Design - Handbook lifgo®- Lifter - CeeIndustrial

Design - Handbook lifgo®- Lifter - CeeIndustrial

Design - Handbook lifgo®- Lifter - CeeIndustrial

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

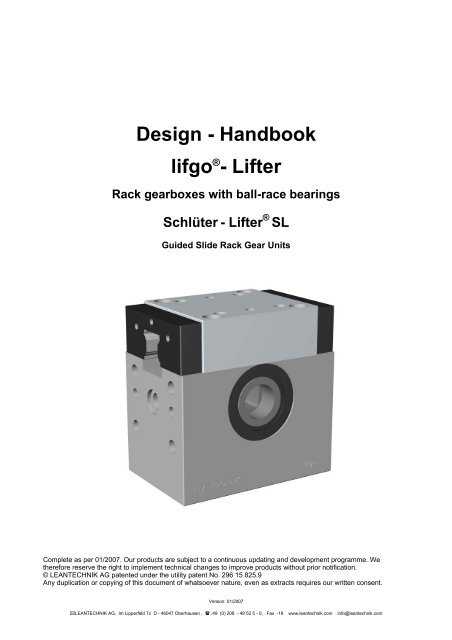

<strong>Design</strong> - <strong>Handbook</strong><br />

lifgo ® - <strong>Lifter</strong><br />

Rack gearboxes with ball-race bearings<br />

Schlüter - <strong>Lifter</strong> ® SL<br />

Guided Slide Rack Gear Units<br />

Complete as per 01/2007. Our products are subject to a continuous updating and development programme. We<br />

therefore reserve the right to implement technical changes to improve products without prior notification.<br />

© LEANTECHNIK AG patented under the utility patent No. 296 15 825.9<br />

Any duplication or copying of this document of whatsoever nature, even as extracts requires our written consent.<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Contents<br />

Chapter 1<br />

Chapter 2<br />

Chapter 3<br />

1.1 References (summary)<br />

1.2 Applications areas for lifgo ® units<br />

2.1 Technical Introduction<br />

2.1.1 Improving successful products<br />

2.1.2 Advantages of the lifting system<br />

2.1.3 Advantages of the lifter<br />

2.1.4 Various positional set-ups of the lifter<br />

2.1.5 Combination<br />

2.1.6 Using the lifter as a rotating and pivoting mechansim<br />

2.2 System Components<br />

2.2.1 Accessories for the lifter<br />

2.2.2 Applications - examples<br />

2.2.2.1 Applications – example 1<br />

2.2.2.2 Applications – example 2<br />

2.2.2.3 Applications – example 3<br />

2.2.2.4 Applications – example 4<br />

2.2.3 Modular designed<br />

2.2.4 Flexible systems - variants<br />

3.1 Line of lifgo ® 3.9 – 4.7<br />

3.1.1 Technical specification of the models<br />

3.1.2 Ascertaining the bearing force<br />

3.1.3 Technical specification - accessories<br />

3.1.4 Unit specification<br />

3.1.5 Unit drilling pattern – Coupling dimensions<br />

3.1.6 VEAS (Vertical Energy Arrest System)<br />

3.1.7 VEAS (Vertical Energy Arrest System) specification<br />

3.1.8 Unit Double specification<br />

3.1.9 Conversion Factors metric / GB – USA<br />

3.2 Gear tooth rack, guide rail and Accessories<br />

Types lifgo ® 3.9 – 4.7<br />

3.2.1 Gear tooth rack specification<br />

3.2.2 Gear tooth rack calculation of length<br />

3.2.3 Lateral load capacity – rack drives<br />

3.2.4 Rack Attachment Points<br />

3.2.5 Rack cover specification<br />

3.2.6 Rack cover calculation of length<br />

3.2.7 Guide rail (without rack profile)<br />

3.2.8 Rack guiding<br />

3.3 Line of lifgo ® linear 4.1 - 4.3<br />

3.3.1 Technical specification of the models<br />

3.3.2 Linear unit specification<br />

3.3.3 VEAS (Vertical Energy Arrest System)<br />

3.3.4 Lifgo linear VEAS unit specification<br />

3.4 Gear tooth rack, guide rail and Accessories<br />

Line of lifgo ® linear 4.1 - 4.3<br />

3.4.1 Linear gear tooth rack specification<br />

3.4.2 Linear Rack guiding<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Contents<br />

Chapter 4<br />

Chapter 5<br />

Chapter 6<br />

Chapter 7<br />

4.1 Line of Schlüter-<strong>Lifter</strong> ® SL 050 - 150<br />

4.1.1 Technical Data<br />

4.1.2 Ascertaining the bearing force<br />

4.1.3 Technical specification - accessories<br />

4.1.4 Lateral load capacity – rack drives<br />

4.1.5 Unit specification<br />

4.2 Gear tooth rack and Accessories<br />

Type Schlüter-<strong>Lifter</strong> ® SL 050 - 150<br />

4.2.1 Gear tooth rack specification<br />

4.2.2 Rack covers<br />

5.1 System Components<br />

Types lifgo ® 3.9 – 4.7, lifgo ® linear 4.1 - 4.3 and Schlüter-<strong>Lifter</strong> ® SL<br />

5.1.1 Profile shaft specification<br />

5.1.2 Locking collar specification<br />

5.1.3 Torsionally rigid tube<br />

5.1.4 Differential coupling<br />

5.1.5 Differential coupling specification<br />

5.1.6 Universal shaft joint specification<br />

5.1.7 Assembly Notices, Cardan Joint<br />

5.1.8 Cardan shaft specification<br />

5.1.9 Fixing brackets drilling pattern<br />

5.1.10 Mounting plates drilling pattern<br />

5.1.11 Lubrication plate<br />

5.1.12 Front-lubricator<br />

5.1.13 Self-lubricator<br />

6.1 Tool Making<br />

Type lifgo ® 4.0<br />

6.1.1 Areas of Application<br />

6.1.2 Rack gear according to company standards<br />

6.1.3 Fixing plate according to WDX standard Ford, Europe<br />

Dimensioned drawing<br />

7.1 Drive Units<br />

Types lifgo ® 3.9 – 4.7, lifgo ® linear 4.1 - 4.3 and Schlüter-<strong>Lifter</strong> ® SL<br />

7.1.1 Drive Units<br />

7.1.2 Drive Units – three phase gear-motor DGM SR/SC<br />

7.1.3 Servomotor<br />

7.1.4 Pneumatic cylinder LZY<br />

7.2 Accessories<br />

Types lifgo ® 3.9 – 4.7, lifgo ® linear 4.1 - 4.3 and Schlüter-<strong>Lifter</strong> ® SL<br />

7.2.1 Gearbox adapter, Coupling and Planet-Gearbox<br />

7.2.2 Bearer block for SGM / ATB units<br />

7.2.3 Shafts adapters<br />

7.2.4 Sliding Naves<br />

7.2.5 Coupling unit specification<br />

7.2.6 Gearbox Adapter for lifgo<br />

7.2.7 Gearbox Adapter for Schlüter<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Contents<br />

Chapter 8<br />

Chapter 9<br />

Chapter 10<br />

Chapter 11<br />

8.1 Assembly and Commissioning<br />

Types lifgo ® 3.9 – 4.7, lifgo ® linear 4.1 - 4.3 and Schlüter-<strong>Lifter</strong> ® SL<br />

8.1.1 Assembly instructions<br />

8.1.2 3.9, 4.0 and 4.1, Insertion of rack<br />

8.1.3 Commissioning<br />

8.1.4 Maintenance & Lubrication intervals and quantity for lifgo<br />

8.1.5 Lubrication intervals for guide blocks and guide rail<br />

8.1.6 VEAS Assembly<br />

9.1 Modular construction of a lifting system an assembly example<br />

Types lifgo ® 3.9 – 4.5<br />

9.1.1 Mounting instructions for lifting device<br />

10.1 Incidentals<br />

Types lifgo ® 3.9 – 4.7, lifgo ® linear 4.1 - 4.3 and Schlüter-<strong>Lifter</strong> ® SL<br />

