Event Guide - Students - SAE

Event Guide - Students - SAE

Event Guide - Students - SAE

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

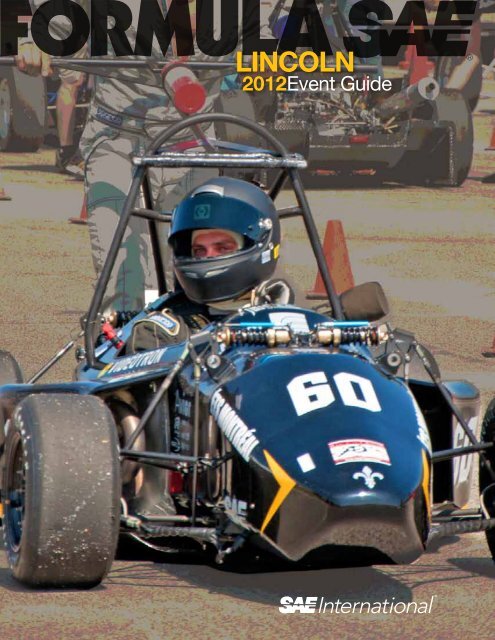

LincoLn<br />

2012<strong>Event</strong> <strong>Guide</strong>

2012 Formula <strong>SAE</strong> Series<br />

Official <strong>Event</strong>s<br />

Formula Hybrid<br />

organized by organized by Dartmouth College<br />

April 30th – May 3rd<br />

New Hampshire, United States<br />

Formula SaE micHigan<br />

organized by <strong>SAE</strong> International<br />

May 9th – 12th<br />

Michigan, United States<br />

Formula SaE lincoln<br />

organized by <strong>SAE</strong> International<br />

June 20th – 23th<br />

Nebraska, United States<br />

Formula SaE-auStralaSia<br />

organized by <strong>SAE</strong> Australia<br />

Australia<br />

www.saea.com.au/formula-sae-a<br />

Formula SaE – braSil<br />

organized by <strong>SAE</strong> Brasil<br />

Brasil<br />

www.saebrasil.org.br<br />

Formula SaE – italy<br />

organized by ATA<br />

Italy<br />

www.ata.it/formulaata/formulasaeit<br />

Formula StudEnt<br />

organized by IMeche in partnership with <strong>SAE</strong><br />

United Kingdom<br />

www.formulastudent.com<br />

Formula StudEnt gErmany<br />

organized by VDI<br />

Germany<br />

www.formulastudent.de<br />

http://students.sae.org/competitions/formulaseries/

Formula <strong>SAE</strong> ® California<br />

2012 <strong>SAE</strong> President’s Message<br />

page 1

tablE oF contEntS:<br />

Concept of the<br />

Competition ..................... 2<br />

Schedule ......................... 4<br />

Awards ............................ 6<br />

Sponsors ......................... 7<br />

CA Teams listed<br />

by Country ....................... 8<br />

Team Information ........... 10<br />

Key Players .................... 40<br />

page 2<br />

Concept of the Competition<br />

The Formula <strong>SAE</strong> ® Series competitions challenge teams of university undergraduate<br />

and graduate students to conceive, design, fabricate and compete with small, formula<br />

style, autocross cars. To give teams the maximum design flexibility and the freedom to<br />

express their creativity and imaginations there are very few restrictions on the overall<br />

vehicle design. Teams typically spend eight to twelve months designing, building,<br />

testing and preparing their vehicles before a competition. The competitions themselves<br />

give teams the chance to demonstrate and prove both their creation and their<br />

engineering skills in comparison to teams from other universities around the world. Registered<br />

for this event are 80 teams from colleges and universities. The end result is a great experience<br />

for young engineers in a meaningful engineering project as well as the opportunity of working in<br />

a dedicated team effort.<br />

For the purpose of this competition, the students are to assume that a manufacturing firm has<br />

engaged them to produce a prototype car for evaluation as a production item. The intended<br />

sales market is the nonprofessional weekend autocross racer. Therefore, the car must have very<br />

high performance in terms of its acceleration, braking, and handling qualities. The car must be<br />

low in cost, easy to maintain, and reliable. In addition, the car’s marketability is enhanced by<br />

other factors such as aesthetics, comfort and use of common parts. The manufacturing firm is<br />

planning to produce four (4) cars per day for a limited production run and the prototype vehicle<br />

should actually cost below $25,000. The challenge to the design team is to design and fabricate<br />

a prototype car that best meets these goals and intents. Each design will be compared and<br />

judged with other competing designs to determine the best overall car.<br />

Over the course of three days, the cars are judged in a series of static and dynamic events<br />

including: technical inspection, cost, presentation, and engineering design, solo performance<br />

trials, and high performance track endurance. These events are scored to determine how well<br />

the car performs. In each event, the manufacturing firm has specified minimum acceptable<br />

performance levels that are reflected in the scoring equations.

Static EvEntS<br />

design report: The students explain their constructive solutions to a jury of experts from<br />

the automotive and motorsport industries in report and discussion. The concept of the<br />

design event is to evaluate the engineering effort that went into the design of the car and<br />

how the engineering meets the intent of the market. The car that illustrates the best use of<br />

engineering to meet the design goals and the best understanding of the design by the team<br />

members will win the design event.<br />

cost report: The students are to assume that a serial production of 1000 cars a year will<br />

follow the prototype. The cost calculation is discussed with a jury based on a report. The<br />

objective of the event is for the participants to learn and understand the manufacturing<br />

techniques and processes of some of the components that they have chosen to purchase<br />

rather than fabricate themselves.<br />

presentation: The objective is to evaluate the team’s ability to develop and deliver a<br />

comprehensive business case that will convince the executives of a fake manufacturing<br />

firm that the team’s design best meets the demands of the amateur weekend autocross<br />

racing market and that it can be profitably manufactured and marketed.<br />

dynamic EvEntS<br />

acceleration: The race cars are evaluated on their accelerating abilities from a standing<br />

start over a distance of 75 meters.<br />

autocross: The objective is to evaluate the car’s maneuverability and handling qualities<br />

on a tight course without the hindrance of competing cars. The course will combine the<br />

performance features of acceleration, braking and cornering into one event. The results of<br />

the Autocross scores determine the starting order for endurance.<br />

Skidpad: The objective is to measure the car’s cornering ability on a flat surface while<br />

making a constant-radius turn. The course will be a pair of concentric circles in shape of<br />

the number 8; the cars demonstrate how good lateral forces can be absorbed (up to 1.4g).<br />

Endurance: Over a distance of 22 kilometers the cars have to prove their durability under<br />

long-term conditions. Acceleration, speed, handling, dynamics, fuel economy, reliability –<br />

the cars have to prove it all.<br />

tHE Following pointS arE poSSiblE:<br />

Static <strong>Event</strong>s 75 Presentation<br />

(Thursday) 150 Design<br />

100 Cost Analysis<br />

dynamic <strong>Event</strong>s 75 Acceleration<br />

(Friday & Saturday) 50 Skid-Pad<br />

150 Autocross<br />

100 Fuel Economy<br />

300 Endurance<br />

total pointS 1000<br />

page 3

page 4<br />

2012 Formula <strong>SAE</strong> ® California<br />

Schedule of <strong>Event</strong>s<br />

(Subject to change)<br />

wEdnESday, JunE 20 ...................................................................................location<br />

5:30 p.m. ......................Welcome Ceremony Sponsored by Honda R&D Americas ..................Main Tent<br />

6:30 p.m. ......................Captain and Advisors Meeting ..........................................................Main Tent<br />

7:30 p.m. ......................Official Closing of the Site<br />

8:00 p.m. ......................EVERYONE MUST BE OFF SITE<br />

tHurSday, JunE 21 (all timES prEcEdEd by “~” arE approximatE) ......................location<br />

7:30 a.m. .......................Judges Meetings for Design ........................................................Danley Bldg.<br />

8:00 a.m. .......................Drivers Meeting - Brake and Practice - MANDATORY ........................Main Tent<br />

8:00 a.m. .......................Judges Meetings for Cost ................................................................ Cost Tent<br />

8:00 a.m. – 5:30 p.m. ....Design Judging – 1st Round Open ...............................................Danley Bldg.<br />

8:30 a.m. .......................Judges Meeting for Presentation .............................. Arnold Elementary School<br />

8:30 a.m. – 5:00 p.m. ....Cost <strong>Event</strong> Open .............................................................................Main Tent<br />

9:00 a.m. – 5:00 p.m. ....Presentation <strong>Event</strong> Open ......................................... Arnold Elementary School<br />

Noon -1:00 p.m. ............Lunch Break<br />

2:00 p.m. ......................Dynamic <strong>Event</strong> Courses Open for Driver Walks<br />

5:30 p.m. ......................Drivers Meeting - All Dynamic <strong>Event</strong>s – MANDATORY ........................Main Tent<br />

5:30 p.m. – 7:30 p.m. ....Design Judges Meeting - Judges only ..........................................Danley Bldg.<br />

7:30 p.m. ......................Official Closing of the Site<br />

8:00 p.m. ......................EVERYONE MUST BE OFF-SITE<br />

9:00 p.m. ......................Design Finalists announced online (www.sae.org and www.fsae.com)<br />

Friday, JunE 22 (all timES prEcEdEd by “~” arE approximatE) ............................location<br />

7:30 a.m. .......................Course Crew Briefing - Acceleration and Skid Pad ...................... <strong>Event</strong> Courses<br />

8:00 a.m. – 11:30 a.m. ..Skid Pad <strong>Event</strong> and Acceleration <strong>Event</strong>s Open .......................................... Track<br />

