tanaka et al. tried to<br />

hydrogenate <strong>Ca</strong>AlSi to obtain <strong>Ca</strong>AlSiH [29]. However they interpreted their results as a<br />

decomposition reaction according to 2<strong>Ca</strong>AlSi + H2 → <strong>Ca</strong>H2 + <strong>Ca</strong>Si + 2Al + Si.<br />

To obtain <strong>Ca</strong>AlSiH, careful control <strong>of</strong> the hydrogenation condition was required. We<br />

tried different reaction conditions (cf. Table 9) while recording XRD patterns. After each<br />

reaction, they were compared with XRD pattern <strong>of</strong> <strong>Ca</strong>AlSi. At a hydrogen pressure <strong>of</strong> 90 bar<br />

with increasing temperature, we found that <strong>Ca</strong>AlSi started to form <strong>Ca</strong>Al2Si2 [25] at 270 ℃. At<br />

this temperature, no hydride was observed. At temperatures above 310 ℃, new peaks <strong>of</strong> a<br />

novel <strong>Ca</strong>AlSiH appeared. However, formation <strong>of</strong> <strong>Ca</strong>Al2Si2 as a second phase was inevitable.<br />

To maximize the yield <strong>of</strong> <strong>Ca</strong>AlSiH with regard to <strong>Ca</strong>Al2Si2, the hydrogenation was performed<br />

at 500 ℃ for 45 minutes. It took some trial <strong>and</strong> error to optimize the reaction conditions.<br />

Table 9: <strong>Ca</strong>AlSi + H2 (H2 pressure 90 bar)<br />

Temperature[ o C] Time[hours] XRD phase analysis.<br />

250 48 No hydride was present (Only <strong>Ca</strong>AlSi was observed).<br />

260 48 No hydride was present (Only <strong>Ca</strong>AlSi was observed).<br />

270 48 No hydride was present. Formation <strong>of</strong> <strong>Ca</strong>Al2Si2.<br />

310 48 Formation <strong>of</strong> <strong>Ca</strong>AlSiH but with <strong>Ca</strong>Al2Si2 [25].<br />

450 48 Formation <strong>of</strong> <strong>Ca</strong>AlSiH but with <strong>Ca</strong>Al2Si2 [25].<br />

500 0.833 Almost single phased <strong>Ca</strong>AlSiH was formed.<br />

The XRD pattern <strong>of</strong> <strong>Ca</strong>AlSiH is shown in Figure 7. The trigonal unit cell parameters<br />

<strong>of</strong> <strong>Ca</strong>AlSiH were determined to a = 4.130(1) c = 4.761(2). The trigonal unit cell parameters <strong>of</strong><br />

<strong>Ca</strong>Al2Si2 were reported to a=4.13(1) c=7.15(2) [25]. The similarities between the cell<br />

parameters leads to peak overlap problems in the XRD pattern, making it difficult to find <strong>and</strong><br />

refine the <strong>Ca</strong>AlSiH phase.<br />

23

Intensity (a.u)<br />

♦<br />

+<br />

Si<br />

♦<br />

+<br />

♦<br />

20 30 40 50 60<br />

24<br />

+<br />

♦<br />

2 theta (degree)<br />

Figure 7: XRD pattern <strong>of</strong> <strong>Ca</strong>AlSiH<br />

♦<br />

Si<br />

♦ <strong>Ca</strong>AlSiH<br />

+ <strong>Ca</strong>Al Si<br />

2 2<br />

Unknown<br />

+<br />

+<br />

♦<br />

♦<br />

+<br />

Si<br />

+<br />

Upon hydrogenation <strong>Ca</strong>AlSi undergoes a unit cell volume expansion <strong>of</strong> 3.67 [Å/Hatom]<br />

compared to 2.45 [Å/H-atom] for <strong>Sr</strong>AlSiH <strong>and</strong> 1.65 [Å/H-atom] for <strong>Ba</strong>AlSiH. The aaxis<br />

shrinks from 4.1838(7) Å to 4.130(1) Å, <strong>and</strong> c-axis exp<strong>and</strong>s from 4.396(1) to 4.761(2).<br />

Such a large expansion <strong>of</strong> cell volume [Å/H-atom] is common for metal hydrides <strong>and</strong> usually<br />

causes the hydride alloy to disintegrate into a fine powder upon hydrogenation. But despite<br />

this larger volume expansion <strong>and</strong> the fact that the a-axis shrinks <strong>and</strong> c-axis exp<strong>and</strong>s,<br />

significantly, the shape is retained also for this system during hydrogenationsdehydrogenations.<br />

The strain introduce, however, problems with the crystallinity, mainly in the cdirection,<br />

resulting in anisotropic broadening <strong>of</strong> the diffraction peaks as will be further<br />

discussed in below.