10.1.1 Coupling nut<br />

10.1.2 Coupling plates<br />

10.1.3 Formular collecting<br />

10.1.4 Data transfer<br />

11.1 Terms<br />

11.1.1 Terms and Conditions of Sale and Delivery<br />

11.1.2 Notes<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Version: 01/2007<br />

Chapter 1<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com<br />

Types<br />

lifgo ®<br />

lifgo ® linear<br />

Schlüter-<strong>Lifter</strong> ® SL<br />

References (summary)<br />

Applications

Chapter 1<br />

1.1 References (summary)<br />

• ABB<br />

• AEG Hausgeräte GmbH<br />

• Agfa Gevaert AG<br />

• AUDI AG<br />

• AUTOEUROPA<br />

• BENTELER AG<br />

• BMW AG<br />

• BMW Motorsport<br />

• BRAUN GmbH<br />

• BSH BOSCH UND SIEMENS Hausgeräte GmbH<br />

• COMAU SYSTEMS S.P.A. (Italien, Indien)<br />

• CONTINENTAL AG<br />

• DAIMLER CHRYSLER AG<br />

• DEMAG ERGOTECH<br />

• EDAG AG<br />

• FASTI Carl.Aug. Fastenrath GmbH & Co.KG<br />

• FLABEG GmbH & Co.KG<br />

• FORD AG (Global)<br />

• KRUPP DRAUZ<br />

• KUKA Schweißanlagen GmbH<br />

• KÜPPERSBUSCH GmbH<br />

• LÄPPLE GmbH & Co.KG<br />

• MAN Nutzfahrzeuge AG<br />

• MIELE + Cie. GmbH & Co.KG<br />

• MÜLLER WEINGARTEN AG<br />

• NOTHELFER GmbH<br />

• OPEL AG (Deutschland, Spanien)<br />

• RHEINZINK GmbH & Co.KG<br />

• SCHULER AUTOMATION GmbH & Co.KG<br />

• SCHULER CARTEC GmbH & Co.KG<br />

• SEAT S.A.<br />

• SIEMENS-MATSUSHITA Compon. GmbH & Co.KG<br />

• SIEMPELKAMP GmbH & Co.KG<br />

• SKODA AUTO A.S.<br />

• THYSSEN Umformtechnik GmbH<br />

• VIESSMANN-WERKE GmbH & Co.KG<br />

• VOLKSWAGEN AG<br />

• VOLVO PERSONVAGNAR AB<br />

• WESER METALL Umformtechnik GmbH<br />

• WIELAND-WERKE AG<br />

• WITTE Umformtechnik GmbH & Co.KG<br />

• YTONG DEUTSCHLAND AG<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 1<br />

1.2 Application areas for lifgo ® units<br />

traction - pushing - lifting – lift and shift - lowering - turning - tipping - swiveling<br />

Synchronous motion systems in the automation- manufacturing- and transfer techniques<br />

car industry ceramic industry foodstuff industry<br />

structural chemical engineering railway industry glass industry<br />

white goods manufacturing aerospace industry packaging processing<br />

plastics processing wood processing tyre manufacture<br />

packaging industry furniture industry shipbuilding industry<br />

power generation<br />

Applications Examples<br />

lifting systems<br />

- vibration free synchronous lifting table<br />

- vibration free secondary positioning of broaching tool<br />

load lift systems<br />

- lift station for belt conveyor<br />

- lifting column system for roller-conveyor<br />

lifting table<br />

- final assembly lift station<br />

- lifting table for automatic bending machine<br />

- lift station – automotive industry<br />

- engine/transmission lift station<br />

- lift station for automotive “modeling” table<br />

- hand operated precision lifting tables for scientific instruments<br />

press transfer system<br />

- three-axis press transfer system<br />

- 2-axis transfer table system<br />

lift and tilt system<br />

- body tilt system with vertical adjustment<br />

- tilt system for roller conveyor handling large steel sheets<br />

lift and shift (shuttle) system<br />

- mono-rail shuttle for automotive supplier<br />

- mono-rail shuttle for con-rod machining<br />

- suspended monorail shuttle system for transport of U-Frames for sliding roof<br />

- standing double beam system<br />

advance and stacking system<br />

- chipboard stacking system<br />

- positioning system<br />

- footstep between railway carriage and railway platform<br />

die automation<br />

- double-headed die tool set<br />

- de-burring press die operation<br />

- re-build of die with lifter system<br />

centering system<br />

- centering and lift system for press components prior to robotic stage<br />

- centering of dies to carcass in tyre production<br />

- synchronous centering for glass sheet manufacturing and stacking<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Version: 01/2007<br />

Chapter 2<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com<br />

Typ<br />

lifgo ®<br />

Technical Introduction<br />

System - Components

Chapter 2<br />

2.1 Technical Introduction<br />

2.1.1 Improving successful products<br />

lifgo is a modular constructed lifting system, which can be used in the widest possible fields of<br />

application. With just one basic arrangement (for each particular model) the module, with which all<br />

the motional systems are interconnected, is formed. By means of the four models available, the<br />

lifting and moving of small to heavy loads can be accomplished rapidly. The innovative design is<br />

based on the principle of a rack and pinion drive system, and follows the tradition of our proven<br />

Schlüter lifters ® .<br />

The objective of the new development was to provide a user-friendly modular system, with the<br />

requirement:<br />

1. to translate greater outputs using smaller sizes of modules<br />

2. to increase flexibility by increasing the range of application and<br />

3. to reduce accessories to a minimum, yet to retain and improve the „ clip and go „®<br />

rapid assembly system.<br />

2.1.2 Advantages of the lifting system<br />

� Smaller size module with greater outputs<br />

� Logical progression in output capacities between all the models<br />

lifting load of 1 kg to 8,000 kg<br />

transverse force of 1 kg to 11.050 kg<br />

� One basic design for each model<br />

� Easy fitting during installation and assembly due to identical design<br />

and method of operation for all models<br />

� High acceleration and operating speeds (load dependent)<br />

� All faces of the module casing can be used as mating and mounting faces when assembling<br />

� Rapid „clip and go ®“ assembly for the entire lifter system<br />

� Fewer accessories with flexibility in their application, suitable for direct<br />

mounting<br />

� The rack is guided by four ball-race bearings. It guarantees exact guide with<br />

slight deviation and due to the design of rack they pickup high moment of flexion.<br />

� Greater absorption of transverse forces by the gear tooth rack, thus providing<br />

excellent guidance capability<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 2<br />

2.1 Technical Introduction<br />

2.1.3 Advantages of the lifter<br />

The lifgo lifter is a completely new concept in terms of the design. Only the principle of the rack and<br />

pinion drive has been retained. The casing is fully enclosed on all sides and is totally unaffected by<br />

external influences, such as spray and pressurised water. This applies equally to all necessary<br />

attachments. The rack is guided by four ball-race bearings and is sealed on three sides. As a result,<br />

any escape of lubricant (after the commissioning phase) and any ingress of dirt is prevented. The<br />

racks are able to absorb substantial lateral forces and thus in axial direction adopt the task of acting<br />

as guides (transverse forces). Further guides are unnecessary, which reduces costs. The pinion<br />

shaft located in the casing is provided with a hollow profile. Upon insertion of the profiled shaft, a<br />

frictionally interlocking interface is created between the lifters or between the lifter(s) and the<br />

motor(s). On both ends is seated a centring ring around the pinion shaft. Its task is to accept all<br />

rotating attachments which rotate around the axis, such as gearmotors, drive block, thrust ring, slip<br />

ring or bearer block.<br />

2.1.4 Various positional set-ups of the lifter<br />

The cubic design of the lifgo lifter enables various combinations of set-up to be effected. Centring<br />

pins in each mounting face facilitate ease of alignment and assembly.<br />

The lifgo lifter can be assembled in six differing positions - the example here illustrates the lifter in<br />

single module mode, the „ single lifter“.<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 2<br />

2.1 Technical Introduction<br />

2.1.5 Combination<br />

In addition to those already shown there are still further possible assembly options such as shown<br />

below. Is not necessary to assemble them adjacent to each other. Please refer here to chapter 2,<br />

sections 2.2.2.1 – 2.2.2.4 Application – examples.<br />

Two single lifters can be assembled in any position in relation to each other uncreasing the<br />

combinations accordingly.<br />

horizontal - vertical on left side horizontal -<br />

vertical on right side aligned<br />

Positioning of the lifter possible on the opposite side or positioned separately!<br />

Use of two lifgo lifter at 90° to each other - shown here the use of a „double lifter“.<br />

2.1.6 Using the lifter as a rotating and pivoting mechanism<br />

By using two modules (of the same model) or bearer blocks, the lifgo lifter system can be used as<br />

rotating and pivoting unit. It is also possible to use combinations off lifters and bearer blocks.<br />

Furthermore, in reverse sequence rotary, linear motion can be converted.<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 2<br />

2.2 Systemkomponenten<br />

2.2.1 Accessories for the lifter<br />

By the use of accessories the lifgo lifter can be united to form a lifgo system. Each accessory is<br />

dimensioned to suit the particular size of model on which it is be used, and is identical in its design in<br />

each case. The small number of flexible accessories fulfil a multitude of requirements. They are<br />

broken down into four main groups:<br />

1. Accessories - for the rack connections and protection against wear, differential/ heavy load<br />

coupling, protective rack cover, rack coupling for pneumatic and hydraulic cylinder<br />

2. Accessories - for making a rotational connecting joint (torsionally rigid)<br />

profiled shaft, locking ring, universal shaft joints<br />

3. Accessories - for attaching the casing mounting plates, fixing brackets<br />

4. Accessories - for lifgo drives - linear and rotary drives servo-motors, servo drive<br />

block, threephase current, servo gear drive motor, pneumatic cylinder, hydraulic cylinder<br />

2.2.2 Applications - examples<br />

The following pages illustrate the lifgo system by depicting typical application examples. You may<br />

well recognise a concept which is appropriate for your specific problem and if not we would be<br />

pleased to advise.<br />

Beneath the illustrations are explanatory notes and where necessary, examples of calculations. In<br />

the sample calculations the lifting force value (FH) is defined in Newton’s (N) in all cases.<br />

