BL-4500 Bladder Lamination System

BL-4500 Bladder Lamination System

BL-4500 Bladder Lamination System

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PTC<br />

<strong>BL</strong>-<strong>4500</strong><br />

<strong>Bladder</strong> <strong>Lamination</strong> <strong>System</strong><br />

P a c i f i c T r i n e t i c s C o r p o r a t i o n<br />

� High Temperature <strong>Lamination</strong>...<br />

Up to 120º C.<br />

� Variable <strong>Lamination</strong> Pressure...<br />

Up to 5,000 psi.<br />

� Isostatic <strong>Lamination</strong> Qualities...<br />

Without Bagging Parts.<br />

� Programmable Parameters...<br />

PLC Controller.<br />

� Optional Automatic Loading/Unloading...<br />

Cassette to Cassette<br />

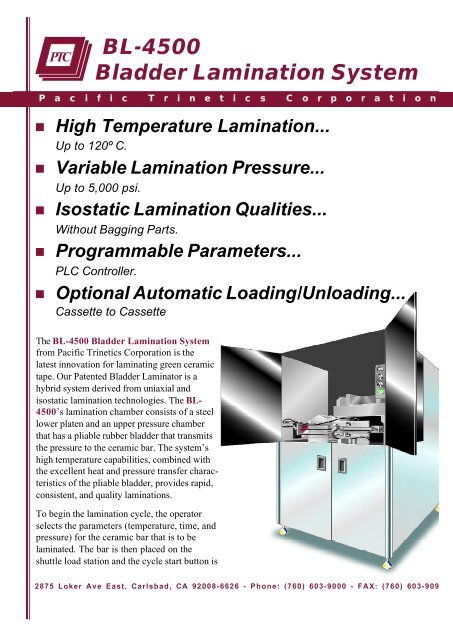

The <strong>BL</strong>-<strong>4500</strong> <strong>Bladder</strong> <strong>Lamination</strong> <strong>System</strong><br />

from Pacific Trinetics Corporation is the<br />

latest innovation for laminating green ceramic<br />

tape. Our Patented <strong>Bladder</strong> Laminator is a<br />

hybrid system derived from uniaxial and<br />

isostatic lamination technologies. The <strong>BL</strong>-<br />

<strong>4500</strong>’s lamination chamber consists of a steel<br />

lower platen and an upper pressure chamber<br />

that has a pliable rubber bladder that transmits<br />

the pressure to the ceramic bar. The system’s<br />

high temperature capabilities, combined with<br />

the excellent heat and pressure transfer characteristics<br />

of the pliable bladder, provides rapid,<br />

consistent, and quality laminations.<br />

To begin the lamination cycle, the operator<br />

selects the parameters (temperature, time, and<br />

pressure) for the ceramic bar that is to be<br />

laminated. The bar is then placed on the<br />

shuttle load station and the cycle start button is<br />

2875 Loker Ave East, Carlsbad, CA 92008-6626 - Phone: (760) 603-9000 - FAX: (760) 603-9090

<strong>BL</strong>-<strong>4500</strong><br />

<strong>Bladder</strong> <strong>Lamination</strong> <strong>System</strong><br />

P a c i f i c T r i n e t i c s C o r p o r a t i o n<br />

activated. The bar is shuttled onto the heated lower<br />

platen, the upper pressure chamber descends, a<br />

vacuum is drawn in the lamination cavity, and the<br />

heated oil is injected behind the bladder at the selected<br />

pressure. When the lamination cycle has timed out, the<br />

Specifications<br />

US Patent :<br />

<strong>Lamination</strong> Type :<br />

<strong>Lamination</strong> Pressure :<br />

<strong>Lamination</strong> Preheat :<br />

<strong>Lamination</strong> Time :<br />

<strong>Lamination</strong> Controller :<br />

Heater :<br />

Heater Temp. Control :<br />

Max. Part Thickness :<br />

Vacuum :<br />

Build-up Plate :<br />

Facility Requirements<br />

Electrical:<br />

Air:<br />

Height:<br />

Width:<br />

Depth:<br />

Weight:<br />

5,722,838 & 4,636,275<br />

Pliable Rubber <strong>Bladder</strong> Filled<br />

with Hot Oil<br />

Up to 5,000 psi<br />

5,000 psi - 5.5” x 5.5” Parts<br />

3,000 psi - 7” x 7” Parts<br />

1 to 30 Seconds<br />

Programmable<br />

PLC<br />

On Top & Bottom Platens<br />

Independent on Top &<br />

Bottom (0 to 120 Degrees C)<br />

0.125” (3.175mm)<br />

Continuous Vacuum Drawn<br />

During <strong>Lamination</strong> Cycle<br />

5.5” x 5.5 ” (140mm x<br />

140mm) to 7” x 7” (178mm x<br />

178mm) Precision Flat Steel<br />

220V, 20 amps, 50/60 Hz<br />

100 psi (5 cfm)<br />

72” (1829mm)<br />

56” (1423mm)<br />

60” (1524mm)<br />

3,400 lbs (1,546 kgs)<br />

Approximately<br />

(These specifications are preliminary and subject<br />

to change without notice.)<br />

upper platen ascends and the bar is automatically<br />

shuttled back to the unload station. This<br />

results in a lamination similar to isostatic,<br />

however, without the vacuum bagging and water<br />

related issues.<br />

The <strong>BL</strong>-<strong>4500</strong> is completely enclosed providing<br />

total operator safety. The system’s controls are<br />

simple and user friendly. All lamination functions<br />

are controlled by a Programmable Logic<br />

Controller (PLC). The optional automatic<br />

cassette-to-cassette load/unload system provides<br />

total automated parts handling of up to ten<br />

ceramic bars per cassette. This eliminates the<br />

need for continuous operator intervention,<br />

resulting in lower production cost.<br />

The <strong>BL</strong>-<strong>4500</strong> provides a quick, safe, and technically<br />

proven method for laminating green<br />

ceramic. Users of the bladder lamination<br />

process will benefit from higher production<br />

levels, higher yields, and lower labor cost. The<br />

<strong>BL</strong>-<strong>4500</strong>, another innovation from Pacific<br />

Trinetics Corporation, an industry leader in<br />

equipment for processing green ceramic tape.<br />

Pacific Trinetics Corporation<br />

2875 Loker Ave East<br />

Carlsbad, CA 92008<br />

Phone: (760) 603-9000<br />

Fax: (760) 603-9090<br />

www.PTChips.com<br />

PTC<br />

P a c i f i c T r i n e t i c s C o r p o r a t i o n