8:00 am – 4:00 p.m. ......Design Feedback for Non-finalists ................................................Danley Bldg.<br />

11:45 – 12:45 p.m. .......Lunch Break ....................................................................................Main Tent<br />

1:00 p.m. ......................Course Crew Briefing – Autocross .......................................................... Track<br />

1:30 p.m. – 4:30 p.m. ...Autocross <strong>Event</strong> Open ............................................................................ Track<br />

5:00 p.m. – 7:30 p.m. ...Design Finals ..............................................................................Danley Bldg.<br />

7:30 p.m. ......................Official Closing of the Site<br />

9:00 p.m. ......................EVERYONE MUST BE OFF-SITE

Saturday, JunE 23<br />

(all timES prEcEdEd by “~” arE approximatE) .....................................location<br />

7:30 a.m. .......................Endurance Course Crew Briefing ......................................Track<br />

8:30 a.m. .......................Top 3 Teams Design Finalists Announced<br />

8:30 a.m. – 4:00 p.m. ....Endurance/Fuel Economy <strong>Event</strong> Open ...............................Track<br />

9:00 a.m. – 2:00 p.m. ....Design Feedback for Finalists not Top 3,<br />

by appointment ..................................................... Danley Bldg.<br />

Noon - 1:00 pm .............Lunch Break ............................................................. Main Tent<br />

4:00 pm ........................Design Review of Top 3 Teams .................................. Main Tent<br />

5:30 pm ........................Presentation Highlights ............................................. Main Tent<br />

6:30 pm ........................Awards Ceremony .................................................... Main Tent<br />

7:30 pm ........................Official Closing of the Site<br />

8:00 pm ........................EVERYONE MUST BE OFF-SITE<br />

All Teams and Transporters Must Exit<br />

Sunday, JunE 24<br />

9:00 a.m. - 2:00 p.m. Site Open ONLY for Pick-Up of Transporters<br />

notES<br />

1) Drivers Meeting – There will be only one drivers meeting covering all dynamic events at 5:30 pm Thursday. There will<br />

be a brief drivers meeting for Brake and Practice at 8:00 am Thursday. Drivers are required to attend drivers meetings.<br />

Failure to attend drivers meetings may result in the revocation of your driving privileges.<br />

2) <strong>Event</strong> Closing Time - Acceleration, Skid Pad and Autocross close exactly at the scheduled time. Your car must have<br />

crossed the starting line before the event closing time in order to be allowed to complete that run.<br />

3) Course Walks – Autocross and Endurance will be available to walk starting Thursday @ 2 p.m. and will be accessible<br />

up to the start of the event. Drivers are required to walk the course for each event in which they will be behind the wheel.<br />

Course walks will not be scheduled for individual events.<br />

4) Removing Vehicles – Vehicles may be taken off site at the individual team’s discretion provided Part 1 of the Inspection<br />

Sticker has been removed by Tech Chief.<br />

5) EMS will provide any/all medical attention.<br />

6) All teams not shipping cars must remove their vehicles, etc. from the site no later than 2:00 p.m. Sunday, June 24,<br />

2012.<br />

7) Teams shipping cars must have them picked up and removed from the site by 10:00 a.m. Monday, June 25, 2012.<br />

8) Announcements can be heard via FM radio (Frequencies will be posted in the Reg. /Info. Tent).<br />

Support SErvicES<br />

4 Food vendors – See map for<br />

location<br />

• All days – 8:00 am – 5:00 pm*<br />

4 ambulance on site:<br />

• Wed. – Sat.7 a.m. - 8 p.m.<br />

4 lincoln Electric welding Services<br />

• Wed. – 1:30 p.m. – 5:00 p.m.<br />

• Th. – Fri. – 9:00 a.m. – 5:00 p.m.<br />

• Sat. – 9:00 a.m. - Noon<br />

4 Hoosier<br />

• Wed. – 1:30 p.m. – 5:00 p.m.<br />

• Th. – Fri. – 9:00 a.m. – 5:00 p.m.<br />

• Sat. – 9:00 a.m. - Noon<br />

* As business dictates. May close earlier if<br />

deemed appropriate.<br />

daily opErationS:<br />

4 lincoln airpark Site open:<br />

• Wed., 9:00 a.m. – 7:30- p.m.<br />

• Th. – Sat., 7:30 a.m. – 7:30 p.m.<br />

4 Student registration (tent):<br />

• Wed., 9:00 a.m. – 4:30 p.m.<br />

• Th. & Fri., 8:00 a.m. – 4:00 p.m.<br />

• Sat., All students will be registered<br />

as spectators<br />

4 volunteer registration<br />

& info (tent):<br />

• Wed., 10:00 a.m. – 4:30 p.m.<br />

• Th. – Sat., 7:30 a.m. – 4:30 p.m.<br />

4 tech inspection (danley bldg.):<br />

• Wed., 3:00 p.m. – 7:00 p.m.<br />

(no new cars after 6:00 p.m.)<br />

• Th., 8:00 a.m. – 5:00 p.m.<br />

• Fri., 8:30 a.m. – 2:00 p.m.<br />

(after 2pm by appointment only)<br />

4 Scales (danley bldg.):<br />

• Wed., 3 p.m. - 7 p.m.<br />

• Th., 8 a.m. - 4 p.m.<br />

4 tilt/noise/brake:<br />

• Th., 8:30 a.m. – 5.00 p.m.<br />

• Fri., 8:30 a.m. – 2:00 p.m.<br />

(after 2pm by appointment only)<br />

4 Fuel Station:<br />

• Th. – Fri., 8:30 a.m. – 4:00 p.m.<br />

• Sat., 8:30 a.m. – 4:00 p.m.<br />

4 practice area:<br />

• Th., 10:00 am – 5:00 pm<br />

• Fri., 8:00 am – 5:00 pm<br />

• Sat., 8:30 am – 3:00 pm<br />

NOTE: Cars must complete all 3 parts of tech by<br />

5:00 p.m. Friday to qualify for Endurance.<br />

30 minutes’ notice is required for all appointments,<br />

which can be booked through the announcer in<br />

Main Tent.<br />

page 5

2012 Formula <strong>SAE</strong> ®<br />

Competition Awards<br />

OVERALL<br />

Spirit oF ExcEllEncE award<br />

This award recognizes the top ten (10)<br />

finishers overall. - $3000, $2000, $1000,<br />

trophies<br />

page 6<br />

NEW!<br />

ISBN: 978-0-7680-0885-2<br />

List Price $109.95<br />

Product Code: R-320<br />

STATIC EVENTS<br />

SaE EnginEEring dESign award<br />

Top 3 team scores in Design – Trophies<br />

plus 1st place will recieve 1 day K&C<br />

testing at Goodyear Facility in Akron, OH<br />

SaE coSt award<br />

Top 3 team scores in Cost – Trophies<br />

SaE prESEntation award<br />

Top 3 team scores in Presentation –<br />

Trophies<br />

DYNAMIC EVENTS<br />

SaE accElEration award<br />

Top 3 team scores in Acceleration -<br />

Trophies<br />

SaE Skid pad award<br />

Top 3 team scores in Skid Pad - Trophies<br />

SaE autocroSS award<br />

Top 3 team scores in Autocross. Trophies<br />

plus 8 free tires, 6 free tires, 4 free tires<br />

sponsored by Hoosier Tire.<br />

SaE EndurancE award<br />

Top 3 team scores in Endurance- Trophies<br />

SaE FuEl Economy award<br />

Top 3 teams that receive best Fuel<br />

Economy Score - Trophies<br />

Figure out why and how engines<br />

fail with this new book!<br />

By Ernst Greuter and Stefan Zima<br />

Translated from a popular German reference work, this English edition sheds<br />

light on determining engine failure and remedies. The authors present a<br />

selection of engine failures, investigate and evaluate why they failed, and<br />