The following lifting force values are used:<br />

lifgo ® 3.9 FH = 550 N/ unit<br />

lifgo ® 4.0 FH = 1.800 N/ unit<br />

lifgo ® 4.1 FH = 3.600 N/ unit<br />

lifgo ® 4.3 FH = 15.800 N/ unit<br />

lifgo ® 4.5 FH = 23.100 N/ unit<br />

lifgo ® 4.7 FH = 80.000 N/ unit<br />

Please Note: Refer to chapter 3, sections 3.1.1 - for Technical specification.<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 2<br />

2.2 System Components<br />

i<br />

2.2.2.1 Applications - examples<br />

Example 1: lifgo system geometry in standard design (pneumatic operated)<br />

The lifgo system here represents a standard arrangement. It can, for example, be used in press-tool<br />

dies. Advantage: greater load capacity for a small installation space, plus high stroke speed - 25<br />

cyclic strokes/min. The pneumatic cylinder pulls the rack through the lifgo casing and rotates the<br />

pinion shaft having a hollow profile. By means of the inserted profiled shaft, a friction locking<br />

interface is created between the units. The rotary motion of the pinion shaft in the first unit (horizontal<br />

racks) is transmitted to the vertical drive lifgo unit. This moves the rack upwards. Due to the positive<br />

close-tolerances mechanical connection this motional sequence occurs simultaneously for all vertical<br />

units. As a consequence, you have a synchronous lift system. Synchronisation is also assured by the<br />

distributed application of the load. In this set-up the horizontal units fulfils the function of a primary<br />

unit. This means it distributes the lifting force to the vertical units and, as a consequence carry the<br />

greatest load. Load distribution then occurs if the load is transmitted via the pinion and profiled shaft<br />

(rotational interface) to a neighbouring unit. For a simple push-pull application the whole thrust force<br />

can be transmitted.<br />

Please Note: Care should be taken to ensure that the introduced lifting force does not exceed the<br />

maximum permitted lifting force of the (horizontal) primary unit! Please note the<br />

technical data!<br />

Calculation to example 1:<br />

To show how of the calculation is made the values from chapter 2, sections 2.2.2 have been used!<br />

Efficiency factors are not taken into account. (refer chapter 3, sections 3.1.1 Technical<br />

specification.) In using two primary lifgo units, the entire lifting force can be applied twice. This can<br />

then be transferred to the lifgo lifter for each half. The pneumatic cylinder can thus introduce the<br />

doubled force of the primary units.<br />

For example 1geometry there is a lifting force as follows:<br />

lifgo ® 3.9 FH = 550 N x 2 = FH = 1.100 N = cylinder force rating<br />

lifgo ® 4.0 FH = 1.800 N x 2 = FH = 3.600 N = cylinder force rating<br />

lifgo ® 4.1 FH = 3.500 N x 2 = FH = 7.000 N = cylinder force rating<br />

lifgo ® 4.3 FH = 15.800 N x 2 = FH = 31.600 N = cylinder force rating<br />

lifgo ® 4.5 FH = 23.100 N x 2 = FH = 46.200 N = cylinder force rating<br />

lifgo ® 4.7 FH = 80.000 N x 2 = FH = 160.000 N = cylinder force rating<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 2<br />

2.2 System Components<br />

2.2.2.2 Applications – example 2, lifgo Systematic arrangement (pneumatic)<br />

This arrangement is further development to example 1. The lifting forces are distributed on 6 lifgo<br />

lifters instead of 4. Since all attachments are plug assembled together, such an enhancement is<br />

achieved without any problems. Based on the unchanged number of primary units, the total lifting<br />

force of the system is equal to that of example 1.<br />

2.2.2.3 Applications – example 3, lifgo Systematic arrangement (pneumatic)<br />

Four primary lifgo units were used in this arrangement. Calculated, this means for:<br />

lifgo ® 3.9 FH = 550 N x 4 = FH = 2.200 N = cylinder force<br />

lifgo ® 4.0 FH = 1.800 N x 4 = FH = 7.200 N = cylinder force<br />

lifgo ® 4.1 FH = 3.500 N x 4 = FH = 14.000 N = cylinder force<br />

lifgo ® 4.3 FH = 15.800 N x 4 = FH = 63.200 N = cylinder force<br />

lifgo ® 4.5 FH = 23.100 N x 4 = FH = 92.400 N = cylinder force<br />

lifgo ® 4.7 FH = 80.000 N x 4 = FH = 320.000 N = cylinder force<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 2<br />

2.2 System Components<br />

2.2.2.4 Applications – example 4, system arrangement using a servo gearmotor<br />

In this case, the drive is a servomotor. Here also, the drive unit is connected to the lifgo lifters via the<br />

profile shafts which are pushed into the lifters, providing a frictional connection. For all lifgo sizes, the<br />

profile shaft has been designed in such a way that upon insertion, the position of the pinions in<br />

relation to one another is synchronised. This ensures that the vertical racks will always have the<br />

same positional height. Incorrect assembly is thus impossible. Under computer control, the<br />

servomotor moves to positions with precise repeatability. When several drives are used, one motor<br />

assumes the control function, which is mirrored by all of the other drives to the same degree of<br />

accuracy.<br />

Calculation to example 4:<br />

The power distribution 3-way gear units have been dimensioned so that they can transmit the<br />

maximum torque of two lifgo units in both axial directions. The total lift force is therefore 4 times that<br />

of a single lifgo unit (please see chapter 2, sections 2.2.2 values).<br />

Calculated, this means:<br />

lifgo ® 3.9 FH = 550 N x 4 = FH = 2.200 N = lift force<br />

lifgo ® 4.0 FH = 1.800 N x 4 = FH = 7.200 N = lift force<br />

lifgo ® 4.1 FH = 3.500 N x 4 = FH = 14.000 N = lift force<br />

lifgo ® 4.3 FH = 15.800 N x 4 = FH = 63.200 N = lift force<br />

lifgo ® 4.5 FH = 23.100 N x 4 = FH = 92.400 N = lift force<br />

lifgo ® 4.7 FH = 80.000 N x 4 = FH = 320.000 N = lift force<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 2<br />

2.2 System Components<br />

2.2.3 Modular designed<br />

The solutions depicted here and in more detail in the separate Application Guide selection only of<br />

practical applications. Most systems make full use of the lifgo “clip and go” assembly system which<br />

simplifies both design layout work and later assembly. In addition however it will be found that<br />

modifications to later for product changes can be made by simple adjustment or at the worst be<br />

interchanging some components eg longer racks for uncreased stroke. Our precise manufacture<br />

provides guaranteed service life with minimal maintenance. As a result, you have more time to spend<br />

on finding the constructive solution and can build this using the lifgo modular system into complete<br />

units.<br />

We will be only too pleased to help in finding a solution !<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 2<br />

2.2 System Components<br />

2.2.4 Flexible systems - variants<br />

basic models lifgo 3.9 – 4.7<br />

The six basic types can be combinated and extended (each type) in different variants.<br />

Lifgo-double - design<br />

With two rack gear guides,<br />

e.g. for acquiring (grab function),<br />

telescoping or for centring parts etc<br />

lifgo rack for integrated feed of medium<br />

air pressure, - vacuum, - cooling liquid, - alkaline solution (conditional)<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Version: 01/2007<br />

Chapter 3<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com<br />

Types<br />

lifgo ®<br />

lifgo ® linear<br />

Technical Data<br />

Gear tooth rack, guide rail and<br />

Accessories

Chapter 3<br />

3.1 Type lifgo ® 3.9 – 4.7<br />

i<br />

3.1.1 Technical specification of the models<br />

lifgo ®<br />

Unit 3.9 4.0 4.1 4.3 4.5 4.7<br />

Casing bearing force N 3.300 5.800 12.000 26.000 63.000 180.000<br />

1) Force of stroke N 550 1.800 3.500 15.800 23.100 80.000<br />

Speed of stroke m/s 1,000 0,830 0,830 0,500 0,416 0,250<br />

Speed of stroke m/min. 60 50 50 30 25 15<br />

Acceleration max. m/s² 5 7 10 4 3 2<br />

Torque max. Nm 3,3 18 70 475 1.040 7800<br />

Pitch circle diameter mm 12 20 40 60 90 196<br />

Gearing mm/α-1° mm 0,1047 0,1745 0,349 0,524 0,785 1,710<br />

Gearing stroke/360° mm 37,69 62,83 125,66 188,49 282,74 615,75<br />

Temperature resistance<br />

Efficiency 1 0,92 0,92 0,92 0,92 0,92 0,90<br />

Profile shaft -<br />

„clip and go ® “ joint<br />

º C 80 80 80 80 80 80<br />

VK 6<br />

square<br />

PG 14<br />

polygonal<br />

Version: 01/2007<br />

PG 20<br />

polygonal<br />

KW 42<br />

spline shaft<br />

SW 46<br />

hexagon<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com<br />

Flange<br />

Acc. Project<br />

Weight kg 0,55 1,2 3 12 39 162<br />

1) Values given for max. acceleration a = 5 m/s². Chapter 3, sections 3.1.2, heed FMA calculation.<br />

Please Note: An estimation of the service life in connection with the rack gear should be<br />

requested as per the project data!

