Translucent Materials

Translucent Materials

Translucent Materials

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

0.7 W/m2K, and with krypton fi I ng a<br />

U-value of 0.5 W/m K.<br />

Fitting a low-emission coated membrane<br />

avoids the weight and thickness of a third<br />

glass pane (ill. 30).<br />

Evacuating the gap can further reduce<br />

heat conduction by the enclosed gas. But<br />

it does create other problems in respect<br />

of seal tightness and thermal separation.<br />

Early vacuum glazing prototypes achieve<br />

a U-value of 0.6 W/m2K, but it will st I take<br />

some time before full industrial production<br />

is possible.<br />

Allings with thermal insulation properties<br />

Transparent heat insulators make it possi<br />

ble to reduce heat loss and at the same<br />

time gain heat from the incident sun ight<br />

(ills. 27,31).<br />

Transparent and translucent materials like<br />

glass, acrylic glass (PMMA), polycar<br />

bonate (PC) and quartz foam are used, in<br />

layers of varying thickness and structure.<br />

They are protected from the weather and<br />

mechanical damage by being bui tin<br />

between two panes (ills. 28, 30).<br />

They are classified according to four geo<br />

metrical arrangements of the structure:<br />

- Structures parallel with the external<br />

glass like double or triple glazing or<br />

membrane systems reduce heat loss<br />

but cause higher reflection loss.<br />

• Structures that are vertical to the exter<br />

nal glass consist of honeycombs or<br />

capillary elements that divide the gaps<br />

into small air cells.<br />

This arrangement reduces reflection<br />

loss, as the incident radiation is<br />

directed inside by multiple reflection on<br />

the parallel walls.<br />

Honeycomb structures look like multistay<br />

bridges made of transparent poly<br />

carbonate. Capillary structures are<br />

assembled from large numbers of small<br />

glass or plastic tubes.<br />

A 100 mm thck capillary sheet made of<br />

small polycarbonate tubes achieves a<br />

U-value of 0.89 W/m2K and a c-va ue of<br />

0.69 (Oka-Lux®).<br />

Capillary structures made up of<br />

100mm long small glass tubes have<br />

achieved U-values around 1 W/m K.<br />

• Cellular structures result from combin<br />

ing parallel and vertical structures, like<br />

acrylic foam, for example.<br />

• Quasi-homogeneous structures such as<br />

aerogels are microscopically cellular.<br />

The manufacture of aerogel sheets is<br />

very elaborate and thus expensive.<br />

Aerogel granules are much more rea<br />

sonably priced; they are packed loose<br />

into the gap between the panes. A 16<br />

mm granular filling (Basogel®) achieves<br />

a U-value of less than 0.8 W/m2K, a<br />

t-value of 0.41 and a gdiff-value of 0.52<br />

(ill. 33).<br />

Comparing the four thermal insulation<br />

groups shows that insulating glass and<br />

plastic membrane systems are best in<br />

areas where transparency is required for<br />

visibility reasons. They also ensure low<br />

U-values.<br />

Other structures are more or less lightdiffusing<br />

and thus suitable for roof-light<br />

glazing.<br />

In summer, transparent heat insulation<br />

needs sunscreening to prevent the<br />

spaces from heating up.<br />

29<br />

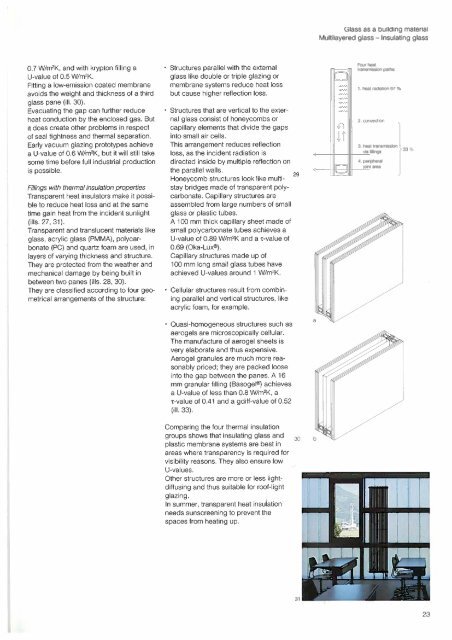

Glass as a building material<br />

Multilayered glass — Insulating glass<br />

C<br />

vn<br />

Four heat<br />

transmission paths:<br />

1. heat radiation 67 %<br />

via Clings<br />

4. peripjieral<br />

ioint area<br />

.33%