Similarly deuterated <strong>Ca</strong>AlSiD (cf. Table 10) was measured by neutron diffraction. The<br />

diffraction pattern was refined by FULLPROF. Starting parameter was taken from the relaxed<br />

equilibrium structure. The refinement confirmed that also <strong>Ca</strong>AlSiD crystallizes in the same<br />

trigonal structure type in P3m1 (RB = 4.99 % <strong>and</strong> RF = 2.51 %). The observed <strong>and</strong> calculated<br />

diffraction pattern is shown in Figure 8. The atomic positions <strong>of</strong> each element in <strong>Ca</strong>AlSiD are<br />

shown in Table 11. Problem with the crystallinity is manifested by anisotropic broadening <strong>of</strong><br />

the peaks. The (00l) reflections are twice as broad as the (hk0) reflections <strong>and</strong> (hkl) reflections<br />

are in between. To get a high yield <strong>of</strong> <strong>Ca</strong>AlSiD, hydrogenation on <strong>Ca</strong>AlSi had to be<br />

performed within a short time <strong>of</strong> about 50 minutes at 500 ℃. This short time <strong>of</strong> hydrogenation<br />

probably was insufficient to get a well defined micro structure <strong>of</strong> <strong>Ca</strong>AlSiD. Intercalation <strong>of</strong><br />

hydrogen along c-axis is probably the reason for the broadening <strong>of</strong> 00l reflections. If we try to<br />

hydrogenate <strong>Ca</strong>AlSi at higher temperature <strong>and</strong> longer time to get better crystallinity, <strong>Ca</strong>AlSi<br />

start to decompose to <strong>Ca</strong>Al2Si2 <strong>and</strong> <strong>Ca</strong>D2 reducing the amount <strong>of</strong> <strong>Ca</strong>AlSiD. Therefore, heat<br />

treatment <strong>and</strong> longer time <strong>of</strong> hydrogenation could not be used to solve the problem.<br />

During the structural refinement, this crystallinity problem was taken into account by<br />

refining the crystal size parameter which is implemented in FULLPROF. This procedure was<br />

not needed for the refinement <strong>of</strong> the corresponding compound <strong>Sr</strong>AlSiD <strong>and</strong> <strong>Ba</strong>AlSiD which<br />

had been hydrogenated for a longer 4 days period. The refinement <strong>of</strong> the crystal size<br />

parameters improved the peak fitting, although we still detected a deviation in the (110)<br />

reflection.<br />

Table 10: <strong>Ca</strong>AlSi + D2 (D2 pressure 70 bar)<br />

Temperature[ o C] Time[hours] XRD phase analysis.<br />

500 0.833 <strong>Ca</strong>AlSiD was formed. Small peaks <strong>of</strong> <strong>Ca</strong>Al2Si2 were<br />

observed.<br />

25

Bragg R-factor: 4.99 % RF-factor: 2.51 %<br />

Some impurity lines are observed in the graph.<br />

Figure 8: The Rietveld refinement with neutron diffraction data <strong>of</strong> <strong>Ca</strong>AlSiD<br />

Table 11: Atomic positions <strong>of</strong> <strong>Ca</strong>AlSiD<br />

Atom Site x y z Biso Occupancy<br />

<strong>Ca</strong> a 0 0 0 1.1(2) 1<br />

Al c 2/3 1/3 0.548(5) 0.4(1) 1<br />

Si b 1/3 2/3 0.462(2) 0.4(1) 1<br />

D c 2/3 1/3 0.915(5) 3.6(2) 1<br />

26

The structure <strong>of</strong> <strong>Ca</strong>AlSiD is shown in Figure 9. As in the case <strong>of</strong> previous <strong>Sr</strong>AlSiD<br />

<strong>and</strong> <strong>Ba</strong>AlSiD, Al <strong>and</strong> Si atoms are alternately distributed in the trigonal Zintl anion. One<br />

hydrogen atom is attached to each Al atom along the c-axis. <strong>Ca</strong> atoms are, as for the precursor<br />

alloy, s<strong>and</strong>wiched by these Zintl anions when building the <strong>Ca</strong>AlSiD structure.<br />

Figure 9: Structure <strong>of</strong> <strong>Ca</strong>AlSiD<br />

Comparing the structures <strong>of</strong> <strong>Ca</strong>AlSiD, <strong>Sr</strong>AlSiD, <strong>and</strong> <strong>Ba</strong>AlSiD suggests some<br />

interesting things. Going from calcium to barium, the cell volumes become larger as the cell<br />

parameters become longer reflecting the ionic side difference between <strong>Ca</strong> 2+ , <strong>Sr</strong> 2+ <strong>and</strong> <strong>Ba</strong> 2+ .<br />

Cell parameters <strong>and</strong> cell volumes <strong>of</strong> the <strong>Ae</strong>AlSiD <strong>and</strong> <strong>Ae</strong>AlSiH (<strong>Ae</strong>=<strong>Ca</strong>, <strong>Sr</strong>, <strong>and</strong> <strong>Ba</strong>) are<br />

shown in Table 12.<br />

Table 12: Cell parameters <strong>of</strong> <strong>Ae</strong>AlSiD <strong>and</strong> <strong>Ae</strong>AlSiH (<strong>Ae</strong> = <strong>Ca</strong>, <strong>Sr</strong> <strong>and</strong> <strong>Ba</strong>)<br />

a[Å] c[Å] V[Å 3 ]<br />

<strong>Ca</strong>AlSiD 4.133(1) 4.761(2) 70.43(1)<br />

<strong>Ca</strong>AlSiH 4.130(1) 4.761(2) 70.33(4)<br />

<strong>Sr</strong>AlSiD[7] 4.2113(3) 4.9518(5) 76.05(1)<br />

<strong>Sr</strong>AlSiH[7] 4.2139(3) 4.9550(6) 76.20(1)<br />

<strong>Ba</strong>AlSiD 4.3087(6) 5.203(1) 83.65(1)<br />

<strong>Ba</strong>AlSiH 4.3146(5) 5.2050(7) 83.91(2)<br />

27

The interatomic distances in <strong>Ca</strong>AlSiD, <strong>Sr</strong>AlSiD [7] <strong>and</strong> <strong>Ba</strong>AlSiD are shown in Table<br />