Chapter 3<br />

3.1 Type lifgo ® 3.9 – 4.7<br />

i<br />

i<br />

3.1.2 Ascertaining the bearing force<br />

Bearing forces in the technical specification (Chapter 2, sections 2.2.2) are based on the max.<br />

acceleration value a (m/s²). If you alter the rate of acceleration, then the bearing force alters too.<br />

Note Less acceleration (a= m/s²) > greater bearing force<br />

Higher acceleration (a= m/s²) > less bearing force.<br />

In the layout of the system, consider the function of the lifgo modules as primary unit,<br />

because even here the total loading on any one lifter must not be exceeded.<br />

FMA - calculation<br />

FL - Static loading [N] FZ - Static loading on rack [N]<br />

mL - Weight of lifting load [kg] mZ - Weight of rack [kg]<br />

a - Acceleration of drive [m/s²] > servo-motor, pneumatic cylinder<br />

Formula 1<br />

Lifting load - vertical FV = FL + FZ + [(mL + mZ) x a] + 20 N x 1,08 = [N]<br />

Lifting load - horizontal FH = [(mL + mZ) x a] + 20 N x 1,08 = [N]<br />

3.1.3 Technical specification - accessories<br />

In arranging the layout, the technical scope of the accessories in terms of application is to be taken<br />

into account. All components which transmit forces for drawing or pushing or transmit moments of<br />

torque can be found in the following table. The data given correspond to the maximum values and<br />

must not be exceeded. They relate to the tabulated values of chapter 3, sections 3.1.1.<br />

lifgo ® Unit 3.9 4.0 4.1 4.3 4.5 4.7<br />

Profile shaft Nm 5 25 110 900 2.100 Acc. Project<br />

Straightness mm/m 0,3 0,3 0,3 0,3 0,3 Acc. Project<br />

Torsional movement °/m 1 1 1 1 1 Acc. Project<br />

Rack buckling length mm 0,055 0,120 0,09 0,10 0,15 Acc. Project<br />

Profile shaft backlash mm 0,020 0,100 0,085 0,020 0,090 ---<br />

Differential-coupling<br />

No./ force vectors pcs. 7 7 9 5 4 Acc. Project<br />

Coupling unit<br />

Pushing/pulling force F N 6.500 18.000 24.000 63.000 99.000 Acc. Project<br />

Please Note: An estimation of the service life in connection with the rack gear should be<br />

requested as per the project data!<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 3<br />

3.1 Type lifgo ® 3.9 – 4.7<br />

i<br />

3.1.4 Unit specification<br />

lifgo ® unit 3.9 4.0 4.1 4.3 4.5 4.7<br />

A mm 59 78 107,2 175,2 265 502<br />

B mm 59 78 107,2 175,2 265 502<br />

C mm 47 63 70 120 170 320<br />

D mm 44 60,05 85,95 137,7 206 407<br />

E mm 38 50 45 79 120 270<br />

F mm 13 20 35 54 110 165<br />

G mm 29,5 39 53,6 87,6 132,5 251<br />

H mm 22 29 32,6 48,1 55 161<br />

I mm 15 20 42 79 115 270<br />

Dowel hole K mm Ø 4x4 6x9 6x9 6x9 6x9 20x20<br />

L mm M 5x6 M 5x10 M 8x10 M 10x17 M 16x26 Acc. Project<br />

M mm M 5x10 M 5x13 M 8x13 M 10x20 M 16x28 Acc. Project<br />

ØN x P mm 19K6x3 26K6x1,5 47K6x1 58H7x2 100H7x2 140H7x4<br />

O mm 5,5 10 14 14,5 32,5 75<br />

Q mm M6 M10x1 M10x1 M10x1 M10x1 Acc. Project<br />

T mm 12 24 48 87,6 132,5 251<br />

W mm TN/TN TN/TN M6/TN M6/TN M8x1/M8x1 Acc. Project<br />

Part-No. Standard 39-059-047 40-088-044 41-107-076 43-175-125 45-265-189 47-502-320<br />

weight kg 0,55 1,2 3 12 39 162<br />

Please Note: Tolerance band precision / interference hole ± 0,03<br />

Lubricating holes, threaded or cone nipple (TN)<br />

During the design phase, please ensure that the lubrication holes remain<br />

accessible<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 3<br />

3.1 Type lifgo ® 3.9 – 4.7<br />

i<br />

i<br />

3.1.5 Unit drilling pattern - Coupling dimensions<br />

In the following table are the drilling patterns of the three lifgo units (for direct assembly). For the use<br />

of brackets refer to chapter 5, sections 5.1.9 - fixing brackets or chapter 5, sections 5.1.10 -<br />

mounting plates.<br />

Please Note: The drilling patterns are marked according to the position (Floor space) chapter 2,<br />

sections 2.1.4, ”Various positional set-ups for the lifter”.<br />

1<br />

2<br />

a<br />

a<br />

b b<br />

4 x drilled hole e<br />

c d d c<br />

j<br />

2 x dowel hole f 2 x dowel hole f<br />

k<br />

R = 3<br />

l<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com<br />

R = 3<br />

4 x drilled hole e<br />

3 4<br />

2 x dowel hole f 2 x dowel hole f<br />

4 x drilled hole e<br />

k<br />

4 x drilled hole e<br />

lifgo ® Unit 3.9 4.0 4.1 4.3 4.5 4.7<br />

a mm 38 50 45 79 120<br />

b mm 30 20 42 79 115<br />

c mm 7,5 10 21 39,5 77,5<br />

d mm 5,5 10 14 14,5 32,5<br />

e mm Ø 5,5 M5 Ø 6 M5 Ø 9 M8 Ø11 M10 Ø17 M16<br />

f mm Ø 4 H7 Ø 6 H7 Ø 6 H7 Ø 6 H7 Ø 6 H7<br />

j mm 5 8 15 26,5 40<br />

k mm 18 22 28 48 67<br />

l mm 18 22 26 48 67<br />

Please Note: Tolerance band precision / interference holes ± 0,03<br />

j<br />

a<br />

a<br />

Special connection.. Please<br />

request drawing

Kapitel 3<br />

3.1 Types lifgo ® 3.9 – 4.7<br />

i<br />

3.1.6 VEAS (Vertical Energy Arrest System)<br />

This mechanical arrest system for the model types listed above includes the following features:<br />

- Precise interlocking interface, robust, designed for every module dependent position.<br />

- Prevents uncontrolled downward travel should the power fail<br />

The VEAS is used to move the system to a “maintenance and repair” position and secure it in this<br />

position. It is also used to lock the system in a particular access position. This is done by first<br />

releasing the pneumatic cylinder; the vertical drive then initiates downward travel at creep speed until<br />

the locking bolt of the VEAS slides into place.<br />

The system is now “mechanically secured”. Maintenance staff can now safely access the area. In<br />

order to release the locked system, the pneumatic cylinder is energised and the VEAS is lifted 2xto at<br />

creep speed working against the load. The system is now released.<br />

The VEAS mechanism can also be used to prevent uncontrolled downward motion in the system in<br />

the event of a power failure..<br />

Important: VEAS is not a brake with which an EMERGENCY STOP can be carried out. VEAS<br />

should only be operated once the system has come to a halt. If the VEAS is operated while the<br />

system is in motion, then the lifgo ® and the VEAS is to be immediately replaced. The VEAS locks<br />

the system in one direction only (the direction against the load). The other direction is not blocked<br />

(ratchet). Each VEAS component is designed to secure one load point only. In order to ensure<br />

correct functionalty at all times, the VEAS should be operated at least once per week. The VEAS<br />

mechanism complies with the requirements of safety class 2.<br />

lifgo ® Unit 4.0 VEAS 4.1 VEAS 4.3 VEAS 4.5 VEAS 4.7 VEAS<br />

Casing bearing<br />

force N --- 12.000 26.000 --- ---<br />

brake holding load N --- 3.500 15.800 --- ---<br />

Part-No.<br />

Pneumatic cylinder<br />

version<br />

Pneumatic Cylinder Version:<br />

Voltage: 24 V direct current 0.83 Ampere<br />

Inductive switch (IS) has been preset at the factory!<br />

2 x PNP make contacts 24 V DC<br />

On Inquiry 41-107-101 43-175-101 On Inquiry On Inquiry<br />

weight kg --- 3,5 13,5 --- ---<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 3<br />

3.1 Types lifgo ® 3.9 – 4.7<br />

i<br />

3.1.7 VEAS (Vertical Energy Arrest System) specification<br />

Pneumatic cylinder version<br />

lifgo ® Unit 4.0 VEAS 4.1 VEAS 4.3 VEAS 4.5 VEAS 4.7 VEAS<br />

Part-no.<br />

R mm --- 53 58 --- ---<br />

ØS mm --- 29 36 --- ---<br />

T mm --- 44 70 --- ---<br />

U mm --- 77 - 87 95 - 110 --- ---<br />

V mm --- 29 38 --- ---<br />

pneumatic cylinder<br />

version<br />

On Inquiry 41-107-101 43-175-101 On Inquiry On Inquiry<br />

weight kg --- 3,5 13,5 --- ---<br />

Please Note: During the design phase, please ensure that the lubrication holes remain accessible!!<br />