provide guidance on how to prevent such failures.<br />

The scope of engines covered includes general-purpose engines found in an<br />

array of industries. This book serves as a welcomed educational reference<br />

for researchers, students and engineers to discover how the theoretically<br />

impossible can-and will-happen.<br />

This book is ideal for those working with engines, including:<br />

• Repair Shops<br />

• Shipyards<br />

• Insurance Companies<br />

• Researchers<br />

• And Engine Manufacturers<br />

SAVE 10% - Pre-Order<br />

your copy by June 11!<br />

Order today!<br />

Online: books.sae.org/book-r-320<br />

E-mail: CustomerService@sae.org<br />

Phone: 1-877-606-7323 (U.S. & Canada)<br />

or 1-724-776-4970<br />

Actual shipping charges will be applied.<br />

P120899

Thanks to Our<br />

2012 Sponsors<br />

GOLD SPONSORS<br />

welcome ceremony<br />

award ceremony<br />

T-SHIRT SPONSORS<br />

BRONzE SPONSOR<br />

FRIENDS OF FORMULA<br />

page page 77

page 8<br />

2012 Formula <strong>SAE</strong> ® Lincoln Registered<br />

Teams<br />

braZil<br />

085 Centro Universitario Da FEI<br />

011 Universidade Estadual de Campinas<br />

canada<br />

007 University of Alberta<br />

016 University of Calgary<br />

032 University of British Columbia<br />

068 University of Manitoba<br />

074 Queen’s University - Ontario Canada<br />

067 McGill University<br />

018 Universite Du Quebec-Chicoutimi<br />

027 University of Saskatchewan<br />

india<br />

050 Vel Tech University<br />

Japan<br />

052 Honda Technical College Kansai<br />

059 Tokyo Denki University<br />

mExico<br />

062 Escuela Sup De Ing Automotriz Tlalnepa<br />

066 Instituto Politecnico Nacional<br />

042 Instituto Tecnologico de Chihuahua<br />

065 IPN - ESIME UP Ticoman<br />

051 Universidad Nacion Autonoma De Mex<br />

puErto rico<br />

044 Polytechnic University of Puerto Rico<br />

unitEd StatES<br />

alabama<br />

078 Auburn University<br />

arizona<br />

049 Arizona State University - Tempe<br />

063 University of Arizona<br />

california<br />

061 California Polytechnic State University-<br />

SLO<br />

048 California State Poly University - Pomona<br />

045 California State University - Fullerton<br />

038 California State University - Long Beach<br />

057 California State University - Northridge<br />

041 California State University - Sacramento<br />

046 San Diego State University<br />

010 San Jose State University<br />

022 University of California - Berkeley<br />

070 University of California-Merced<br />

033 University of Southern California<br />

colorado<br />

012 Colorado State University<br />

connecticut<br />

053 University of Connecticut<br />

delaware<br />

056 University of Delaware<br />

Florida<br />

060 Florida Institute of Technology<br />

084 University of South Florida<br />

georgia<br />

083 Georgia Southern University<br />

illinois<br />

072 Northern Illinois University<br />

030 Southern Illinois University - Edwardsville<br />

055 University of Illinois - Chicago<br />

006 University of Illinois - Urbana Champaign<br />

indiana<br />

076 Purdue University - W Lafayette<br />

iowa<br />

023 Iowa State University<br />

kansas<br />

020 Pittsburg State University<br />

069 University of Kansas - Lawrence<br />

047 Wichita State University<br />

maryland<br />

004 University of Maryland - College Park<br />

massachusetts<br />

064 University of Massachusetts – Dartmouth<br />

michigan<br />

079 Michigan State University<br />

080 Oakland University<br />

040 Saginaw Valley State University<br />

073 University of Michigan - Dearborn<br />

024 Wayne State University<br />

077 Western Michigan University<br />

minnesota<br />

039 Minnesota State University - Mankato<br />

019 University of Minnesota-Duluth<br />

missouri<br />

071 Missouri University of Science and<br />

Technology<br />

031 Saint Louis University<br />

081 University of Missouri<br />

montana<br />

029 Montana State University – Bozeman<br />

nebraska<br />

017 University of Nebraska - Lincoln<br />

new Jersey<br />

058 Stevens Institute of Technology<br />

new mexico<br />

037 University of New Mexico<br />

new york<br />

082 Rochester Institute of Technology<br />

north dakota<br />

026 University of North Dakota<br />

oklahoma<br />

002 University of Oklahoma<br />

oregon<br />

043 Oregon Institute of Technology<br />

014 Portland State University<br />

pennsylvania<br />

015 Drexel University<br />

South dakota<br />

075 South Dakota School of Mines &<br />

Technology<br />

054 South Dakota State University<br />

texas<br />

025 Texas A & M University - College Station<br />

028 University of Texas - Arlington<br />

008 University of Texas - Austin<br />

013 University of Texas - San Antonio<br />

utah<br />

036 University of Utah<br />

washington<br />

021 University of Washington<br />

wisconsin<br />

003 University of Wisconsin - Madison<br />

034 University of Wisconsin – Platteville

VISIONARIES<br />

WELCOME<br />

CHALLENGING SPIRIT REQUIRED<br />

INDIVIDUALITY RESPECTED<br />

ACCOMPLISHMENTS ROUTINE<br />

Honda is an equal opportunity employer and we are accepting applications now!<br />

For more information about career opportunities with Honda please visit:<br />

www.corporate.honda.com

2<br />

univ of oklahoma<br />

The Sooner Racing Team’s 2012 entry, affectionately known as Emily, employs<br />

an Aprilia 5.5 RXV engine and is the expansion of an innovative design concept<br />

focused around effective tire management. For the endurance event, real-time<br />

control of servo-actuated aerodynamic elements manages tire normal load.<br />

The team focused on mass properties, reliability, and ease of service during the<br />

design of the 2012 car. Critical vehicle performance parameters are selected<br />

using an analytical, simulation-based approach with emphasis placed on physical<br />

validation.<br />

3<br />

Sooner racing uw Formula SaE<br />

brakE : Outboard disc brakes, Dual piston calipers<br />

bScd : 80mm / 55mm / 2 cylinders / 553cc<br />

cooling : Dual parallel radiators<br />

drivE : Chain<br />

ElEctronicS : PE3 ECU, National Instruments sbRIO<br />

Embedded Control and Acquisition<br />

EnginE : Aprilia RXV5.5<br />

Fr/rr track : 45.5 / 45.5 (in)<br />

FramE : 4130 steel tubular space frame<br />

FuEl SyStEm : Sequential fuel injection<br />

FuEl typE : 93 Octane<br />

matErial :<br />

mpd : 10000<br />

mpt : 8000<br />

olwH : 112 / 54 / 48 (in)<br />

SuSpEnSion : SLA<br />

tirE : 18x6.0-10 LC0<br />

uniQuE :<br />

wEigHt : 490 lbs<br />

wHEElbaSE : 62.5 (in)<br />

univ of wisconsin - madison<br />

For 2012 the University of Wisconsin- Madison looks to improve on their 2011<br />

finish. Through the use of aerodynamics, a heavily modified 605cc forced induction<br />

single cylinder, and refined chassis kinematics the WR-212 is poised to be<br />

the most competitive car in Wisconsin Racing’s 22 year history.<br />

Wisconsin Racing would like to give special thanks to our sponsors:<br />

Diamond: The United Wisconsin Grain Producers<br />

Platinum: The Wisconsin Corn Promotion Board, Midwest Composite Technologies,<br />

Eric Gorr’s Forward Motion, Engineered Metal Products, Axon Systems, Craft<br />

Patterns, Black Stone Tek<br />

Gold: Baum Machine, QMI, Reuther, Mercury, Trim-Tex Drywall Products, Machining,<br />

Isthmus Engineering, Bosch, C-Ideas, Ricard<br />

As well as our Silver and Bronze sponsors listed at www.uwracing.com<br />

brakE : Wilwood Front Calipers, AP Racing Rear Calipers,<br />

Custom Rotors<br />

bScd : 100mm / 77mm / 1 / 605cc<br />

cooling : Parallel dual pass with right side fan<br />

drivE : 520 Chain, Drexler Differential<br />

ElEctronicS : Mototron ECU, AiM EVO3 DAQ, LED<br />

Steering Wheel Display<br />

EnginE : KTM 525-XC, Turbocharged, Single-Cylinder<br />

Fr/rr track : 47"/46"<br />

FramE : 4130 Chromoly Spaceframe<br />

FuEl SyStEm : Student-designed fuel injection<br />

FuEl typE : E85<br />

matErial :<br />

mpd : 8100<br />

mpt : 5000<br />

olwH : 110.3", 53", 45.5"<br />

SuSpEnSion : Double unequal length A-Arm, Push rod<br />

tirE : Hoosier 18x6-10 LC0<br />

uniQuE : Feed forward wastegate and feedback ignition<br />

traction control<br />

wEigHt : 506 lb<br />

wHEElbaSE : 60.5"<br />

United States<br />

United States<br />

page 10 Information published as supplied by teams on or before March 26, 2012

4univ of maryland - college park<br />

terps racing<br />

The University of Maryland’s 2012 entry into the Formula <strong>SAE</strong> Lincoln competition<br />

represents the result of a 1.5 year design cycle. For once, the chassis was designed<br />

in conjunction with the aerodynamics package resulting in a unique hybrid<br />

spaceframe/monocoque design. Furthermore, accommodations were made in<br />

the powertrain/driveline package to maximize diffuser width. The result is a car<br />

that redefines aerodynamic effectiveness and efficiency.<br />

And yes, it makes a lot of downforce.<br />

United States<br />

brakE : Wilwood GP320 (Front) / PS1 (Rear)<br />

bScd : Stock CRF450X<br />

cooling : C&R double pass, NACA duct<br />

drivE : Dual Chain w/Jackshaft<br />

ElEctronicS : PE ECU3<br />

EnginE : Honda CRF450X<br />

Fr/rr track : 45 in / 45 in<br />

FramE : Spaceframe (Front) / Moncooque (Rear)<br />

FuEl SyStEm : Electronic Fuel Injection<br />

FuEl typE : 100 Octane<br />

matErial : Downforce<br />

mpd : 8400<br />

mpt : 7800<br />

olwH : 134" length, 54.5" width, 52" height<br />

SuSpEnSion : Unequal Length A-arms, Very Stiff<br />

tirE : Hoosier R25B 7.5"x18" - 10<br />

uniQuE : Narrow rear driveline/packaging, 18" high<br />

diffusers<br />

wEigHt : 570 lb<br />

wHEElbaSE : 78 in<br />

Information published as supplied by teams on or before March 26, 2012<br />

7univ of alberta<br />

university of alberta Formula SaE<br />

The 2012 University of Alberta Formula <strong>SAE</strong> Team endeavored to design and<br />

build a prototype of an open-wheeled, F1 inspired race car geared towards the<br />

weekend autocross market. Following the motto “Anything is possible”, the team<br />

undertook the challenge of constructing a carbon monocoque chassis, the first in<br />

the team’s history. The 2012 entry is affectionately known as Candace.<br />

We would like to thank all of our sponsors and Faculty advisor for making another<br />

season of racing possible. For more details please see our website: http://www.<br />

