- Page 1 and 2:

AVANCES 2012 Sistema métrico AVANC

- Page 3 and 4:

Avances Introducción . . . . . . .

- Page 5 and 6:

La familia de marcas más fuerte de

- Page 7 and 8:

Programas de formación amplios Com

- Page 9 and 10:

Responsabilidad medioambiental Mant

- Page 11:

WIDIA-GTD 1993 Se presenta la serie

- Page 14 and 15:

Nuevos productos Nuestras últimas

- Page 16 and 17:

Machos de roscar de metal duro inte

- Page 18 and 19:

Taladrado • Machos de roscar de a

- Page 20 and 21:

Machos de roscar de alto rendimient

- Page 22 and 23:

Taladrado • Machos de roscar de a

- Page 24 and 25:

Taladrado • Machos de roscar de a

- Page 26 and 27:

Taladrado • Machos de roscar de a

- Page 28 and 29:

Taladrado • Machos de roscar de a

- Page 30 and 31:

Taladrado • Machos de roscar de a

- Page 32 and 33:

Taladrado • Machos de roscar de a

- Page 34 and 35:

Taladrado • Machos de roscar de a

- Page 36 and 37:

Taladrado • Machos de roscar de a

- Page 38 and 39:

Taladrado • Machos de roscar de a

- Page 40 and 41:

Machos de roscar HSS-E-PM de alto r

- Page 42 and 43:

Taladrado • Machos de roscar de a

- Page 44 and 45:

Taladrado • Machos de roscar de a

- Page 46 and 47:

Taladrado • Machos de roscar de a

- Page 48 and 49:

Taladrado • Machos de roscar de a

- Page 50 and 51:

Taladrado • Machos de roscar de a

- Page 52 and 53:

Taladrado • Machos de roscar de a

- Page 54 and 55:

Taladrado • Machos de roscar de a

- Page 56 and 57:

Taladrado • Machos de roscar de a

- Page 58 and 59:

Taladrado • Machos de roscar de a

- Page 60 and 61:

Taladrado • Machos de roscar de a

- Page 62 and 63:

Taladrado • Machos de roscar de a

- Page 64 and 65:

Taladrado • Machos de roscar de a

- Page 66 and 67:

Machos de roscar para segmento eól

- Page 68 and 69:

Taladrado • Machos de roscar de a

- Page 70 and 71:

Taladrado • Machos de roscar de a

- Page 72 and 73:

Taladrado • Machos de roscar de a

- Page 74 and 75:

Taladrado • Machos de roscar de a

- Page 76 and 77:

Taladrado • Machos de roscar de a

- Page 78 and 79:

Taladrado • Machos de roscar de a

- Page 80 and 81:

Taladrado • Machos de roscar de a

- Page 82 and 83:

Taladrado • Machos de roscar de a

- Page 84 and 85:

Taladrado • Machos de roscar de a

- Page 86 and 87:

Taladrado • Machos de roscar de a

- Page 88 and 89:

Fresas de roscado Disponibles por p

- Page 90 and 91:

Taladrado • Fresas de roscado de

- Page 92 and 93:

Fresas de roscado de alto rendimien

- Page 94 and 95:

Taladrado • Fresas de roscado de

- Page 96 and 97:

Taladrado • Fresas de roscado de

- Page 98 and 99:

Taladrado • Fresas de roscado de

- Page 100 and 101:

Taladrado • Fresas de roscado de

- Page 102 and 103:

Taladrado • Fresas de roscado de

- Page 104 and 105:

Taladrado • Fresas de roscado de

- Page 106 and 107:

Taladrado • Fresas de roscado de

- Page 108 and 109:

Lightning WIDIA-GTD Lightning Ser

- Page 110 and 111:

Nuestra completa gama de productos.

- Page 112 and 113:

Taladrado • Información técnica

- Page 114 and 115:

Taladrado • Información técnica

- Page 116 and 117:

Taladrado • Información técnica

- Page 118 and 119:

Taladrado • Información técnica

- Page 120 and 121:

Rápida respuesta y un rendimiento

- Page 122 and 123:

Taladrado • Información técnica

- Page 124 and 125:

Taladrado • Información técnica

- Page 126 and 127:

Taladrado • Información técnica

- Page 128 and 129:

Obtenga dinero en efectivo o un abo

- Page 130 and 131:

Taladrado • Información técnica

- Page 132 and 133:

Taladrado en múltiples materiales

- Page 134 and 135:

Taladrado • Brocas de metal duro

- Page 136 and 137:

Taladrado • Brocas de metal duro

- Page 138 and 139:

