Juratek believe in continuous improvement in all aspects of our ...

Juratek believe in continuous improvement in all aspects of our ...

Juratek believe in continuous improvement in all aspects of our ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

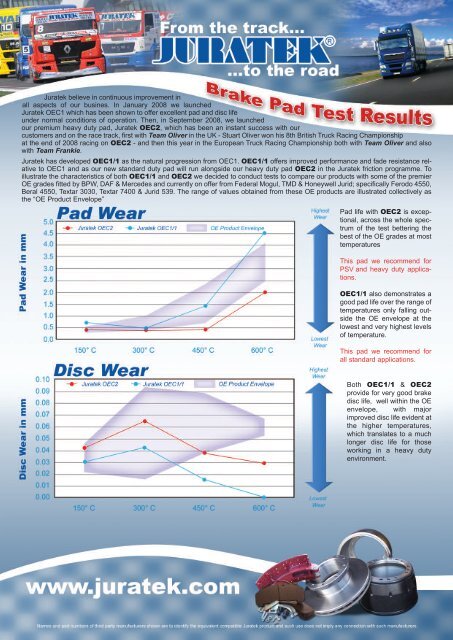

<strong>Juratek</strong> <strong>believe</strong> <strong>in</strong> cont<strong>in</strong>uous <strong>improvement</strong> <strong>in</strong><br />

<strong>all</strong> <strong>aspects</strong> <strong>of</strong> <strong>our</strong> bus<strong>in</strong>es. In January 2008 we launched<br />

<strong>Juratek</strong> OEC1 which has been shown to <strong>of</strong>fer excellent pad and disc life<br />

under normal conditions <strong>of</strong> operation. Then, <strong>in</strong> September 2008, we launched<br />

<strong>our</strong> premium heavy duty pad, <strong>Juratek</strong> OEC2, which has been an <strong>in</strong>stant success with <strong>our</strong><br />

customers and on the race track, first with Team Oliver <strong>in</strong> the UK - Stuart Oliver won his 8th British Truck Rac<strong>in</strong>g Championship<br />

at the end <strong>of</strong> 2008 rac<strong>in</strong>g on OEC2 - and then this year <strong>in</strong> the European Truck Rac<strong>in</strong>g Championship both with Team Oliver and also<br />

with Team Frankie.<br />

<strong>Juratek</strong> has developed OEC1/1 as the natural progression from OEC1. OEC1/1 <strong>of</strong>fers improved performance and fade resistance relative<br />

to OEC1 and as <strong>our</strong> new standard duty pad will run alongside <strong>our</strong> heavy duty pad OEC2 <strong>in</strong> the <strong>Juratek</strong> friction programme. To<br />

illustrate the characteristics <strong>of</strong> both OEC1/1 and OEC2 we decided to conduct tests to compare <strong>our</strong> products with some <strong>of</strong> the premier<br />

OE grades fitted by BPW, DAF & Mercedes and currently on <strong>of</strong>fer from Federal Mogul, TMD & Honeywell Jurid; specific<strong>all</strong>y Ferodo 4550,<br />

Beral 4550, Textar 3030, Textar 7400 & Jurid 539. The range <strong>of</strong> values obta<strong>in</strong>ed from these OE products are illustrated collectively as<br />

the “OE Product Envelope”<br />

Pad life with OEC2 is exceptional,<br />

across the whole spectrum<br />

<strong>of</strong> the test better<strong>in</strong>g the<br />

best <strong>of</strong> the OE grades at most<br />

temperatures<br />

This pad we recommend for<br />

PSV and heavy duty applications.<br />

OEC1/1 also demonstrates a<br />

good pad life over the range <strong>of</strong><br />

temperatures only f<strong>all</strong><strong>in</strong>g outside<br />

the OE envelope at the<br />

lowest and very highest levels<br />

<strong>of</strong> temperature.<br />

This pad we recommend for<br />

<strong>all</strong> standard applications.<br />

Both OEC1/1 & OEC2<br />

provide for very good brake<br />

disc life, well with<strong>in</strong> the OE<br />

envelope, with major<br />

improved disc life evident at<br />

the higher temperatures,<br />

which translates to a much<br />

longer disc life for those<br />

work<strong>in</strong>g <strong>in</strong> a heavy duty<br />

environment.

These tests were conducted on <strong>our</strong> behalf by Brake Test<strong>in</strong>g International (BTI) - a completely<br />

<strong>in</strong>dependent Government accredited (VCA, RDW etc) test<strong>in</strong>g authority us<strong>in</strong>g a<br />

Knorr Bremse SB7000 brake c<strong>all</strong>iper and discs at 10 tonne axle loads. The range <strong>of</strong> values<br />

obta<strong>in</strong>ed from the OE products we tested are illustrated collectively as the "OE<br />

Product Envelope"<br />

The stopp<strong>in</strong>g power <strong>of</strong> <strong>all</strong><br />

grades was compared at 40,<br />

60, 80, 100 & 120kph to<br />

check both the absolute level<br />

<strong>of</strong> stopp<strong>in</strong>g power at these<br />

speeds and the variation that<br />

occurs with <strong>in</strong>creas<strong>in</strong>g<br />

speed.<br />

As can be seen from <strong>our</strong><br />

chart OEC1/1 fits with<strong>in</strong> the<br />

envelope <strong>of</strong> performance<br />

provided by the pr<strong>in</strong>cipal OE<br />

products at <strong>all</strong> speeds.<br />

OEC2 fits <strong>in</strong> the middle <strong>of</strong><br />

the OE performance envelope<br />

with exceptional stability<br />

over the speed range, a factor<br />

detected by Stuart Oliver <strong>in</strong><br />

his races.<br />

This gives him exceptional predictability <strong>in</strong> the<br />

selection <strong>of</strong> his brak<strong>in</strong>g po<strong>in</strong>ts and brak<strong>in</strong>g efforts<br />

and <strong>all</strong>ows him to “stand the truck on its nose” no<br />

matter at what speed he is brak<strong>in</strong>g from!<br />

The fade test selected for<br />

<strong>our</strong> comparison is the ECE<br />

R13 test used to Type<br />

approve new OE vehicle<br />

brak<strong>in</strong>g systems.<br />

The fade behavi<strong>our</strong> <strong>of</strong><br />

OEC1/1 & OEC2 are similar<br />

to each other on this test<br />

with only relatively sm<strong>all</strong><br />

changes <strong>in</strong> brake pressure<br />

be<strong>in</strong>g required to ma<strong>in</strong>ta<strong>in</strong><br />

the required deceleration<br />

throughout the 20 stop test.<br />

For the majority <strong>of</strong> the test<br />

<strong>Juratek</strong> products fit with<strong>in</strong><br />

the over<strong>all</strong> envelope <strong>of</strong> fade<br />

performance displayed by<br />

the range <strong>of</strong> pr<strong>in</strong>cipal OE<br />

products tested.