ualbertafsae.com<br />

Canada<br />

brakE : Four floating rotors, Tilton 77series MC,<br />

Brembo & AP Caliper front/rear<br />

bScd : 98mm/63.4mm/1cylinder/478cc<br />

cooling : Dual 10"x6" aluminum radiators<br />

drivE : 420 Chain to Drexler Differential, 4340 driveshafts<br />

ElEctronicS : Link ECU w/ 25 channel onboard<br />

datalogging<br />

EnginE : 2006 Yamaha WR450<br />

Fr/rr track : 1168mm/46inches Front,<br />

1118mm/44inches Rear<br />

FramE : Carbon Fiber monocoque; 3K 2x2 twill w/<br />

aluminum honeycomb<br />

FuEl SyStEm : Single Injector, In tank fuel pump &<br />

regulator, returnless<br />

FuEl typE : 100 octane<br />

matErial :<br />

mpd : 40 hp @ 8000 RPM<br />

mpt : 26 lb-ft @ 7000 RPM<br />

olwH : 2692 x 1371 x 1143 mm / 106 x 54 x 45 in<br />

SuSpEnSion : Dual unequal length A-arms, pullrod<br />

front, pushrod rear, U type ARBs<br />

tirE : Hoosier 6.0/18.0-10.0 LC0<br />

uniQuE : Lightweight<br />

wEigHt : 465lb with 150lb driver<br />

wHEElbaSE : 1524mm / 60 inches<br />

page 11

8<br />

univ of texas - austin<br />

longhorn racing<br />

For the 2012 season, Longhorn Racing is building on the success of previous<br />

years while moving in a direction that will keep its future vehicles at the forefront<br />

of F<strong>SAE</strong> performance. After a thorough look at the most important components<br />

affecting overall competition performance, we have decided to adopt a lightweight,<br />

single-cylinder engine as the new heart of our car. To retain a competitive<br />

power to weight ratio, forced induction is applied, and a robust support system is<br />

employed to ensure reliability. Also in place is a full aero package, an evolution of<br />

the 2010 aero kit, which was a substantial performance adder in both simulation<br />

and testing. The end result is an aggressive package capable propelling UT Austin<br />

to the podium.<br />

Longhorn Racing would like to thank its sponsors for their support: Cummins,<br />

Schlumberger, Cobb Tuning, 034 Motorsport, Honeywell, UT Co-op, Austin Bolt<br />

brakE : Vented 4 wheel disc<br />

bScd : 95/63.4/1/449<br />

cooling : Water cooled<br />

drivE : Chain drive<br />

ElEctronicS : zoom ECU<br />

EnginE : YFz 450<br />

Fr/rr track : 49/47<br />

FramE : Steel Spaceframe<br />

FuEl SyStEm : EFI<br />

FuEl typE : Gasoline<br />

matErial :<br />

mpd : 9400<br />

mpt : 7500<br />

olwH : 110/49/44<br />

SuSpEnSion : Unequal length double wishbone<br />

tirE : Hoosier 20.5x7.0-13 R25B<br />

uniQuE : Forced Induction, Aero package, In house ECU,<br />

Launch control<br />

wEigHt : 550<br />

wHEElbaSE : 63.5<br />

Jose State university<br />

10San<br />

Spartan racing<br />

The San Jose State University Spartan Racing Formula <strong>SAE</strong> Team presents SR-4,<br />

our 4th race vehicle, for the 2012 Formula <strong>SAE</strong> Lincoln competition. The primary<br />

goals of the 2012 team were to design and build a well tested, reliable, and easy<br />

to drive vehicle. Lightweight designs were utilized where possible, and simplicity<br />

and “raceability” were emphasized for ease of repair and replacement in a race<br />

environment.<br />

The chassis was designed using 4130 Chromoly steel tubing and carbon-fiber<br />

sandwich floor panels for increased stiffness. Pushrod actuated double-adjustable<br />

Kaz/Penske 7800 dampers were utilized for their low weight and adjustability. The<br />

Honda CBR600-F4i engine utilizes a modified 4-speed gearbox and studentdesigned<br />

dry-sump oil system. Power is fed to the rear wheels through a Honda<br />

clutch-type limited slip differential and Taylor Race half shafts and tripod joints.<br />

This year, the 2012 Spartan Racing Team looks to improve in all aspects of the<br />

competition and continue our strong run of finishing every event. We would also<br />

like to thank all of our sponsors and supporters who have continued to help us<br />

throughout the years.<br />

brakE : Tilton 77 Master Cylinders, Wilwood PS1<br />

Calipers, Cast-Iron Outboard Rotors<br />

bScd : 67mm/42.5mm/4/600cc<br />

cooling : Single sidepod mounted dual-pass radiator<br />

w/ electric water pump<br />

drivE : Chain Driven w/ Honda Differential<br />

ElEctronicS : Megasquirt 3, Modulo, Integra, Rynex<br />

EnginE : Honda CBR 600 F4i<br />

Fr/rr track : 1270mm/1220mm<br />

FramE : 4130 Chromoly Space Frame<br />

FuEl SyStEm : 45 psi, Vacuum referenced regulator<br />

FuEl typE : 100 Octane<br />

matErial :<br />

mpd : 10,000<br />

mpt : 8,500<br />

olwH : 2540mm/1420mm/1150mm<br />

SuSpEnSion : Double unequal length control arms with<br />

pushrod actuated dampers<br />

tirE : Hoosier R25B, 18.0x6.0-10<br />

uniQuE :<br />

wEigHt : 575lbs<br />

wHEElbaSE : 1575mm<br />

United States<br />

United States<br />

page 12 Information published as supplied by teams on or before March 26, 2012

SolidWorks is a registered trademark of Dassault Systèmes. ©2012 Dassault Systèmes. All rights reserved.<br />

THE HOT ROD<br />

BABY BUGGY<br />

IS ROAD READY<br />

PROJECT 3 OF LET’S GO DESIGN<br />

In this interactive web series, SolidWorks brings together CAD fanatics from<br />

around the world to collaborate on innovative design projects. With their help, our<br />

host Jeremy Luchini successfully designed the fi rst hardcore baby buggy for dads.<br />

Watch its development from design to build - and how SolidWorks was used to<br />

bring ideas, comments and your votes to life at LetsGoDesign.tv

11<br />

universidade Estadual de campinas<br />

FSaE-unicamp<br />

We’re a Brazilian team and this is our first competition outside Brazil! This model<br />

is F2011E, which is an evolution of our F2011 model that was runner-up in<br />

Formula <strong>SAE</strong> Brazil in November, 2011.<br />

The team was created in 2006, and F2011E is our 5th car! The team worked very<br />

hard for a long time to represent Brazil in a competition outside our country, so<br />

we’re very glad and honored to take part in Formula <strong>SAE</strong> Lincoln.<br />

Our Formula is quite light, considering that has a Yamaha R6 model 2010 engine<br />

and a tubular steel frame, and the weight of our model is 210kg! This is because<br />

we’ve focused our Project in light weight design. Also, the fuel of our engine is<br />

ethanol, which is a very important and well developed fuel in our country!<br />

We’d like to thank our 2012 sponsors: CBMM, SCHAEFFLER GROUP, MAHLE,<br />

CORTAG, SSAB, HBM, ETHOS, EATON, RICARDO, 3M, GIBA ESCAPAMENTOS,<br />

MSC SOFTWARE, SANTIAGO, CISER, RODAMIX, FLOW, ALPINO, PLOTTAR, MAG-<br />

NETI MARELLI and all UNICAMP staff involved in the Project.<br />

brakE: Wilwood caliper and custom stainless steel floating<br />

discs<br />

bScd: 600cc and 4 cylinders<br />

cooling: Water-Air<br />

drivE: Chain drive and Quaife ATB differential<br />

ElEtronicS: ECU, electronic shifter and digital dashboard<br />

EnginE: Yamaha YzF R6 2010<br />

Fr/rr track: 1200mm / 1180mm<br />

FramE: Tubular Frame – AISI 1020<br />

FuEl SyStEm: Megasquirt - ECU<br />

FuEl typE: E85<br />

matErial: AISI 1020<br />

mpd: 83HP – 12000rpm<br />

mpt: 65Nm – 7500rpm<br />

olwH: 2600mm x 1380mm x 1220mm<br />

SuSpEnSion: Independent, Custom double A-Arms,<br />

Ohlins shocks<br />

tirE: Hoosier 20,5x7,0x13 – R25B<br />

uniQuE: High Strength Steel Components<br />

wEigHt: 210kg<br />

wHEElbaSE: 1575mm<br />

State university<br />

12colorado<br />

ram racing<br />

The Ram Racing Team proudly presents the Colorado State University 2012 Formula<br />