13, 14 <strong>and</strong> 15, respectively. All the Al-D distances in <strong>Ae</strong>AlSiD are very similar. The Al-D<br />

distance for <strong>Ca</strong>AlSiD, <strong>Sr</strong>AlSiD <strong>and</strong> <strong>Ba</strong>AlSiD are 1.75(3), 1.77(1) Å <strong>and</strong> 1.73(2) Å<br />

respectively. The <strong>Ae</strong>-D distances in <strong>Ae</strong>AlSiD are similar to the <strong>Ae</strong>-D distances in <strong>Ae</strong>D2. The<br />

<strong>Ca</strong>-D distance is 2.420(4) Å in <strong>Ca</strong>AlSiD <strong>and</strong> 2.17(7)-2.8(1) Å in <strong>Ca</strong>D2 [30]. The <strong>Sr</strong>-D<br />

distance is 2.476(1) Å in <strong>Sr</strong>AlSiD <strong>and</strong> 2.36-2.79 Å in <strong>Sr</strong>D2 [30]. The <strong>Ba</strong>-D distance is 2.581(3)<br />

Å in <strong>Ba</strong>AlSiD <strong>and</strong> 2.57-2.98 Å in <strong>Ba</strong>D2 [31].<br />

These support a picture that D atoms are covalently bonded to Al atoms.<br />

Simultaneously, D atoms are also ionically interacting with the <strong>Ae</strong> atoms explaining the<br />

increasing <strong>Ae</strong>-D distance from calcium to barium.<br />

Because <strong>of</strong> problem with poor crystallinity along the c-axis in <strong>Ca</strong>AlSiD, the atomic<br />

positions may include some systematic errors in the z-coordinates. However, the obtained<br />

values, as given in table 13-15, are well in line with the relaxed values from the related total<br />

energy calculations.<br />

28

Table 13: Selected interatomic distances (Å) <strong>and</strong> angles (˚) in <strong>Ca</strong>AlSiD. The values from the<br />

total energy calculation are shown in brackets.<br />

<strong>Ca</strong>-3D 2.420(4) [2.433] Al-D 1.75(3) [1.746]<br />

3Si 3.245(6) [3.155] 3Si 2.421(4) [2.451]<br />

3Al 3.21(2) [3.237] 3<strong>Ca</strong> 3.21(2) [3.237]<br />

3Si 3.501(7) [3.610] D 3.01(3) [3.011]<br />

3Al 3.54(2) [3.519] 3<strong>Ca</strong> 3.54(2) [3.519]<br />

6Al 4.133(0) [4.147]<br />

Si-3Al 2.421(4) [2.451]<br />

3D 3.22(2) [3.299]<br />

3<strong>Ca</strong> 3.245(6) [3.155]<br />

3<strong>Ca</strong> 3.501(7) [3.610]<br />

2Si 4.76(1) [4.757]<br />

D-Al 1.75(3) [1.753]<br />

3<strong>Ca</strong> 2.420(4) [2.497] 3Al-Si-Al 117.20(0) [115.57]<br />

Al 3.01(3) [3.212] 3Si-Al-Si 117.20(0) [115.57]<br />

6D 4.133(0) [4.147] 3Si-Al-D 99.74(0) [102.33]<br />

Table 14: Selected interatomic distances (Å) <strong>and</strong> angles (˚) in <strong>Sr</strong>AlSiD [7]. The values from<br />

the total energy calculation are shown in brackets.<br />

<strong>Sr</strong>-3D 2.476(1) [2.497] Al-D 1.77(1) [1.753]<br />

3Si 3.229(7) [3.295] 3Si 2.502(3) [2.484]<br />

3Al 3.305(7) [3.342] 3<strong>Sr</strong> 3.305(7) [3.342]<br />

3Si 3.729(8) [3.677] D 3.18(1) [3.212]<br />

3Al 3.644(7) [3.625] 3<strong>Sr</strong> 3.644(7) [3.625]<br />

6Al 4.211(0) [4.226]<br />

Si-3Al 2.502(3) [2.484]<br />

3D 3.386 (8) [3.298]<br />

3<strong>Sr</strong> 3.229(7) [3.295]<br />

3<strong>Sr</strong> 3.729(8) [3.677]<br />

2Si 4.95(1) [4.965]<br />

D-Al 1.77(1) [1.753]<br />

3<strong>Sr</strong> 2.476(1) [2.497] 3Al-Si-Al 114.63(0) [116.55]<br />

Al 3.18(1) [3.212] 3Si-Al-Si 114.63(0) [116.55]<br />

6D 4.211(0) [4.226] 3Si-Al-D 103.62(0) [100.83]<br />

29

Table 15: Selected interatomic distances (Å) <strong>and</strong> angles (˚) in <strong>Ba</strong>AlSiD. The values from the<br />