Taladrado • Brocas de metal duro

- Page 140 and 141:

Taladrado • Brocas de metal duro

- Page 142 and 143:

Taladrado • Brocas de metal duro

- Page 144 and 145:

Taladrado • Brocas de metal duro

- Page 146 and 147:

Taladrado • Brocas de metal duro

- Page 148 and 149:

Taladrado • Brocas de metal duro

- Page 150 and 151:

Taladrado • Brocas de metal duro

- Page 152 and 153:

Taladrado • Brocas de metal duro

- Page 154 and 155:

Taladrado • Brocas de metal duro

- Page 156 and 157:

Taladrado • Brocas de metal duro

- Page 158 and 159:

Taladrado • Brocas de metal duro

- Page 160 and 161:

Taladrado • Brocas de metal duro

- Page 162 and 163:

Taladrado • Brocas de metal duro

- Page 164 and 165:

Taladrado • Brocas de metal duro

- Page 166 and 167:

Taladrado específico para cada apl

- Page 168 and 169:

Taladrado • Brocas de metal duro

- Page 170 and 171:

Taladrado • Brocas de metal duro

- Page 172 and 173:

Taladrado • Brocas de metal duro

- Page 174 and 175:

Taladrado • Brocas de metal duro

- Page 176 and 177:

Taladrado • Brocas de metal duro

- Page 178 and 179:

Taladrado • Brocas de metal duro

- Page 180 and 181:

Taladrado • Brocas de metal duro

- Page 182 and 183:

Taladrado • Brocas de metal duro

- Page 184 and 185:

Taladrado • Brocas de metal duro

- Page 186 and 187:

Taladrado • Brocas de metal duro

- Page 188 and 189:

Taladrado • Brocas de metal duro

- Page 190 and 191:

Excelente taladrado de orificios pr

- Page 192 and 193:

Taladrado • Brocas de metal duro

- Page 194 and 195:

Taladrado • Brocas de metal duro

- Page 196 and 197:

Aplicaciones de taladrado difícile

- Page 198 and 199:

Taladrado • Brocas de metal duro

- Page 200 and 201:

Taladrado • Brocas de metal duro

- Page 202 and 203:

Taladrado • Brocas de metal duro

- Page 204 and 205:

Taladrado • Brocas de metal duro

- Page 206 and 207:

Taladrado • Brocas de metal duro

- Page 208 and 209:

Taladrado • Brocas de metal duro

- Page 210 and 211:

Taladrado • Brocas de metal duro

- Page 212 and 213:

Taladrado • Brocas de metal duro

- Page 214 and 215:

WIDIA Victory TOP DRILL M1 Las b

- Page 216 and 217:

Taladrado • Hojas de pala Hojas d

- Page 218 and 219:

Taladrado • Hojas de pala Hojas d

- Page 220 and 221:

Taladrado • Hojas de pala Hojas d

- Page 222 and 223:

Taladrado • Hojas de pala Hojas d

- Page 225 and 226:

Fresado intercambiable Serie Victor

- Page 227 and 228:

Fresas de planear 12 Plaquita HNGJ0

- Page 229 and 230:

• Doce filos de corte. • La pri

- Page 231 and 232:

HNGJ-LDJ HNGJ-LD HNPJ-GD HNPJ-HD

- Page 233 and 234:

TN6525 TN6540 TN7535 THM-U Geometr

- Page 235 and 236:

• Doce filos de corte. • La pri

- Page 237 and 238:

• Doce filos de corte. • La pri

- Page 239 and 240:

HNPJ-HD WWW.WIDIA.COM Serie Victory

- Page 241 and 242:

TN6525 TN6540 TN7535 THM-U Geometr

- Page 243 and 244:

HNGJ-LDJ HNGJ-LD HNPJ-GD HNPJ-HD

- Page 245 and 246:

TN6525 TN6540 TN7535 THM-U Geometr

- Page 247 and 248:

Fresas de planear WWW.WIDIA.COM M12

- Page 249 and 250:

HNGJ-LDJ HNGJ-LD HNPJ-GD HNGJ-GD

- Page 251 and 252:

TN5515 TN6501 TN6510 TN6520 TN6525

- Page 253 and 254:

Fresas para escuadrado a 90° WWW.W

- Page 255 and 256:

SDMX-MM ¡NOVEDAD! SDMX-MH WWW.WID

- Page 257 and 258:

Serie M690 de WIDIA de fresas para

- Page 259 and 260:

Fresas de copiar WWW.WIDIA.COM M270

- Page 261 and 262:

• Altas tasas de evacuación del

- Page 263 and 264:

TN2505 TN6525 TN6540 Diámetro de p

- Page 265 and 266:

SISTEMAS DE HERRAMIENTAS Portaherra

- Page 267 and 268:

Fresas de copiar WWW.WIDIA.COM M370

- Page 269 and 270:

• Seis filos de corte de doble ca

- Page 271 and 272:

WOEJ-MH WEOJ-MM WOEJ-MH y -MM WWW.