<strong>SAE</strong> competition vehicle. This year’s vehicle is built upon a full space frame<br />

and utilizes a longitudinally mounted 2010 Kawasaki zX-6R engine and a shaftdriven<br />

limited slip differential. The suspension is composed of an unequal length<br />

double A-arm linking to custom CNC machined aluminum uprights, center-lock<br />

BBS wheels, four-wheel disk brakes and centrally located, pushrod activated fourway<br />

adjustable dampers. The suspension geometry and kinematics are designed<br />

around the Goodyear D2696 racing slick.<br />

The design goals for the 2012 team were to design and build a vehicle that<br />

utilizes a 4 cylinder, 600cc engine, and double unequal length suspension with a<br />

wet weight under 500 lbs with a full aerodynamics package.<br />

brakE : 4 Wheel Disk<br />

bScd : 67.0 × 42.5 mm (2.64 × 1.67 in) / 599 cc<br />

(36.6 cu in)<br />

cooling : Radiator and Oil Cooler<br />

drivE : Longitudinal<br />

ElEctronicS : Megasquirt Programmable<br />

EnginE : Kawasaki Ninja zX-6R<br />

Fr/rr track : (48in/46in) (1220/1170)<br />

FramE : 4130 Steel Tube Frame<br />

FuEl SyStEm : Electronically controlled Fuel injection<br />

FuEl typE : E-85<br />

matErial : Unobtanium<br />

mpd : 100 BHP (10,500)<br />

mpt : 43 FT-LB (9,000)<br />

olwH : ( 3070/124) (1400/55) (1220/48)<br />

SuSpEnSion : Carbon Fiber Double Unequal Length<br />

Wishbone<br />

tirE : 13x7 Goodyear D2704<br />

uniQuE : Honey Badger<br />

wEigHt : 630lb<br />

wHEElbaSE : 1625mm/64in<br />

Brazil<br />

United States<br />

page 14 Information published as supplied by teams on or before March 26, 2012

13<br />

univ of texas - San antonio<br />

roadrunner racing<br />

UTSA’s Formula Society of Automotive Engineers team strives for the classic<br />

automotive balance between performance, reliability, and safety.<br />

Performance that bonds driver and car so that driving responses become inherent<br />

in all parts of the race track is a must in any sports car. Our suspension and frame<br />

were designed to maximize this relationship.<br />

Reliability’s importance in a Race Car parallels the significance of performance on<br />

the basis that the car will be driven to its full extent. This is where the potential<br />

of the car is unlocked and our robust electrical system, in combination with our<br />

resilient powertrain system, provides the means to remain at this point.<br />

By no means is our car’s safety overlooked. A car should be able to protect its<br />

driver to further the driver’s faith in the car. A driver of any skill level is allowed to<br />

pursue the extent of their capabilities when they feel safe.<br />

When all three of these aspects are perfectly combined the car ceases to be an<br />

assembly of parts. It becomes something more. It becomes a tuned machine, a<br />

tool for the driver, and an extension of their body. It becomes UTSA’s 2012 F<strong>SAE</strong><br />

Race Car: zEN.<br />

United States<br />

brakE : Polaris Disk Brakes<br />

bScd : 100mm/72mm/single cylinder/565.5cm^3<br />

cooling : Water - Honda F3 Radiator<br />

drivE : Chain<br />

ElEctronicS : MicroSquirt<br />

EnginE : KTM 560 SMR<br />

Fr/rr track : Front 1237mm Rear 1140 mm<br />

FramE : Steel Space Frame<br />

FuEl SyStEm : Custom fuel injection system, LS9<br />

Injector<br />

FuEl typE : 100 Octane<br />

matErial : Mild Steel<br />

mpd : N/A<br />

mpt : N/A<br />

olwH : 2401mm long, 1326mm wide, 1111mm high<br />

SuSpEnSion : Penskie Racing: Push Rod Front, Pull Rod<br />

Rear<br />

tirE : 10 inch Hoosier<br />

uniQuE : Awesomeness!<br />

wEigHt : 560 lbs<br />

wHEElbaSE : 1530.35mm<br />

Information published as supplied by teams on or before March 26, 2012<br />

State univ<br />

14portland<br />

viking motorsports<br />

The 2012 Viking Motorsports F<strong>SAE</strong> car is PSU’s first ever iteration car. The team<br />

has moved away from disjointed capstone projects and into a more sustainable<br />

student group. Documentation and tribal knowledge have made this team (and<br />

car) the most successful yet. Because of the nature of an iteration design, the<br />

team was able to focus on the finer details of formula car building, which is an<br />

exciting and new prospect for PSU.<br />

Design decisions for this car were based on mathematical models and how each<br />

decision affected points gained at competition, a new philosophy for PSU. To fulfill<br />

our main goal (points), we chose to build a car for reliability, simplicity, and performance.<br />

Following last year’s competition, an analysis of points and competitors<br />

took place to determine our philosophy for the current year. We concluded that to<br />

get more points at competition, we had many things to focus on beyond vehicle<br />

design. Hopefully, our new, more organized team and car will help us reach our<br />

goal!<br />

United States<br />

brakE : Disc<br />

bScd : 67mm/42.5mm/4/599cc<br />

cooling : Single pass radiator<br />

drivE : Chain drive, Taylor Race differential<br />

ElEctronicS : DTA Fast ECU, wireless telemetry<br />

EnginE : Honda CBR600 F4i<br />

Fr/rr track : 48/48in<br />

FramE : Steel Space Frame<br />

FuEl SyStEm : Suzuki fuel pump,<br />

FuEl typE : 100 Octane<br />

matErial :<br />

mpd : 8000<br />

mpt : 8000<br />

olwH : 110, 57, 46<br />

SuSpEnSion : Double unequal length A-arms<br />

tirE : Hoosier 20.5x7-13 R25B<br />

uniQuE : In-car driver feedback system, wireless telemetry,<br />

traction control<br />

wEigHt : 630 lbs.<br />

wHEElbaSE : 60in<br />

page 15

16<br />

Schulich Racing has had several design changes over the previous year. The<br />

biggest being a new space frame chassis. The design hoped to drop the cars ride<br />

height, correct for lack of stiffness through an increase in triangulation and allow<br />

for interchangeability for parts not requiring a redesign. A need was also present<br />

to accommodate the wide range of driver heights, from 5’4” to 6’4”. In addition<br />

much work was put into increasing reliability. A new Vi-PEC ECU is replacing the<br />

outdated AEM, the cooling system was to be moved away from the exhaust and<br />

the electrical system to be simplified. The bodywork also took priority. It was key<br />

to optimize flow over/under the car and that going into the radiator. In addition<br />

greater importance was placed on a having the car look as great as it performs.<br />

Through testing, we are confident this is the most competitive car Schulich Racing<br />

has ever produced!<br />

Canada<br />

univ of calgary<br />

17<br />

univ of nebraska - lincoln<br />

Schulich racing Husker motorsports<br />

brakE : Floating cast iron rotors with ISR calipers<br />

bScd : 67 mm bore/ 42,5 mm stroke/ 4 cylinder /<br />

599cc<br />

cooling : Single, side mounted radiator<br />

drivE : Chain<br />

ElEctronicS : Vi-PEC ECU with PI systems data<br />

logger<br />

EnginE : Honda CBR 600F4I<br />

Fr/rr track :<br />

FramE : Space frame<br />

FuEl SyStEm : Custom fuel tank, with OEM injectors<br />

and Bosch pump<br />

FuEl typE : 91<br />

matErial :<br />

mpd : 78hp at 7800 rpm<br />

mpt :<br />

olwH : 3031mm long, 1421mm wide, 1201mm high<br />

SuSpEnSion : Double unequal, non-parallel A-Arms.<br />

Pull rod actuated. Cane Creek dampers<br />

tirE : 20x7.0-13 D2696 Goodyear<br />

uniQuE : Adjustable Pedalbox<br />

wEigHt : 690lb<br />

wHEElbaSE : 1700mm<br />

This will be University of Nebraska-Lincoln’s debut entry into the Formula <strong>SAE</strong><br />

competition. Husker Motorsports Formula <strong>SAE</strong> is a team of multi-disciplinary<br />

students ranging from freshman to doctoral students across all majors. Our team<br />

intends to represent our University in the finest tradition; fielding a simple, reliable,<br />

and competitive vehicle. As a young team, HMS is very ambitious and passionate<br />

about competing with our first car right in our hometown as F<strong>SAE</strong> Lincoln kicks<br />

off in 2012.<br />

Passion. Pride. Performance.<br />

United States<br />

brakE : Floating Rotors, Wilwood PS1 Calipers<br />

bScd : 67 mm Bore/ 42mm Stroke/ 4 Cylinders/ 599 cc<br />

cooling : Single Aluminum Radiator with thermostatically<br />

controlled fan<br />

drivE : Chain Drive with Quaife QDF7R Differential<br />

ElEctronicS : Kawasaki Racing<br />

EnginE : 2009 Kawasaki zX-6R<br />

Fr/rr track : FR Track 1219.2mm (48in) / RR Track<br />

1308.1 mm (51.5 in)<br />

FramE : Tubular Space Frame<br />

FuEl SyStEm : Kawasaki Electronic Fuel Injection<br />

FuEl typE : E85<br />

matErial : 4130 Chromoly<br />

mpd : 11000 rpm<br />

mpt : 10500 rpm<br />

olwH : 2994.15 mm (117.88 in) long, 1308.1 mm (51.5<br />

in) wide, 1422.4 mm (56 in)high<br />

SuSpEnSion : Double unequal length A-Arm. Pull rod<br />

actuated spring / damper Ohlins TTX25<br />

tirE : Hoosier R25B 18.0 x 6.0 -10<br />

uniQuE : First Nebraska Formula <strong>SAE</strong> Car<br />

wEigHt : A Stuffed Pig<br />

wHEElbaSE : 1727.2 mm (68 in)<br />

page 16 Information published as supplied by teams on or before March 26, 2012

du Quebec-chicoutimi<br />

18universite<br />

FSaE uQac<br />

For 2012, the F<strong>SAE</strong> UQAC team have for goal to save more weight as possible<br />

from the previous design. For this, we include the carbon fiber to our suspension<br />

and shrink all the components of the car. We also use the carbon fiber for our<br />

body, but it is not structural. The wheels diameter also change, this parameter<br />

allow the entire vehicle to become significantly smaller and lighter. We also<br />

improve with our drivetrain with 2 shafts thats increase our torque ratio from 4<br />

