12 Needle 4 Head embroidery machine - Borduurmachine-Service.nl

12 Needle 4 Head embroidery machine - Borduurmachine-Service.nl

12 Needle 4 Head embroidery machine - Borduurmachine-Service.nl

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

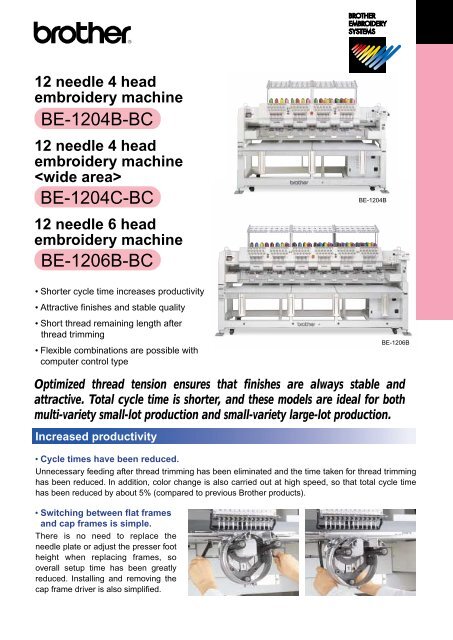

<strong>12</strong> needle 4 head<br />

<strong>embroidery</strong> <strong>machine</strong><br />

BE-<strong>12</strong>04B-BC<br />

<strong>12</strong> needle 4 head<br />

<strong>embroidery</strong> <strong>machine</strong><br />

<br />

BE-<strong>12</strong>04C-BC<br />

<strong>12</strong> needle 6 head<br />

<strong>embroidery</strong> <strong>machine</strong><br />

BE-<strong>12</strong>06B-BC<br />

• Shorter cycle time increases productivity<br />

• Attractive finishes and stable quality<br />

• Short thread remaining length after<br />

thread trimming<br />

• Flexible combinations are possible with<br />

computer control type<br />

Optimized thread tension ensures that finishes are always stable and<br />

attractive. Total cycle time is shorter, and these models are ideal for both<br />

multi-variety small-lot production and small-variety large-lot production.<br />

Increased productivity<br />

• Cycle times have been reduced.<br />

Unnecessary feeding after thread trimming has been eliminated and the time taken for thread trimming<br />

has been reduced. In addition, color change is also carried out at high speed, so that total cycle time<br />

has been reduced by about 5% (compared to previous Brother products).<br />

• Switching between flat frames<br />

and cap frames is simple.<br />

There is no need to replace the<br />

needle plate or adjust the presser foot<br />

height when replacing frames, so<br />

overall setup time has been greatly<br />

reduced. Installing and removing the<br />

cap frame driver is also simplified.<br />

BE-<strong>12</strong>04B<br />

BE-<strong>12</strong>06B

Increased productivity<br />

• Reduced downtime, with thread breakages and thread<br />

tangling prevented before they occur.<br />

Highly-sensitive upper thread breakage sensors which monitor<br />

lower thread breakages as well are equipped as standard, so that if<br />

a thread breakage occurs or bobbin runs out, it is detected straight<br />

away. This keeps downtime to an absolute minimum.<br />

Rotary hooks that reduce the load placed on the threads have been<br />

adopted. In addition, an optimized thread take-up mechanism has<br />

also been adopted to prevent thread breakages.<br />

A thread take-up cover is provided to accurately prevent the thread<br />

tangles around the take-up levers.<br />

Stable and attractive finishes are provided.<br />

The adoption of a thread take-up mechanism that has been optimized to provide the ideal thread tightness<br />

and a high-precision feed control mechanism provide stable seam tightness under an even wider range of<br />

conditions so that high-quality finishes can always be obtained. Newly-developed double-capacity rotary<br />

hooks ensure stable thread tightness, and correct thread tensions can be obtained for light through to<br />

heavy materials.<br />

Short thread remaining lengths<br />

The thread trimming knife is located as close to the needle plate as possible. The thread remaining length<br />

underneath the material is approx. 6 mm short. Because the thread remaining length is so short, the<br />

thread does not need to be manually trimmed.<br />

Low vibration and low noise<br />

A reduction in jump noise means that vibration has been greatly reduced, and at the same time operation<br />