- Page 273 and 274:

Aplicación de herramientas de alto

- Page 275 and 276:

Desbaste y acabado en una única he

- Page 277 and 278:

M4000CA- MDHX10CA Número de pedido

- Page 279 and 280:

Fresas para escuadrado a 90° Fresa

- Page 281 and 282:

TN6520 TN6525 TN6540 Geometría de

- Page 283:

Serie WIDIA M370 Diseñada para u

- Page 286 and 287:

Para operaciones de semiacabado y a

- Page 288 and 289:

Fresas de mango integral • Fresas

- Page 291 and 292: WWW.WIDIA.COM Torneado WIDIA Victor

- Page 293 and 294: esistencia al desgaste resistencia

- Page 295 and 296: Plaquitas negativas ..MA 16,0 FW 16

- Page 297 and 298: En la web Registro rápido, gratuit

- Page 299 and 300: Con esta guía de fácil uso, podr

- Page 301 and 302: DIN ISO 513 VDI 3323 Grupo de mater

- Page 303 and 304: CNMA CNMG-FF CNMG-FW WWW.WIDIA.CO

- Page 305 and 306: CNMG-RH CNMG-UF CNMG-UM WWW.WIDIA

- Page 307 and 308: CPMT-MP DCMT-FP DCMT-MP WWW.WIDIA

- Page 309 and 310: DNMG-FF DNMG-FW DNMG-ML WWW.WIDIA

- Page 311 and 312: DNMG-UF DNMG-UM DNMG-UR WWW.WIDIA

- Page 313 and 314: LNUX-T RCMT RCMT-T RCMX WWW.WIDI

- Page 315 and 316: SCMW SNMA SNMG-FF WWW.WIDIA.COM

- Page 317 and 318: SNMG-UF SNMG-UM SNMG-UR WWW.WIDIA

- Page 319 and 320: SPMT-FP SPMT-MP SPU SPU-T WWW.WI

- Page 321 and 322: TNMA TNMG-FF TNMG-ML WWW.WIDIA.CO

- Page 323 and 324: TNMG-UM TNMG-UR TNMP WWW.WIDIA.CO

- Page 325 and 326: TPMT-FP TPMT-MP TPU WWW.WIDIA.COM

- Page 327 and 328: VNMG VNMG-FF VNMG-ML VNMG-MR WWW

- Page 329 and 330: WNMA WNMG-FF WNMG-FW WWW.WIDIA.CO

- Page 331 and 332: WNMG-RH WNMG-UF WNMG-UM WWW.WIDIA

- Page 333 and 334: Plaquitas CBN para torneado duro La

- Page 335 and 336: Portaherramientas integrales Mano R

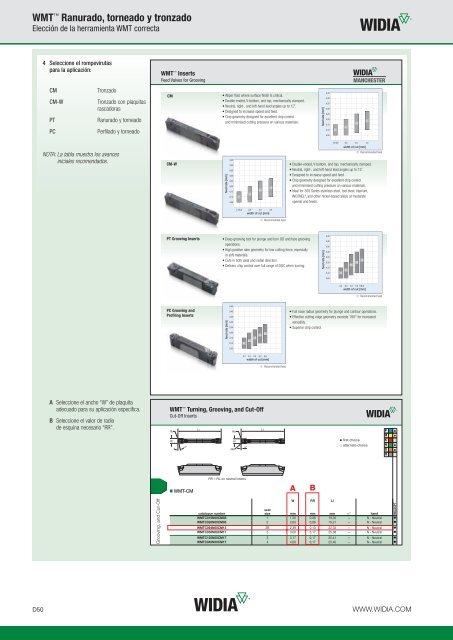

- Page 337 and 338: Plaquitas CM y CM-W WWW.WIDIA.COM V

- Page 339: 3 Seleccione un portaherramientas e

- Page 343 and 344: Sistema de identificación de WMT T

- Page 345 and 346: Sistema WMT El sistema WIDIA WMT

- Page 347 and 348: WMT-CM-W WWW.WIDIA.COM a derechas n

- Page 349 and 350: RR = RL WMT-U-PC • Moldeado WMT

- Page 351 and 352: Plaquitas para tronzar WGF y WGT Pl

- Page 353 and 354: WGF-N WGF-L WGF-R WWW.WIDIA.COM R

- Page 355 and 356: WWW.WIDIA.COM Obtener el máximo de

- Page 357 and 358: WWW.WIDIA.COM WIDIA Value Tabla de

- Page 359 and 360: Calidad Recubrimiento TN10P TN20P T

- Page 361 and 362: Con esta guía de fácil uso, podr

- Page 363 and 364: CNMA CNMG-2P CNMG-4P WWW.WIDIA.CO

- Page 365 and 366: DCMT-1P DNGP DNMA WWW.WIDIA.COM

- Page 367 and 368: DNMG-7N RNMG-7N SCMT-1P WWW.WIDIA

- Page 369 and 370: SNMG-6P SNMG-7N TCGT-1P WWW.WIDIA

- Page 371 and 372: TNMG-2P TNMG-4P TNMG-6P WWW.WIDIA