to 6. For this year, we use the CVT transmission and the Genesis 80 FI (499cc, 2<br />

cylinder) 4 strokes motor.<br />

Canada<br />

brakE : Wilwood<br />

bScd : 500 cc<br />

cooling : Custom design cooling package<br />

drivE : CVT<br />

ElEctronicS : AEM, EMS 4<br />

EnginE : Yamaha Genesis 80Fi<br />

Fr/rr track : 1193mm / 1155 mm<br />

FramE : Tubular space frame<br />

FuEl SyStEm : EFI<br />

FuEl typE : Octane 92<br />

matErial :<br />

mpd : 52 kW<br />

mpt :<br />

olwH :<br />

SuSpEnSion : Double unequal A-Arm, Push-rod actuated<br />

tirE : 10'' Hooziers<br />

uniQuE : Carbon fiber suspension design<br />

wEigHt : 268 kg<br />

wHEElbaSE : 1 550 mm<br />

Information published as supplied by teams on or before March 26, 2012<br />

21<br />

univ of washington<br />

uwashington FSaE<br />

With a very new car for 2012, the UWashington Formula Motorsport team is<br />

excited to show off our best car yet. Building off of 23 years of innovation, our car<br />

runs a new single cylinder motor, has a full unidirectional carbon fiber chassis,<br />

integrated CV/hubs, a full aero package, pneumatic paddle shifter, and tightly<br />

packaged drivetrain. Relying heavily on physical test validated analysis, a great<br />

deal of care and attention to detail went into every part on the car. With one of the<br />

earliest assembly completions in recent team history, ample time has been spent<br />

testing and tuning the car for ultimate speed, reliability, and overall success.<br />

After Lincoln, the team will compete outside the US for the first time every at<br />

Formula Student Germany.<br />

United States<br />

brakE : Brembo/AP, Floating Slotted Disk<br />

bScd : 95.0x63.4mm / 1 / 449cc<br />

cooling : Single Radiator w/ PWM Fan<br />

drivE : Chain<br />

ElEctronicS : EngineLab EL140, MoTec ADL, Student<br />

Designed Periphery<br />

EnginE : Yamaha WR450F<br />

Fr/rr track : 1220 / 1168mm<br />

FramE : Toray T700 Monocoque<br />

FuEl SyStEm : Returnless in Tank<br />

FuEl typE : 92-95 Octane<br />

matErial : BRC (Beryllium Reinforced Carbon)<br />

mpd : 7500<br />

mpt : 5000<br />

olwH : 3007 / 1412 / 1130mm<br />

SuSpEnSion : Unequal A-Arm Pullrod<br />

tirE : Goodyear 2704<br />

uniQuE : Integrated CV, hub, and centerlock system<br />

wEigHt : 233kg<br />

wHEElbaSE : 1537mm<br />

page 17

23<br />

iowa State univ<br />

cyclone racing<br />

Cyclone Racing’s 17th car, CR-17B was designed to the following priorities:<br />

1) Make the car easy to drive and predictable in all scenarios so an amateur can<br />

hop in and look like a hero;<br />

2) Keep the car as simple as possible, with compromises towards ease of manufacture<br />

over a “more ideal” design if the “more ideal” design requires significant<br />

development with only a minimal return in performance;<br />

3) Keep the design as lightweight as practical without compromising functionality<br />

or ease of manufacture;<br />

4) Serviceability is a minimum requirement, but reliability is even better.<br />

These requirements were developed based on competition experience as well as<br />

extensive participation in SCCA events. The car’s chassis was designed around<br />

suspension kinematics, torsional rigidity and ergonomics while minimizing weight,<br />

CG height and inertia. The suspension kinematics were designed around Tire Test<br />

Consortium data as well as track test data from previous cars. CR-17B will debut<br />

at Formula North 2012 before competing at F<strong>SAE</strong> West 2012 and F<strong>SAE</strong> MI 2013.<br />

brakE : Laser Cut Floating Rotors with Wilwood PS-1<br />

calipers<br />

bScd : Stock, 1-cylinder, 439cc<br />

cooling : Twin PWR Radiators<br />

drivE : Torsen Type 1 Delrin Eccentric Mounted Differential<br />

ElEctronicS : EngineLab EL1 Series 96L<br />

EnginE : Yamaha YFz 450<br />

Fr/rr track : 50/46.5<br />

FramE : TIG welded steel tubing<br />

FuEl SyStEm : Electric Pump<br />

FuEl typE : Hydrocarbons<br />

matErial : Rapid Prototyped ABS<br />

mpd : 45 (9500)<br />

mpt : 37 (7500)<br />

olwH : 88, 58, 44 (in)<br />

SuSpEnSion : Pushrod Actuated Unequal Length<br />

Double Wishbones<br />

tirE : 10" Hoosier LC3, 6" front, 8" Phatties in the Rear<br />

uniQuE : Ergonomic Carbon Fiber Seat, Bonded Aluminum<br />

Shear Panels<br />

wEigHt : 505 lb<br />

wHEElbaSE : 64<br />

25<br />

texas a & m univ - college Station<br />

texas a&m racing<br />

After competing in Formula Hybrid for three successful years, Texas A&M returns<br />

to Formula <strong>SAE</strong> with its lightest car to date. This year’s team conceived an<br />

easily manufactured, uncomplicated, and reliable design, which translates to<br />

ample testing and development—a formula that has proven successful time and<br />

time again. A combination of a tubular steel frame with a single cylinder 450cc<br />

Yamaha engine resulted in an agile car with a high power to weight ratio while<br />

the implementation of a conservative aerodynamic package improves traction<br />

without a drag penalty. All design decisions were based on extensive analysis<br />

and simulations. The design went from a clean sheet/screen to a running car in<br />

eight months to provide the students with the most realistic work experience in<br />

academia.<br />

brakE : Outboard front, diff mounted rear<br />

bScd : 95mm, 63.4mm, 1 cyl, 449cc<br />

cooling : Rear mounted water to air<br />

drivE : Chain-Drexler Differential<br />

ElEctronicS : PE3 ECU<br />

EnginE : Yamaha YFz-450R<br />

Fr/rr track : 1168mm,1168mm<br />

FramE : 4130 Tubular Steel Frame<br />

FuEl SyStEm : Performance Electronics PE3 EFI<br />

FuEl typE : 100 Octane<br />

matErial :<br />

mpd : 9500rpm<br />

mpt : 7000rpm<br />

olwH : 2438mm, 1350mm, 1200 mm<br />

SuSpEnSion : SLA, pushrod actuated springs and<br />

dampers<br />

tirE : Hoosier<br />

uniQuE :<br />

wEigHt : 482.5lbs<br />

wHEElbaSE : 1524mm<br />

United States<br />

United States<br />

page 18 Information published as supplied by teams on or before March 26, 2012

27<br />

univ of Saskatchewan<br />

Huskie motorsports<br />

The University of Saskatchewan’s 2012 Formula <strong>SAE</strong> entry, dubbed “S8” due to<br />

its position as the team’s 8th-generation car, is a realization of the team’s best<br />

efforts. The overall goal of scoring more points at competition was broken down<br />

into two strategic areas of focus. First, an increased emphasis on testing to verify<br />

theory-based performance was undertaken. This includes chassis torsional testing,<br />

as well as material property testing on composite components. The second<br />

strategic focus was on project management; clear deadlines and tasks were<br />

assigned to ensure the timely completion of a driveable car.<br />

Several key components were redesigned to achieve the end goal of scoring<br />

more points: firstly, the frame of the vehicle. Previous generations were lacking in<br />

torsional rigidity, which was addressed successfully. The second major redesign is<br />

the engine intake system, which has been simplified and lightened considerably.<br />

The third major focus was in the drivetrain system, which addressed the weaknesses<br />

of the previous components, and also resulted in a net weight reduction.<br />

Canada<br />

brakE : Front: Wilwood Billet Dynalite Single Rear:<br />

Wilwood PS1<br />

bScd : 67.0 mm/42.5 mm/4 cylinder/599 cc<br />

cooling : Water-cooled<br />

drivE : Torsen differential with aluminum carrier<br />

ElEctronicS : AEM engine management system<br />

EnginE : Honda CBR 600 F4i<br />

Fr/rr track : 1321 mm / 1270 mm<br />

FramE : Chromoly spaceframe<br />

FuEl SyStEm : Single stage injection<br />

FuEl typE : 91 octane<br />

matErial : 4130 Alloy<br />

mpd : 85 hp (9000 rpm)<br />

mpt : 42 ft-lbs (5500 rpm)<br />

olwH : 2960 mm/1520 mm/1070 mm<br />

SuSpEnSion : Unequal-length A-Arms. Front: pullrodactivated.<br />

Rear: pushrod-activated<br />

tirE : Hoosier R25B, 20.5 x 7-13<br />

uniQuE : A gentleman never tells.<br />

wEigHt : 635<br />

wHEElbaSE : 1702 mm / 67.0 in<br />

Information published as supplied by teams on or before March 26, 2012<br />

of texas - arlington<br />

28univ<br />

uta Formula SaE racing<br />

UTA Racing has developed the 2012 car with the design philosophy of simplicity,<br />

reliability, and performance. UTA has made great advancements in aerodynamic<br />

development creating a new wing package utilizing extensive CFD analysis run<br />

with a UTA developed optimization code. The 2012 car (F12) uses a Yamaha YFz<br />