is much quieter overall.<br />

Flexible response to customer needs (computer control type)<br />

• Machines can be combined to meet customer needs.<br />

A single computer can control maximum four units. These four units can be operated independently at the<br />

same time, which is ideal for large-variety small-lot production runs and for producing different items at the<br />

same time. It also allows productivity to be greatly increased.<br />

4 head and 6 head<br />

<strong>embroidery</strong> <strong>machine</strong>s can<br />

also be combined, so that<br />

you can select the number<br />

of heads -- for example, 8<br />

heads (4 + 4), 10 heads (6<br />

+ 4) or <strong>12</strong> heads (6 + 6) --<br />

in accordance with your<br />

needs.<br />

Layouts can use factory space more efficiently 1 PC controls 4 units<br />

PC<br />

PC<br />

PC<br />

PC<br />

PC<br />

Thread stud base<br />

Rotary disk

Flexible response to customer needs (computer control type)<br />

• Computer control allows centralized control.<br />

The progress of embroidering jobs are displayed on the computer<br />

screen. Details such as number of stitches, job progress,<br />

embroidering speed and speed ranges are visible in real time.<br />

Production statistics can also be collated to provide information for<br />

better production control. The information can also be displayed in<br />

graphs by using commercially-available graph plotting software.<br />

Embroidery patterns can be classified and stored in separate<br />

folders.<br />

Stand-alone type is also available for operating <strong>machine</strong>s individually without computer.<br />

Option<br />

Border frame Tubular frame Cap frame<br />

Bobbin winder<br />

The bobbins can be wound either while<br />

embroidering is in progress or while the<br />

<strong>machine</strong> is stopped.<br />

Peripheral equipment<br />

BES-300N<br />

Integrated network system<br />

Height adjustable table<br />

When using a tubular frame or cap frame, the<br />

table can simply be lowered without needing to be<br />

removed. (Available soon)<br />

Spider net frame<br />

Multiple <strong>embroidery</strong> <strong>machine</strong>s are connected together for more efficient<br />

management. (Distribution of <strong>embroidery</strong> data, Centralized database management,<br />

Real-time monitoring of <strong>embroidery</strong> <strong>machine</strong>s, Generation of production reports)<br />

O<strong>nl</strong>y stand-alone <strong>embroidery</strong> <strong>machine</strong>s can be connected. Computer-controlled<br />

<strong>machine</strong>s cannot be connected.<br />

Company Internet / Intranet<br />

<strong>Head</strong>quarters<br />

Network Server Design Center Client, Customer<br />

Factory 1 Factory 2<br />

�Production Report<br />

�Data Distribution<br />

1 head<br />

(SA type)<br />

1 head<br />

(SA type)<br />

4 head (SA type)<br />

�Production Monitor<br />

�Data Distribution, Job Management<br />

Local Server Local Server Local Server<br />

�Production Report<br />

�Data Distribution<br />

1 head (SA type)<br />

4 head (SA type)<br />

6 head (SA type)<br />

Production Report�<br />

Data Distribution�<br />

6 head (SA type)<br />

6 head (SA type)<br />

6 head (SA type)<br />

(Example)

Specifications<br />

BE-<strong>12</strong>04B-BC BE-<strong>12</strong>04C-BC BE-<strong>12</strong>06B-BC<br />

Model<br />

BE-<strong>12</strong>04B<br />

BE-<strong>12</strong>04C<br />

BE-<strong>12</strong>06B<br />

Display<br />

Lock stitch<br />

�<br />

Feed system<br />

Power source / consumption<br />

Distance between <strong>machine</strong> head<br />

Weight<br />

Machine dimension (W x L x H)<br />

Storage medium<br />

<strong>Needle</strong> bar/speed range<br />

Area trace<br />

Step-forward / Step-back<br />

Automatic color changing<br />

No. of recordable patterns<br />

Memory<br />

Pattern rotation<br />

Pattern repeating<br />

Pattern e<strong>nl</strong>argement/reduction<br />

Embroidery start/stop position<br />

changing<br />

No. of needles Double hook<br />

<strong>12</strong> 2<br />

15-1,Naeshiro-cho,Mizuho-ku,Nagoya 467-8561, Japan.<br />

Phone:81-52-824-2177 Fax:81-52-811-7789 http://www. brother. com/<br />

Light materials<br />

Max. field size (X-Y) and Max. sewing speed<br />

BE-<br />

<strong>12</strong>04B-BC<br />

BE-<br />

<strong>12</strong>04C-BC<br />

BE-<br />

<strong>12</strong>06B-BC<br />

No. of <strong>machine</strong><br />

heads<br />

4<br />

4<br />

6<br />

To preserve environment, this catalog is produced using the ECF paper (Elemental Chlorine-Free) and SOY INK.<br />