An estimation of the service life in connection with the rack gear should be<br />

requested as per the project data!<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 3<br />

3.1 Types lifgo ® 3.9 – 4.7<br />

i<br />

3.1.8 Unit Double specification<br />

lifgo ® Unit 3.9 4.0 4.1 4.3<br />

A mm 59 78 107,2 175,2<br />

B mm 59 78 107,2 175,2<br />

C mm 47 63 70 120<br />

D mm 44 60,05 85,95 137,7<br />

E mm 38 50 45 79<br />

G mm 29,5 39 53,6 87,6<br />

I mm 15 20 42 79<br />

Dowel hole K mm Ø 4x4 6x9 6x9 6x9<br />

L mm M 5x6 M 5x10 M 8x10 M 10x17<br />

M mm M 5x10 M 5x13 M 8x13 M 10x20<br />

ØN x P mm 19K6x3 26K6x1,5 47K6x1 58H7x2<br />

O mm 5,5 10 14 14,5<br />

Q mm M6/M6 M10x1/ M10x1 M10x1/ M10x1 M10x1/ M10x1<br />

W mm TN/TN TN/TN M6/TN 1) M6/TN 1)<br />

Part-no. Standard 39-059-050 40-088-050 41-107-080 43-175-135<br />

weight kg/m 0,65 1,42 3,50 14,40<br />

Please Note: Tolerance band precision / interference hole ± 0,03<br />

Lubricating holes (W), threaded or cone nipple (TN)<br />

During the design phase, please ensure that the lubrication holes remain<br />

accessible!<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 3<br />

3.1 Types lifgo ® 3.9 – 4.7<br />

3.1.9 Conversion Factors metric / USA - GB<br />

Metric units USA - GB units<br />

Mass Kilogramm 1,0000 kg pound mass 2,20500 lbm<br />

0,4535 kg 1,00000 lbm<br />

Force Newton 1,0000 N pound force 0,22480 lbf<br />

4,4830 N 1,00000 lbf<br />

Torque Newtonmeter 1,0000 Nm Inches,<br />

pound<br />

Version: 01/2007<br />

2,20510 in.lb<br />

0,1127 Nm 1,00000 in.lb<br />

Length Meter 1,0000 m feet 3,28100 ft<br />

0,3048 m 1,00000 ft<br />

Meter 1,0000 m inches 39,37000 in<br />

0,2540 m 1,00000 in<br />

Millimeter 1,0000 mm inches 0,03940 in<br />

25,4000 mm 1,00000 in<br />

Speed Meter/minute 1,0000 m/min. feet/minute 3,28100 ft/min.<br />

0,3048 m/min. 1,00000 ft/min.<br />

1,0000 m/min. 0,05468 ft/s<br />

Meter/Second 1,0000 m/s feet/second 3,28100 ft/s<br />

0,3048 m/s 1,00000 ft/s<br />

18,2900 m/min. 1,00000 ft/s<br />

Acceleration Meter/Second² 1,0000 m/s² feet/second² 3,28100 ft/s²<br />

0,3048 m/s² 1,00000 ft/s²<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 3<br />

3.2 Gear tooth rack, guide rail and Accessories<br />

Types lifgo ® 3.9 – 4.7<br />

i<br />

i<br />

i<br />

i<br />

3.2.1 Gear tooth rack specification<br />

The rack is used as a pull or push action rack and, at the same time, convents linear motion into<br />

rotary (angular) motion. It is also possible to effect the action in reserve. Sequence (angular to<br />

linear). With the rack-to-pinion shaft interface, positioning of +/- 0,01 mm can be accomplished with<br />

accurate repetition.<br />

The rack is guided by four ball-race bearings and can therefore absorb transverse force.<br />

Consequently, it is suitable as a guide. Additional components are not needed.<br />

Threads are provided at the ends, which are for attaching accessories, i.e. a differential couplings, a<br />

coupling unit (for pneumatic cylinder) or a heavy duty coupling, for effecting an interface for pulling or<br />

pushing actions. In addition. The threads are used for accepting attachments, e.g. devices, which<br />

can be directly mounted.<br />

The rack is supplied in lengths in accordance with your requirement. Please state the length,<br />

defined by the number or teeth. Refer to chapter 3, sections 3.2.2, Equation 2 and 3.<br />

A special rack gear is used for particularly demanding, constant operation with high cycle rates in<br />

three shifts. Please be sure to request a calculation of service life. This model is available in<br />

lengths of up to 1,500 mm.<br />

lifgo ® Unit 3.9 4.0 4.1 4.3 4.5 4.7<br />

Part-no.<br />

Part-no.<br />

A mm 7,2 8,50 9,50 17,35 28,85 50<br />

B mm M6 M8 M10 M16 M20 M36<br />

C mm 15 25 25 44 50 40<br />

D mm 9 12,05 15 22,5 31 65<br />

E mm 15 20 23 45 63 125<br />

m mm 0,5 1,00 2,50 2,50 2,50 7<br />

to mm 1,5708 3,1416 7,8540 7,8540 7,8540 21,9911<br />

rack<br />

standard 12-39-00 12-40-00 12-41-00 12-43-00 12-45-00 12-47-00<br />

rack<br />

special --- 12-40-01 12-41-01 12-43-01 12-45-01 12-47-01<br />

weight kg/m 1,37 2,10 3,10 10,40 22,20 75,20<br />

Note for ordering: Always add the number of teeth to the item reference no. by Z =<br />

Example: Rack for lifgo 4.1, length 162,85 mm > 12-41-00, Z = 21.<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 3<br />

3.2 Gear tooth rack, guide rail and Accessories<br />

Types lifgo ® 3.9 – 4.7<br />

i<br />

i<br />

i<br />

3.2.2 Gear tooth rack calculation of length<br />

Racks are manufactured in length’s according to your application. These should be identical within a<br />

given system. Ascertain the required length by calculating the number of teeth „Z“. This must be<br />

added to the item reference number of ordering purposes.<br />

Proceed as follows:<br />

Firstly, the theoretical number of teeth „Zt“ of the rack is determined. The values, i.e. the length of<br />

lifgo casing(s), the required stroke, the installation space for protective rack cover and, if needed, the<br />

installation space for any attachments are entered into „equation 2”<br />

Round up the value to the next full number.<br />

The actual length of the rack „Xi“ is determined by „equation 3”.<br />

Calculation:<br />

Zt - theoretical number of teeth GL - length of lifgo casing (s)<br />

Herf- required stroke LZS - Installation space for protect. rack cover<br />

K1 - constant = 5 t0 - tooth pitch = (1,5708; 3,1416; 7,8540; 21,9911)<br />

Z - actual number of teeth B - Installation space according to drawing plan of the<br />

System<br />

Xi - actual length of rack BS - Installation space for the lubrication plate<br />

TS - Installation space of rack<br />

Please Note: Round up this value to the next full number.<br />

Equation 2<br />

Zt = (GL + Herf + LZS + B + BS + TS + K1) : t 0 = > round up to a whole number = Z number of teeth<br />

Equation 3<br />

X i = Z x t0 = mm<br />

Example:<br />

A system containing lifgo 4.1 should allow for a stroke of 120 mm. The rack must traverse a beam<br />

having a depth of 50 mm. A protective rack cover is not provide. Z = ?, X i = ?<br />

Zt = (107,2 + 120 + 0 + 50 + 0 + 0 + 5) : 7,8540 = 35,93 > Z = 36 qty. off<br />

Result: Rack with 36 teeth. > Part No. 12-41-00, Z = 36<br />

Xi = 36 x 7,8540 = 282,744 mm<br />

Result: Total length of rack 282,7 mm.<br />

Please Note: Refer to chapter 3, sections 3.2.6, equation 4 and 5 for calculation the installation<br />

space for the protective rack cover (L ZS).<br />

When using, please take into account the installation space required for the lubrication<br />

plate (Bs), chapter 5, sections 5.1.11 and the AZ mounting plate (Ts), chapter 3,<br />

sections 3.2.4, when calculating the toothed rack.<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 3<br />

3.2 Gear tooth rack, guide rail and Accessories<br />

Types lifgo ® 3.9 – 4.7<br />

i<br />

i<br />

3.2.3 Lateral load capacity - rack drives<br />

The rack profiles for lifgo lifters are fully supported in linear bearings. As a consequence, the rack<br />

profiles can accommodate high lateral loads. The maximum static and dynamic torque (X, Y and Z<br />

axis) for each size of lifgo unit is shown in the table below.<br />

50% of the linear force rating can be applied at a distance of 100 mm from the lifgo unit!<br />

Check your complete Force Rate, this must not be exceeded under any circumstances.<br />

F x 0,5<br />

100<br />

Y Y<br />

Z<br />

Z<br />

lifgo ® Unit 3.9 4.0 4.1 4.3 4.5 4.7<br />

M ty = M tz dyn. Nm 30 100 270 1.300 4.600 57.000<br />

M ty = M tz stat. Nm 70 165 510 2.430 8.100 99.140<br />

M tx = dyn. Nm 55 190 330 1.800 6.400 72.400<br />

M tx = stat. Nm 130 310 650 3.450 11.400 125.400<br />

Please Note: Should you need to calculate the bending distance of the rack ends, please contact<br />

our technical sales office.<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com<br />