450R engine incorporating a carbon fiber intake, for its lightweight properties and<br />

desired internal flow profile. F12’s new ergonomics package has shortened our<br />

front bulkhead, thus reducing weight of the frame. F12 also integrates a compact<br />

drivetrain package, an easily tunable suspension system, and a steel space<br />

frame chassis to provide a well-rounded, high-performing, and competitive 2012<br />

racecar.<br />

United States<br />

brakE : 2 front, 1 rear cast iron brake rotors<br />

bScd : 95mm bore / 63.4mm stroke / 1 cylinder / 449<br />

cc<br />

cooling : Aluminum radiator<br />

drivE : Chain drive<br />

ElEctronicS : AiM MXL/ Performance Electronics PE3<br />

EnginE : Yamaha YFz 450R<br />

Fr/rr track : 1219mm (48 in), 1181mm (46.5 in)<br />

FramE : 4130 Steel space frame<br />

FuEl SyStEm : Performance Electronics PE3 Series ECU<br />

FuEl typE : 93 Octane<br />

matErial :<br />

mpd : 9500<br />

mpt : 8000<br />

olwH : 1770mm (69.7 in) long, 1386mm (54.6 in) wide,<br />

1067mm (42 in) high<br />

SuSpEnSion : Double unequal length A-Arm. Pull rod<br />

actuated spring / damper.<br />

tirE : 20.5x6-13 R25B Hoosier<br />

uniQuE : Computer optimized wing package<br />

wEigHt : 540 Lbs<br />

wHEElbaSE : 1600mm (63 in)<br />

page 19

30<br />

Southern illinois univ - Edwardville<br />

The main purpose of this year’s car was to build a solid, yet versatile, baseline<br />

car that future teams will be able to use to evolve the next generation of cars<br />

designed by SIUE students. This car will use simple yet effective designs that will<br />

ensure the car remains competitively light and agile while being easy to maintain.<br />

The engine also has a simple bore/stroke kit to improve power; however,future<br />

upgrades may see the use of fuel injection and possibly even forced induction.<br />

The design idea at SIUE is to keep the car as simple as possible in order to reduce<br />

cost and improve reliability. By doing this, the car is able to maintain a relatively<br />

light tube steel frame and be competitive in the F<strong>SAE</strong> competitions. Additionally,<br />

the car is capable of increasing its competitive advantage through new designs by<br />

future teams that will strive for excellence within our competitions.<br />

31<br />

Saint louis univ<br />

Formula SiuE parks racing<br />

brakE : Wilwood Cart Brakes/Master Cyclinders<br />

bScd : 99mm/65mm/1/500cc<br />

cooling : Water/Stock Pump & Radiator<br />

drivE : Chain & Sprocket<br />

ElEctronicS : Stock ECU & Vapor Tech Guage<br />

EnginE : 2006 Honda TRX450ER<br />

Fr/rr track : 1570.74/1530.86mm (61.84/60.27in)<br />

FramE : Mig Welded Mild Steel<br />

FuEl SyStEm : Low Pressure Carbureted<br />

FuEl typE : Gasoline, 100 octane<br />

matErial : A-36 Steel/6061 T6 Aluminum/Mild Steel<br />

Sheet/Aluminum Sheet<br />

mpd : 9800<br />

mpt : 6500<br />

olwH : 2844.8/1570.74/868.07 (112/61.84/34.176in)<br />

SuSpEnSion : Fox VanRC W/ Pushrods<br />

tirE : Dry: 20x Wet: 19.5x WET<br />

uniQuE : Adjustable Pedals/Interchangeable Seat<br />

Inserts/Adjustable Camber via spacers<br />

wEigHt : 575lbs<br />

wHEElbaSE : 1660.4/65.35<br />

Although SLU has competed in two prior competitions we are a all new, small,<br />

and inexperienced team this year. The goal of this years team is to design and<br />

build a functional car that will do well at Lincoln and provide a baseline design for<br />

future teams to build upon.<br />

brakE : 3 Disk, Brembo P34G, Tokico 6 Piston, Tilton 75<br />

Master Cylinders<br />

bScd : 95mm bore / 72.0 mm stroke / 1 cylinder /<br />

510.4 cc<br />

cooling : Aluminum Radiator with fan<br />

drivE : Chain Drive LSD Differential<br />

ElEctronicS :<br />

EnginE : KTM 525<br />

Fr/rr track :<br />

FramE : 1020 Tube Frame<br />

FuEl SyStEm : Aluminum floor mounted gas tank<br />

FuEl typE : 100 Octaine<br />

matErial :<br />

mpd :<br />

mpt :<br />

olwH : 110 in long, 57 in wide, 50 in high<br />

SuSpEnSion : Double unequal length A-Arm. Pull rod<br />

actuated spring / damper.<br />

tirE :<br />

uniQuE :<br />

wEigHt : 575 lbs<br />

wHEElbaSE : 62 in.<br />

United States<br />

United States<br />

page 20 Information published as supplied by teams on or before March 26, 2012

33<br />

univ of Southern california<br />

Sc racing<br />

As a young team, USCRacing has aimed to develop and refine a base of knowledge<br />

for the future of our club. In this spirit, the main design objectives this year<br />

were reliability and manufacturability.<br />

The steel space frame supports a Yamaha R6 engine with custom intake and<br />

exhaust as well as a modified oil pan to decrease cg height. The car employs a<br />

conventional push-rod suspension system with double unequal length A-arms.<br />

The carbon fiber airfoil and body panels were optimized in STAR-CCM to minimize<br />

weight and increase downforce. A Performance Electronics ECU allows for engine<br />

tuning, while a custom electro-pneumatic system allows easy shifting.<br />

United States<br />

brakE : Custom water-jetted rotors, Wilwood PS-1<br />

calipers<br />

bScd : 65.5mm/44.5mm/4 cylinder/599.8cc<br />

cooling : Single, side mounted radiator<br />

drivE : Torsen Differential<br />

ElEctronicS : Performance Electronics ECU<br />

EnginE : Yamaha R6<br />

Fr/rr track : 49"/47"<br />

FramE : Chromoly Spaceframe<br />

FuEl SyStEm : Custom fuel injection<br />

FuEl typE : 93 Octane<br />

matErial : 4130<br />

mpd :<br />

mpt :<br />

olwH :<br />

SuSpEnSion : Push rod. Double, unequal A-arms<br />

tirE : 20x7.0-13 D2704<br />

uniQuE : Electro-pneumatic shifting system<br />

wEigHt :<br />

wHEElbaSE : 61.5 in<br />

Information published as supplied by teams on or before March 26, 2012<br />

of wisconsin - platteville<br />

34univ<br />

pioneer racing<br />

The University of Wisconsin-Platteville has been involved in Formula <strong>SAE</strong> since<br />

2003. Our Formula team has been, and will continue to be a team that prides<br />

themselves on ambitious design and implementation of new ideas. After having<br />

an educational year in 2011, we are enthusiastic for the 2012 competition. Since<br />

2011, we have focused on simplification and optimization of essential systems<br />

to improve reliability of our car. Some of the highlights of our car are the pushrod<br />

suspension, pushbutton electronic shifting and aerodynamic undertray. Engineering<br />

new, reliable, and efficient vehicle components to implement in their Formula<br />

cars gets us excited for competition every year.<br />

We would like to thank all of our sponsors and supporters for their help during the<br />

construction and testing of PR12.<br />

United States<br />

brakE : 4 Wheel Disc Brakes<br />

bScd : 67mm / 42.5 mm/ 4 cylinder, 599.4 cc<br />

cooling : Single Side pod mounted radiator with High<br />

Performance electric fan<br />

drivE : 520 Chain<br />

ElEctronicS : Powercommander V with autotune<br />

EnginE : 2006 Yamaha YzF-R6<br />

Fr/rr track : 1193.8 mm / 1168.4 mm<br />

FramE : Tubular Space Frame<br />

FuEl SyStEm : Fuel Injection with Autotune<br />

FuEl typE : 91 Octane<br />

matErial : 4130 Chro-moly Tube<br />

mpd : 12500<br />

mpt : 10500<br />

olwH : 2651.8 mm, 1397 mm, 1296.7 mm<br />

SuSpEnSion : Double unequal length A-Arm. Push rod<br />

actuated parallel shocks<br />

tirE : 20x7-13 R075 Hoosier<br />

uniQuE : Pingel Electronic Shifter with engine kill<br />

wEigHt : 261 kg<br />

wHEElbaSE : 1676.4 mm<br />

page 21

36<br />

univ of utah<br />

FSaE uofu<br />

The F<strong>SAE</strong> team for the 2012 school year at the University of Utah is broken into<br />

three sub teams each of who are concerned with an important aspect of the cars<br />

eventual success. The three teams are Chassis, Drive-train, and Suspension. The<br />

overall team goals for 2012 includes an inexpensive race car that provides the<br />

end user with high performance, ease of maintenance, reliability in all systems,<br />

adjustability, and comfort for all users. These goals are achieved using a steel<br />

space frame chassis with a separable rear motor cradle, adjustable suspension<br />

components, adjustable seat and pedals, 4-cylinder fuel-injection engine with<br />

minimal modifications, and a chain-driven limited slip differential. All non-essential<br />

components such as wings and other aerodynamic devices were left off of the<br />

