download pdf version - Contractors World

download pdf version - Contractors World

download pdf version - Contractors World

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Whilst JCB's UK developed small loaders have been radial arm models, the first<br />

of the new generation machines from Savannah are all vertical lift path models. The<br />

new range will be expanded in future to embrace radial arm <strong>version</strong>s but JCB has<br />

chosen to launch the line with vertical lift path units as it states that this<br />

configuration now accounts for 70% of market volume.<br />

Compared to the radial arm arrangement, the vertical lift path configuration<br />

provides greater forward reach at maximum height. As the forks or bucket<br />

move up vertically rather than in an arc, the machine can stand closer to a<br />

vehicle it is loading.<br />

Cheaper to produce<br />

As well as having the vertical lift path design, the first of the new generation<br />

JCB small loaders score over the company's existing Series 2 designs by having<br />

less parts and being more cheaper to manufacture. They are also easier to service and will allow greater coverage<br />

in the large North American market. The company contends that, where as its eight Series 2 models could cover<br />

53% of the market, its 18 new generation units will ultimately be able to cover 97%.<br />

JCB states that skid steer and compact tracked loaders account for 42% of the North American compact<br />

equipment market which, with matched attachments, is worth $1.5 billion a year. According to Larry Ashley, JCB's<br />

Sales Support Manager in North America, the biggest sectors within this market opportunity are landscaping (31%),<br />

farming (20%) and rental (20%) followed by excavation, concrete and road construction (12%).<br />

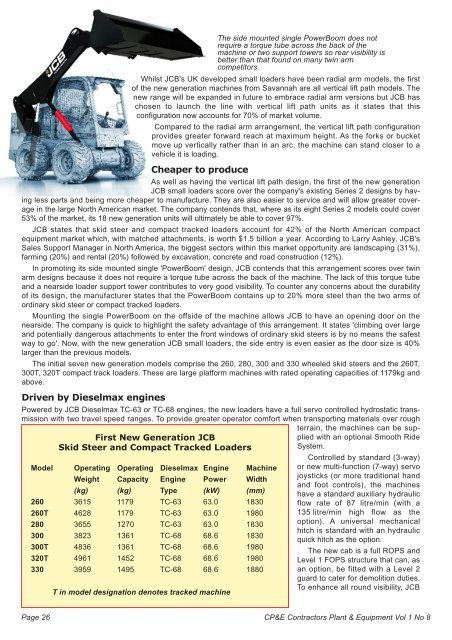

In promoting its side mounted single 'PowerBoom' design, JCB contends that this arrangement scores over twin<br />

arm designs because it does not require a torque tube across the back of the machine. The lack of this torque tube<br />

and a nearside loader support tower contributes to very good visibility. To counter any concerns about the durability<br />

of its design, the manufacturer states that the PowerBoom contains up to 20% more steel than the two arms of<br />

ordinary skid steer or compact tracked loaders.<br />

Mounting the single PowerBoom on the offside of the machine allows JCB to have an opening door on the<br />

nearside. The company is quick to highlight the safety advantage of this arrangement. It states 'climbing over large<br />

and potentially dangerous attachments to enter the front windows of ordinary skid steers is by no means the safest<br />

way to go'. Now, with the new generation JCB small loaders, the side entry is even easier as the door size is 40%<br />

larger than the previous models.<br />

The initial seven new generation models comprise the 260, 280, 300 and 330 wheeled skid steers and the 260T,<br />

300T, 320T compact track loaders. These are large platform machines with rated operating capacities of 1179kg and<br />

above.<br />

Driven by Dieselmax engines<br />

Powered by JCB Dieselmax TC-63 or TC-68 engines, the new loaders have a full servo controlled hydrostatic transmission<br />

with two travel speed ranges. To provide greater operator comfort when transporting materials over rough<br />

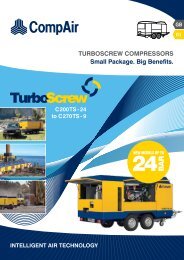

First New Generation JCB<br />

Skid Steer and Compact Tracked Loaders<br />

Model Operating Operating Dieselmax Engine Machine<br />

Weight Capacity Engine Power Width<br />

(kg) (kg) Type (kW) (mm)<br />

260 3615 1179 TC-63 63.0 1830<br />

260T 4628 1179 TC-63 63.0 1980<br />

280 3655 1270 TC-63 63.0 1830<br />

300 3823 1361 TC-68 68.6 1830<br />

300T 4836 1361 TC-68 68.6 1980<br />

320T 4961 1452 TC-68 68.6 1980<br />

330 3959 1495 TC-68 68.6 1880<br />

T in model designation denotes tracked machine<br />

The side mounted single PowerBoom does not<br />

require a torque tube across the back of the<br />

machine or two support towers so rear visibility is<br />

better than that found on many twin arm<br />

competitors.<br />

terrain, the machines can be supplied<br />

with an optional Smooth Ride<br />

System.<br />

Controlled by standard (3-way)<br />

or new multi-function (7-way) servo<br />

joysticks (or more traditional hand<br />

and foot controls), the machines<br />

have a standard auxiliary hydraulic<br />

flow rate of 87 litre/min (with a<br />

135 litre/min high flow as the<br />

option). A universal mechanical<br />

hitch is standard with an hydraulic<br />

quick hitch as the option.<br />

The new cab is a full ROPS and<br />

Level 1 FOPS structure that can, as<br />

an option, be fitted with a Level 2<br />

guard to cater for demolition duties.<br />

To enhance all round visibility, JCB<br />

Page 26 CP&E <strong>Contractors</strong> Plant & Equipment Vol 1 No 8