X<br />

X

Chapter 3<br />

3.2 Gear tooth rack, guide rail and Accessories<br />

Types lifgo ® 3.9 – 4.7<br />

i<br />

3.2.4 Rack Attachment Points<br />

1. Attachment points on end face and sides<br />

with holes for dowel pins and/or holes for<br />

screws.<br />

2. Attachment points on sides and end face.<br />

3. AZ mounting plate set, consisting of:<br />

� Upper welded and fastening plate<br />

� Lower fastening plate with rack-shaped<br />

seat ensuring that the rack is secured<br />

(interlocking) without twisting and tilting<br />

4. AZ mounting plate set (as in 3, above) with<br />

additional fully enclosed rack cover<br />

(bellows). The bellows fastening plate can<br />

be screwed to the AZ mounting plate from<br />

below (see hole J).<br />

Mounting plate with toothed rack profile Upper welded and fastening plate<br />

AZ-Mounting<br />

Plate<br />

Unit 3.9 4.0 4.1 4.3 4.5 4.7<br />

A mm 50 50 60 120 170 ----<br />

B mm 50 50 70 136 170 ----<br />

C mm 50 50 60 136 170 ----<br />

D mm 38 30 45 79 120 ----<br />

E mm 30 38 42 79 120 ----<br />

F mm 24,5 32,4 38,2 70 100 ----<br />

G mm 8,7 10,5 9,2 17 5,5 ----<br />

I mm M4 M4 M8 M10 M16 ----<br />

J mm M3 M3 M3 M4 M4 ----<br />

K mm Ø4H7 Ø6H7 Ø6H7 Ø6H7 Ø6H7 ----<br />

T mm 10 10 10 15 20 ----<br />

Part-no.<br />

Mounting<br />

Plate Set 16-39-50 16-40-50 16-41-50 16-43-50 16-45-50 ---weight<br />

kg 0,350 0,320 0,480 3,400 8,080 ----<br />

Part-no.<br />

Mounting<br />

Plate Rack 16-39-51 16-40-51 16-41-51 16-43-51 16-45-51 ---weight<br />

kg 0,170 0,150 0,250 1,630 3,900 ----<br />

Please Note: Including fastening materials.<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com<br />

4<br />

3<br />

2<br />

1

Chapter 3<br />

3.2 Gear tooth rack, guide rail and Accessories<br />

Types lifgo ® 3.9 – 4.7<br />

i<br />

i<br />

i<br />

3.2.5 Rack cover specification<br />

In case of high levels of pollution and welding plants, the use of protective rack covers is essential.<br />

Rack guides and casings are thus protected from excessive wear. Fixturing is done either using<br />

Velcro on both sides which is simply pressed onto the facing plate or the Velcro is on one side only<br />

(the lifgo side) and is complemented with a plate on the rack side. Please be sure to take into<br />

account the installation space required, see chapter 3, section 3.2.6.<br />

Please Note: In order to pre-empt the failure of the Velcro fastenings in the case of extreme<br />

contamination (e.g. grease) the bellows fastening should be used.<br />

Fitting and removal can be done in a matter of seconds. The individual folds of the rack cover are<br />

guided over the rack gear by specially shaped intermediate plates. This ensures that a blockage<br />

caused by obstruction of the gearing cannot occur.<br />

The rack cover is supplied according to your requirements . Please state the length, defined by the<br />

number of folds. Rack cover supplied as an assembly unit, including screws. Calculation chapter 3,<br />

sections 3.2.6, Equation 4 and 5.<br />

Important Note: Ambient temperature max. 80° C.<br />

lifgo ® Unit 3.9 4.0 4.1 4.3 4.5 4.7<br />

A mm 45 46 48 85 120 ---<br />

B1 mm 50 43 50 80 118 ---<br />

(Velcro) C1 mm 10 10 10 11 13 ---<br />

(Plate) C2 mm 8 8 8 8 9 ---<br />

a mm 3,5 3,0 3,0 3,0 3,0 ---<br />

c mm 19,5 13 13 18 40 ---<br />

Part-no. Fully<br />

Velcro / Plate 12-39-20 12-40-20 12-41-20 12-43-20 12-45-20 On Inquiry<br />

Part-no. Fully<br />

Velcro / Velcro 12-39-21 12-40-21 12-41-21 12-43-21 12-45-21 On Inquiry<br />

Part-no. Velcro<br />

fastening 12-39-29 12-40-29 12-41-29 12-43-29 12-45-29 On Inquiry<br />

Note for ordering: Including fastening materials<br />

Please add the number of folds to the item ref. number when ordering by F=.<br />

Example: Expansion bellows, full protection for lifgo 4.1, length 57 mm > 12-41-20, F=13<br />

Please Note: During the design phase, please ensure that the lubrication holes remain accessible!<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 3<br />

3.2 Gear tooth rack, guide rail and Accessories<br />

Types lifgo ® 3.9 – 4.7<br />

i<br />

i<br />

i<br />

i<br />

3.2.6 Rack cover calculation of length<br />

Rack covers are manufactured according to your applications. These should be identical within a<br />

given system. Ascertain the required length by calculating the number of folds „F“. The must be<br />

added to the item reference number for ordering purposes. Two versions, (depending on the model)<br />

are calculated in the same manner.<br />

Proceed as follows:<br />

Firstly, the theoretical number of folds „F“ of the cover is determined. The values, i.e. required stroke<br />

or the extended length of the rack, are entered into „equation 5“.<br />

Calculation:<br />

F t - theoretical number of fold a - installation length - min. per fold<br />

H erf - required stroke b (c-a) - extended length - max. per fold<br />

C1 + C2 - installation space c - draw-out length over all<br />

for Velcro fastener pads (Velcro/Plate)<br />

C1 + C1 - installation space<br />

for Velcro fastener pads (Velcro/Velcro)<br />

Please Note: Round up this value to the next full number.<br />

Equation 4<br />

F t = H erf : b = > round up to whole number = F[qty. off]<br />

Equation 5<br />

L ZS = F x a + C1 + C2 = mm<br />

Please Note: If, for design reasons, the lifter has to be installed to a greater depth than the length<br />

of the standard rack permits for effective operation, then the length of the rack must be manufactured<br />

correspondingly longer. This longer rack length can also be calculated by applying equation 3.<br />

However, if after calculating „L ZS“, it is found to be less than the extra depth involved, the rack need<br />

not be lengthened, and a standard rack would be still surface.<br />

Example:<br />

A system containing lifgo 4.1 should allow for a stroke of 130 mm. The rack cover should be used as<br />

a fully enclosed cover to ensure full protection. > F = ?, L ZS = ?<br />

F t = 130 mm : 10 = 13 > F = 13 qty. off<br />

Result: Rack cover with 13 folds Part No. 12-41-20, F = 13<br />

L ZS = 13 x 3,0 + 10 + 8 = 57 mm<br />

Result: The installation length of rack cover is 57 mm.<br />

Please Note: Length L ZS must be used in „equation 2“, chapter 3, sections 3.2.2. If two covers are<br />

provided for each rack, insert L ZS x 2 into the equation.<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 3<br />

3.2 Gear tooth rack, guide rail and Accessories<br />

Types lifgo ® 3.9 – 4.7<br />

3.2.7 Guide rail (without rack profile)<br />

Version: 01/2007<br />

Note: „n“= Qty. of hole<br />

Guide rail Unit 3.9 4.0 4.1 4.3 4.5 4.7<br />

A mm 16,20 20,55 24,25 39,85 ---- ----<br />

B mm 15 20 23 45 ---- ----<br />

C mm 4,4 6,0 7,0 14 ---- ----<br />

D mm 7,4 9,4 11,0 20 ---- ----<br />

E mm 5,9 7,4 9,1 16,4 ---- ----<br />

F mm M5 M6 M6 M12 ---- ----<br />

G mm 7,5 9,0 12,0 19,0 ---- ----<br />

H mm 10 10 10 16 ---- ----<br />

I mm 60 60 60 105 ---- ----<br />

Part-no.<br />

for mounting<br />

from above rail 12-39-08 12-40-08 12-41-08 12-43-08 12-45-08 12-47-08<br />

for mounting<br />

from below rail 12-39-09 12-40-09 12-41-09 12-43-09 12-45-09 12-47-09<br />

according to<br />

customer’s<br />

specification rail 12-39-05 12-40-05 12-41-05 12-43-05 12-45-05 12-47-05<br />

weight kg/m 1,4 2,2 3,2 10,6 22,4 75,6<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 3<br />