total energy calculation are shown in brackets.<br />

<strong>Ba</strong>-3D 2.581(3) [2.595] Al-D 1.73(2) [1.741]<br />

3Si 3.416(7) [3.469] 3Si 2.527(3) [2.538]<br />

3Al 3.470(7) [3.483] 3<strong>Ba</strong> 3.470(7) [3.483]<br />

3Si 3.792(8) [3.778] D 3.47(2) [3.488]<br />

3Al 3.733(8) [3.763] 3<strong>Ba</strong> 3.733(8) [3.763]<br />

6Al 4.309(0) [4.338]<br />

Si-3Al 2.527(3) [2.538]<br />

3D 3.30(1) [3.300]<br />

3<strong>Ba</strong> 3.416(7) [3.469]<br />

3<strong>Ba</strong> 3.792(8) [3.778]<br />

2Si 5.20(2) [5.229]<br />

D-Al 1.73(1) [1.741]<br />

3<strong>Ba</strong> 2.581(3) [2.595] 3Al-Si-Al 117.0(0) [117.47]<br />

Al 3.47(1) [3.488] 3Si-Al-Si 117.0(0) [117.47]<br />

6D 4.309(1) [4.338] 3Si-Al-D 100.08(1) [99.25]<br />

Upon heating under vacuum, <strong>Ca</strong>AlSiH <strong>and</strong> <strong>Ba</strong>AlSiH are observed to start to release<br />

hydrogen at around 420 ℃ <strong>and</strong> 500 ℃, according to the reactions 2<strong>Ca</strong>AlSiH ↔ <strong>Ca</strong>AlSi + H2<br />

<strong>and</strong> 2<strong>Ba</strong>AlSiH ↔ 2<strong>Ba</strong>AlSi + H2. Both reactions are reversible <strong>and</strong> the <strong>Ca</strong>AlSi <strong>and</strong> <strong>Ba</strong>AlSi<br />

alloys were recovered after dehydrogenation. The decomposition temperature <strong>of</strong> <strong>Ca</strong>AlSiH is<br />

lower than that <strong>of</strong> <strong>Ba</strong>AlSiH <strong>and</strong> <strong>Sr</strong>AlSiH (Decomposition <strong>of</strong> <strong>Ba</strong>AlSiD <strong>and</strong> <strong>Sr</strong>AlSiD was<br />

observed at similar temperatures). The decomposition temperature <strong>of</strong> <strong>Ba</strong>H2 <strong>and</strong> <strong>Sr</strong>H2 is<br />

675 ℃ <strong>and</strong> 675 ℃ respectively, <strong>and</strong> <strong>Ca</strong>H2 decompose at lower temperature 600 ℃ [32]. This<br />

means that the <strong>Ae</strong>AlSiH follow a similar trend to <strong>Ae</strong>H2, confirming the importance <strong>of</strong> <strong>Ae</strong>-D<br />

interaction in <strong>Ae</strong>AlSiD.<br />

30

As shown above, the decomposition temperatures <strong>of</strong> <strong>Ae</strong>AlSiD are high <strong>and</strong> this<br />

indicate that <strong>Ae</strong>AlSiD are fairly stable hydrides. By comparing the structures <strong>of</strong> <strong>Sr</strong>Al2D2 [5]<br />

with <strong>Sr</strong>AlSiD [7], we can underst<strong>and</strong> this. The structures <strong>of</strong> these compounds are shown in<br />

Figure 10. D atoms are covalently bonded to Al atoms in both structures. The Al-D distance is<br />

1.77(1) Å in <strong>Sr</strong>AlSiD compared to 1.706(4) Å in <strong>Sr</strong>Al2D2. Even if <strong>Sr</strong>AlSiD has a longer Al-D<br />

distance, D atoms are apparently bonded more strongly in <strong>Sr</strong>AlSiD <strong>and</strong> this was unexpected.<br />

The decomposition temperature (<strong>of</strong> atmospheric pressure) is 600 ℃ for <strong>Sr</strong>AlSiH <strong>and</strong> 300 ℃<br />

for <strong>Sr</strong>Al2H2. But on the other h<strong>and</strong>, the <strong>Sr</strong>-D bond is significantly shorter in <strong>Sr</strong>AlSiD<br />

compared to in <strong>Sr</strong>Al2D2. The <strong>Sr</strong>-D distance in <strong>Sr</strong>AlSiD <strong>and</strong> <strong>Sr</strong>Al2D2 is 2.476(1) Å <strong>and</strong><br />

2.653(1) Å, respectively. Thus a stronger ionic interaction between <strong>Sr</strong> <strong>and</strong> D may bind the D<br />

atom more firmly in the structure <strong>of</strong> <strong>Sr</strong>AlSiD, <strong>and</strong> this compensates for a weaker covalent Al-<br />

D bond [7]. Also, the relatively short D-D distance in <strong>Sr</strong>Al2D2 is to some extent probably also<br />

weakening the metal-hydrogen bond strength. The D-D distance is 2.770(1) Å <strong>and</strong> 4.211(0) Å<br />

in <strong>Sr</strong>Al2D2 <strong>and</strong> <strong>Sr</strong>AlSiD, respectively.<br />

Figure 10: Structural comparison between <strong>Sr</strong>Al2D2 [5] <strong>and</strong> <strong>Sr</strong>AlSiH [7]<br />