R<br />

�<br />

Medium materials<br />

�<br />

Stitch length<br />

0.1-<strong>12</strong>.7 mm<br />

Computer control type<br />

Computer monitor<br />

Icon display, mixed kanji/kana display<br />

(Japanese, English, French, German, Spanish,<br />

Italian; other languages to be added later)<br />

U<strong>nl</strong>imited<br />

U<strong>nl</strong>imited<br />

U<strong>nl</strong>imited (depending on computer hard disk<br />

capacity)<br />

-359 – 359˚ (units of 1˚ or 90˚ )<br />

Specified number (1 to 100 times in each direction)<br />

Possible<br />

Thread trimmer<br />

�<br />

Max. sewing speed<br />

1,000 rpm<br />

BE-<strong>12</strong>04B-BC<br />

BE-<strong>12</strong>04C-BC/BE-<strong>12</strong>06B-BC<br />

By timing belt and stepping motor drive<br />

Single phase 200V, 220V, 230V, 240V 1.1kVA<br />

360 mm<br />

600 kgf<br />

At delivery: 2,320 x 810 x 1,400 mm<br />

After set up: 2,320 x 1,360 x 1,750 mm<br />

Tajima format 3.5" 2DD floppy disks, 3.5" 2HD floppy disks based on Tajima format,<br />

Barudan FDR/FMC format 3.5" 2DD floppy disks, ZSK format 3.5" 2DD floppy disks,<br />

Brother ECS format 3.5" floppy disks<br />

Border frame Plain frame Tubular frame Cap frame<br />

360 x 450 mm<br />

(1,000 rpm)<br />

500 x 450 mm<br />

(1,000 rpm)<br />

360 x 450 mm<br />

(1,000 rpm)<br />

Windows is a registered trademark of Microsoft Corporation in the U.S. and other countries.<br />

300 x 430 mm<br />

(1,000 rpm)<br />

400 x 440 mm<br />

(1,000 rpm)<br />

300 x 430 mm<br />

(1,000 rpm)<br />

300 x 430 mm<br />

(1,000 rpm)<br />

400 x 440 mm<br />

(1,000 rpm)<br />

300 x 430 mm<br />

(1,000 rpm)<br />

Separate setting for each needle bar<br />

Boundaries selectable from rectangle or hexagon; stop, forward and back control functions<br />

Units of 1, 10 or 100 stitches, color change units, movement by directly-specified number of stitches<br />

50 – 200% (units of 1˚ )<br />

Wide<br />

360 x 85 mm<br />

(850 rpm)<br />

360 x 85 mm<br />

(850 rpm)<br />

360 x 85 mm<br />

(850 rpm)<br />

Product specifications are subject to change for improvement without notice. Please read instruction manual before using the <strong>machine</strong> for safety operation.<br />

700 kgf<br />

At delivery: 3,040 x 810 x 1,400 mm<br />

After set up: 3,040 x 1,360 x 1,750 mm<br />

Stand-alone type<br />

Operation panel display<br />

Icon display, mixed kanji/kana display<br />

(Japanese, Chinese (unsimplified), English,<br />

French, German, Spanish, Italian, Portuguese)<br />

Up to 99 recordable for each pattern<br />

45 pattern<br />

480,000 stitches equipped as standard<br />

0 – 359˚ (units of 1˚ or 90˚ )<br />

Specified number (1 to 99 times in each direction)<br />

Impossible<br />

Semi wide<br />

180 x 70 mm<br />

(850 rpm)<br />

180 x 70 mm<br />

(850 rpm)<br />

180 x 70 mm<br />

(850 rpm)<br />

Printed in Japan 2004.01. I3040835B Vol.2