3.2 Gear tooth rack, guide rail and Accessories<br />

Types lifgo ® 3.9 – 4.7<br />

i<br />

3.2.8 Rack guiding<br />

Rack guiding Unit 3.9 4.0 4.1 4.3 4.5 4.7<br />

A mm 59 78 107,2 175,2 ---- ----<br />

B mm 47 63 70 120 ---- ----<br />

C mm 24 30 36 60 ---- ----<br />

D mm 19,65 25 30 50 ---- ----<br />

E mm 24,55 32,4 38,2 70,0 ---- ----<br />

F mm 15 20 42 79 ---- ----<br />

G mm 38 50 45 79 ---- ----<br />

ØH mm 4 X 4 6 X 9 6 X 9 6 X 9 ---- ----<br />

I mm M5 X 6 M5 X 10 M8 X 10 M10 X 17 ---- ----<br />

(lubrication hole) W mm TN/TN TN/TN M6/TN M6/TN ---- ----<br />

Part-no. Standard 10-02-39 10-02-40 10-02-41 10-02-43 10-02-45 10-02-47<br />

weight kg 0,20 0,45 1,00 4,80 16,20 ---<br />

Please Note: Tolerance band precision / interference holes ± 0,03<br />

Cone nipple (TN)<br />

During the design phase, please ensure that the lubrication holes remain<br />

accessible!<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 3<br />

3.3 Line of lifgo ® linear 4.1 – 4.3<br />

i<br />

3.3.1 Technical specification of the models<br />

lifgo ® linear Unit 4.1 4.3<br />

a x b x c mm 107 x 70 x 88,95 175 x 120 x 132,15<br />

Casing bearing force N 8.000 17.000<br />

1) Force of stroke max. N 3.500 12.000<br />

Acceleration max. m/s² 10 10<br />

Speed of stroke m/s 2 2<br />

Speed of stroke m/min. 120 120<br />

Torque max. Nm 70 360<br />

Pitch circle diameter mm 40 60<br />

Gearing mm/α-1° mm 0,349 0,524<br />

Gearing stroke/360° mm 125,66 188,49<br />

Temperature resistance °C 80 80<br />

Efficiency 1 0,92 0,92<br />

Profile shaft -<br />

„clip and go ® “ joint<br />

PG 20<br />

Polygonal<br />

Version: 01/2007<br />

KW 42<br />

spline shaft<br />

Weight kg 3 12<br />

1) Values given for max. acceleration a = m/s². Chapter 3, sections 3.1.2, heed FMA calculation.<br />

Please Note: An estimation of the service life in connection with the rack gear should be requested<br />

as per the project data.!<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 3<br />

3.3 Line of lifgo ® linear 4.1 – 4.3<br />

i<br />

3.3.2 linear unit specification<br />

lifgo ® linear Unit 4.1 4.3<br />

A mm 88,95 132,15<br />

B mm 107 175<br />

C mm 70 120<br />

D mm 90 135<br />

E mm 45 79<br />

F mm 42 79<br />

G mm 48,15 67,65<br />

H mm Ø 60 90<br />

Ø I x P mm Ø 47 K6 tief 1,5 72 K6 tief 2<br />

J mm M 8x13 M 10x20<br />

Dowel hole K mm Ø 6x9 6x9<br />

L mm M 6x6 M 10x20<br />

M mm 27,95 36,15<br />

N mm 44 --<br />

O mm 53 --<br />

Q mm M10x1 (both side) M10x1 (both side)<br />

S<br />

W<br />

V<br />

mm<br />

mm<br />

mm<br />

43,95<br />

--<br />

2xM10x1 (one side)<br />

90,15<br />

1)<br />

M6/TN<br />

--<br />

Part-no. Standard 41-090-100 43-132-160<br />

weight kg 3 12<br />

Please Note: Tolerance band precision/ interference hole ± 0,02<br />

1) Front side threaded/opposite side lubrication nipple<br />

During the design phase, please ensure that the lubrication holes remain<br />

accessible!<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 3<br />

3.3 Line of lifgo ® linear 4.1 – 4.3<br />

i<br />

3.3.3 VEAS (Vertical Energy Arrest System)<br />

This mechanical arrest system for the model types listed above includes the following features:<br />

- Precise interlocking interface, robust, designed for every module dependent position.<br />

- Prevents uncontrolled downward travel should the power fail<br />

The VEAS is used to move the system to a “maintenance and repair” position and secure it in this<br />

position. It is also used to lock the system in a particular access position. This is done by first<br />

releasing the pneumatic cylinder; the vertical drive then initiates downward travel at creep speed until<br />

the locking bolt of the VEAS slides into place.<br />

The system is now “mechanically secured”. Maintenance staff can now safely access the area. In<br />

order to release the locked system, the solenoid is energised and the VEAS is lifted 2xto at creep<br />

speed working against the load. The system is now released.<br />

The VEAS mechanism can also be used to prevent uncontrolled downward motion in the system in<br />

the event of a power failure..<br />

Exploded drawing, Refer to chapter 3, sections 3.1.6<br />

Important: VEAS is not a brake with which an EMERGENCY STOP can be carried out. VEAS<br />

should only be operated once the system has come to a halt. If the VEAS is operated while the<br />

system is in motion, then the <strong>lifgo®</strong> and the VEAS is to be immediately replaced. The VEAS locks<br />

the system in one direction only (the direction against the load). The other direction is not blocked<br />

(ratchet). Each VEAS component is designed to secure one load point only. In order to ensure<br />

correct functionalty at all times, the VEAS should be operated at least once per week. The VEAS<br />

mechanism complies with the requirements of safety class 2.<br />

lifgo ® linear Unit --- --- 4.3 VEAS --- ---<br />

Casing bearing force N --- --- 17.000 --- ---<br />

Force of stroke max N --- --- 12.000 --- ---<br />

Part-no. --- --- 43-132-100 --- ---<br />

weight kg --- --- 12 --- ---<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 3<br />

3.3 Line of lifgo ® linear 4.1 – 4.3<br />

i<br />

i<br />

3.3.4 lifgo linear VEAS unit specification<br />

Please Note: For dimensions not given here, please see chapter 3, page 3.3.2<br />

lifgo ® linear Unit --- --- 4.3 VEAS --- ---<br />

Part-no.<br />

E mm --- --- 79 --- ---<br />

J mm --- --- M10x20 --- ---<br />

K mm --- --- Ø6H7x9 --- ---<br />

MN mm --- --- 62,5 --- ---<br />

Q mm --- --- M10x1 --- ---<br />

R mm --- --- 58 --- ---<br />

S mm --- --- 36 --- ---<br />

T mm --- --- 70 --- ---<br />

U mm --- --- 58 --- ---<br />

V mm --- --- 37,5 --- ---<br />

X mm --- --- 42,5 --- ---<br />

Y mm --- --- 45 --- ---<br />

Z mm --- --- 20 --- ---<br />

pneumatic cylinder<br />

version --- On Inquiry 43-132-101 --- ---<br />

weight kg --- --- 12 --- ---<br />

Please Note: During the design phase, please ensure that the lubrication holes remain accessible!<br />

An estimation of the service life in connection with the rack gear should be<br />

requested as per the project data!<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 3<br />

3.4 Gear tooth rack, guide rail and Accessories<br />

Line of lifgo ® linear 4.1 – 4.3<br />

i<br />

i<br />

i<br />

3.4.1 linear gear tooth rack specification<br />

The gear teeth rack of the Lifgo® Linear in combination with the drive pinion converts rotary motion<br />

to a push-pull linear motion, or equally linear motion to rotary motion. The Lifgo® Linear rack drive<br />

with profiled ‘plug-in’ drive shaft can achieve a repeatability of +/-0.01mm. The profiled rack is<br />

guided all round by four recirculating ball bearing assemblies and is able to accommodate very high<br />

lateral forces. For this reason the profiled rack can be used as both drive and guide element<br />

avoiding the need for further components.<br />

The mounting face of the Lifgo® Linear rack is provided with tapped holes for assembly to base<br />

frame. Our recommended minimum finish: machined surfaces. Where two Lifgo® Linear rack<br />

rails are used with two drive units (or 4 etc) the linear thrust force is doubled (or quadrupled).<br />

Please Note: A special rack gear is used for particularly demanding, constant operation with high<br />

cycle rates in three shifts. Please be sure to request a calculation of service life. This model is<br />

available in lengths of up to 1,500 mm.<br />

The rack gear is manufactured to your specific requirements. Please define the length by stating<br />

the number of gear teeth. Please note that the rack gear is always divided (to) in a trough of the<br />

gearing. For lengths exceeding 509 gear teeth (3,998mm) the rack gear will be delivered in two or<br />

more parts.<br />

lifgo ® linear Unit 4.1 4.3<br />

A mm 24,25 39,85<br />

B mm 23 45<br />

C mm 12 19<br />

D mm M8 M12<br />

E mm 18,25 37,31 R – R distance radius centre<br />

H mm 10 16<br />

I mm 60 105<br />

R mm 0,40 0,50<br />

Modul mm 2,50 2,50<br />

to mm 7,854 7,854<br />

Part-no.<br />

Part-no.<br />

Rack<br />

Standard 12-41-02 12-43-02<br />

Rack<br />

Sonder 12-41-03 12-43-03<br />

weight kg/m 3,1 10,4<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 3<br />