31

3.2.2 <strong>Ba</strong>Al2-xSixH2-x (0 < x < 2)<br />

A series <strong>of</strong> <strong>Ba</strong>Al2-xSix alloys were hydrogenated as described in tables 16-19 below,<br />

where also the results from subsequent powder x-ray diffraction phase analysis <strong>of</strong> the reaction<br />

products are given. A careful control <strong>of</strong> the hydrogenation conditions was required. Optimum<br />

hydrogenation reaction temperatures <strong>of</strong> <strong>Ba</strong>Al2-xSixH2-x are dependent on x. To hydrogenate<br />

<strong>Ba</strong>AlSi (x = 1), 600 ℃ <strong>and</strong> 70 bars hydrogen pressure is required. On the other h<strong>and</strong>,<br />

<strong>Ba</strong>Al0.4Si1.6H0.4 <strong>and</strong> <strong>Ba</strong>Al1.6Si0.4H1.6 could be hydrogenated at lower temperature, 300 ℃<br />

using 70 bars <strong>of</strong> hydrogen pressures. At higher temperature, aluminium rich <strong>Ba</strong>Al2-xSixH2-x (0<br />

< x < 1) tend to decompose to composition close to <strong>Ba</strong>AlSiH (x = 1), <strong>Ba</strong>Al4 [33] <strong>and</strong> so far<br />

unknown phases. Also, at higher temperature, silicon rich <strong>Ba</strong>Al2-xSixH2-x (1 < x < 2) tends to<br />

decompose to a composition close to <strong>Ba</strong>AlSiH(x = 1) <strong>and</strong> <strong>Ba</strong>Si2 (orthorhombic) [28] <strong>and</strong> so<br />

far unknown phases. This indicates that <strong>Ba</strong>AlSiH (x = 1) is a specially stable phase in the<br />

<strong>Ba</strong>Al2-xSixH2-x system. This was unexpected because we expected that the stability <strong>of</strong> <strong>Ba</strong>Al2xSixH2-x<br />

would become higher with increasing Si amount, similar to the homologous system<br />

<strong>Sr</strong>Al2-xSixH2-x. The decomposition temperature <strong>of</strong> <strong>Sr</strong>AlSiH is higher than that <strong>of</strong> <strong>Sr</strong>Al2H2.<br />

Also, the <strong>Sr</strong>AlSiH (x = 1) is more stable than <strong>Sr</strong>Al2H2 (x = 0) to air <strong>and</strong> moisture.<br />

32

Table 16: <strong>Ba</strong>Al1.6Si0.4 + H2 (H2 pressure 70 bar)<br />

Temperature[ o C] Time[hours] XRD phase analysis.<br />

230 24 No hydride was formed.<br />

300 48 Formation <strong>of</strong> an assumed <strong>Ba</strong>Al1.6Si0.4H1.6. So far unknown<br />

phases were also observed.<br />

700 48 Formation <strong>of</strong> <strong>Ba</strong>AlSiH instead <strong>of</strong> <strong>Ba</strong>Al1.6Si0.4H1.6.<br />

Additionally, strong peaks <strong>of</strong> <strong>Ba</strong>Al4 <strong>and</strong> so far unknown<br />

phases were also observed.<br />

Table 17: <strong>Ba</strong>Al1.4Si0.6 + H2 (H2 pressure 70 bar)<br />

Temperature[ o C] Time[hours] XRD phase analysis.<br />

300 48 Formation <strong>of</strong> an assumed <strong>Ba</strong>Al1.4Si0.6H1.4. Additionally, so<br />

far unknown phases were also observed.<br />

550 3 Formation <strong>of</strong> an assumed <strong>Ba</strong>Al1.4Si0.6H1.4. Additionally,<br />

<strong>Ba</strong>Al4, <strong>Ba</strong>AlSiH <strong>and</strong> so far unknown phases were also<br />

observed.<br />

600 3 Formation <strong>of</strong> an assumed <strong>Ba</strong>Al1.4Si0.6H1.4. Additionally,<br />

<strong>Ba</strong>Al4 <strong>and</strong> so far unknown phases were also observed.<br />

700 48 Formation <strong>of</strong> <strong>Ba</strong>AlSiH instead <strong>of</strong> <strong>Ba</strong>Al1.4Si0.6H1.4.<br />

Additionally strong peaks <strong>of</strong> <strong>Ba</strong>Al4 <strong>and</strong> so far unknown<br />

phases were also observed.<br />

Table 18: <strong>Ba</strong>Al0.6Si1.4 + H2 (H2 pressure 70 bar)<br />

Temperature[ o C] Time[hours] XRD phase analysis.<br />

300 48 No hydride was formed.<br />

550 3 Formation <strong>of</strong> an assumed <strong>Ba</strong>Al0.6Si1.4H0.6, but additionally<br />

<strong>Ba</strong>Si2 <strong>and</strong> so far unknown phases were also observed.<br />

600 12 Formation <strong>of</strong> a phase close to <strong>Ba</strong>Al0.6Si1.4H0.6.<br />

Additionally <strong>Ba</strong>Si2 <strong>and</strong> unknown phases were also<br />

observed.<br />

700 48 Formation <strong>of</strong> <strong>Ba</strong>AlSiH instead <strong>of</strong> <strong>Ba</strong>Al0.6Si1.4H0.6.<br />