- Page 373 and 374: VNGP VNMA VNMG-2P WWW.WIDIA.COM

- Page 375 and 376: WNMG-2P WNMG-4P WNMG-6P WWW.WIDIA

- Page 377: Serie de herramientas para orificio

- Page 380 and 381: WIDIA KM4X La interfaz de husillo

- Page 382 and 383: Sistemas de herramientas • Herram

- Page 384 and 385: Sistemas de herramientas • Herram

- Page 386 and 387: Sistemas de herramientas • Herram

- Page 388 and 389: Sistemas de herramientas • Herram

- Page 390 and 391:

Sistemas de herramientas • Herram

- Page 392 and 393:

Sistemas de herramientas • Herram

- Page 395 and 396:

Servicios y asistencia WIDIA ToolBo

- Page 397 and 398:

Maximice el tiempo de operación. A

- Page 399 and 400:

Obtenga dinero en efectivo o un abo

- Page 401 and 402:

En la web Registro rápido, gratuit

- Page 403 and 404:

Asistencia técnica sobre aplicacio

- Page 405 and 406:

WWW.WIDIA.COM Polo simple de gran c

- Page 407 and 408:

WWW.WIDIA.COM Pelotas de golf Title

- Page 409 and 410:

Nº de pedido Nº de catálogo Pág

- Page 411 and 412:

WWW.WIDIA.COM Índice por número d

- Page 413 and 414:

WWW.WIDIA.COM Índice por número d

- Page 415 and 416:

WWW.WIDIA.COM Índice por número d

- Page 417 and 418:

WWW.WIDIA.COM Índice por número d

- Page 419 and 420:

WWW.WIDIA.COM Índice por número d

- Page 421 and 422:

WWW.WIDIA.COM Índice por número d

- Page 423 and 424:

WWW.WIDIA.COM Índice por número d

- Page 425 and 426:

WWW.WIDIA.COM Índice por número d

- Page 427 and 428:

WWW.WIDIA.COM Índice por número d

- Page 429 and 430:

WWW.WIDIA.COM Índice por número d

- Page 431 and 432:

WWW.WIDIA.COM Índice por número d

- Page 433 and 434:

WWW.WIDIA.COM Índice por número d

- Page 435 and 436:

Nº de Nº de Nº de Nº de pedido

- Page 437 and 438:

WWW.WIDIA.COM Índice por número d

- Page 439 and 440:

WWW.WIDIA.COM Índice por número d

- Page 441 and 442:

WWW.WIDIA.COM Índice por número d

- Page 443 and 444:

WWW.WIDIA.COM Índice por número d

- Page 445 and 446:

WWW.WIDIA.COM Índice por número d

- Page 447 and 448:

WWW.WIDIA.COM Índice por número d

- Page 449 and 450:

WWW.WIDIA.COM Índice por número d

- Page 451 and 452:

WWW.WIDIA.COM Índice por número d

- Page 453 and 454:

WWW.WIDIA.COM Índice por número d

- Page 455 and 456:

WWW.WIDIA.COM Índice por número d

- Page 457 and 458:

WWW.WIDIA.COM Índice por número d

- Page 459 and 460:

WWW.WIDIA.COM Índice por número d

- Page 461 and 462:

Nº de catálogo Página(s) Nº de

- Page 463 and 464:

Este/Asia Pacífico • Australia V

- Page 465 and 466:

WWW.WIDIA.COM Notas

- Page 467 and 468:

Seguridad en el corte de metal INST

- Page 469 and 470:

Aplicación, geometría e iconos de