3.4 Gear tooth rack, guide rail and Accessories<br />

Line of lifgo ® linear 4.1 – 4.3<br />

i<br />

3.4.2 linear Rack guiding<br />

Rack guiding Unit 4.1 4.3<br />

A mm 107 175<br />

B mm 70 120<br />

C mm 31,05 52,85<br />

D mm 30 50<br />

E mm 38 70<br />

F mm 42 79<br />

G mm 45 79<br />

ØH mm 6 X 9 6 X 9<br />

I mm M8 X 9 M10 X 17<br />

J<br />

K<br />

Lubrication hole W<br />

Lubrication hole V<br />

mm<br />

mm<br />

mm<br />

mm<br />

--<br />

21,4<br />

--<br />

M6 (both side)<br />

8<br />

--<br />

1)<br />

M6/TN<br />

--<br />

Part-no. Standard 10-41-33 10-43-33<br />

weight kg 1,00 4,80<br />

Please Note: Tolerance band precision / interference holes ± 0,03<br />

1) Front side threaded/opposite side lubrication nipple (TN)<br />

During the design phase, please ensure that the lubrication holes remain<br />

accessible!!<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com<br />

i<br />

Please Note:<br />

A suitable guide rail is to be<br />

found in chapter 3, section<br />

3.2.7, version: “screwed in<br />

place from above”

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Version: 01/2007<br />

Chapter 4<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com<br />

Types<br />

Schlüter-<strong>Lifter</strong> ® SL<br />

Technical Data<br />

Gear tooth rack and Accessories

Chapter 4<br />

4.1 Line of Schlüter-<strong>Lifter</strong> ® SL<br />

i<br />

4.1.1 Technical Data<br />

Schlüter-<strong>Lifter</strong> ® SL Unit SL 050 SL 150<br />

Casing bearing force N 4.000 10.000<br />

Force of stroke N 500 1.500<br />

Speed of stroke m/s 1,0 1,0<br />

Speed of stroke m/min. 60,0 60,0<br />

Torque max. Nm 5 30<br />

Pitch circle diameter mm 20 40<br />

Gearing mm/α-1° mm 0,1745 0,349<br />

Gearing stroke/360° mm 62,83 125,66<br />

Temperature resistance °C -30 bis +100 -30 bis +100<br />

Efficiency 1 0,8 0,8<br />

Profile shaft -<br />

„clip and go ® “ joint<br />

Version: 01/2007<br />

PG 14 Polygonal PG 20 Polygonal<br />

weight kg 0,6 2,0<br />

Please Note: An estimation of the service life in connection with the rack gear should be<br />

requested as per the project data!<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 4<br />

4.1 Line of Schlüter-<strong>Lifter</strong> ® SL<br />

i<br />

i<br />

4.1.2 Ascertaining the bearing force<br />

Bearing forces in the technical specification are based on the max. acceleration value a (m/s²). If<br />

you alter the rate of acceleration, then the bearing force alters too.<br />

Note Less acceleration (a= m/s²) > greater bearing force<br />

Higher acceleration (a= m/s²) > less bearing force.<br />

In the layout of the system, consider the function of the Schlüter modules as primary unit, because<br />

even here the total loading on any one lifter must not be exceeded<br />

FMA - calculation<br />

FL - Static loading [N] FZ - Static loading on rack [N]<br />

mL - Weight of lifting load [kg] mZ - Weight of rack [kg]<br />

a - Acceleration of drive [m/s²] > servo-motor, pneumatic cylinder<br />

Formula 1<br />

Lifting load - vertical FV = FL + FZ + [(mL + mZ) x a] + 20 N x 1,08 = [N]<br />

Lifting load - horizontal FH = [(mL + mZ) x a] + 20 N x 1,08 = [N]<br />

4.1.3 Technical specification - accessories<br />

In arranging the layout, the technical scope of the accessories in terms of application is to be taken<br />

into account. All components which transmit forces for drawing or pushing or transmit moments of<br />

torque can be found in the following table. The data given correspond to the maximum values and<br />

must not be exceeded. They relate to the tabulated values of chapter 4, sections 4.1.1<br />

Schlüter ® SL Unit SL 050 SL 150<br />

Profile shaft Nm 25 110<br />

Straightness mm/m 0,3 0,3<br />

Torsional movement °/m 1 1<br />

Rack buckling length mm 0,04 0,1<br />

Profile shaft backlash mm 0,100 0,085<br />

Differential-coupling<br />

No./ force vectors Stück 7 9<br />

Coupling unit<br />

Pushing/pulling force F N 18.000 24.000<br />

Please Note: The wear on the slide bearing is 0.01mm/km at a torque of 0 Nm and with no<br />

additional radial forces bearing on the rack gear!<br />

An estimation of the service life in connection with the rack gear should be<br />

requested as per the project data!<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 4<br />

4.1 Line of Schlüter-<strong>Lifter</strong> ® SL<br />

i<br />

4.1.4 Lateral load capacity - rack drives<br />

The Schlüter ® SL rack gears are mounted in sliding bearings. Bearing wear is 0.01mm/km at a<br />

torque of 0 Nm and with no additional radial forces acting on the rack gear:<br />

max. slide bearing wear SL 050 ≤ 0.5 mm SL 150 ≤ 1.0 mm<br />

The moments of the rack gear guides (x, y and z) are shown in the table below.<br />

Schlüter ® SL Unit SL 050 SL 150<br />

M tx = dyn. Nm 0 0<br />

M tx = stat. Nm 0 0<br />

M ty = dyn. Nm 45 100<br />

M ty = stat. Nm 500 1000<br />

M tz = dyn. Nm 20 35<br />

M tz = stat. Nm 200 400<br />

Please Note: Should you need to calculate the bending distance of the rack ends, please contact<br />

our technical sales office.<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 4<br />

4.1 Line of Schlüter-<strong>Lifter</strong> ® SL<br />

i<br />

4.1.5 Unit specification<br />

Schlüter ® SL Unit SL 050 SL 150<br />

A mm 75 110<br />

B mm 75 110<br />

C mm 50 70<br />

D mm 56,5 87,5<br />

E mm 36 50<br />

F mm 60 90<br />

G mm 60 90<br />

H mm 37,5 55<br />

I mm 31,5 55<br />

Dowel hole J mm Ø 6 x 10 6 x 10<br />

K mm Ø 7 9<br />

L mm Ø 26 K 6 47 K 6<br />

M mm 2 2<br />

N mm M10 x 1 M10 x 1<br />

Part-no. Standard SL 050 SL 150<br />

weight kg 0,6 2,0<br />

Hinweis: Tolerance band precision / interference holes ± 0,03<br />

Front side threaded<br />

During the design phase, please ensure that the lubrication holes remain<br />

accessible!<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 4<br />

4.2 Gear tooth rack and Accessories<br />

Type Schlüter-<strong>Lifter</strong> ® SL<br />

i<br />

i<br />

4.2.1 Gear tooth rack specification<br />

The rack is used as a pull or push action rack and, at the same time, convents linear motion into<br />

rotary (angular) motion. It is also possible to effect the action in reserve.<br />

Threads are provided at the ends, which are for attaching accessories, i.e. a differential couplings, a<br />

coupling unit (for pneumatic cylinder) or a heavy duty coupling, for effecting an interface for pulling or<br />

pushing actions. In addition. The threads are used for accepting attachments, e.g. devices, which<br />

can be directly mounted.<br />

The rack is supplied in lengths in accordance with your requirement. Please state the length,<br />

defined by the number or teeth. Refer to chapter 3, sections 3.2.2, Equation 2 and 3.<br />

Schlüter ® SL Unit SL 050 SL 150<br />

A mmØ 20 30<br />

B mm M8 M10<br />

C mm 20 20<br />

to mm 3,1416 7,8540<br />

Part-no. Rack ZA 050 /.. ZA 150 /..<br />

weight kg/m 2,3 5,1<br />

Note for ordering: Always add the number of teeth to the item reference no. by Z =<br />

Example: Rack for Schlüter ® SL 050, length 162,85 mm > ZA 050, Z = 52.<br />

Version: 01/2007<br />

�LEANTECHNIK AG, Im Lipperfeld 7c D - 46047 Oberhausen , �..49 (0) 208 - 49 52 5 - 0, Fax -18 www.leantechnik.com info@leantechnik.com

Chapter 4<br />

4.2 Gear tooth rack and Accessories<br />

Type Schlüter-<strong>Lifter</strong> ® SL<br />

4.2.2 Rack Covers<br />

It is necessary to fit rack covers if operating in a dirty environment. This will ensure that guide blocks<br />

and casings are protected against high rates of wear. When installed vertically, the spiral covers are<br />

fitted with the end with the largest diameter at the top; if installed horizontally, the end with the<br />

largest diameter is fitted in the direction in which the swarf is ejected. The way in which the individual<br />

spiral windings overlap ensures that they are self-cleaning.<br />

These Schlüter ® SL rack component covers are manufactured for each customer individually.<br />

Please contact us at an early stage so that we can determine your requirements.<br />

i<br />

i<br />

Installation:<br />

Secure the Schlüter ® SL, push the rack inside and<br />

position it. Place the rack cover while still closed over the<br />

rack and on to the base flange, with the narrow end<br />

down. Place the retaining flange on to the rack and<br />

secure it against the matching component opposite.<br />

Set the shortest length of rack travel possible. Check that<br />

the rack cover is properly seated on the base flange.<br />

Release the rack cover as described in the installation<br />

guide. The rack cover will spring open and will<br />

automatically take up the correct position inside the<br />

retaining flange.<br />