Additionally strong peaks <strong>of</strong> <strong>Ba</strong>Si2 <strong>and</strong> so far unknown<br />

phases were also observed.<br />

33

Table 19: <strong>Ba</strong>Al0.4Si1.6 + H2 (H2 pressure 70 bar)<br />

Temperature[ o C] Time[hours] XRD phase analysis.<br />

300 48 Formation <strong>of</strong> an assumed <strong>Ba</strong>Al0.4Si1.6H0.4. Additionally,<br />

small peaks <strong>of</strong> <strong>Ba</strong>Si2 <strong>and</strong> unknown phases were observed.<br />

500 48 Formation <strong>of</strong> a phase closes to <strong>Ba</strong>Al0.6Si1.4H0.6 instead<br />

<strong>Ba</strong>Al0.4Al1.6H0.4. Strong peaks <strong>of</strong> <strong>Ba</strong>Si2 <strong>and</strong> unknown<br />

phases were also observed.<br />

700 48 Formation <strong>of</strong> <strong>Ba</strong>AlSiH instead <strong>of</strong> <strong>Ba</strong>Al0.4Si1.6H0.4. Strong<br />

peaks <strong>of</strong> <strong>Ba</strong>Si2 <strong>and</strong> so far unknown phases were also<br />

observed.<br />

34

The color <strong>of</strong> the all <strong>Ba</strong>Al2-xSixH2-x (0.4 < x < 1.6) hydrides was dark gray, in contrast<br />

to the metallic silver <strong>of</strong> the <strong>Ba</strong>Al2-xSix (0.4 < x < 1.6) alloys.<br />

The obtained samples were measured by powder x-ray diffraction <strong>and</strong> the cell<br />

parameters <strong>of</strong> each composition are shown in Table 20. Figure 11 shows how the cell<br />

parameters <strong>of</strong> <strong>Ba</strong>Al2-xSixH2-x nicely extrapolates with x, between the cell parameters <strong>of</strong><br />

<strong>Ba</strong>Al2H2 (x = 0) <strong>and</strong> <strong>Ba</strong>Si2 (x = 2) [34]. The structures <strong>of</strong> <strong>Ba</strong>Al2H2 <strong>and</strong> <strong>Ba</strong>Si2 are very similar<br />

to that <strong>of</strong> <strong>Ba</strong>AlSiH as shown in Figure 13. Also, all <strong>of</strong> them have the same electron count. The<br />

<strong>Ba</strong>Al2H2 has so far not been experimentally obtained. The structural parameters were obtained<br />

from our total energy calculation. Also, in the figure 11, the cell parameters <strong>of</strong> the<br />

corresponding <strong>Sr</strong>Al2-xSixH2-x system (<strong>Sr</strong>Al2H2 [5] <strong>and</strong> <strong>Sr</strong>AlSiH [7]) are plotted, showing a<br />

similar trend to the <strong>Ba</strong> compound. Similar to the alloys, the a-axis length decrease with<br />

increasing x in <strong>Ba</strong>Al2-xSixH2-x as the bigger Al atoms are replaced by smaller Si atoms. The caxis<br />

increases with increasing x. This trend is different from the alloy, where the c-axis length<br />

is rather independent <strong>of</strong> x. By comparing the structures <strong>of</strong> <strong>Ba</strong>Al2H2 (x = 0), <strong>Ba</strong>AlSiH (x = 1)<br />

<strong>and</strong> <strong>Ba</strong>Si2 (x = 2) [34], it can be explained (cf. Figure 12). Three main reasons are responsible<br />

for the c-axis elongation. Firstly, a [Si] - lone pair needs more space compared to an [Al-H] -<br />

entity. Secondly, the Al-H bond length in <strong>Ba</strong>AlSiH is apparently longer than in <strong>Ba</strong>Al2H2. The<br />

computationally obtained Al-H bond length is 1.71 Å in <strong>Ba</strong>Al2H2 compared to 1.74 Å in<br />

<strong>Ba</strong>AlSiH. The experimentally obtained Al-H bond length is 1.73(2) Å in <strong>Ba</strong>AlSiH. In other<br />

words, the Al-H bond is elongated when x is increased. The same observation could be<br />

obtained for the corresponding system <strong>Sr</strong>Al2-xSixH. Experimentally obtained Al-H bond<br />

length is 1.706(4) Å for <strong>Sr</strong>Al2H2 <strong>and</strong> 1.77(1) Å for <strong>Sr</strong>AlSiH. Thirdly, the degree <strong>of</strong> the<br />

hexagonal network puckering is increased with increasing x-values. <strong>Ba</strong>Si2 [34] has a more<br />

puckered trigonal network compared to <strong>Ba</strong>AlSiH <strong>and</strong> <strong>Ba</strong>Al2H2. This more puckered trigonal<br />

network at higher x-value is also observed in the <strong>Sr</strong>Al2-xSixH2-x system, where <strong>Sr</strong>AlSiH [7]<br />

has a more puckered trigonal network compared to that <strong>of</strong> <strong>Sr</strong>Al2H2 [5].Taken together, the<br />

observed c-axis elongation at higher x-value <strong>of</strong> <strong>Ba</strong>Al2-xSixH2-x is thus very reasonable.<br />