vehicle to reduce weight and cost.<br />

brakE : 4-Wheel Disc, Inboard front<br />

bScd : 600CC<br />

cooling : Liquid Cooled<br />

drivE : Chain<br />

ElEctronicS : Power Commander<br />

EnginE : Yamaha R6<br />

Fr/rr track : 1.25m / 1.17m<br />

FramE : Tube Frame<br />

FuEl SyStEm : Fuel Injection<br />

FuEl typE : 100 Octane<br />

matErial : 4130 Steel<br />

mpd :<br />

mpt :<br />

olwH : 2.75m,1.66m,1.32m<br />

SuSpEnSion : Short-Long Arm Adjustable<br />

tirE : 20x7.5-13 / 25A<br />

uniQuE : Removable Motor Cradle, Driver Ergonomics<br />

wEigHt : 600lbs<br />

wHEElbaSE : 1.54 meters<br />

of new mexico<br />

37univ<br />

lobomotorSports<br />

The LMS-12 is an evolutionary design building upon the success of previous<br />

teams and adapting cutting-edge knowledge to develop a F<strong>SAE</strong> racecar that leads<br />

the pack. Focusing on three primary design goals: weight reduction, drivability,<br />

and reliability, the LMS-12 has become the most advanced display of engineering<br />

and craftsmanship to come through the University of New Mexico.<br />

Tracking the evolution of the LMS-series, leaps and bounds have been made<br />

in each subsystem, while always focusing on the overall performance of the<br />

complete racecar. By the addition of a full aerodynamic package with reduced<br />

weight by 10% and center of gravity height by 13.7% over previous designs,<br />

the LMS-12 is the fastest vehicle to come from UNM. The focus on driveability<br />

is realized by the integration of the CVT, allowing drivers to solely focus on driving<br />

line and braking points, vastly improving lap times and consistency.<br />

Reliability is key to the success of any vehicle, and the LMS-12 is no different. All<br />

components were tested using FEA with a strict safety factor limit. Systems were<br />

designed with minimum maintenance in mind.<br />

The LMS-12 is the epitome of engineering. Careful design, analysis, and experimentation<br />

coupled with hard work and dedication has produced a racecar that<br />

once again pushes the limits.<br />

brakE : 2-Piece Floating Rotors, Wilwood PS-1 Calipers,<br />

Adjustable Bias Bar<br />

bScd : 77mm/53.6mm/Parallel Twin/499cc<br />

cooling : 2-Row Single Pass Aluminum Air-to-Water,<br />

800cfm Electric Fan<br />

drivE : CVT, Syncronous Belt Final Drive, Wavetrac<br />

Differential<br />

ElEctronicS : Performance Electronics PE3 ECU,<br />

Launch Control<br />

EnginE : Yamaha Genesis 80fi Odd-Fire 5V DOHC<br />

Fr/rr track : 50"Front / 48" Rear<br />

FramE : TIG Welded 4130<br />

FuEl SyStEm : 370cc/min Injectors, Common Rail<br />

FuEl typE : E85<br />

matErial : 4130, Carbon Fiber, Aluminum<br />

mpd : 11500 RPM<br />

mpt : 9000 RPM<br />

olwH : 117"/57"/46"<br />

SuSpEnSion : Unequal, Non-Parallel Double Wishbone,<br />

Ohlins MKII Dampers, 3-Way Adj. ARBs<br />

tirE : 20.5x7.0-13 Hoosier R25B<br />

uniQuE : 2.5" BDS<br />

wEigHt : 640 lb<br />

wHEElbaSE : 61"<br />

United States United States<br />

page 22 Information published as supplied by teams on or before March 26, 2012

38<br />

california State univ - long beach<br />

cSulb racing<br />

Chassis:<br />

The central concept behind our car’s chassis was to build it tight and compact.<br />

Our chassis design centered around one that takes up minimal space to reduce<br />

weight, provide stiffness, and to move more mass towards the center of the car.<br />

The chassis was designed with SolidWorks CAD software and analysis done with<br />

SolidWorks and NX-7.5 finite element analysis<br />

Suspension:<br />

The suspension components of our car were designed to be nimble and specifically<br />

for the tight, quick corners that are characteristic of an autocross course.<br />

This combined with the compact size of our chassis make it well suited for small,<br />

slower courses where handling and cornering are of primary concern.<br />

Brake System:<br />

The car’s braking system is comprised of dual piston brake calipers acting on<br />

solid disks. The front brake system is of outboard design while the rear consists<br />

of a single rotor mounted to the differential. The front and rear brakes each have<br />

their own closed circuit system to isolate them from each other to prevent total<br />

brake system failure in the event that a leak develops at any single point in the<br />

system.<br />

United States<br />

brakE : Front-Dual Outboard 10” disks, Rear-Single<br />

Inboard 10” disk<br />

bScd : 67.0mm x 42.5mm, 4cyl, 599cc<br />

cooling : Water cooled, single bar and plate radiator<br />

drivE : Chain drive<br />

ElEctronicS : MegaSquirt 3 Engine Management<br />

EnginE : 2007 CBR 600RR<br />

Fr/rr track : FR-1444 mm, RR-1415mm<br />

FramE : <strong>SAE</strong> 4130 chromoly steel tube frame<br />

FuEl SyStEm : Full sequential multi-port fuel injection<br />

FuEl typE : 100 octane unleaded<br />

matErial : <strong>SAE</strong> 4130 chromoly steel<br />

mpd :<br />

mpt :<br />

olwH : 2505mm long, 730mm wide and 1092mm high<br />

SuSpEnSion : Double unequal length A-Arm, push rod<br />

actuated spring and damper<br />

tirE :<br />

uniQuE :<br />

wEigHt :<br />

wHEElbaSE : 1676mm<br />

Information published as supplied by teams on or before March 26, 2012<br />

39<br />

minnesota State university - mankato<br />

minnesota State university- mankato<br />

The 2012 MNSU F<strong>SAE</strong> car is a single year senior design project that was<br />

designed and built by a team of 18 undergraduate Automotive Engineering<br />

Technologist students. This year the vehicle will be powered by a turbocharged<br />

single cylinder KTM 525 engine housed within a steel tube frame. The vehicle<br />

was designed using Pro Engineer, Mechanica, and Star-CCM+.<br />

The engine is equipped with a Garret GT1241 turbocharger, a custom intercooler<br />

that also serves as an air plenum, and a redesigned camshaft. The engine operates<br />

on an 83 lb-hr fuel injector, and runs on E-85. The engine produces 65 lb ft<br />

of torque at 5000RPM and 75 horsepower at 6500RPM.<br />

The chassis weighs 63 lb as a steel space frame with carbon fiber pushrods, and<br />

floating front and rear rotors. The vehicle is equipped with a limited slip Drexler<br />

differential and Hoosier R25B tires.<br />

The body was designed using CFD software to improve airflow across the radiator<br />

and create low pressure beneath the vehicle undertray to generate down force.<br />

To aid in driver ergonomics an auto engaging clutch, paddle shift system, and<br />

adjustable foot pedals have been added.<br />

United States<br />

brakE : Floating Front and Rear Rotors, Fixed dual piston<br />

caplipers<br />

bScd : 510cc single cylinder<br />

cooling : Single circuit /w single radiator<br />

drivE : Chain<br />

ElEctronicS : MoTeC<br />

EnginE : Turbocharged KTM 525cc<br />

Fr/rr track : 1219.2mm(48")/1193.8mm(47")<br />

FramE : Tubular<br />

FuEl SyStEm : EFI returnless<br />

FuEl typE : E85<br />

matErial : 1020 Mild Steel<br />

mpd : 75 Hp @ 6500 RPM<br />

mpt : 65 lb-ft @ 5000 RPM<br />

olwH : 2489.2mm(98"), 1422.4mm(56"),<br />

1168.4mm(46")<br />

SuSpEnSion : Unequal length double wishbone with<br />

pushrods<br />

tirE : 10" Hoosier R25B<br />

uniQuE : Aerodynamic design incorporated into the body,<br />

wEigHt : 575 lbs<br />

wHEElbaSE : 1549.4mm(61")<br />

page 23

41<br />

california State univ - Sacramento<br />

Hornet Racing at California State University, Sacramento strives to produce the<br />

finest and most competitive Formula <strong>SAE</strong> car every year. The team enriches its<br />

members’ learning experience beyond what can be obtained in the classroom<br />

through extensive hands on design and manufacturing experience. The team<br />

makes every effort to include any student that is willing to participate regardless<br />

of academic level or major and provides a constructive learning environment in<br />

order to help build the program further and increase its knowledge base every<br />

year. Hornet Racing will accomplish these goals through honest hard work, dedication,<br />

mentoring and teamwork.<br />

The 2012 Hornet Racing Formula <strong>SAE</strong> car builds upon 2011’s solid platform with<br />

a primary goal of reducing weight in all areas. Attention was also given to simplicity<br />

and efficiency of part design and manufacturability. This led to a reduction in<br />

overall part count resulting in an earlier assembly thus allowing generous time to<br />

test and refine HR2012.<br />

42<br />

Hornet racing pantEraS racing<br />

brakE : Floating Rotors, fixed Calipers<br />

bScd : CBR 600 F4i<br />

cooling : Water Cooled<br />

drivE : Student Built Torsen<br />

ElEctronicS : AEM ECU<br />

EnginE : Honda F4i<br />

Fr/rr track : 1245mm/1219 mm<br />

FramE : Tubular Space Frame<br />

FuEl SyStEm : In-line Fuel Pump/Filter, Fuel Injected<br />

FuEl typE : 91<br />

matErial : Organic & Inorganic Materials<br />

mpd : 10500<br />

mpt : 8900<br />

olwH : 2667mm long, 1400mm wide, 1160mm high<br />

SuSpEnSion : Unequal Double A-arm, Push Rod Front<br />

& Rear<br />

tirE : Hoosier’s 43162 20.5 x 7.0-13<br />

uniQuE :<br />

wEigHt : 605<br />

wHEElbaSE : 61<br />