Compact 32V - X-Flow

Compact 32V - X-Flow

Compact 32V - X-Flow

- TAGS

- compact

- x-flow.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

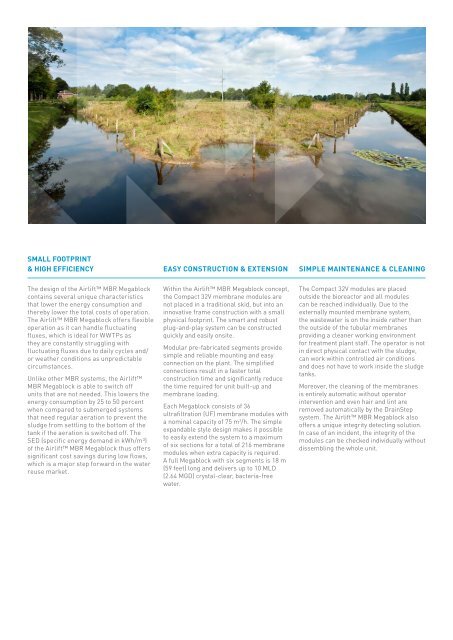

sMall FooTPrinT<br />

& high eFFiciency easy consTrucTion & eXTension siMPle MainTenance & cleaning<br />

The design of the Airlift MBR Megablock<br />

contains several unique characteristics<br />

that lower the energy consumption and<br />

thereby lower the total costs of operation.<br />

The Airlift MBR Megablock offers flexible<br />

operation as it can handle fluctuating<br />

fluxes, which is ideal for WWTPs as<br />

they are constantly struggling with<br />

fluctuating fluxes due to daily cycles and/<br />

or weather conditions as unpredictable<br />

circumstances.<br />

Unlike other MBR systems, the Airlift<br />

MBR Megablock is able to switch off<br />

units that are not needed. This lowers the<br />

energy consumption by 25 to 50 percent<br />

when compared to submerged systems<br />

that need regular aeration to prevent the<br />

sludge from settling to the bottom of the<br />

tank if the aeration is switched off. The<br />

SED (specific energy demand in kWh/m³)<br />

of the Airlift MBR Megablock thus offers<br />

significant cost savings during low flows,<br />

which is a major step forward in the water<br />

reuse market.<br />

Within the Airlift MBR Megablock concept,<br />

the <strong>Compact</strong> <strong>32V</strong> membrane modules are<br />

not placed in a traditional skid, but into an<br />

innovative frame construction with a small<br />

physical footprint. The smart and robust<br />

plug-and-play system can be constructed<br />

quickly and easily onsite.<br />

Modular pre-fabricated segments provide<br />

simple and reliable mounting and easy<br />

connection on the plant. The simplified<br />

connections result in a faster total<br />

construction time and significantly reduce<br />

the time required for unit built-up and<br />

membrane loading.<br />

Each Megablock consists of 36<br />

ultrafiltration (UF) membrane modules with<br />

a nominal capacity of 75 m3 /h. The simple<br />

expandable style design makes it possible<br />

to easily extend the system to a maximum<br />

of six sections for a total of 216 membrane<br />

modules when extra capacity is required.<br />

A full Megablock with six segments is 18 m<br />

(59 feet) long and delivers up to 10 MLD<br />

(2.64 MGD) crystal-clear, bacteria-free<br />

water.<br />

The <strong>Compact</strong> <strong>32V</strong> modules are placed<br />

outside the bioreactor and all modules<br />

can be reached individually. Due to the<br />

externally mounted membrane system,<br />

the wastewater is on the inside rather than<br />

the outside of the tubular membranes<br />

providing a cleaner working environment<br />

for treatment plant staff. The operator is not<br />

in direct physical contact with the sludge,<br />

can work within controlled air conditions<br />

and does not have to work inside the sludge<br />

tanks.<br />

Moreover, the cleaning of the membranes<br />

is entirely automatic without operator<br />

intervention and even hair and lint are<br />

removed automatically by the DrainStep<br />

system. The Airlift MBR Megablock also<br />

offers a unique integrity detecting solution.<br />

In case of an incident, the integrity of the<br />

modules can be checked individually without<br />

dissembling the whole unit.