35

Figure 11: Cell parameters <strong>of</strong> <strong>Ba</strong>Al2-xSixH2-x as a function x. (■: Computationally obtained<br />

<strong>Ba</strong>Al2H2, ★: <strong>Sr</strong>Al2H2 [5], ▲: <strong>Sr</strong>AlSiH [7], ●: <strong>Ba</strong>Si2 [34])<br />

<strong>Ba</strong>Al2H2 <strong>Ba</strong>AlSiH <strong>Ba</strong>Si2 [34]<br />

Figure 12: Structures <strong>of</strong> <strong>Ba</strong>Al2-xSixH2-x (x=0, 1 <strong>and</strong> 2)<br />

36

Table 20: Cell parameters <strong>of</strong> <strong>Ba</strong>Al2-xSixH2-x. The cell parameters before hydrogenation are<br />

shown in brackets.<br />

Composition a-axis[Å] c-axis[Å] V[Å 3 ]<br />

<strong>Ba</strong>Al2H2 (calculated) 4.6524 4.9768 93.29<br />

<strong>Ba</strong>Al1.6Si0.4H1.6 4.451(3) [4.416(2)] 5.125(4) [5.141(2)] 87.9(1) [86.82(7)]<br />

<strong>Ba</strong>Al1.4Si0.6H1.4 4.429(2) [4.3884(2)] 5.147(3) [5.137(2)] 87.44(4) [85.67(4)]<br />

<strong>Ba</strong>AlSiH 4.3146(5) [4.2989(6)] 5.2050(7) [5.1438(7)] 83.97(4) [82.32(2)]<br />

<strong>Ba</strong>Al0.6Si1.4H 4.283(3) [4.2342(4)] 5.239(5) [5.1345(6)] 83.2(1) [79.72(1)]<br />

<strong>Ba</strong>Al0.4Si1.6H 4.188(1) [4.1947(2)] 5.276(2) [5.1229(6)] 80.09(4) [78.07(1)]<br />

<strong>Ba</strong>Si2 [35] 4.047(3) 5.330(5) 75.6(1)<br />

We could observe an interesting stability problem when hydriding the <strong>Ba</strong>Al2-xSix<br />

alloys with compositions deviating from x = 1. If an aluminium rich <strong>Ba</strong>Al2-xSix (0 < x < 1) or<br />

a silicon rich <strong>Ba</strong>Al2-xSix (1 < x < 2) are hydrogenated, at the lowest temperatures when a<br />

reaction is observed to proceed, (as given in Tables from 16 to 19), then a hydride with the<br />

same metal atom composition will be produced. But if the temperature is increased, the<br />

hydride composition will start to move towards the stable <strong>Ba</strong>AlSiH (x = 1).<br />

Also, from the point <strong>of</strong> synthesis condition, comparison <strong>of</strong> <strong>Ba</strong>Si2 [34] <strong>and</strong> <strong>Ba</strong>Al2xSixH2-x<br />

system is very interesting. The <strong>Ba</strong>Si2 has three phases, orthorhombic, cubic <strong>and</strong><br />

trigonal structure [28] [34] [35]. The orthorhombic phase is the stable phase <strong>and</strong> the other<br />

phases are metastable high pressure phases. The metastable cubic <strong>and</strong> trigonal <strong>Ba</strong>Si2 are<br />

obtained when the orthorhombic phase is subjected with the high-pressure <strong>and</strong> high-<br />

temperature conditions (4GPa, 600-800 ℃ for the cubic phase <strong>and</strong> 4GPa <strong>and</strong> 1000 ℃ for the<br />

trigonal phase) [34] [35]. In other words, the trigonal <strong>Ba</strong>Si2 is difficult to form. This is in<br />

contrast to <strong>Ba</strong>Al2-xSixH2-x. Because, by substituting Si - in <strong>Ba</strong>Si2 with [Al-H] - , we could obtain<br />

<strong>Ba</strong>Al0.4Si1.6H0.4 which is structurally <strong>and</strong> compositionally very close to trigonal <strong>Ba</strong>Si2 at<br />

moderate conditions (300 ℃ at 70 bar hydrogen <strong>of</strong> pressure).<br />

37

3.3 Computational results<br />

3.3.1 Computationally relaxed structural parameters<br />

Experimentally obtained structural parameters <strong>of</strong> <strong>Ae</strong>AlSi (<strong>Ae</strong> = <strong>Ca</strong> <strong>and</strong> <strong>Ba</strong>) <strong>and</strong><br />

computationally relaxed structural parameters <strong>of</strong> <strong>Ae</strong>AlSiH are compared. Structural<br />

parameters <strong>of</strong> <strong>Ca</strong>AlSiH <strong>and</strong> <strong>Ba</strong>AlSiH from both calculation <strong>and</strong> experiment are shown in<br />

Table 21 <strong>and</strong> Table 22, respectively. The structural parameters for <strong>Ba</strong>AlSiH agreed well with<br />

each other. Also for <strong>Ca</strong>AlSiH, where we had problem with poor crystallinity, the<br />

experimental <strong>and</strong> calculated values are in good agreement.<br />

Table 21: Experimentally obtained <strong>and</strong> computationally relaxed structural parameters for<br />

<strong>Ca</strong>AlSiH<br />

<strong>Ca</strong>AlSIH (calculated) <strong>Ca</strong>AlSiD (experimental)<br />

V[Å 3 ] 71.72 70.43(1)<br />

a[Å] 4.1363 4.133(1)<br />

c[Å] 4.7673 4.761(2)<br />

c/a 1.1526 1.152<br />

<strong>Ca</strong> position 0,0,0 0,0,0<br />

Si position 1/3, 2/3, 0.446 1/3, 2/3, 0.462(2)<br />

Al position 2/3, 1/3, 0.541 2/3, 1/3, 0.548(5)<br />

H position 2/3, 1/3, 0.893 2/3, 1/3, 0.915(5)<br />

Table 22: Experimentally obtained <strong>and</strong> computationally relaxed structural parameters for<br />

<strong>Ba</strong>AlSiH<br />

<strong>Ba</strong>AlSiH (calculated) <strong>Ba</strong>AlSiD (experimental)<br />

V[Å 3 ] 85.22 82.25(1)<br />

a[Å] 4.3381 4.3087(6)<br />

c[Å] 5.2289 5.203(1)<br />

c/a 1.2053 1.208<br />

<strong>Ba</strong> position 0,0,0 0,0,0<br />

Si position 1/3, 2/3, 0.458 1/3, 2/3, 0.450(2)<br />

Al position 2/3, 1/3, 0.537 2/3, 1/3, 0.535(2)<br />

H position 2/3, 1/3, 0.869 2/3, 1/3, 0.868(2)<br />

38

3.3.2 DOS <strong>of</strong> <strong>Ae</strong>AlSiD<br />

We calculated the density <strong>of</strong> states (DOS) for the <strong>Ca</strong>AlSiH, <strong>Sr</strong>AlSiH <strong>and</strong> <strong>Ba</strong>AlSiH as<br />

compared in Figure 13. All hydrides have a narrow b<strong>and</strong> gap. From this, we can expect that<br />

<strong>Ca</strong>AlSiH <strong>and</strong> <strong>Ba</strong>AlSiH compounds are semi-conductors, as in the case <strong>of</strong> previously reported<br />

corresponding <strong>Sr</strong>AlSiH system. The b<strong>and</strong> gap is 0.71 eV <strong>and</strong> 0.42 eV in <strong>Ba</strong>AlSiH <strong>and</strong><br />

<strong>Ca</strong>AlSiH respectively, compared to 0.65 in <strong>Sr</strong>AlSiH [7]. The DOS <strong>of</strong> <strong>Ae</strong>AlSiD (<strong>Ae</strong> = <strong>Ca</strong>, <strong>Sr</strong><br />

<strong>and</strong> <strong>Ba</strong>) is characterized by a pronounced singularity just below Fermi level.<br />

DOS<br />

10<br />

8<br />

6<br />

4<br />

2<br />

DOS<br />

8<br />

6<br />

4<br />

2<br />

0<br />

-1.0 -0.5 0<br />

E-E [eV]<br />

F<br />

0.5 1.0<br />

0<br />

-10 -8 -6 -4 -2 0 2<br />

E-E F [eV]<br />

39<br />

<strong>Ca</strong> Al Si H<br />

<strong>Sr</strong> Al Si H<br />

<strong>Ba</strong> Al Si H<br />

Figure 13: DOS comparison between <strong>Ae</strong>AlSiH (<strong>Ae</strong> = <strong>Ca</strong>, <strong>Sr</strong> <strong>and</strong> <strong>Ba</strong>)

3.3.3 DOS <strong>of</strong> <strong>Ba</strong>Al2-xSixH2-x<br />

DOS <strong>of</strong> <strong>Ba</strong>Al2H2 (x = 0), <strong>Ba</strong>AlSiH (x = 1) <strong>and</strong> <strong>Ba</strong>Si2 (x = 2) [34] are compared in<br />

Figure 15. Trigonal <strong>Ba</strong>Si2 (x = 2) is reported to have metallic conductivity [36] which could<br />

also be confirmed by our DOS calculation. The DOS calculation for <strong>Ba</strong>Al2H2 also indicated it<br />

to have metallic conductivity. This is interesting, because by substituting Si - with [AlH] - in<br />

<strong>Ba</strong>Al2-xSixH2-x, the electric property <strong>of</strong> <strong>Ba</strong>Al2-xSixH2-x can be changed. From this, we expect<br />

that at some x-value between 2 <strong>and</strong> 1, a transformation from a metallic conductor to a<br />

semiconductor will occur <strong>and</strong> again at some x value between 1 <strong>and</strong> 0, the transition will be<br />

reversed. In other word, the b<strong>and</strong> gap <strong>of</strong> <strong>Ba</strong>Al2-xSixH2-x may be tuneable by substituting Si -<br />

with [AlH] - .<br />

Moreover, to investigate a possible superconductivity <strong>of</strong> <strong>Ba</strong>Al2-xSixH2-x would be very<br />

interesting. The DOS <strong>of</strong> <strong>Ba</strong>AlSiH (x = 1) is characterized by a pronounced singularity below<br />

the Fermi level. If we could move the singularity onto the Fermi level, we may able to<br />

increase the Tc. This could be attempted by tuning the Al/Si ratio in the compound, but also<br />

by varying the hydrogen content. <strong>Ba</strong>AlSi, which is precursor material <strong>of</strong> <strong>Ba</strong>AlSiH, was<br />